Professional Documents

Culture Documents

No-Hassle Clothes Hanger Final Report

Uploaded by

Ali GhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No-Hassle Clothes Hanger Final Report

Uploaded by

Ali GhCopyright:

Available Formats

24-441 Design 2: Conceptualization

and Realization

The No-Hassle

Clothes Hanger

Final Report

Group B4: Mark T. Brandau, Meehyun Jang, Patrick Ward

5/12/2009

2

Contents

Summary ........................................................................................................................................ 3

Introduction ................................................................................................................................... 3

Motivation ................................................................................................................................................................. 3

Existing Product ........................................................................................................................................................ 4

New Product/Solution ............................................................................................................................................... 5

Design Team .................................................................................................................................. 5

Market Research ........................................................................................................................... 6

User Study ................................................................................................................................................................ 6

SET Factor Analysis ................................................................................................................................................. 9

VOA ........................................................................................................................................................................ 10

Concept Generation .................................................................................................................... 11

Brainstorming 1 ...................................................................................................................................................... 11

Brain Storming 2 ..................................................................................................................................................... 13

Sketches of Top Concepts ....................................................................................................................................... 15

Prototype Design ......................................................................................................................... 17

Prototype 1: ............................................................................................................................................................. 17

Prototype 2 .............................................................................................................................................................. 18

Prototype 3 .............................................................................................................................................................. 19

Conclusion from the Prototypes .............................................................................................................................. 19

Detailed Design ............................................................................................................................ 20

Design Parts ............................................................................................................................................................ 20

Engineering Analysis .............................................................................................................................................. 21

Manufacturing Techniques ..................................................................................................................................... 22

Assembly of the Parts ............................................................................................................................................. 23

Life Cycle Assessment................................................................................................................. 24

Cost Report .................................................................................................................................. 24

Evaluation .................................................................................................................................... 25

Conclusion ................................................................................................................................... 27

What We Learned ................................................................................................................................................... 27

Revisiting SET, VOA, and Pugh Charts ................................................................................................................. 28

What would have we done differently? .................................................................................................................. 29

Unresolved Issues and Note for Continuation of Project ........................................................................................ 29

Appendix A .................................................................................................................................. 31

3

Summary

Using the time and materials available in one semester, we have identified a need and

issue of an existing product and we searched for a new answer. After a market research, a scope

of clothes organization was chosen and we sought for any particular issue or need for the

consumer until a certain discovery was made; the current tools available for clothes shopping

creates large amount of hassle and waste of time. From this point, a concept was generated and

refined through multiple brainstorming sessions, and then final concept was made into a final

product after 3 prototypes. As the time of deadline drew closer, the design and engineering

analysis processes become much more detailed. Through the designing process, the progress and

outcomes were constantly evaluated to find flaws and maximize the result. The project itself

faced many challenges as there were various issue regard to its design, but as well as the team

work involved. As the final result, clothes hanger with variable geometry was manufactured that

fulfilled mostly to our initial evaluation of improvement from the original, existing clothes

hanger.

Introduction

Motivation

Organization is one of the key factors relating to productivity in clothing stores as it can

greatly improve the experience for both the employees and the customers. Unfortunately, the

current products available to display, store, and organize clothing articles are not entirely

promising. These insufficient products lead to many awkward behaviors that are frequently

observed in both the employees and the customers. In addition, the insufficient functionality of

the available devices causes disorganization to escalate very quickly during busy shopping hours.

It was discovered that inefficiency of organizing caused inconvenience to both shoppers and the

employees as frustrated shoppers refuse to keep clothes in an organized state which creates more

work for the employees. These employees must also make time to take care of customers other

needs in a store, which is difficult when their time is sapped away trying to keep clothes

organized. We identified this to be the problem and sought for the best solution that would

increase the efficiency of organizing devices in clothing stores.

4

Existing Product

Existing hangers used in clothing shop come in many different shapes but there are

definitely some governing features such as slight angle on the shoulder pads and the overall

triangular shape due to the hook. Even though there are variations depending on the store, the

amount of time required for users to handle them does not vary at all. This is mainly because of

the way the hanger is shaped; the hanger must have a hook extending out from the neck-opening

of the clothing articles while still supporting the clothes by applying force on the shoulder area.

Due to a requirement that clothes must be suspended in a vertical manner, the clothes hanger

must be shaped like shown above. While this shape is optimal for hanging clothing articles, it is

not very friendly for inserting and removing the hanger in and out of clothes rapidly. This hanger

is also notoriously troublesome to use if the clothes have inflexible, thin neck area such as

sweaters and even some shirts. This information was extracted from market research, which will

be discussed in detail in Market Research Section in page 6.

5

New Product/Solution

As a solution, the hanger was designed to be able to change its shape so that it can be

quickly inserted from the top, through neck-opening of clothes instead from entering from the

bottom. This variable geometry also have handles on the top so that this tool would be operated

easily using one hand, giving only a single motion for it to enter clothing and be released once

the hanger is fully inserted, and ready to be hanged promptly.

Design Team

Meehyun Jang: A senior mechanical engineering, she has a strong interest in drawing which

she used to great effect during the conceptualization of the product. During the early stage, she

was also active for brainstorming and market researching for the issue and narrowing down the

project scope.

Mark Brandau: Mark is a graduating senior entering the US Navy submarine fleet. His

main contribution to the project was in the manufacture of the prototypes. He also played a big

part in our market research and in the writing of our reports.

Patrick Ward: A senior mechanical engineering student who will be working next year in his

hometown of Washington, D.C. doing naval engineering for CSC. Handled the bulk of the

Computer-aided Design work in SolidWorks, and put verbal and interpersonal skills to good use

in taking the lead in the writing of design reports and the giving of design presentations.

6

Market Research

We looked into the market to see what could be improved at the retail level for clothing

management. We asked employees at several major retail outlets, including Marshalls, Macys

and TJ Max what their main issues with their jobs were. They described it as constantly turning

over clothing that customers had tried on and carelessly left out, or, in the fitting rooms, where

there is always turnover to be done. Employees often complained that their job is repetitive and

inefficient. Employees to whom we showed our second prototype were greatly enthused by it,

saying it would be a major help to them if we could make it work as advertised.

User Study

User 1: Home users and students

This portion of the research, unfortunately, was done prior to the conclusion made about

the correct question form. Therefore they were asked in a form of what are the inconveniences

of using the following devices? or what are the inconveniences encountered while organizing

clothes? Half of the users were interviewed by physical contact while the other half were

contacted over the internet. The users from the physical contacts were 6 students entirely from

Carnegie Mellon University. Many were still utilizing the clothes hangers with some use of

drawers, and only 1 out of 6 students did not mention any trouble. Through this interaction, it

was concluded that hangers and drawers have the following issues.

