Professional Documents

Culture Documents

Robust Self-Tuning MTPA Algorithm For IPMSM Drives 2008

Uploaded by

Giang LamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Robust Self-Tuning MTPA Algorithm For IPMSM Drives 2008

Uploaded by

Giang LamCopyright:

Available Formats

Robust Self-Tuning MTPA Algorithm

for IPMSM Drives

Dianov Anton, Kim Young-Kwan, Lee Sang-Joon, Lee Sang-Taek

Digital Appliance Division, Samsung Electronics

416, Maetan-3Dong, Yeongtong-Gu, Suwon-City, Gyeonggi-Do, 443-742, Korea

Email: anton.dianov@samsung.com

Abstract-This paper presents robust self-tuning maximum

torque per ampere (MTPA) control algorithm for an interior

permanent magnet synchronous motor (IPMSM) drives.

Proposed algorithm utilizes conventional control scheme, where

speed controller produces stator current command signal for the

MTPA block. That block decomposes commanded current I

s

into its components along direct and quadrature axes i

d

and i

q

respectively, which are used as a current commands for the

current control loops. MTPA angle , which is used for the

decomposition is defined by the MTPA tuning algorithm, which

continually varies that angle trying to find the one which

provides the minimum of stator current at the given load torque.

I. INTRODUCTION

Permanent magnet synchronous motors (PMSM) are

widely used for low-power drive applications due to high

efficiency, high torque to current ratio, low noise and

robustness [1]. They can be divided into surface-mounted

(SMPMSM) and IPMSM. The first ones have permanent

magnets (PM) mounted on the surface of rotor, which means

that motor parameters along direct and quadrature axes are

almost similar. It simplifies motor equations and allows to

utilize simple control schemes. However the main

disadvantage of the SMPMSM is limited speed range. At the

high speed the magnets can detach from the surface of the

rotor and cause drive failure. Unlike the surface-mounted

PMSM the IPMSM have magnets buried inside the rotor. It

improves motor reliability and increases speed range.

However such rotor design causes motor asymmetry along its

electrical axes d and q, which complicates motor models and

its control schemes. Furthermore, the difference in motor

inductances L

d

and L

q

causes reluctance torque of the motor,

which high-efficient control system has to utilize.

During last years many researchers paid their attention to

the MTPA algorithms and many papers with different

solutions have been proposed. The conventional approach to

this problem is to calculate maximum torque per ampere

trajectory. It can be obtained by differentiating motor torque

equation with respect to the stator current. These formulas are

well known [2] and are widely used in simple control systems.

However such approach does not take into account motor

parameters variations, which significantly affect motor

performance. In the IPM motors the permanent magnet flux

varies with the temperature and motor inductances L

d

and L

q

depend on the stator current. Furthermore, such variation can

be significant, e.g. the values of the inductances can decrease

more than two times. So high-efficient control system must

take into account such variations and adapt to them.

Many papers, dedicated to the MTPA control, suggest

several methods which can be divided into two groups.

First group includes methods, which utilize conventional

MTPA scheme, but use motor parameters estimators, which

monitor parameters variation and correct MTPA trajectory.

One of such methods is described in [3]. Authors propose

simple on-line adaptive estimation algorithm for the motor

inductances identification. However practical results showed

that L

q

estimation is sensitive to the stator resistance r

s

variation at higher torque and accuracy of L

d

estimation is

affected by the variation of PM flux linkage

m

. Improved

method is proposed in [1]. It uses adaptive parameter

estimator with iterative gradient algorithm, which is applied

to the q-axis current. For unbiased parameter estimation

proposed estimator is combined with a robust active-state

decoupling scheme. This method shows better results than the

previous one, however it is much more calculation intensive.

One more interesting method, developed for the sensorless

control of the IPMSM including MTPA, is described in [4].

Authors propose to perform motor position and speed

estimation in the maximum torque control (MTC) reference

frame, where one axis is aligned with the current vector at the

MTPA condition. They proved that motor inductances in the

MTC reference frame are not significantly affected by the

current magnitude and their variations can be neglected.

Second group consists of the methods which do not use

motor parameters. Such methods are based on seeking of the

minimum of the current magnitude at the given torque. A

self-tuning MTPA algorithm based on the high-frequency

signal injecting is described in [5]. However high-frequency

signal causes additional noises and stresses for the drive and

sometimes is not applicable.

One more interesting method, which is based on the

current vector phase variation, is introduced in [6, 7]. This

method adds and subtracts small angle to the current phase.

After that motor torque at three operational points is

calculated and the best point is selected. To increase

robustness of the algorithm, authors added on-line motor

parameter estimator to the proposed scheme.

The purpose of this paper is to present robust self-tuning

algorithm, which belongs to the second group and does not

use motor parameters for its work. The algorithm

continuously varies phase of the stator current and analyzes

1355 978-1-4244-1766-7/08/$25.00 2008

changes of its amplitude. After that the control algorithm

selects the best angle and utilizes MTPA control. The validity

of the proposed method has been verified by simulation and

experimentation.

