Professional Documents

Culture Documents

D3282

Uploaded by

masterlemtarmaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D3282

Uploaded by

masterlemtarmaCopyright:

Available Formats

Designation: D 3282 93 (Reapproved 1997)

e1

Standard Practice for

Classication of Soils and Soil-Aggregate Mixtures for

Highway Construction Purposes

1

This standard is issued under the xed designation D 3282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e

1

NOTEThe title was corrected and Section 1.3 was added editorially in January 1999.

1. Scope

1.1 This standard describes a procedure for classifying

mineral and organomineral soils into seven groups based on

laboratory determination of particle-size distribution, liquid

limit, and plasticity index. It may be used when a precise

engineering classication is required, especially for highway

construction purposes. Evaluation of soils within each group is

made by means of a group index, which is a value calculated

from an empirical formula.

NOTE 1The group classication, including the group index, should be

useful in determining the relative quality of the soil material for use in

earthwork structures, particularly embankments, subgrades, subbases, and

bases. However, for the detailed design of important structures, additional

data concerning strength or performance characteristics of the soil under

eld conditions will usually be required.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.3 This practice offers a set of instructions for performing

one or more specic operations. This document cannot replace

education or experience and should be used in conjunction

with professional judgment. Not all aspects of this practice may

be applicable in all circumstances. This ASTM standard is not

intended to represent or replace the standard of care by which

the adequacy of a given professional service must be judged,

nor should this document be applied without consideration of

a projects many unique aspects. The word Standard in the

title of this document means only that the document has been

approved through the ASTM consensus process.

2. Referenced Documents

2.1 ASTM Standards:

D 420 Guide to Site Characterization for Engineering De-

sign and Construction Purposes

2

D 421 Practice for Dry Preparation of Soil Samples for

Particle-Size Analysis and Determination of Soil Con-

stants

2

D 422 Test Method for Particle-Size Analysis of Soils

2

D 653 Terminology Relating to Soil, Rock, and Contained

Fluids

2

D 1140 Test Method for Amount of Material in Soils Finer

Than the No. 200 (75-m) Sieve

2

D 1452 Practice for Soil Investigation and Sampling by

Auger Borings

2

D 1586 Test Method for Penetration Test and Split-Barrel

Sampling of Soils

2

D 1587 Practice for Thin-Walled Tube Getotechnical Sam-

pling of Soils

2

D 2217 Practice for Wet Preparation of Soil Samples for

Particle-Size Analysis and Determination of Soil Con-

stants

2

D 4318 Test Method for Liquid Limit, Plastic Limit, and

Plasticity Index of Soils

2

2.2 AASHTO Document:

M 145 The Classication of Soils and Soil Aggregate Mix-

tures for Highway Construction Purposes

3

3. Terminology

3.1 Denitions of Terms Specic to This Standard:

3.1.1 The following terms are frequently used in this stan-

dard. These terms differ slightly from those given in Terminol-

ogy D 653, but are used here to maintain consistency with

common highway usage.

3.1.2 bouldersrock fragments, usually rounded by weath-

ering or abrasion, that will be retained on a 3-in. (75-mm)

sieve.

3.1.3 coarse sandparticles of rock or soil that will pass a

No. 10 (2-mm) sieve and be retained on a No. 40 (425-m)

sieve.

3.1.4 ne sandparticles of rock or soil that will pass a No.

1

This standard is under the jurisdiction of ASTM Committee D-18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.07 on Identication and

Classication of Soils.

Current edition approved Sept. 15, 1993. Published November 1993. Originally

published as D 328273. Last previous edition D 3282 92.

2

Annual Book of ASTM Standards, Vol 04.08.

3

Available from American Asssociation of State Highway and Transportation

Officials, 444 N Capitol St., NW, Suite 225, Washington, DC 20001.

1

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

40 (425-m) sieve and be retained on a No. 200 (75-m) sieve.

3.1.5 gravelparticles of rock that will pass a 3-in. (75-

mm) sieve and be retained on a No. 10 (2-mm) sieve.

3.1.6 silt-clay (combined silt and clay)ne soil and rock

particles that will pass a No. 200 (75-m) sieve.

3.1.7 siltyne-grained material that has a plasticity index

of 10 or less.