Hangers: Very inconvenient with shirts with buttons. They tend to break in the base of its

triangular structure. They are often let the clothes slip off.

Drawers: They are not deep enough.

The contacts obtained from internet were entirely students as well (2 out of 12 were high school

students. 1 out of 12 graduated but have no job. The rest were still attending college), but they

were not from the same school, and surprisingly, none of them were using hangers except for

hanging larger clothes such as winter coat.

Hangers: Not used except for coats or pants.

Drawers: Clothes become stuck in the small gap between the drawer and its containing

box. The drawer themselves get stuck. They are incapable of being spacey.

Baskets: More convenient than hangers and drawers, thus most users claimed to use

them. However the accessibility is too low (they cannot find the clothes they want

quickly).

Other odd devices the users were utilizing were pillow cases, shelves, and cubes.

All of them appeared to be substitutes with which to avoid using clothes hangers.

7

User 2: Department store employees

For these users, the questioning approach changed; now they were asked to go through

their typical day at work. Depending on the structure of the store, the workers schedule was

different.

Large Malls [Macys] : We defined this type of store to be oriented by categories.

Employees work by their station which also includes their sections of clothes. Workers

schedule flexibly changes between three tasks: taking care of customers, organizing or

cleaning up, and relocating or redistributing clothes back to display. Taking care of

customers mainly involved helping the customers check out or accepting unwanted clothes.

Organizing clothes required workers to walk around their section and pick up any items that

are not displayed correctly, such as ones abandoned by customers or dropped to the floor.

Redistributing clothes was done to return all clothes into their correct section. These clothes

pile up from multiple sources; from their station, clothes in wrong categories or section, and

clothes from the fitting room. Taking care of customers had the highest priority, but the

workers shared that the redistributing task took the longest time, thus the redistributing task is

not initiated until the clothes have piled up significantly or there are no customers in their

station. Some employees explained their tasks before the stores opens up. The tasks were

mainly organizing, but a device called folding table and folding board(more mobile) was

introduced. These tools are considered unattractive, thus they are usually hidden from

being seen by the customers. This causes the employees to fold clothes using their hands

during the time the shop is open.

Small Store [Gap, Express] : We also defined this type of store to be oriented by

categories, except in a smaller form. The tasks were very similar among the employees

except that there are no stations, thus employees are separated to take care of different

tasks (but these switch after a certain amount of time). One observation we made in the

Express left us an odd impression was that the employees were folding clothes using folding

boards in sight. After few questioning, they moved it away but they claimed that this was due

to larger quantity of clothes were displayed in a folded manner on table and shelves.

Other [TJ Max, Marshalls]: We defined this type of store to be oriented by discounts

because the categorizing in these stores was a lot more general, and everything was displayed

in a cluttered and chaotic fashion, only separated by sizes or by very general categories such

as man and woman. The workers also rotated changing their tasks which were mainly

standing by the cashier, redistributing items, and watching over the fitting room. The unique

features of these stores was that employees were required to stand by the fitting room and

wait for enough clothes to pile up on their rack, which are redistributed later into the correct

section. Because organized look of the store is not as important as category-oriented stores,

workers do not take care of clothes as much but collecting and redistributing clothes are done

in a bigger bulk.

8

The following behaviors were observed when not employees were uninterrupted.

Nearly constantly go back to pick up clothes from shelves, racks, and floors. (For

Category-oriented shops) In a large mall, because each employee must take care of each

section, they move around quite frequently.

Look for clothes missing hangers, and hangers missing clothes.

Reorient clothes to face the correct directions of they are not.

When their pile in their back station is big enough, put hangers into each clothes and

return each of them to display. (According to the worker, a mobile rack is used on very

busy days)

Use folding board to fold shirts, but very often simply use hands.

User 3: Shoppers

The same approach was used for questioning these audiences. The answers were less

thorough as they have only one task to perform; to buy the item they desire. After a few attempts

of directly approaching the customers, we moved on to observing instead. The following

behaviors were observed when uninterrupted. Both behaviors were equally found in all three

types of stores studied.

Shoppers carried items using hands and arms to hold all clothes; it seemed to lack

security as some clothes slide off or the hanger drops from the clothes. Even so, the

shoppers avoided using carts unless they were planning to buy non-clothing items.

Unless they were navigating the clothes in the correct direction, the clothes often end up

oriented in an incorrect direction by the time the customers are trying to put the cloth

back into the rack. The customers either reoriented hangers hook, or return the cloth on

the rack by reversing the way cloth faces.

They easily left clothes on the rack or any flat surfaces available if it was too

inconvenient to return them to hangers.

Push brackets of clothes on rack forcefully to create space to navigate/insert/remove

items.

Various methods for inserting hanger into clothes quickly such as shoving hangers into

clothes through the neck, or pushing their hand through the clothes, grab the hanger, and

pull it inside. All methods required two hands.

9

SET Factor Analysis

Social:

Disorganized look have many negative impact on how one view another, a group, or even

a company. Organizing and taking care of the neat look is frequently practiced among many

different groups of people, and one of the objects that often fall under need of organizing is

clothes; shirts and pants laying on the floor, or jackets and coats hanging sloppily is not a very

nice sight under various surrounding. One of the reason the clothes are found unorganized is due

to the fact that effort is required to maintain an organized area. Depending on the individual, if

the effort is too much for them, the clothes will be found unorganized more frequently. If the

current device available for clothes organization was made to be more effective, allowing it to be

used with less time and effort, people would keep their personal spaces more organized, and

department stores would too. This would benefit personal users since they would have a neater

home and that would allow them to feel less awkward about inviting friends over.

Economy:

Currently, our economy is going down, this will cause many consumers to be more

careful and sensitive how much they spend on their every need, and look for cheaper products

when available. Department store like to emphasize current clearance to the consumers and this

will may attract shoppers more due to the current economy status. As observed, the clearance

section of the stores does not categorize clothes as much. Also, they are displayed in a cluttered

fashion which forces shoppers to go through each clothing articles; more clothing will be

touched, taken out, tried on, and sloppily put back. Because of this, department stores will be

more prone to chaos and so will the shopping environment for the shoppers. The ease of access,

faster and more efficient transfers, and the organization of clothing are essential to create better

shopping environment. With a neater environment, shoppers will be happier. Happier people

spend more money at stores. Also, if things are more organized, then they may spot something

they like that they would have missed if it was chaos instead of order. On the employee side of

the house, a disorganized store caused by shopper negligence will both give them more pointless

work and make them unhappier, both of which detract from their performance. If it is far easier

for consumers to replace their stuff, then the employees will have less pointless work and be

happier, increasing their productivity.

