Professional Documents

Culture Documents

Samole of Legaloc

Uploaded by

Visas SivaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Samole of Legaloc

Uploaded by

Visas SivaCopyright:

Available Formats

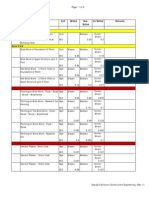

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.:

JSL/EMS/L/OC01

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: Procedure to establish monitoring of water consent for Legal compliance.

SCOPE: Applicable to Effluent Treatment Plant (ETP) and Sewage Treatment Plant(STP)

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS:

Monitoring of !uantit" discharged and parameters specified in the consent for ETP # STP treated and

untreated effluents on a predefined fre!uenc" of once in a month and comparing the same with standards.

The standard $alue prescribed for different parameters b" T%P&' are as following.

PA(AMETE(S ST) *AL+ES.

,. P- ... T/ 0

1. Total dissol$ed solids 1,22 mg3lt.

4. Total suspended solids ,22 mg3lt.

5. &hlorides ,222 mg3lt.

.. /il and 6rease ,2 mg3 lt

7. '/) 4 da"s 8 19& 42 mg3 lt.

9. &/) 8 (eflu: condense method 1.2 mg3lt.

;. Sulphates ,222 mg3lt.

GENERAL:

Measure the !uantit" of effluent generated on dail" basis and record the discharge from ETP and STP.

Ensure the calibration of the water flow meter and other instruments used for monitoring.

Ensure the submission of the application in the e$ent of an" change in !uantit" and !ualit" of (aw

material and end product manufacturing process of !uantit" and !ualit" of effluent.

Ensure good house <eeping in the area and chec< for all lea<ing pipes # $al$es is made lea< proof.

Ensure no floor washing water is drained to the storm water drains3 on land instead it should be routed

to ETP3STP for treatment.

Ensure to dr" the sludge from ETP on sand dr"ing beds and the drained water has to be routed to

e!uali=ation tan<.

Ensure to e$aporate the trade effluent generated from spent degreasing section after neutrali=ing and

ma<e sure that there shall not be an" o$er flow 3 seepage3 percolation from it.

Ensure that the ETP3STP effluent is discharged after treatment to the garden onl" if it complies with the

norms lied down b" T%P&'.

Ensure the paint booth and rinsing effluent is let in to the sewage treatment plant onl" after

neutrali=ation and necessar" p- correction.

Ensure that the paint sludge after treatment at ETP and the sludge at the paint booth are stored in area

safe from rain water.

)uring running of ETP and STP plants no effluent should be allowed to the storm water drain 3

discharged to others premises. >n occurrence of such de$iations report to T%P&' has to be ensured for

the same.

Ensure the monthl" submission of Effluent test reports to T%P&' on or before the ,2

th

of the following

month. All the parameters specified in the consent to be anal"=ed once in a "ear the reports of the same

to be sent to T%P&'.

>nform T%P&' about an" de$iations from the standards prescribed and appropriate correcti$e action

for the same.

Ensure that the application for grant of consent has been submitted before 72 da"s of date of e:pired of

current consent.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

Potential for o$er discharge? spillage? o$erflow of effluent leading to land contamination # water

pollution.

%on monitoring of parameters? specification for effluent ma" lead to noncompliance of statutor"

re!uirement 3 T%P&'.

CORRECTIVE ACTION IN CASE O$ DEVIATION:

Sit clean up acti$ities for the de$iation obser$ed causing land contamination or water pollution will be

initiated

Submission of correcti$e action report to T%P&' regarding the de$iation obser$ed.

Appropriate correcti$e action will be initiated immediatel".

CROSS RE$ERENCE I$ ANY:

Pictorial la"out of ETP 3 STP.

Monitoring (ecords. @ )ail" discharge? Anal"sis (eports

6reen belt @ Pictorial la"out.

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC02

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: Procedure for establishing monitoring of Air &onsent for Legal &ompliance.

SCOPE: Applicable to Sembiam Plant.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS:

,. Measure the discharge # emission parameters from &himne"s on monthl" basis. (Submission of

monthl" report to T%P&'? on or before ,2

th

of following month.)

1. Measure the noise le$el on monthl" basis. (Submission of %oise monthl" report to

T%P&' on or before ,2

th

of following month.

4.

>n occurrence of such de$iations report to T%P&' has to be ensured for the same and correcti$e action

in terms of ha$ing appropriate treatment technologies installed for chimne"s form paint booth? test beds?

)6 set etc.

5.

Ensure that all the stac<s or chimne"s ha$e port or holes for sampling the emission. The general

prescribed limits for particulate matter in the stac< emission should be ,.omicro gram3m

4

..