3.1.8 clayeyne-grained material that has a plasticity

index of 11 or more.

4. Signicance and Use

4.1 The standard described classies soils from any geo-

graphic location into groups (including group indexes) based

on the results of prescribed laboratory tests to determine the

particle-size characteristics, liquid limit, and plasticity index.

4.2 The assigning of a group symbol and group index can be

used to aid in the evaluation of the signicant properties of the

soil for highway and aireld purposes.

4.3 The various groupings of this classication system

correlate in a general way with the engineering behavior of

soils. Also, in a general way, the engineering behavior of a soil

varies inversely with its group index. Therefore, this standard

provides a useful rst step in any eld or laboratory investi-

gation for geotechnical engineering purposes.

5. Apparatus

5.1 Apparatus for Preparation of SamplesSee Practices

D 421 or D 2217.

5.2 Apparatus for Particle-Size AnalysisSee Test Meth-

ods D 1140 and D 422.

5.3 Apparatus for Liquid Limit and Plastic Limit TestsSee

Test Method D 4318.

6. Sampling

6.1 Conduct eld investigations and sampling in accordance

with one or more of the following procedures:

6.1.1 Guide D 420,

6.1.2 Practice D 1452,

6.1.3 Method D 1586,

6.1.4 Practice D 1587.

7. Test Sample

7.1 Test samples shall represent that portion of the eld

sample ner than the 3-in. (75-mm) sieve and shall be obtained

as follows:

7.1.1 Air-dry the eld sample,

7.1.2 Weigh the eld sample,

7.1.3 Separate the eld sample into two fractions on a 3-in.

(75-mm) sieve,

7.1.4 Weigh the fraction retained on the 3-in. (75-mm)

sieve. Compute the percentage of plus 3-in. material in the eld

sample, and note this percentage as auxiliary information, and

7.1.5 Thoroughly mix the fraction passing the 3-in. (75-

mm) sieve and select the test samples.

NOTE 2If visual examination indicates that no boulder size material is

present, omit 7.1.3 and 7.1.4.

7.2 Prepare the test sample in accordance with Practices

D 421 or D 2217. Determine the percentage of the sample ner

than a No. 10 (2-mm) sieve.

NOTE 3It is recommended that the method for wet preparation be

used for soils containing organic matter or irreversible mineral colloids.

8. Testing Procedure

8.1 Determine the percentage of the test sample ner than a

No. 200 (75-m) sieve in accordance with Test Methods

D 1140 or D 422.

NOTE 4For granular materials the percentage of the sample ner than

a No. 40 (425-m) sieve must also be determined.

8.2 Determine the liquid limit and the plasticity index of a

portion of the test sample passing a No. 40 (425-m) sieve in

accordance with Test Method D 4318.

9. Classication Procedure

9.1 Using the test data determined in Section 8, classify the

soil into the appropriate group or subgroup, or both, in

accordance with Table 1 or Table 2. Use Fig. 1 to classify

silt-clay materials on the basis of liquid limit and plasticity

index values.

NOTE 5All limiting values are shown as whole numbers. If fractional

numbers appear on test reports, convert to the nearest whole numbers for

the purpose of classication.

9.1.1 With the required test data available, proceed from left

to right in Table 1 or Table 2 and the correct classication will

be found by the process of elimination. The rst group from the

TABLE 1 Classication of Soils and Soil-Aggregate Mixtures

General Classication

Granular Materials

(35 % or less passing No. 200)

Silt-Clay Materials

(More than 35 % passing No. 200)

Group Classication A-1 A-3

A

A-2 A-4 A-5 A-6 A-7

Sieve analysis, % passing:

No. 10 (2.00 mm) ... ... ... ... ... ... ...

No. 40 (425 m) 50 max 51 min ... ... ... ... ...

No. 200 (75 m) 25 max 10 max 35 max 36 min 36 min 36 min 36 min

Characteristics of fraction passing No. 40

(425 m):

Liquid limit

Plasticity index

...

6 max

...

N.P.

B

B

40 max

10 max

41 min

10 max

40 max

11 min41 min

11 min

General rating as subgrade Excellent to Good Fair to Poor

A

The placing of A-3 before A-2 is necessary in the left to right elimination process and does not indicate superiority of A-3 over A-2.

B

See Table 2 for values.