Technology:

The techniques used for storage of items here are technological factors that can be

adapted to other industries. Additionally, there is serious gadget factor potential in this area,

since existing products are so bland.

10

VOA

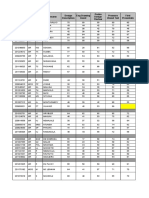

[Red = Existing, Yellow = existing tied with planned, Green = Planned Improvement]

Low Med High

Emotion Adventure

Independence

Security

Sensuality

Confidence

Power

Ergonomics Comfort

Safety

Ease of use

Aesthetics Visual

Auditory

Tactile

Olfactory

Gustatory

Identity Point in time

Sense of place

Personality

Impact Social

Environmental

Core Tech Reliable

Enabling

Quality Craftsmanship

Durability

11

Concept Generation

After our research, we identified several areas that could be improved through the

use of engineering. We saw that the hanger, folding board, and clothing rack could be improved

by our team. We then had a brainstorming session that outlined a large number of concepts we

could use, and came up with the following ideas for our product. Our project had total of 2 major

brainstorming sessions. The first one served as a very general and unrestricted conceptual

brainstorming whereas the second one was done with a more realistic, solution-oriented purpose.

Also note that the first brainstorming session had a much wider scope, also including ideas for

other products such as clothing rack and even drawers, as the final product had not been

specifically chosen.

Brainstorming 1

Only the concepts that are more relevant to our final design are listed here.

Clothes Hangers

Folding clothes hanger with Spring Mechanism

Pull-string retraction, possibly with some kind of lock.

Magnetic hangers

Ball hanger with hollow rack

Click-top release

Electronic alarm for misplaced clothes

Helical device wrapping around

Variable Length to vary separation amount

Color coded divider by size

Fat hanger tops to create separation

Double-sided hook or a hook that automatically goes in correct direction

Higher strength plastic or possibly cheap metal

Robot to grab and sort all of the clothes

Multiple locked settings to make it variable-width

Customizable notches to fit different types of clothing

Bendable small hanger you can wear your clothes with

Loop Hanger that is adjustable

Disconnectable hanger

12

Clothes Rack

Cut notches into clothes rack

Removable pants rack (hinged)

Telescoping rack pole

Clamps to hold clothing still while ironing

Stacking baskets with lock to keep together

Template for folding board for each set of clothes

Compartmentalized clothing rack

Bendable rack

A clothes shopping Cart/Removable Rack

Customer Relations

Label showing portion of store it belongs in

Signs encouraging customer to help keep organized

Drop-bar/basket for loose items

Put extra hangers at drop-box

With this brainstorming session finished, we then selected several of the most promising

possibilities from these concepts and then ran a detailed analysis on them by creating Pugh

Charts.

Selection

Criteria

Pull

String

Magnetic

head

Push-

and-

Release

Torsional

Spring

with

lock.

Existing

Fixed

Hanger

Weight

of

Category

Ease of Use

4 1 4 4 -2 1

Reduction

of Effort

3 2 3 4 0 1

Ease of

Manufacture

-1 -1 -4 -1 0 0.6

Gadget

Appeal

1 2 3 2 0 0.25

Durability

2 2 3 1 -1 0.7

Structure

Complexity

-2 0 -2 -1 0 0.5

Possible

Cost

-2 0 -1 -1 3 0.6

Weight

1 0 0 1 2 0.3

Net Score 6.15 4.3 5.85 7.8 -0.3

13

From our Pugh analysis, we saw that a torsional spring with a lock would be the best

solution to fill in our opportunity gap. A pull string mechanism was also considered for this one,

but the torsional spring was selected because it allowed easy one-handed operation, unlike the

string, which would require the use of both hands.

Brain Storming 2

Second brainstorming was done to search for better conceptual ideas. In parallel, it was

also done to design the product in more detail. The second brainstorming session was not

carefully recorded but there are examples of the outcomes:

This is a sketch for the joint concept where all the joints are shaped so that all arms can stay in

the same plane no matter how they rotate. The sketch also includes early concept for the snap

joints.

14

This is sketch of a different version of hanger with torsional spring. The design was made so that

it uses two handles instead of one. The angular distance between two handles is crucial since the

first handle is used to unlock the clothes hanger so that it can become collapsed. This design

was disregarded due to too much number of parts as well as undesirably high amount of

complication.

15

The outcome of the second prototype did not drastically change the direction from the top

concepts chosen from the first prototype, but it provided the project sufficient concepts for it to

develop more into the detail.

Sketches of Top Concepts

Pull-String Hanger

Push

Simple folding clothes hanger with stoppers

16

Push-Button Locking Mechanism

Torsional Spring in Joint

Simple folding clothes hanger with stoppers

17

Prototype Design

Prototype 1:

Purpose:

Prior to building this prototype, the brainstorming stage had reduced all of our initial

candidates down to four concepts. Even though, through Pugh chart analysis, the ranks of each

concept were pretty clear, due to each concepts unique features, especially for the joint

constructions, it was difficult to completely disregard any one idea. Therefore, this prototype was

created prior to officially choosing one design, with the hope that a simple prototype would

reveal the better concepts to use based on movement constraints and any problems encountered

with the prototype. It was also created to be made quickly and cheaply and give us the option of

trying out multiple designs at one time.

Construction:

This step of prototype itself had its own prototype and the final prototype was reached

after multiple tries and change in plan of construction. As a result, a cardboard prototype with

four joints and a stopper was created. This prototype design was expected to remove the

complicated need of multiple locks for joints but instead operate only with one lock and release

mechanism on the top joint. How it works it that, when an amount of weight is applied to two top

arms of the structure, the lower two arms would collapse upward, but they will be prevented

from actually collapsing by a catcher was installed at an arbitrary location where the lower

arms and the upper arm intersect.

18

Prototype 2

Purpose:

This prototype has the same basic role as the first prototype, except that it had a more

elaborate construction. This prototype was built in order to see whether the hanger will behave

correctly with its peculiar geometry along with stoppers installed, especially when the user

want to collapse the clothes hanger, and return it to its original position using handles.