II. CONVENTIONAL MAXIMUM TORQUE PER AMPERE

CONTROL

A. Motor Equations

Fig. 1 shows a sixteen pole IPM motor, which was used for

the experiments. Voltage equations for such motor in the

synchronous reference frame dq on the assumption that motor

parameters are constant and do not depend on the other

variables are expressed by (1):

+

+

=

m q

d

q s d

q d s

q

d

i

i

pL r L

L pL r

u

u

0

, (1)

where

p -differential operator,

-electrical angular velocity,

r

s

-stator resistance,

L

d

, L

q

-d-axis and q-axis inductances respectively,

i

d

, i

q

-d-axis and q-axis currents components respectively,

u

d

, u

q

-d-axis and q-axis voltage components respectively,

m

-permanent magnet flux linkage.

Electromagnetic torque of the motor can be expressed as:

( ) ( )

m d q d q

i L L Pi T + =

2

3

, (2)

where

P -number of pole pairs.

It is evident that motor torque contains two components:

excitation torque, which is caused by the magnet flux linkage

and reluctance torque, which is caused by the by the rotor

magnetic asymmetry along d and q axes.

B. Non-MTPA control

Conventional vector control systems, which do not utilize

MTPA control, use only excitation torque, setting i

d

command to zero (for non-field weakening modes). Speed

and current controllers in such systems are connected as

shown in Fig. 4. The speed controller uses speed error signal

as input and produces i

q

command. At the same time i

d

command is set to zero. Such control scheme is simple since

the torque is controlled only by one variable, however it does

not use the whole potentiality of the motor.

C. MTPA equations

To utilize the reluctance torque of the motor, d-axis current

should be controlled as well. The relationship between i

d

and

i

q

for the archiving minimum of the stator current

2 2

q d s

i i I + = (3)

at the given torque can be obtained by differentiating (2) with

respect to (3) and equating result to zero. The result is:

( ) ( )

2

2

2

4 2

q

q d

m

q d

m

d

i

L L L L

i +

=

. (4)

MTPA trajectory for the rated motor parameters is shown

in the Fig. 2. Fig. 3. shows dependences of the motor torques

on the stator current for MTPA and non-MTPA controls for

the rated motor parameters.

Control algorithm built according to (4) has the structure,

which is shown in Fig. 5. It is similar to the scheme shown in

Fig. 4, but commanded value for the d-axis current is not set

to zero. It is calculated by the MTPA block according to (4)

Fig. 1. IPM motor

Speed

Controller

i

q

Controller

i

q

i

d

Controller

i

d

i

d c

= 0

u

q c

u

d c

i

q c

i

q

i

d

Fig. 4. Non-MTPA vector control scheme

i

d

[A]

i

q

[A]

4

8

12

-4 -8

Fig. 2. MTPA trajectory

Fig. 5. MTPA vector control scheme

I [A]

5 10

40

80

T [Nm]

i

d

= 0

MTPA

Fig. 3. Motor torques under MTPA and non-MTPA

controls for rated parameters

1356 978-1-4244-1766-7/08/$25.00 2008

using commanded value for the q-axis current.

However, main disadvantage of such control is calculation

of (4), which is processor intensive. Many authors suggest to

approximate (4) with polynomial, however low-order

polynomial sometimes are not applicable.

The way out is to change control scheme a little. Equation

(2) can be rewritten in the terms of current vector I

s

and its

phase:

( ) ( )

m s q d s

I L L pI T + = cos sin

2

3

, (5)

where is the angle between i

d

and I

s

. Calculation of the

torque derivative with respect to the full current phase and

equalization it to zero results MTPA curve in the terms of the

stator current and its phase:

( ) 0 2 cos cos

2

2

3

2

3

= + =

s q d s m

I L L p I p

T

(6)

The solution of (6) is:

( )

( )

+ +

=

s q d

s q d m m

I L L

I L L

4

8

arccos

2 2 2

, (7)

This function is also difficult for calculation, however it

can be easily approximated by the second order polynomial.

Fig. 6 shows such function for the motor which was used for

the experiments.

Control algorithm built according to (6) has structure,

which is shown in Fig. 7. The speed controller produces

stator current commanded value, which is fed to the MTPA

block. MTPA block calculates phase of the stator current

using polynomial approximation of (7) and then outputs i

d

and i

q

commanded values for the current controllers.

As it was mentioned earlier, all analytical approaches

toward MTPA condition use rated motor parameters, whish

are considered to be constant in every operating point. It

means that effects of saturation, cross-saturation and

dependence of the permanent magnet flux linkage on the

temperature are not taken into account.

However variation of the motor inductances L

d

and L

q

with

the change of operating point (i

d

and i

q

) is significant. Such

dependence for the prototype motor is shown in Fig. 8. These

inductances are functions of the d-q axes currents. In this

figure effect of the cross saturation is not taken into account.

Since motor inductances are functions of its currents i

d

and

i

q

, MTPA equations deduced earlier are not valid, because

they were obtained on the assumption that motor parameters

are unchangeable. Next paragraph proposes new algorithm

which can overcome described problem and perform MTPA

control of the motor.

III. PROPOSED MTPA ALGORITHM

In order to overcome previously described problem and

perform MTPA control of the motor, new algorithm has been

developed. It does not use motor parameters and can adjust to

every operating point of the motor.