Reprinted with permission of American Association of State Highway and Transportation Officials

D 3282

2

left into which the test data will t is the correct classication.

NOTE 6Classication of materials in the various groups applies only

to the fraction passing the 3-in. (75-mm) sieve. Therefore, any specica-

tion regarding the use of A-1, A-2, or A-3 materials in construction should

state whether boulders (retained on 3-in. sieve) are permitted.

10. Description of Classication Groups

10.1 Granular Materials, containing 35 % or less passing

the No. 200 (75-m) sieve:

10.1.1 Group A-1The typical material of this group is a

TABLE 2 Classication of Soils and Soil-Aggregate Mixtures

General Classication

Granular Materials

(35 % or less passing No. 200)

Silt-Clay Materials

(More than 35 % passing No. 200)

Group classication

A-1

A-3

A-2

A-4 A-5 A-6

A-7

A-1-a A-1-b A-2-4 A-2-5 A-2-6 A-2-7

A-7-5,

A-7-6

Sieve analysis, % passing:

No. 10 (2.00 mm) 50 max ... ... ... ... ... ... ... ... ... ...

No. 40 (425 m) 30 max 50 max 51 min ... ... ... ... ... ... ... ...

No. 200 (75 m) 15 max 25 max 10 max 35 max 35 max 35 max 35 max 36 min 36 min 36 min 36 min

Characteristics of fraction passing

No. 40 (425 m):

Liquid limit

Plasticity index

...

6 max

...

N.P.

40 max

10 max

41 min

10 max

40 max

11 min

41 min

11 min

40 max

10 max

41 min

10 max

40 max

11 min

41 min

11 min

A

Usual types of signicant consti-

tuent materials

Stone Fragments,

Gravel and Sand

Fine

Sand

Silty or Clayey Gravel and Sand Silty Soils Clayey Soils

General rating as subgrade Excellent to Good Fair to Poor

A

Plasticity index of A-7-5 subgroup is equal to or less than LL minus 30. Plasticity index of A-7-6 subgroup is greater than LL minus 30 (see Fig. 1).

Reprinted with permission of American Association of State Highway and Transportation Officials.

NOTE 1A-2 soils contain less than 35 % ner than 200 sieve.

FIG. 1 Liquid Limit and Plasticity Index Ranges for Silt-Clay Materials

D 3282

3

well-graded mixture of stone fragments or gravel, coarse sand,

ne sand, and a nonplastic or feebly-plastic soil binder.

However, this group also includes stone fragments, gravel,

coarse sand, volcanic cinders, etc., without a soil binder.

10.1.1.1 Subgroup A-1-a includes those materials consisting

predominantly of stone fragments or gravel, either with or

without a well-graded binder of ne material.

10.1.1.2 Subgroup A-1-b includes those materials consisting

predominantly of coarse sand, either with or without a well-

graded soil binder.

10.1.2 Group A-3The typical material of this group is ne

beach sand or ne desert-blow sand without silty or clay nes,

or with a very small amount of nonplastic silt. This group also

includes stream-deposited mixtures of poorly-graded ne sand

and limited amounts of coarse sand and gravel.

10.1.3 Group A-2This group includes a wide variety of

granular materials which are borderline between the materi-

als falling in Groups A-1 and A-3, and the silt-clay materials of

Groups A-4, A-5, A-6, and A-7. It includes all materials

containing 35 % or less passing a No. 200 (75-m) sieve which

cannot be classied in Groups A-1 or A-3, due to the nes

content or the plasticity indexes, or both, in excess of the

limitations for those groups.

10.1.3.1 Subgroups A-2-4 and A-2-5 include various granu-

lar materials containing 35 % or less passing a No. 200

(75-m) sieve and with a minus No. 40 (425-m) portion

having the characteristics of Groups A-4 and A-5, respectively.

These groups include such materials as gravel and coarse sand

with silt contents or plasticity indexes in excess of the

limitations of Group A-1 and ne sand with nonplastic-silt

content in excess of the limitations of Group A-3.

10.1.3.2 Subgroups A-2-6 and A-2-7 include materials simi-

lar to those described under Subgroups A-2-4 and A-2-5,

except that the ne portion contains plastic clay having the

characteristics of the A-6 or A-7 group, respectively.