Construction:

Similar to the last prototype, the basic components of the model were four heavy-paper

joints, two identical upper arms, two identical lower arms, and a hook at the top. However, this

time the arms were constructed from wires which were wrapped around each joint to reduce the

friction. These wires were then wrapped in cardboard sleeves to provide extra stability, as the

wires were very malleable and not very rigid. Also to add rigidity, the spool-joints were

extended out to provide a guiding track for the arms as they rotated and prevent unwanted

twisting. Also, additional foam pieces were added near the side joints to serve as the catcher

mechanism. Lastly, to prevent bending in wires, they became secured between two cardboard

arms. The lengths of the card board arms are not long enough to touch the spool.

19

Prototype 3

Purpose:

The third prototype, which was the last prototype that was built before the construction of

the final design, was made to test one of the concerns of a new change in the design; the scissor-

like handle operation unlike the previous prototype where each handles were simple protrusion

from each of the arms. In this design, because the handles are in scissor like orientation,

squeezing action on the system will collapse will only apply more load onto the hanger, only

causing it to press on the stopper without resulting any movement.

Construction:

It was constructed from cut wooden dowel rods, using thick paper rolls as the joints, and

a hook cut off a conventional clothes hanger as the hook. The scissor-like handles were

implemented hoping that it would work better if an elastic mechanism is applied, but because

third prototype was not very well constructed, it resulted no new insights.

Conclusion from the Prototypes

One of the key facts we learned during our prototyping was the idea that we could use the

hangers geometry to hold it up rather than a spring or a lock, something we didnt know until

we constructed our first prototype. From the second prototype, we concluded that a scissoring

mechanism, which we attempted to implement, wasnt practical.

20

Detailed Design

Design Parts

Custom Made Parts: The final product consisted of total of 6 separate parts; 5 out of 6

of the parts were custom-made while one was purchased. The custom-made parts were

manufactured using multiple 3D printers available on CMU campus. Multiple printers were used

in order to meet the time requirement as well as due to each machines different size constraints

as some parts were bigger than the printing area of the printer. All of the in-house components

were modeled in SolidWorks to accurately detail the final design, and was printed in the material

of ABS plastic. All the details of the dimension specifications of the manufactured parts is

displayed in Appendix A We employed no purchased or electrical parts in this model in an effort

to keep costs down.

Purchased Parts: Only one portion of the final design consisted of purchased

component, that component being the torsional spring. The details of the purchased springs

specifications are shown below. This specific spring was chosen mainly for its wind direction

and number of active coils. Wind direction and the leg length were chosen to fit into the shape

and size of the final product, especially for the handle area; two handles must cross each other,

which require one handle to overlap. This gap between two handles make flat springs difficult to

be implemented. It can be said the same for other dimensions such as spring outside diameter

and the leg length. Note that there were few changes in the final design in order to fit for the

spring as well.

Specification Detail

Material Steel Music Wire

Deflection Angle 180

Wind Direction Clockwise (Left-Hand) Wound

Spring Outside Diameter .803

Wire Diameter 0.078

Leg Length 2.000

Maximum Rod Outside Diameter 0.500

Spring Length at Torque 0.660

Number of Active Coils 7

Torque 10.446in-lbs

21

Engineering Analysis

We ran several analyses on our final model. We had to determine if our handles were

ergonomic enough for users to handle comfortably, and we also had to determine whether or not

it our parts would mechanically fail under standard loading. The more important analysis was

the ergonomic analysis we ran on the handles we used. The handles were intended for one

handed operation, and as such we designed them so that you could easily grip with one hand.

However, in addition to that, we had to ensure that when the handles were squeezed, the hands

remained comfortable. To do that, we designed the handles in such a fashion that as you

squeezed, your hand slid down, remaining comfortable, not crossing over, and sliding right into

the notch we carved for it.

In addition to the ergonomic analysis, we ran FEA analysis on our parts to determine if

they would fail under load.

22

We analyzed the snap joints, which we determined were the most likely point of

mechanical failure on the final assembly. Since we could only do proper FEA analysis on a part,

it was important to make sure that the conditions given to the part will be as close as possible to

the case where the part is assembled into the complete system. Boundary condition was applied

on the flat, round surface of the joint, and the neck area of the joint since both of the surface

will be in full contact when assembled. The loading was applied on the thinner part of the

mushroom shaped snap joint and the magnitude was 10N. This number was chosen so that the

clothes hanger can hold up to 2Kg of clothes. Initially, this was thought to be an overestimate

because of the angled surface of the top arm, distribution of clothing weight on the clothes

hanger would not be converted to a point force at the end of the joint. Unfortunately, this was

verified to be an underestimate because it did not take account of weight of the material; ABS

plastic. Based on the results of this FEA analysis, we determined that the maximum stress on the

snap joints was well within acceptable tolerances; the maximum stress in the joint was 10.4 times

smaller than the yield strength of ABS. Our loading conditions assumed the maximum loading

conditions expected under normal wear and tear. This analysis did not account for any extreme

loading conditions, but those are outside normal use.

Manufacturing Techniques

In order to construct our final prototype, we utilized the Art Departments 3D Printer,

which took our final CAD model and output a perfect match in ABS plastic. While a good

method for rapid prototyping, this is a poor method for mass production, since it is far more

expensive to use the 3D printer than is economical for mass production. No other methods were

tested as other machines available could not manufacture parts in plastic but aluminum instead. It

was important that our final design is not heavy, thus 3D printer was utilized. Also, because most

of parts of our design were rather miniscule, printing method appeared to be most optimal.

23

Assembly of the Parts

Our final design was made so that each part can be easily assembled by applying light

force into the snap joints to drive the mushroom-shaped joint into its slot. However, in the earlier

attempt of assembling printed parts, it required too much force. Using hammer, the parts were

able to be assembled but it resulted fracture in some of the snap joints. After this mistake, the

design joints were modified to have more clearance between the protruding head and its hole.

For the final assembly, a total of 7 parts were printed. These parts are displayed and

described on Appendix A; hook part, two handles, two top joints and two bottom joints. Once

our final parts had been 3D printed, it was assembled in a similar manner as the previous

assembling attempt with the test print, but required very light tap of hammer. The use of the

hammer may have been unnecessary, but doing so helped the joints remain flush throughout the

process which put less stress on the parts of the mechanism. The bottom joints were assembled

first, and then the spring was inserted into the hole available in the top joints handles. After the

spring was secure, the top handles snap joints were assembled into the holes made on the hook

part. As a result, these joints allowed full rotation of the parts while preventing the hangers parts

from twisting and moving out of the proper plane.