The block diagram of the control system, which utilizes

MTPA algorithm, is the same as in Fig. 7. The speed

controller uses speed error as input and produces stator

current command I

s

. This command is fed to the MTPA block,

which calculates phase of the stator current and outputs i

d

and i

q

. The difference from the conventional control schemes

is that angle is not calculated according to (7) or its

polynomial approximation. This angle is defined by the

special adjusting algorithm, which works in quasi real time

mode.

Proposed adjusting algorithm defines current phase angle ,

which minimizes motor current I

s

at the demanded torque.

For this purpose MTPA tuning algorithm seeks the best angle

for the current load conditions, which are considered to be

constant during execution of the corresponding procedure.

Tuning algorithm continuously changes current phase angle

by the small value , i.e. disturbs the system, and compares

results after end of the transients. After changing it waits till

the speed controller adjusts stator current I

s

. Since the

disturbance is small the transients are short, so after short

delay the new value of the motor current can be obtained and

currents before and after disturbance can be compared. If the

current obtained at the current step is less than the current at

previous iteration, it means that current vector has been

Fig. 6. MTPA trajectory in terms of stator current and its phase

Fig. 7. MTPA vector control scheme

Fig. 8. Motor inductances vs. current

1357 978-1-4244-1766-7/08/$25.00 2008

rotated to the right direction, otherwise to the wrong. In that

case the sign of the disturbance angle must be changed and

at the next step tuning algorithm will rotate current to the

opposite direction. Fig. 9 illustrates current vector rotation

under constant load torque.

Such approach has a significant advantage to tune to the

different operational condition of the motor, because it can

find the minimum of the stator current even when the motor

parameters change with the current variation. It means that

inductance variation due to the saturation and cross-saturation

and flux variation due to the temperature change do not affect

the performance of the method.

However proposed tuning algorithm has weak points,

inherent to all searching algorithms. It can fail in transients

because changes of the minimizing variable are caused by the

impact of external factors. For example, if the load torque

increases quickly the stator current is also increasing

regardless of its phase variation. In that case is not changing

significantly, it swings by near the value, which was

before the load transient. The worst case for the tuning

algorithm is rapid decrease of the load torque. In that case

motor current at the next step is always less than at the

previous one and tuning algorithm continuously changes

into direction, which depends on the sign of before the

transient. This problem can be solved by setting limits for the

. These limits can be defined by simulation or measured

during motor test. Another solution is to define the transient

and switch the tuning algorithm off during that time. Usually

there are two external factors, which can cause the transient:

commanded speed and load torque. So control system has to

analyze commanded speed and commanded stator current and

if they are changing the control system has to stop tuning.

Since tuning algorithm uses current magnitude only for

comparison, it is better to use squared value of this parameter,

which skips square root calculation and saves processor time.

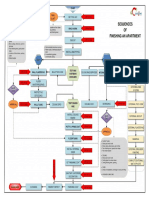

The flowchart of the described algorithm is shown in Fig. 10.

It should be taken into account that current minimum at the

constant torque usually is not strongly pronounced, so

typically current vector is oscillating near its minimum. It

should be also noted that current vectors which phases differ

by small angle have almost the same magnitudes, so

measurement error can affect the algorithm. To avoid it the

current filtering should be used or variation value should

be increased.

1 + k

s

I

k

s

I

Fig. 9. Motor current phase variation

Start of MTPA

tuning

Define new current phase

k+1

=

k

+

Set new value of the for

MTPA block

k

=

k+1

min

k+1

max

Correct

k+1

Wait till speed controller

commands new current vector

and it is set

Calculate average squared

amplitude of the current vector

End of MTPA

tuning

( ) ( )

2 2

1 k

s

k

s

I I <

+

Fig. 10. Flowchart of MTPA tuning algorithm

TABLE I

MOTOR PARAMETERS

Parameter Value

Number of poles 2P = 16

Rated power, W 1000

Rated current, A 6

Rated speed, rpm 400

Phase resistance, 8.3

d-axis inductance, mH 144

q-axis inductance, mH 168

Back-EMF constant, Vs/rad 0.53

1358 978-1-4244-1766-7/08/$25.00 2008

IV. EXPERIMENTAL RESULTS

A. Experimental system

Experiments have been performed on the 1 kW IPMSM

coupled with the DC load machine. Rated motor parameters

are given in the Table 1. The load machine is controlled from

the PC and is used as a programmable load for the tested

motor. The motor is driven by the three-phase voltage source

PWM inverter, which is based on the Fairchild

FSBB20CH60F (20 A/600 V) smart power module. Motor

position is measured by means of 4096 pulse per revolution

quadrature encoder. Control system is built on the base of 60

MIPS Matsushita microcontroller MN103SFA7K, which

controls inverter with 10 kHz PWM. There are 3 sensors in

the developed system: two current hall-sensors in the motor

phases and DC-link voltage sensor. All the analog signals are

converted by the 10-bit ADC of microcontroller with

sampling time of 100 s. Test installation was designed to be

supplied from the standard 220 V (50 60) Hz source.

Experimental board also contains RS-232 interface, which is

used for connection with PC for monitoring of the algorithm

variables. For the experiments there was used conventional

MTPA control scheme with additional block of the MTPA

tuning algorithm. Fig. 14 shows a schematic of the

experimental system.