10.2 Silt-Clay Materials, containing more than 35 % pass-

ing a No. 200 (75-m) sieve:

10.2.1 Group A-4The typical material of this group is a

nonplastic or moderately plastic silty soil usually having 75 %

or more passing a No. 200 (75-m) sieve. This group also

includes mixtures of ne silty soil and up to 64 % of sand and

gravel retained on a No. 200 sieve.

10.2.2 Group A-5The typical material of this group is

similar to that described under Group A-4, except that it is

usually of diatomaceous or micaceous character and may be

highly elastic as indicated by the high liquid limit.

10.2.3 Group A-6The typical material of this group is a

plastic clay soil usually having 75 % or more passing a No. 200

(75-m) sieve. This group also includes mixtures of ne clayey

soil and up to 64 % of sand and gravel retained on a No. 200

sieve. Materials of this group usually have a high volume

change between wet and dry states.

10.2.4 Group A-7The typical material of this group is

similar to that described under Group A-6, except that it has the

high liquid limits characteristic of Group A-5 and may be

elastic as well as subject to high-volume change.

10.2.4.1 Subgroup A-7-5 includes those materials with

moderate plasticity indexes in relation to the liquid limit and

which may be highly elastic as well as subject to considerable

volume change.

10.2.4.2 Subgroup A-7-6 includes those materials with high

plasticity indexes in relation to liquid limit and which are

subject to extremely high volume change.

NOTE 7Highly organic soils (peat or muck) may be classied in

Group A-8. Classication of these materials is based on visual inspection

and is not dependent on the percentage passing the No. 200 (75-m) sieve,

liquid limit, or plasticity index. The material is composed primarily of

partially-decayed organic matter, generally has a brous texture, a dark

brown or black color, and an odor of decay. These organic materials are

unsuitable for use in embankments and subgrades. They are highly

compressible and have low strength.

11. Group Index Computation

11.1 The classications obtained from Table 1 or Table 2

may be modied by the addition of a group-index value.

Group-index values should always be shown in parentheses

after the group symbol as A-2-6(3), A-4(5), A-6(12), A-7-

5(17), etc.

11.1.1 Calculate the group index from the following empiri-

cal formula:

Group index 5 ~F 2 35!@0.2 1 0.005~LL 2 40!# (1)

1 0.01~F 2 15!~PI 2 10!

where:

F 5 percentage passing No. 200 (75-m) sieve, expressed

as a whole number (this percentage is based only on

the material passing the 3-in. (75-mm) sieve),

LL 5 liquid limit, and

PI 5 plasticity index.

11.1.2 If the calculated group index is negative, report the

group index as zero (0).

11.1.3 If the soil is nonplastic and when the liquid limit

cannot be determined, report the group index as zero (0).

11.1.4 Report the group index to the nearest whole number.

11.1.5 The group index value may be estimated using Fig. 2

by determining the partial group index due to the liquid limit

and that due to the plasticity index, then obtaining the total of

the two partial group indexes.

11.1.6 The group index of soils in the A-2-6 and A-2-7

subgroups shall be calculated using only the PI portion of the

formula (or Fig. 2).

11.2 The following examples illustrate the calculations for

the group index:

11.2.1 Assume that an A-6 material has 55 % passing a No.

200 (75-m) sieve, a liquid limit of 40, and a plasticity index

of 25, then:

Group index 5 ~55 2 35!@0.2 1 0.005~40 2 40!# (2)

1 @0.01~55 2 15!~25 2 10!# 5 4.0 1 6.0 5 10

11.2.2 Assume that an A-7 material has 80 % passing a No.

200 (75-m) sieve, a liquid limit of 90, and a plasticity index

of 50, then:

Group index 5 ~80 2 35!@0.26 0.005~90 2 40!# (3)

1 @0.01~80 2 15!~50 2 10!# 5 20.3 1 26.0 5 46.3 ~report as 46!

11.2.3 Assume that an A-4 material has 60 % passing a No.

200 (75-m) sieve, a liquid limit of 25, and a plasticity index

of 1, then

D 3282

4

Group index 5 ~60 2 35!@0.2 1 0.005~25 2 40!# (4)

1 @0.01~60 2 15!~1 2 10!# 5 25 3 ~0.2 2 0.075!