24

Life Cycle Assessment

If our final design was mass produced, it would require a great deal of ABS

plastic, or whichever other plastic the injection molding process utilized. The manufacturing will

also require stocks of springs which would be made of steel. Since it would be optimal to use

injection molding to make all the parts of the hanger, a heavy amount of heat input would be

required. Fortunately, there would not be much excess material that will become unusable since

they will be in liquid form to cast instead of other manufacturing techniques that creates excess

waste material such as forging or extruding. By comparison, this product will use more

resources as well as manufacturing time and cost than the existing hangers. Therefore this

product is not very energy efficient during the manufacturing part of the life cycle.

While in use in the market sector, the newly designed product has an advantage when it

comes to damage since if the bottom joints break the two bottom joints are identical and

therefore easily replaceable;. This reduces the chance of the hanger becoming completely useless

because a piece of part has failed, which would reduce the amount of waste from the users. Also,

all the part except the spring should be recyclable as the spring is the only part of the product that

is not made of plastic. For this part of the life cycle, our final design would have more advantage

by reducing amount of waste.

Overall, it is concluded that our product will not be entirely environmentally friendly due

to significantly high amount of energy and resources required to make a single unit of product

compared to the existing product which has no extra parts, but is made of single piece of

material. Even though our product showed reduces in waste during the consumer part of the

cycle, it would not overcome the negative impact done by the manufacturing process; the

prevention of hanger losing its usability completely is not significant enough.

Cost Report

We spent approximately 32 man-hours of engineering time between the research, CAD

modeling, and assembly of our product. Assuming that an engineering man-hour costs $40, this

puts our final engineering costs at $1280. Our labor costs, which would be significantly less

costly per hour, probably about $20 an hour, would be about $80, since we spent about 4 man-

hours in labor on our final prototype. The manufacturing costs of our final prototype were high

about $270 for the unit but that was due to the nature of the manufacturing as a 3D print. Once

mass produced, injection molding could likely reduce unit costs to less than $1 a unit for

manufacturing costs.

25

Itemized list:

3D print of bottom joints from Chemical Engineering Machine Shop - $70

Torsional springs - $68.95

o 3D print of components from Digital Fabrication Lab - $ 129.49

Total: $268.44

Evaluation

The final version of our project was had some successful components and some that were

a little disappointing. One highly successful aspect of the final product was the motion of the

hinges and their range of travel. A user could ergonomically apply pressure all of the way up to

a vertical position of the handles and easily get the hanger width down below the 10 centimeter

mark we set as our goal based on the average width of a shirt neck. Also, the hinge joints were

highly successful at creating a snag-free, single-plane motion that allowed our design to very

easily slip in and out of shirt-necks.

Operation of Hanger in SolidWorks

26

Operation of Hanger in Physical Prototype

However, the one disappointing aspect of our design was the functionality of the torsional

spring we used. In the tests we ran preparing for the implementation of the spring, we performed

all of our analysis assuming that the spring applied a moment only in the plane of desired

motion. However, due to the spacing created by the coils a twisting moment was created in an

orthogonal direction that put some strange stresses on the hanger that were not tested previously.

In addition, the twisting created a good deal of rubbing between the handles that created a lot of

friction and made it very difficult for the spring to smoothly move the part. Therefore, the

prototype ended up being used predominately without the spring which enabled very smooth

movement and a good demonstration of our product. In order to better optimize the designs

functionality, however, we would need to either find a truly single-planar torsional spring or

revert to our old design which had the inverted bottom angle and so relied on geometry rather

than spring energy to operate.

These shortcomings aside, the overall user-response was very positive. The majority of

those who were shown the product acknowledged that they themselves had problems with the

problem addressed by the hanger, and also said that the design we presented would be a very

clever and very functional solution to the problem. The selling point that seemed to be the most

pleasing was different based on who was asked. While the commercial-setting employees most

appreciated the speed aspect, the individual consumers addressed great interest in its use for

specialty garments such as sweaters and dresses that would be especially to use hangers with,

and that might be damaged by carelessness while using the hanger. In each market segment,

however, we got great response and so we really feel like we ended up making a useful product

with a legitimate opportunity gap to be filled.

27

In the final manufacture and distribution of our product, there are several key points that

we figured out will be important. One would be the gadget appeal of the snap joints we used,

with demonstrations of their smooth operation and the way that they hold their disk shape to

prevent snags in the clothing. Another would be to devote a lot of attention to making people

realize the hassles that they put up with using regular hangers to make them realize the ways that

our product could benefit them. Finally, the key point would vary based on who the target

audience is. For large-scale chains we would need to have effective demonstrations laid out that

show how much efficiency can be improved by our product with every article of clothing, and

thus make the case of how much more effective their employees could be if our product was

implemented. As for home-users, it would be very important to show how effective it is on the

specialty garments, as they will not interact with the hanger as much and therefore will need to

see significant improvement in each use to make it worthwhile.

Conclusion

What We Learned

Through lectures and group works, we felt our exposure to the earlier stage of design

process was extremely valuable. While some parts were intuitive, such as brainstorming and

researching sessions, optimizing the outcome and method for effective early design process was

obtained as well as identifying flaws of our own methods. During the early design process, it was

identified that the communication between teammates were not very sufficient and believed that

tasks such as brainstorming and researching could be achieved individually. We decided that this

must be rectified due to insufficient results as well as extreme difficulty of processes because

each of the tasks was being completed by a single person separately. It was also noted during this

time that when researching and brainstorming occurs in parallel, the results improved. As we

moved on in the design process, our function as a group improved significantly, and much more

progress was made of higher quality. These group work skills were another place that we grew a

great deal over the course of the semester as a result of this project.

We felt we received a very rare opportunity to see how engineers must explore the users

in order to identify the problem with the highest opportunity. It was not entirely intuitive in the

beginning that the way the problems and questions are posed the consumer can affect how they

respond. We treasure the researching guides given to us to improve communication between the

consumers, and we believe that method used on this stage can create very strong impact on the

final design.

The general process of the entire design was rather intuitive, but it felt significant for us

that we were exposed to some of the details and its methods. For example, the concept of

28

prototype was very easy to understand, but to be exposed to its true purpose, evaluating

discoveries and going through multiple iterations made us take a second look at what we are

actually doing and how the design evolves through the changes we make. We also felt it was

important that we were assigned to make a short progress report on prototypes as we were to

evaluating our own process and were able to pick out flaws in our method and approach. We are

slightly disappointed that we failed to make a very detailed prototype that showed clear

improvements. Due to lack of effort in planning ahead, our third prototype would not give us

many insights what issues or advantages our final product would have. We also felt that this

hindrance reduced our maximum possible experience of the process of prototyping.