B. Motor characteristics

To verify validity of the proposed MTPA control algorithm

real motor characteristics have been obtained. They were

measured by manual changing of the stator current phase

with the step of 1 for several values of the load torque. Then

the points with the lowest current have been selected and

motor MTPA characteristics have been plotted. Fig. 11 shows

dependence of the motor torque on its current under MTPA

control. Fig. 12 shows motor MTPA trajectory in the terms of

stator current and its phase and Fig. 13 shows the MTPA

trajectory in the terms of stator current components i

d

and i

q

.

I [A]

5 10

20

40

T [Nm]

Experimental

Calculated using rated

parameters

Fig. 11. Motor torque vs. current

under MTPA control

I

s

[A]

[]

5 10

100

110

120

90

Experimental

Calculated using rated

parameters

Fig. 12. MTPA trajectory in terms of

stator current and its phase

Fig. 13. MTPA trajectory in terms of

i

d

and i

q

Speed

Controller

i

q

Controller

i

q

i

d

Controller

i

d

u

q c

u

d c

I

s c

i

q

i

d

i

d c

MTPA

i

q c

SVPWM

I

n

v

e

r

t

e

r

ref

u

DC

VT 220 V

Tuning

algorithm

IPMSM

Encoder

d

s

,q

s

d

e

,q

e

Speed and

position

calculation

a,b

d

e

,q

e

Fig. 14. Schematic of the experimental system

1359 978-1-4244-1766-7/08/$25.00 2008

Dashed lines show dependences, which were calculated using

rated parameters of the motor. It is seen that saturation

strongly impact motor characteristics and conventional

MTPA algorithms based on (3) and (7) are not applicable.

C. Performance of the proposed algorithm

Proposed MTPA algorithm has been implemented in C and

tested with the system, which was described earlier. Fig. 15

shows commanded load torque and current phase, selected by

the tuning algorithm. At this experiment the tuning algorithm

ran with the frequency of 20 Hz and phase variation of 2 .

Fig. 15 shows commanded load torque (a), current phase,

which was selected by the tuning algorithm, when it operated

during transients (b) and when it was disabled (c).

It is clear that tuning algorithm fails at the rapid change of

the load torque. At that, when load torque increases the

current phase oscillates near the value before rising, but when

the load torque decreases, the current phase changes until it

reaches maximum or minimum limit.

Fig. 16 shows commanded load torque and corresponding

current phase . For the load torque there were selected the

same points as for motor testing, which allow to compare

output of the algorithm with the motor MTPA trajectory.

Fig. 16 shows that proposed algorithm successfully detects

motor MTPA trajectory, especially at the load torque over

20 Nm.

V. CONCLUSION

In this paper, robust self-tuning MTPA algorithm for

IPMSM drives has been presented. The proposed method

does not use computed motor parameters, which vary

depending on motor operational point. The control structure

is similar to the conventional one, but uses additional MTPA

tuning block, which sets phase for the stator current. This

block continuously varies current phase and selects the angle,

which corresponds to the lowest current at the given load

torque.

Experimental results have been presented to demonstrate

validity of the developed algorithm. They showed that

proposed algorithm works well even with motors, which have

small difference between L

d

and L

q

.

REFERENCES

[1] Y.A.-R.I. Mohamed, T.K. Lee, Adaptive self-tuning MTPA vector

controller for IPMSM drive system, IEEE Transactions on Energy

Conversion, vol. 21, pp. 529-551, September 2006.

[2] T.M. Jahns, G.B. Kliman, T.W. Neumann, Interior Permanent-Magnet

Synchronous Motors for Adjustable-Speed drives, IEEE Trans. On Ind.

Appl., Vol IA-22, pp. 738-747, July/Aug. 1986.

[3] H.B. Kim, J. Hartwig, R.D. Lorenz, Using on-line parameter

estimation to improve efficiency of IPM machine drives, IEEE 33

rd

Power Electronics Specialists Conference, vol. 2, pp. 815-820, June

2002.

[4] H. Hajime, T. Yoshio, K. Keiji, Novel sensorless control for pm

synchronous motors based on maximum torque control frame,

European Conference on Power Electronics and Applications, pp. 1-10,

September 2007.

[5] S. Bolognani, L. Sgarbossa, M. Zordan, Self-tuning of MTPA current

vector generation scheme in IPM synchronous motor drives, European

Conference on Power Electronics and Applications, pp. 1-10,

September 2007.

[6] P. Niazi, H.A. Toliyat, A. Goodarzi, Robust Maximum Torque per

Ampere (MTPA) Control of PM-Assisted SynRM for Traction

Applications, IEEE Transactions on Vehicular Technology, vol. 56, pp.

1538-1545, July 2007.

[7] P. Niazi, H.A. Toliyat, Robust maximum torque per amp (MTPA)

control of PM-assisted synchronous reluctance motor, Twenty-First

Annual IEEE Applied Power Electronics Conference and Exposition,

pp. 1-8, March 2006.