1 0.01~45!~29! 5 3.1 2 4.1 5 21.0 ~report as 0!

11.2.4 Assume that an A-2-7 material has 30 % passing a

No. 200 (75-m) sieve, a liquid limit of 50, and a plasticity

index of 30, then

Group index 5 0.01~30 2 15!~30 2 10! (5)

5 3.0 or 3 ~note that only the PI portion of the

formula was used!

12. Discussion of Group Index

12.1 The empirical group index formula devised for ap-

proximate within-group evaluation of the clayey-granular

materials and the silt-clay materials is based on the follow-

ing assumptions:

NOTE 8Group index values should only be used to compare soils

within the same group and not between groups.

12.1.1 Materials falling within Groups A-1-a, A-1-b, A-2-4,

A-2-5, and A-3 are satisfactory as subgrade when properly

drained and compacted under moderate thickness of pavement

(base or surface course, or both) of a type suitable for traffic to

be carried or can be made satisfactory by additions of small

amounts of natural or articial binders.

12.1.2 Materials falling within the clayey granular

Groups A-2-6 and A-2-7 and the silt-clay Groups A-4, A-5,

A-6, and A-7 will range in quality as subgrade from the

Reprinted with permission of American Association of State Highway and Transportation Officials

FIG. 2 Group Index Chart

D 3282

5

approximate equivalent of the good A-2-4 and A-2-5 subgrades

to fair and poor subgrades requiring a layer of subbase material

or an increased thickness of base course over that required in

12.1.1, in order to furnish adequate support for traffic loads.

12.1.3 Aminimum of 35 % passing a No. 200 (75-m) sieve

is assumed to be critical if plasticity is neglected, but the

critical minimum is only 15 % when affected by plasticity

indexes greater than 10.

12.1.4 Liquid limits of 40 and above are assumed to be

critical.

12.1.5 Plasticity indexes of 10 and above are assumed to be

critical.

12.2 There is no upper limit of group index value obtained

by use of the formula: The adopted critical values of percent-

age passing the No. 200 (75-m) sieve, liquid limit, and

plasticity index, are based on an evaluation of subgrade,

subbase, and base-course materials by several highway orga-

nizations that use the tests involved in this classication

system.

12.3 Under average conditions of good drainage and thor-

ough compaction, the supporting value of a material as

subgrade may be assumed as an inverse ratio to its group index;

that is, a group index of 0 indicates a good subgrade material

and a group index of 20 or greater indicates a very poor

subgrade material.

13. Keywords

13.1 Atterberg limits; classication; clay; gradation; high-

ways; sand gravel; silt; soil classication; soil tests

APPENDIX

(Nonmandatory Information)

X1. RATIONALE

X1.1 The 1992 edition differs from the previous edition in

that the title was changed to better indicate the use of the

standard.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

D 3282

6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Yasnac Mx-3 Fault Finding GuideDocument70 pagesYasnac Mx-3 Fault Finding Guidechidambaram kasi100% (1)

- Astm c10c10mDocument4 pagesAstm c10c10mmasterlemtarmaNo ratings yet

- Quicklime For Structural PurposesDocument3 pagesQuicklime For Structural PurposesDe GaulleNo ratings yet

- Astm c22c22mDocument2 pagesAstm c22c22mmasterlemtarmaNo ratings yet

- Scan App Review - CamScanner PDF ScannerDocument2 pagesScan App Review - CamScanner PDF ScannermasterlemtarmaNo ratings yet

- Attendance 8ettin: The Procedures BelowDocument1 pageAttendance 8ettin: The Procedures BelowmasterlemtarmaNo ratings yet

- 15 Model To Demonstrate How Rockbolts WorkDocument8 pages15 Model To Demonstrate How Rockbolts WorkMiguel Eulufi VillenaNo ratings yet

- Intergranular Viscosity of Zeevaert PDFDocument25 pagesIntergranular Viscosity of Zeevaert PDFmasterlemtarmaNo ratings yet

- Runatullo Plan General ModelDocument1 pageRunatullo Plan General ModelmasterlemtarmaNo ratings yet

- Equipo Corte Directo 26-2114Document23 pagesEquipo Corte Directo 26-2114masterlemtarmaNo ratings yet