This was not done through any specific activity, but we learned, throughout the process,

important considerations that must be put into the design. For example, learning about the

evaluation of a life cycle of a product left us a great impression. It was not something that was

reminded us to think about during early conceptualization, but it was extremely important to take

it into consideration as all the product is part of the giant cycle within our environment.

We all entered the class assuming once we had identified the problem we would

implement a solution and be done with it. We also learned a lot about the entire process of going

from initial design to final physical implementation. Moving from problem identification to

concept generation via brainstorming, to concept selection via Pugh analysis, all the way to final

prototyping really gave us an appreciation of the entire arc or the design process, something we

hadnt been through before in other classes and it was really beneficial. The brainstorming

session and guidance we received from the course faculty were in particular useful towards our

overall understanding of the design process.

Revisiting SET, VOA, and Pugh Charts

As for our goals, we accomplished much of what we set out to in our SET and VOA

goals. Socially, our product could easily lead to neater, better organized homes and retail outlets,

as well as creating a far nicer and neater shopping environment. That would carry over into our

economic factor successes, with the neater store and better environment encouraging people to

shop at the location using our product. Our product would also increase employee efficiency,

leading to higher profits for the parent company. As for our VOA factors, we accomplished

much of what we set out to do there as well. In the areas of durability and comfort, we created a

product that is flatly superior to the existing clothes hanger. Our product is also significantly

easier to use, which was the primary goal of our project. The aesthetic look of our product is

also much better, creating a look that makes our product look good rather than the appearance of

existing products, which look cheap. Overall our final prototype accomplished much of what our

SET and VOA analyses indicated we needed to do.

29

Looking back at our Pugh Analysis, we accomplished most of what we set out to do with

that set of criteria. Our two biggest goals were to improve ease of use and reduction of effort.

While we solidly accomplished ease of use, the reduction of effort category still leaves some

room for improvement. As for the other criteria, our hanger certainly has a great deal of gadget

appeal, and while it is harder to manufacture and costs more than existing products the long-term

savings from increased employee efficiency our product allows for would offset these.

Unfortunately we believe our final product had significantly large negative effect on the ease of

manufacturing criteria as well as some other important criteria that was not mentioned in the

Pugh chart. First off, our final design uses much more amount of material in order to be

produced compared to the original clothes hanger. Secondly, our final design requires act of

assembling. While joints were required to accomplish our design, it adds too much complexity of

the overall product and will not be ideal for a product that must be mass-produced very quickly.

However, we believe the complexity was added in order to fulfill the project requirement and

decided not to update our Pugh chart.

What would have we done differently?

We see many things would have done differently in our project. One of the biggest

weaknesses came during the prototyping process where we did not use our opportunity to make

huge design leaps effectively, instead settling for a more gradual evolution that was less helpful.

Toward the end, this left too many significant design changes to implement which led to such

difficulties as the torsional spring operation. We believe that if we went through more iterative

process creating prototypes, these issues would have been addressed earlier and created a more

functional final product.

In addition, early on in the design process the group coordination was a major weakness

for us. This led to a lack of progress that put us into an early hole as there was not enough

collaboration to accomplish enough in a timely fashion. While we improved during the later

stages of the project, we certainly would start out the project working much better in the early

stages were we to go through this again, and we feel confident that this would yield better

results.

Unresolved Issues and Note for Continuation of Project

The major unresolved issue at present is that our hanger does not allow for easy one-

handed operation. One of the issues was friction between the legs of the spring and the ABS

hole supporting the spring. In fact, the support for the spring was not very well constructed, thus

the spring could not apply equal amount of torque onto both top legs, which caused irregular

movements and prevent two arms from smoothly folding together. Also, our plan to use a

torsional spring did not consider the extra torque into the unwanted axis; the torque that will

cause snap joints on the hook to pop out. As such, our final prototype was imperfect. By either

creating a torsional spring that does not impart a twisting moment on the hanger or by returning

30

to a pure geometry system for maintaining shape similar to our second prototype, we feel this

issue could be easily addressed. Future teams attempting this project should look into either of

these as solutions to fully finish the design.

31

Appendix A

Engineering drawing of custom made parts

Hook

32

Bottom Joints

There are two bottom joints in the final assembly. Note that both are identical and were both

manufactured using specifications shown below.

33

Right Handle

Note that when assembled, this handle is actually interacted in the left side.

34

Left Handle

Note that when assembled, this handle is actually interacted in the right side.

35

Right Top Arm

36

Left Top Arm

You might also like

- Designing Clothing for Extended UseDocument330 pagesDesigning Clothing for Extended UseClarisse DoriaNo ratings yet

- End TRMDocument73 pagesEnd TRMNeel KanthNo ratings yet

- Men DressDocument60 pagesMen DressjanNo ratings yet

- CRI-Assignment 2 SimpleDocument19 pagesCRI-Assignment 2 SimpleMohammed HakimNo ratings yet

- PDDDocument88 pagesPDDapi-336689769No ratings yet

- CBM 001 Activity#3 MidtermDocument4 pagesCBM 001 Activity#3 MidtermTrisha SacmanNo ratings yet

- Production Design Strategies and Capacity PlanningDocument6 pagesProduction Design Strategies and Capacity PlanningIvory WilkesNo ratings yet

- Sales Forecasting & TrainingDocument15 pagesSales Forecasting & TrainingANKITA CHANDEL100% (1)

- Frehiwot Eyasu Finall ProjectDocument52 pagesFrehiwot Eyasu Finall ProjectBirhanu Alemu100% (1)

- Overview of Garment Industry AssignmentsDocument33 pagesOverview of Garment Industry AssignmentsMekuria MelkamuNo ratings yet

- Improvement in Merchandising ProcessDocument61 pagesImprovement in Merchandising ProcessAbhishek Kumar100% (1)

- Sample Room ActivitiesDocument16 pagesSample Room ActivitiesMianAbrarAnjumNo ratings yet

- Assignment of Operation & Production Management ADocument10 pagesAssignment of Operation & Production Management Afikremaryam hiwiNo ratings yet

- Report On Feasibility Study On Made To Measure GarmentsDocument19 pagesReport On Feasibility Study On Made To Measure GarmentsPrachi_Garg_8226No ratings yet

- NPD 1Document21 pagesNPD 1Amir HsmNo ratings yet

- NPD Ent2Document12 pagesNPD Ent2aliffpadziNo ratings yet

- Ebook How To Master Apparel Sizing and Measuring 1Document60 pagesEbook How To Master Apparel Sizing and Measuring 1Office BDNo ratings yet