Fig. 15. Commanded load torque (a) and current phase (b), (c)

Fig. 16. Commanded load torque (a) and current phase (b)

1360 978-1-4244-1766-7/08/$25.00 2008

You might also like

- PMSM Control Strategy ComparisonDocument4 pagesPMSM Control Strategy Comparisonpersian67No ratings yet

- Model Reference Adaptive Control Based Parameters Estimation of Permanent Magnet Synchronous Motor DriveDocument9 pagesModel Reference Adaptive Control Based Parameters Estimation of Permanent Magnet Synchronous Motor DriveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Direct Torque Control Method For CSC Based PMSG Wind Energy Conversion SystemsDocument7 pagesA Direct Torque Control Method For CSC Based PMSG Wind Energy Conversion SystemsLê Xuân ThăngNo ratings yet

- PMSM Flux Weakening ControlDocument8 pagesPMSM Flux Weakening ControlOsama AttookNo ratings yet

- A54 2 Korzeniewski Improved Algorithms of Direct Torque Control MethodDocument11 pagesA54 2 Korzeniewski Improved Algorithms of Direct Torque Control MethodMohamed Elsaid El ShallNo ratings yet

- Research Article: A DSP-Controlled Permanent Magnet Synchronous Motor Control System For Hybrid VehiclesDocument9 pagesResearch Article: A DSP-Controlled Permanent Magnet Synchronous Motor Control System For Hybrid VehiclesMeryouma LarbNo ratings yet

- DSP Control of Stepper MotorDocument5 pagesDSP Control of Stepper MotorAhmedHyderMohdNo ratings yet

- Speed Regulation An Induction Motor Using Reference Adaptive ControlDocument5 pagesSpeed Regulation An Induction Motor Using Reference Adaptive ControlAtakan OzturKNo ratings yet

- Archive of SID: Performance Analysis of A Cost Effective 4-Switch 3-Phase Inverter Fed IM DriveDocument6 pagesArchive of SID: Performance Analysis of A Cost Effective 4-Switch 3-Phase Inverter Fed IM DrivePranav VyasNo ratings yet

- Sensorless Control of Permanent Magnet Synchronous Motor A Survey WWW - Daneshpajooh.irDocument8 pagesSensorless Control of Permanent Magnet Synchronous Motor A Survey WWW - Daneshpajooh.ira1690074No ratings yet

- Thesis On Direct Torque ControlDocument6 pagesThesis On Direct Torque Controlericabaldwinpittsburgh100% (2)

- 2019-Field Weakening Operation Control Strategies of PMSM Based On LinearizationDocument18 pages2019-Field Weakening Operation Control Strategies of PMSM Based On LinearizationKiki RamadhanNo ratings yet

- Sliding ModeDocument13 pagesSliding ModeSiva Ganesh MallaNo ratings yet

- Fuzzy Mras PMSMDocument6 pagesFuzzy Mras PMSMFrancisco Liszt Nunes JuniorNo ratings yet

- A New MTPA Control Strategy For Sensorless V-FDocument5 pagesA New MTPA Control Strategy For Sensorless V-FmmnamaziNo ratings yet

- Adaptive Bandwidth Approach ON DTC Controlled Induction MotorDocument9 pagesAdaptive Bandwidth Approach ON DTC Controlled Induction MotorijicsjournalNo ratings yet

- ANN PMSM Speed ControlDocument8 pagesANN PMSM Speed ControlKushagra KhamesraNo ratings yet

- New Sensor LessDocument10 pagesNew Sensor LessAbhishek AgarwalNo ratings yet

- 2015 Fast-SpeedDrivesforPermanentMagnetDocument7 pages2015 Fast-SpeedDrivesforPermanentMagnetjemmyducNo ratings yet

- 445 AndradaDocument5 pages445 AndradaNishant GoyalNo ratings yet

- Calculation of Total Current Harmonic Distortion by PWM Method For Permanent Magnet Synchronous MotorsDocument4 pagesCalculation of Total Current Harmonic Distortion by PWM Method For Permanent Magnet Synchronous MotorsShakeel RanaNo ratings yet

- PID Controller For A Two Quadrant Chopper Fed DC Motor DriveDocument5 pagesPID Controller For A Two Quadrant Chopper Fed DC Motor DriveSalman HabibNo ratings yet

- Fuzzy Logic Based Direct Power Control of Induction Motor DriveDocument11 pagesFuzzy Logic Based Direct Power Control of Induction Motor DriveNagulapati KiranNo ratings yet

- Project Title-4Document24 pagesProject Title-4Sallapally Durga bhavaniNo ratings yet

- Runge-Kutta Model Predictive Speed Control For PerDocument17 pagesRunge-Kutta Model Predictive Speed Control For PerAmir KrzNo ratings yet

- Parameter Estimation For Electric Motor Condition MonitoringDocument12 pagesParameter Estimation For Electric Motor Condition MonitoringNatarajNo ratings yet

- Sliding Mode Control of Induction Motor ThesisDocument6 pagesSliding Mode Control of Induction Motor Thesiss0kuzej0byn2100% (2)

- Vector Control Simulation of AC MotorDocument16 pagesVector Control Simulation of AC MotorJosedocampocastro100% (1)

- Design and Implementation of The Extended Kalman Filter For The Speed and Rotor Position Estimation of Brushless DC MotorDocument9 pagesDesign and Implementation of The Extended Kalman Filter For The Speed and Rotor Position Estimation of Brushless DC MotorSoujanya VinnakotaNo ratings yet