- JETL industrial wastewater treatment reportDocument6 pagesJETL industrial wastewater treatment reportPremKumarNo ratings yet

- Insulation Castables Application Procedure - Rev-2 - PDFDocument10 pagesInsulation Castables Application Procedure - Rev-2 - PDFNatarajan MurugesanNo ratings yet

- PI Digital Panel Indicator - B0Document7 pagesPI Digital Panel Indicator - B0dtoxidNo ratings yet

- 1,3,3-Trinitroazetidine (TNAZ) - Part I. Syntheses and PropertiesDocument23 pages1,3,3-Trinitroazetidine (TNAZ) - Part I. Syntheses and PropertiesThanh XomNo ratings yet

- MEITRACK MVT100 User Guide V2.4Document19 pagesMEITRACK MVT100 User Guide V2.4MeitrackNo ratings yet

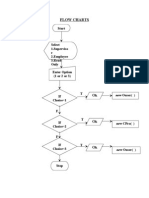

- Flow Charts Option: StartDocument13 pagesFlow Charts Option: StartbalabooksNo ratings yet

- Single and Multiphase CFD Simulations For Designing Cavitating VenturiDocument12 pagesSingle and Multiphase CFD Simulations For Designing Cavitating VenturiCarlos GamarraNo ratings yet

- Complex Instruction Set ComputerDocument17 pagesComplex Instruction Set ComputerkangkanpaulNo ratings yet

- DiGas 4000 Light E 08.02Document2 pagesDiGas 4000 Light E 08.02manit1963No ratings yet

- Under Water WeldingDocument23 pagesUnder Water WeldingNishanth GowdaNo ratings yet

- GDCF 2 240 - 2nd - 01 10Document2 pagesGDCF 2 240 - 2nd - 01 10edgardomichligNo ratings yet

- TI Oxydur PTB 206 - en PDFDocument5 pagesTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- D3755-14 Standard Test Method For Dielectric BreakdowDocument6 pagesD3755-14 Standard Test Method For Dielectric Breakdowjose flores100% (1)

- FST DFS Ge-EgdDocument5 pagesFST DFS Ge-EgdEric DunnNo ratings yet

- Pressure Regulators (DRV Valve) Suitable ForDocument4 pagesPressure Regulators (DRV Valve) Suitable ForNOUREDDINE BERCHAOUANo ratings yet

- Structural Analysis of Beams Using Moment Distribution MethodDocument15 pagesStructural Analysis of Beams Using Moment Distribution MethodneetuNo ratings yet

- Stop Motion Pre Production - Negotiated BriefDocument10 pagesStop Motion Pre Production - Negotiated Briefp4nd3m0n1c100% (1)

- Iso Dis 20283-4 2011Document27 pagesIso Dis 20283-4 2011Ricardo RamirezNo ratings yet

- SSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Document60 pagesSSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Jose Ramón Orenes ClementeNo ratings yet

- Flyer M 10id 12 ENDocument2 pagesFlyer M 10id 12 ENTrevor SalazarNo ratings yet

- 61 35 122 Removing and Installing - Replacing General ModuleDocument2 pages61 35 122 Removing and Installing - Replacing General ModuleTung NguyenNo ratings yet

- High Voltage Grease Reduces Wear and ArcingDocument2 pagesHigh Voltage Grease Reduces Wear and ArcingtlnferreiraNo ratings yet

- d-Copia3500MF 4500MF 5500MFsmY113351-4Document1,051 pagesd-Copia3500MF 4500MF 5500MFsmY113351-4ctecisbNo ratings yet

- Usage of Regular Expressions in NLPDocument7 pagesUsage of Regular Expressions in NLPInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Describe The Physical Properties of Propylene Glycols.: PrintDocument4 pagesDescribe The Physical Properties of Propylene Glycols.: PrintKaarthicNatarajanNo ratings yet

- Engineering Structures: SciencedirectDocument8 pagesEngineering Structures: SciencedirectFeleki AttilaNo ratings yet

- How To Sputter Thin Films of Metal Onto GlassDocument5 pagesHow To Sputter Thin Films of Metal Onto Glassfred_m_48601No ratings yet

- Comb Manual IM 106 6888QSDocument36 pagesComb Manual IM 106 6888QSsathish2829No ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)