- Bahir Dar Universty: Ethiopian Institute of Textile and Fashion Technology (Eitex)Document88 pagesBahir Dar Universty: Ethiopian Institute of Textile and Fashion Technology (Eitex)Mênfës Mgb GèdēchãNo ratings yet

- Full Text 01Document120 pagesFull Text 01ESWARAN SANTHOSHNo ratings yet

- Second Chapter: Product and Service DesignDocument8 pagesSecond Chapter: Product and Service DesignMominul MominNo ratings yet

- Inventory & Logistics OperationsDocument14 pagesInventory & Logistics OperationsSyed Shahid SheraziNo ratings yet

- Activities and Importance of Sample RoomDocument18 pagesActivities and Importance of Sample RoomChuong Nguyen100% (1)

- CRI AssignmentDocument19 pagesCRI AssignmentLim Keng LiangNo ratings yet

- StatementDocument12 pagesStatementSanthosh 8055No ratings yet

- Nat 4+5 DM - DesignDocument13 pagesNat 4+5 DM - Designapi-246905731No ratings yet

- Product Design and DevelopmentDocument17 pagesProduct Design and Development39SEAShashi KhatriNo ratings yet

- UsabilityDocument38 pagesUsabilityJokerNo ratings yet

- POM - 2123063 Div. BDocument10 pagesPOM - 2123063 Div. BAkashay JainNo ratings yet

- BA4204 Operations ManagementDocument7 pagesBA4204 Operations Managementkumarakannan.reNo ratings yet

- How To Make A Spec Sheet For GarmentsDocument27 pagesHow To Make A Spec Sheet For Garmentsyaread seifuNo ratings yet

- Chapter 8 Prototyping and Usage TestingDocument9 pagesChapter 8 Prototyping and Usage TestingRuth Isabel Laynes CuNo ratings yet

- Evaluating Supplier Performance in the Textile IndustryDocument80 pagesEvaluating Supplier Performance in the Textile IndustrysamchikkuNo ratings yet

- Topic 3 Product DesignDocument19 pagesTopic 3 Product Designjohn nderituNo ratings yet

- Operations ManagementDocument6 pagesOperations ManagementRami smartNo ratings yet

- Lightning Strike MobilizationDocument97 pagesLightning Strike MobilizationSiddharth AsokanNo ratings yet

- Buyers Guide To Injection Molded PartsDocument15 pagesBuyers Guide To Injection Molded Partsalejandro hurtadoNo ratings yet

- Unit Ii OmDocument40 pagesUnit Ii Om1234 KrjrNo ratings yet

- Repositioning Thesis, LuissDocument99 pagesRepositioning Thesis, Luissspri2003No ratings yet

- Smart TrolleyDocument41 pagesSmart Trolleyhelene ganawaNo ratings yet

- Proposal GuideDocument8 pagesProposal GuidelaphidNo ratings yet

- C Extended Essay: Line ExtensionsDocument47 pagesC Extended Essay: Line ExtensionsHolaNo ratings yet

- ZARA Final PaperDocument62 pagesZARA Final PaperOlga Gherega88% (8)

- Methods of ProductionDocument5 pagesMethods of ProductionOshane BaileyNo ratings yet

- POM Assignment 1Document6 pagesPOM Assignment 1FzUsmanNo ratings yet

- Operations Management Answer 1.: Concept and ApplicationDocument7 pagesOperations Management Answer 1.: Concept and ApplicationkanchanNo ratings yet

- University of South Asia: Department of Textile EngineeringDocument42 pagesUniversity of South Asia: Department of Textile Engineeringmehedi hasanNo ratings yet

- Engineering Design ProjectDocument50 pagesEngineering Design ProjectPaviNo ratings yet

- Alto Seven Silkscreen Case Study AnalysisDocument27 pagesAlto Seven Silkscreen Case Study AnalysisJimmy Golberg83% (6)

- EssayDocument14 pagesEssaypersephoniseNo ratings yet

- A Study On Product Development and MerchandisingDocument26 pagesA Study On Product Development and MerchandisingMosharaf HossainNo ratings yet

- Ikenya Mark ProjectDocument20 pagesIkenya Mark ProjectpatrickNo ratings yet

- Assignment: Supply Chain ProcessDocument6 pagesAssignment: Supply Chain ProcessRajarshi ChakrabortyNo ratings yet

- Group 1 Object Oriented System Analysis Design ProjectDocument51 pagesGroup 1 Object Oriented System Analysis Design Projectseyfe100% (2)

- Assignment 1 (Zara)Document13 pagesAssignment 1 (Zara)Julius Danielczak100% (2)

- AND Quality Control: Product ManagementDocument28 pagesAND Quality Control: Product Managementsurbhi sharmaNo ratings yet

- Topic 7 Design For Quality Product and Product Excellence StudentsDocument7 pagesTopic 7 Design For Quality Product and Product Excellence StudentsMonica Pablo SabadoNo ratings yet

- Kanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryFrom EverandKanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryRating: 5 out of 5 stars5/5 (1)

- Lean Pull System and Kanban: Toyota Production System ConceptsFrom EverandLean Pull System and Kanban: Toyota Production System ConceptsRating: 4 out of 5 stars4/5 (1)

- Semester Assignment 1st Semester 2016Document1 pageSemester Assignment 1st Semester 2016Ali GhNo ratings yet

- Agile ManufacturingDocument7 pagesAgile ManufacturingAli GhNo ratings yet

- 80 Degrees Angle: Input Wind Tunnel SpeedDocument4 pages80 Degrees Angle: Input Wind Tunnel SpeedAli GhNo ratings yet

- ReadmeDocument2 pagesReadmeTan Yu AngNo ratings yet

- CodeDocument2 pagesCodeAli GhNo ratings yet

- Point LoadsDocument1 pagePoint LoadsAli GhNo ratings yet

- Group 54 Excel 1Document6 pagesGroup 54 Excel 1Ali GhNo ratings yet

- ReadmeDocument1 pageReadmeAli GhNo ratings yet

- Dist LoadsDocument1 pageDist LoadsAli GhNo ratings yet

- Point LoadsDocument1 pagePoint LoadsAli GhNo ratings yet

- Dist LoadsDocument1 pageDist LoadsAli GhNo ratings yet

- Sample FitDocument1 pageSample FitAli GhNo ratings yet

- MatLab Project 1Document1 pageMatLab Project 1Ali GhNo ratings yet

- Coding For Tut 5Document1 pageCoding For Tut 5Ali GhNo ratings yet

- Tut 4 SolutionDocument1 pageTut 4 SolutionAli GhNo ratings yet

- File I/O and Sorting in PythonDocument2 pagesFile I/O and Sorting in PythonAli GhNo ratings yet