- Application of Space Vector Modulation in Direct Torque Control of PMSMDocument4 pagesApplication of Space Vector Modulation in Direct Torque Control of PMSMenmnabilNo ratings yet

- Jeas 0408 94Document7 pagesJeas 0408 94Jun Chee LimNo ratings yet

- A Modified Sensorless Control of Induction Motor Based On Reactive PowerDocument4 pagesA Modified Sensorless Control of Induction Motor Based On Reactive PowerSherif M. DabourNo ratings yet

- 3 Methods for Controlling Stepper Motor SpeedDocument9 pages3 Methods for Controlling Stepper Motor SpeedChayan MondalNo ratings yet

- Simulation and Analysis of Modified DTC of PMSMDocument10 pagesSimulation and Analysis of Modified DTC of PMSMpreetivermaeeeNo ratings yet

- Direct Torque Control of Induction Motor Using Artificial Neural NetworkDocument7 pagesDirect Torque Control of Induction Motor Using Artificial Neural NetworkMohamed SomaiNo ratings yet

- Three-Phase Induction Motor DTC-SVM Scheme With Self-Tuning PI-Type Fuzzy ControllerDocument6 pagesThree-Phase Induction Motor DTC-SVM Scheme With Self-Tuning PI-Type Fuzzy Controllerjorgeluis.unknownman667No ratings yet

- 12.an Enhanced MPPT Technique For Small-Scale Wind Energy Conversion SystemsDocument7 pages12.an Enhanced MPPT Technique For Small-Scale Wind Energy Conversion SystemsRamesh KomarasamiNo ratings yet

- Adaptive Torque Pulsation Compensation For A High-Torque DC Brushless Permanent Magnet MotorDocument6 pagesAdaptive Torque Pulsation Compensation For A High-Torque DC Brushless Permanent Magnet Motorfong jeffNo ratings yet

- Model Predictive Control Based Hybrid MPPT... Irmak2019Document28 pagesModel Predictive Control Based Hybrid MPPT... Irmak2019hafiz858No ratings yet

- Speed Control of DC MotorDocument10 pagesSpeed Control of DC MotorYadira RocanoNo ratings yet

- ST Motor Controller 1878Document22 pagesST Motor Controller 1878Ali ErNo ratings yet

- High-Speed and High-Precision Tracking Control Ofultrahigh-Acceleration Moving-Permanent-Magnetlinear Synchronous MotoDocument9 pagesHigh-Speed and High-Precision Tracking Control Ofultrahigh-Acceleration Moving-Permanent-Magnetlinear Synchronous MotoDoru DumitracheNo ratings yet

- Dynamic Performance and Analysis of Direct Torque Control Method Based On DSP For PMSM DrivesDocument5 pagesDynamic Performance and Analysis of Direct Torque Control Method Based On DSP For PMSM DrivesRaspy ReddyNo ratings yet

- DC Link Approach To Variable-Speed, Sensorless,: Induction Motor DriveDocument5 pagesDC Link Approach To Variable-Speed, Sensorless,: Induction Motor DrivesamirmansourNo ratings yet

- Acta 2013 1 07 PDFDocument6 pagesActa 2013 1 07 PDFAhmet Yasin BaltacıNo ratings yet

- DSP-Based Speed Adaptive Flux Observer of Induction MotorDocument5 pagesDSP-Based Speed Adaptive Flux Observer of Induction MotorthavaselvanNo ratings yet

- Speed Control of PMSM by Using DSVM - DTC TechniqueDocument5 pagesSpeed Control of PMSM by Using DSVM - DTC TechniqueKushagra KhamesraNo ratings yet

- 2017 - Finite-Control Set MPC Method For Tourque Control of IM Using A State Tracking Cost IndexDocument13 pages2017 - Finite-Control Set MPC Method For Tourque Control of IM Using A State Tracking Cost IndexjemmyducNo ratings yet

- Identification of The Machine Parameters IN Vector Controlled Induction Motor DriveDocument6 pagesIdentification of The Machine Parameters IN Vector Controlled Induction Motor DriveBelkacem BerrehailNo ratings yet

- Induction Motor Design Using FEMMDocument13 pagesInduction Motor Design Using FEMMJunaid AhmadNo ratings yet

- Modeling and Simulation of PermanentDocument83 pagesModeling and Simulation of PermanentSriram Anil Kumar GandhamNo ratings yet

- DC Motor Speed Control Methods Using MATLAB - Simulink and Their Integration Into Undergraduate Electric Machinery CoursesDocument9 pagesDC Motor Speed Control Methods Using MATLAB - Simulink and Their Integration Into Undergraduate Electric Machinery CoursesWen ZJNo ratings yet

- Sarac 2016Document7 pagesSarac 2016Marko_DelNo ratings yet

- Parameter Identification and Comparision of An Induction Motor ModelsDocument11 pagesParameter Identification and Comparision of An Induction Motor ModelsJUAN4201No ratings yet

- A Vector Control System of PMSM With The Assistance of Fuzzy PID ControllerDocument6 pagesA Vector Control System of PMSM With The Assistance of Fuzzy PID ControllerFelix Adrian Trujillo PerdomoNo ratings yet

- Vector Control of A Permanent-Magnet Synchronous Motor Using AC-AC Matrix ConverterDocument11 pagesVector Control of A Permanent-Magnet Synchronous Motor Using AC-AC Matrix ConverterKushagra KhamesraNo ratings yet

- Average Torque Control of The Switched Reluctance Motor in High Speed ZoneDocument5 pagesAverage Torque Control of The Switched Reluctance Motor in High Speed ZoneAlexander KrasovskyNo ratings yet

- Tesis JuanCamiloNustes Article Format Draft2Document19 pagesTesis JuanCamiloNustes Article Format Draft2kamdem kouam ynnickNo ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Coteccons ProfileDocument49 pagesCoteccons ProfileGiang LamNo ratings yet

- Coteccons ProfileDocument49 pagesCoteccons ProfileGiang LamNo ratings yet

- Singapore VDC Guide Version1 Oct2017Document204 pagesSingapore VDC Guide Version1 Oct2017Le Thi Anh TuyetNo ratings yet

- Design For Deconstruction Using Integrated Lean Principles and BIM ApproachDocument19 pagesDesign For Deconstruction Using Integrated Lean Principles and BIM ApproachGiang LamNo ratings yet

- Specific Registration Requirements For Mechanical & Electrical Workhead (Me)Document5 pagesSpecific Registration Requirements For Mechanical & Electrical Workhead (Me)Giang LamNo ratings yet

- Michael Judd Hawkins Brown CompressedDocument68 pagesMichael Judd Hawkins Brown CompressedGiang LamNo ratings yet

- BIM Booklet20 Full Version LRDocument86 pagesBIM Booklet20 Full Version LRGiang LamNo ratings yet

- BIM-lean Construction-A Case StudyDocument10 pagesBIM-lean Construction-A Case StudyGiang LamNo ratings yet

- MEP CoordinationDocument42 pagesMEP CoordinationGiang LamNo ratings yet

- Arcadis Insights Mar 2019 - DFMADocument5 pagesArcadis Insights Mar 2019 - DFMAGiang LamNo ratings yet

- Plug-and-Play Solutions For Energy-Efficiency Deep Renovation of European Building StockDocument5 pagesPlug-and-Play Solutions For Energy-Efficiency Deep Renovation of European Building StockGiang LamNo ratings yet

- MEP Method For CoordinationDocument35 pagesMEP Method For CoordinationGiang Lam100% (1)

- IAEA SOW Dismantle and Installation of Cooling SystemDocument6 pagesIAEA SOW Dismantle and Installation of Cooling SystemAnonymous ZnuMEWN1No ratings yet

- BIM-lean Construction-A Case StudyDocument10 pagesBIM-lean Construction-A Case StudyGiang LamNo ratings yet

- Singh Et Al. 2018 - Implementation of Mass Customization For Mep Layout Design To Reduce Manufacturing Cost in One-Off ProjectsDocument10 pagesSingh Et Al. 2018 - Implementation of Mass Customization For Mep Layout Design To Reduce Manufacturing Cost in One-Off ProjectsGiang LamNo ratings yet

- Finishing Sequence: Trade: PlasteringDocument1 pageFinishing Sequence: Trade: PlasteringGiang LamNo ratings yet

- Plug-and-Play Solutions For Energy-Efficiency Deep Renovation of European Building StockDocument5 pagesPlug-and-Play Solutions For Energy-Efficiency Deep Renovation of European Building StockGiang LamNo ratings yet

- IAEA SOW Dismantle and Installation of Cooling SystemDocument6 pagesIAEA SOW Dismantle and Installation of Cooling SystemAnonymous ZnuMEWN1No ratings yet

- SmartLogger3000A - 80 device monitoring, IP20 protection, -40°C to 60°C operationDocument1 pageSmartLogger3000A - 80 device monitoring, IP20 protection, -40°C to 60°C operationGiang LamNo ratings yet

- R 505 0128 Dismantling and Assembling Plant or Machinery Components To Replace Worn Damaged or Faulty Parts in The WorkplaceDocument4 pagesR 505 0128 Dismantling and Assembling Plant or Machinery Components To Replace Worn Damaged or Faulty Parts in The WorkplaceGiang LamNo ratings yet

- Case bán lẻDocument2 pagesCase bán lẻGiang LamNo ratings yet

- R 505 0128 Dismantling and Assembling Plant or Machinery Components To Replace Worn Damaged or Faulty Parts in The WorkplaceDocument4 pagesR 505 0128 Dismantling and Assembling Plant or Machinery Components To Replace Worn Damaged or Faulty Parts in The WorkplaceGiang LamNo ratings yet

- Fan Source BookDocument92 pagesFan Source Bookapi-3808778100% (10)

- Finishing Sequence: Trade: PlasteringDocument1 pageFinishing Sequence: Trade: PlasteringGiang LamNo ratings yet

- Fan Input Power Calculation Made Easy: Example 1 - Direct Drive MotorDocument7 pagesFan Input Power Calculation Made Easy: Example 1 - Direct Drive MotorGiang LamNo ratings yet

- Quy Trinh Hoan Thien Can HoDocument1 pageQuy Trinh Hoan Thien Can HoGiang LamNo ratings yet

- LV MT/MT Series Datasheet: Technical DataDocument2 pagesLV MT/MT Series Datasheet: Technical DataGiang LamNo ratings yet