- Coding AgainDocument2 pagesCoding AgainAli GhNo ratings yet

- CodingDocument2 pagesCodingAli GhNo ratings yet

- MECN2012: Computing Skills and Software Development: Python - Object Oriented ProgrammingDocument6 pagesMECN2012: Computing Skills and Software Development: Python - Object Oriented ProgrammingAli GhNo ratings yet

- VishDocument3 pagesVishAli GhNo ratings yet

- University of The Witwatersrand, Johannesburg School of Mechanical, Industrial & Aeronautical EngineeringDocument2 pagesUniversity of The Witwatersrand, Johannesburg School of Mechanical, Industrial & Aeronautical EngineeringAli GhNo ratings yet

- Tut 6Document2 pagesTut 6Ali GhNo ratings yet

- Valves EatDocument1 pageValves EatAli GhNo ratings yet

- Tutorial 11 LaTeXDocument2 pagesTutorial 11 LaTeXAli GhNo ratings yet

- Matlab TutorialsDocument5 pagesMatlab TutorialsAli GhNo ratings yet

- Algorithms and Flowcharts - 2Document13 pagesAlgorithms and Flowcharts - 2Ali GhNo ratings yet

- CodeDocument2 pagesCodeAli GhNo ratings yet

- Algorithms and Flowcharts - 1Document32 pagesAlgorithms and Flowcharts - 1Ali GhNo ratings yet

- ExamplelfFlowChart PDFDocument5 pagesExamplelfFlowChart PDFSachithHiroshanaWijethungaNo ratings yet

- OIP Marks 21 Sep 2015Document39 pagesOIP Marks 21 Sep 2015Ali GhNo ratings yet

- Organization Behaviour Understanding Organizations: Dr. Sumi JhaDocument32 pagesOrganization Behaviour Understanding Organizations: Dr. Sumi JhakartikNo ratings yet

- Analysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck ConverterDocument12 pagesAnalysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck Converterdaber_huny20No ratings yet

- Webpage Evaluation GuideDocument1 pageWebpage Evaluation Guideankit boxerNo ratings yet

- University of Tripoli Faculty of Engineering Petroleum EngineeringDocument10 pagesUniversity of Tripoli Faculty of Engineering Petroleum EngineeringesraNo ratings yet

- This Study Resource Was: Question AnswersDocument3 pagesThis Study Resource Was: Question AnswerskamakshiNo ratings yet

- 1 s2.0 S1366554522001557 MainDocument23 pages1 s2.0 S1366554522001557 MainMahin1977No ratings yet

- Installation and Tuning Guide for AEM EMS on 1990-1994 Mitsubishi EclipseDocument12 pagesInstallation and Tuning Guide for AEM EMS on 1990-1994 Mitsubishi EclipseJose AbreuNo ratings yet

- (1X Erma First Fit 400) : Technical OfferDocument23 pages(1X Erma First Fit 400) : Technical OfferVikas Singh100% (1)

- Global Economics 13th Edition by Carbaugh ISBN Solution ManualDocument5 pagesGlobal Economics 13th Edition by Carbaugh ISBN Solution Manualdorothy100% (31)

- Brochure DRYVIEW 5700 201504 PDFDocument4 pagesBrochure DRYVIEW 5700 201504 PDFRolando Vargas PalacioNo ratings yet

- 9 Little Translation Mistakes With Big ConsequencesDocument2 pages9 Little Translation Mistakes With Big ConsequencesJuliany Chaves AlvearNo ratings yet

- Xtract V 3 0 8Document72 pagesXtract V 3 0 8Don Ing Marcos LeónNo ratings yet

- 004.7 - VCE150 Session 7 Cabin LiftDocument24 pages004.7 - VCE150 Session 7 Cabin LiftMahmoud Elpop ElsalhNo ratings yet

- Philip B. Crosby: Quality Guru Who Pioneered Zero Defects ConceptDocument29 pagesPhilip B. Crosby: Quality Guru Who Pioneered Zero Defects Conceptphdmaker100% (1)

- Forever Living ContractDocument2 pagesForever Living ContractRishi SehgalNo ratings yet

- Critical Path Method: A Guide to CPM Project SchedulingDocument6 pagesCritical Path Method: A Guide to CPM Project SchedulingFaizan AhmadNo ratings yet

- Joe Armstrong (Programmer)Document3 pagesJoe Armstrong (Programmer)Robert BonisoloNo ratings yet

- Nordstrom Physical Security ManualDocument13 pagesNordstrom Physical Security ManualBopanna BolliandaNo ratings yet

- Housing TypesDocument14 pagesHousing Typessushmita hazarikaNo ratings yet

- Wesleyan University-Philippines Graduate SchoolDocument6 pagesWesleyan University-Philippines Graduate SchoolRachel Joy RosaleNo ratings yet

- Rohtak:: ICT Hub For E-Governance in HaryanaDocument2 pagesRohtak:: ICT Hub For E-Governance in HaryanaAr Aayush GoelNo ratings yet

- Final Exam EM 210 (COSA) : Information Technology Education ReadinessDocument2 pagesFinal Exam EM 210 (COSA) : Information Technology Education ReadinessDonna DoradoNo ratings yet

- Draft Questionnaire - Identifying Good Practices, Documentation and Sharing - CP & VAC in (Host & Camps) - Introduction To Organization and PersonDocument3 pagesDraft Questionnaire - Identifying Good Practices, Documentation and Sharing - CP & VAC in (Host & Camps) - Introduction To Organization and PersonAminul QuayyumNo ratings yet

- 2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONDocument5 pages2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONkkumar_717405No ratings yet

- MV Capacitor CalculationDocument1 pageMV Capacitor CalculationPramod B.WankhadeNo ratings yet

- Convention of Film Blocking Day 2Document6 pagesConvention of Film Blocking Day 2GENELYN GAWARANNo ratings yet

- Contanuity Case StudyDocument14 pagesContanuity Case StudyUsama TariqNo ratings yet

- Barangay Clearance2014Document68 pagesBarangay Clearance2014Barangay PangilNo ratings yet

- Ds Esprimo c910 LDocument9 pagesDs Esprimo c910 Lconmar5mNo ratings yet

- Scenario Pack 3048-3050 - Operational Turning Points - REVIVAL TrialsDocument41 pagesScenario Pack 3048-3050 - Operational Turning Points - REVIVAL TrialsSly MantisNo ratings yet