- Quy Trinh Tran Thach CaoDocument1 pageQuy Trinh Tran Thach CaoGiang LamNo ratings yet

- Finishing Sequence: Trade: PlasteringDocument1 pageFinishing Sequence: Trade: PlasteringGiang LamNo ratings yet

- 20170808.master Schedule Block C For Client - rv02Document3 pages20170808.master Schedule Block C For Client - rv02Giang LamNo ratings yet

- Laboratory Activity No. 01 - Properties of LiquidDocument2 pagesLaboratory Activity No. 01 - Properties of LiquidCzarina Relleve0% (1)

- XG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial NumbersDocument153 pagesXG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial Numbersalexandre donizetiNo ratings yet

- Create Login Application In Excel Macro Using Visual BasicDocument16 pagesCreate Login Application In Excel Macro Using Visual Basicfranklaer-2No ratings yet

- Murat Kenedy: Bu Içerik Tarafından HazırlanmıştırDocument2 pagesMurat Kenedy: Bu Içerik Tarafından HazırlanmıştırChatorg. orgNo ratings yet

- Hybrid Electric Bike ResearchDocument31 pagesHybrid Electric Bike Researchmerlinson1100% (5)

- Module 1 SIMPLE INTERESTDocument15 pagesModule 1 SIMPLE INTERESTElle Villanueva VlogNo ratings yet

- BSBCRT511 Project Portfolio - Revised - Answers IncludedDocument26 pagesBSBCRT511 Project Portfolio - Revised - Answers IncludedShivanee JhaumalNo ratings yet

- 2219 Aluminium Alloy - WikipediaDocument2 pages2219 Aluminium Alloy - WikipediaVysakh VasudevanNo ratings yet

- Us00-000 831 01 02 02Document18 pagesUs00-000 831 01 02 02Cristian Camilo0% (1)

- COE 107.04 Cathodic Protection Monitoring Instruments and ProceduresDocument42 pagesCOE 107.04 Cathodic Protection Monitoring Instruments and ProceduresMo'tasem Serdaneh100% (1)

- Caso de Estudio 14.1, 14.2 y 14.3Document6 pagesCaso de Estudio 14.1, 14.2 y 14.3Rodolfo G. Espinosa RodriguezNo ratings yet

- Teknik JWB Maths Spm-PANGDocument42 pagesTeknik JWB Maths Spm-PANGhidayahNo ratings yet

- ACL-PDC-01 - Rev01 (Procurement Document Control)Document3 pagesACL-PDC-01 - Rev01 (Procurement Document Control)Mo ZeroNo ratings yet

- 6.1 Calculation of Deflection: 1) Short Term Deflection at Transfer 2) Long Term Deflection Under Service LoadsDocument7 pages6.1 Calculation of Deflection: 1) Short Term Deflection at Transfer 2) Long Term Deflection Under Service LoadsAllyson DulfoNo ratings yet

- Maintenance Procedure For Switchyard Equipment Volume-II (EHDocument39 pagesMaintenance Procedure For Switchyard Equipment Volume-II (EHbisas_rishiNo ratings yet

- 3.dummy VariablesDocument25 pages3.dummy VariablesUnushka ShresthaNo ratings yet

- Coal Gasification, Liquid Fuel Conversion (CTL), and CogenerationDocument66 pagesCoal Gasification, Liquid Fuel Conversion (CTL), and CogenerationVăn Đại - BKHNNo ratings yet

- Off-Highway 6600 Series Transmission SpecsDocument2 pagesOff-Highway 6600 Series Transmission SpecsIng Dimatiguz0% (1)

- GF - 4 - GF - 6 - 790 700 337 - 01 - enDocument2 pagesGF - 4 - GF - 6 - 790 700 337 - 01 - enAdrianNo ratings yet

- PandoraFMS Alerts WhatsappDocument6 pagesPandoraFMS Alerts Whatsapppacolo89No ratings yet

- LG - Week 1 - Operations - ManagementDocument4 pagesLG - Week 1 - Operations - ManagementMechaella Shella Ningal ApolinarioNo ratings yet

- What Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageDocument5 pagesWhat Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageNiraj MistryNo ratings yet

- Universal Chargers and GaugesDocument2 pagesUniversal Chargers and GaugesFaizal JamalNo ratings yet

- A320 Flex CalculationDocument10 pagesA320 Flex CalculationMansour TaoualiNo ratings yet

- 104 Joycecaroloates Wrug ElectraDocument1 page104 Joycecaroloates Wrug ElectraAnca LascuNo ratings yet

- Follow The Directions - GR 1 - 3 PDFDocument80 pagesFollow The Directions - GR 1 - 3 PDFUmmiIndia100% (2)

- ETEEAP Application SummaryDocument9 pagesETEEAP Application SummaryAlfred Ronuel AquinoNo ratings yet

- Katsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsDocument33 pagesKatsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsHamisu TafashiyaNo ratings yet

- Public Dealing With UrduDocument5 pagesPublic Dealing With UrduTariq Ghayyur86% (7)

- Exp# 1c Exec System Call Aim: CS2257 Operating System LabDocument3 pagesExp# 1c Exec System Call Aim: CS2257 Operating System LabAbuzar ShNo ratings yet