Measure wind direction? temperature? humidit" rain fall etc.? dail" to ensure monitoring and

maintenance of Meteorological &enter .

7.

Measure additional parameters li<e (PM # Lead once in si: months # submit the report to T%P&'.

9.

>nitiate immediate correcti$e action in case of an" de$iation.

;.

Measure the following parameters on monthl" basis.

0.

Standard $alues prescribed b" T%P&' are as follows:

a) S/1 B ,12 Microgram3m

4

b) %/C B ,12 D

c) SPM B .22 D

d) &/ B .222 D

f) Ambient noise le$el

)a" time B 9. db.

%ight time B 92 db.

,2.

An" de$iation in the standard prescribed $alue b" T%P&' it must be reported to T%P&'.

,,.

Ensure the $alues (Emission and noise) within the T%P&' norms.

,1.

The renewal application to be filed 72 da"s before the e:pired date.

,4.

&alibration of e!uipment to be ensured.

,5.

Ensure no e:pansion acti$it" is carried out without obtaining prior consent of T%P&'.

ASSOCIAT ED IMPACT IN CASE O$ DEVIATION:

Potential for e:cess emission will lead Air Pollution %on conformance.

Potential for e:cess noise will lead to noise pollution # %on conformance to statutor" re!uirements.

CORRECTIVE ACTION IN CASE O$ DEVIATION:

&ommunication to T%P&' regarding the de$iation obser$ed.

Appropriate &orrecti$e Action (eport will be initiated immediatel" in case of an" emergenc".

CROSS RE$ERENCE I$ ANY:

Pictorial la"out for stac< position # Air monitoring station.

Air monitoring # %oise monitoring records.

Meteorological report

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC0%

Rev. No.:00

Date: 7/10/02

Pae:1 o! 1

P"RPOSE: To Establish procedure for the water pre$ention and control of pollution

+nder Eater &ess act ,099 Amendment ,00,.

SCOPE: Applicable for Sembiam plant.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS

Eater meter to be affi:ed at the source of water for measuring the !uantit" of water.

The separate meters for the affi:ing the !uantit" of water used for each of the purposes.

a) &ooling

b) )omestic

c) Process

The meter should be fi:ed at the entrance of water suppl" and such are easil" accessible for

>nspection and maintenance.

Ensure that at no point of time water is e:tracted before the source.

Furnish returns on or before .

th

e$er" month? Form > to be filed.

ASSOCIATED IMPACTS IN CASE O$ DEVIATION:

$iolation of the act

CORRECTIVE ACTION

>nformation to gi$en to respecti$e officials.

To pa" the &ess amount

CROSS RE$ERANCE

(eceipt of cess pa"ment

Furnishing of returns Form > submission

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC0&

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: Procedure for establish 3 monitoring of -a=ardous waste Management and -andling

(ules 1221.

SCOPE: Applicable to Sembiam plant.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS:

-a=ardous waste to be labeled D 'A(ARDO"S )ASTE D on each pac<age.( in Tamil # English )

Ensure that the area of storing -a=ardous wastes identified with sign of danger? no smo<ing displa"?

Fire e:tinguisher etc.

Ensure the facilit" has obtained %/ /'GE&T>/% &E(T>F>&ATE from T%P&'.

Ensure that the container must hold the stic<er D T->S S>)E +P D

The -a=ardous waste must not be stored for a period of more than 02 da"s and the ma:imum !uantit"

not e:ceeding ,2?222 <gs or truc< load which e$er is less.

-a=ardous waste should be in closed container and in isolated area enmar<ed e:clusi$el" for

ha=ardous wastes.

-a=ardous waste storage area to be fenced properl".

Appropriate Safet" protecti$e e!uipment li<e hand glo$es? nose mas<s? gum boots etc to be pro$ide

while handling of ha=ardous waste.

Application to be submitted in Form , for obtaining authori=ation 3 (enewal of authori=ation for

collection 3 (eception 3 treatment 3 transport 3 storage 3 disposal of ha=ardous wastes

Form for grant of authori=ation for occupier or operator handling ha=ardous wastes ( Form 1)

Ensure that the collection? reception ? treatment ? storage and disposal of the ha=ardous waste shall be

maintained in form 4 and the same to be shown to the inspecting officer as and when re!uired.

Annual returns for the facilit" shall be sent to T%P&' in form @ 5.

An" occurrence of accidents to be communicated to T%P&' in form @ .

All the ha=ardous waste with in the organi=ation to be handled as per the operation control procedure

for handling of ha=ardous wastes.

Ensure that all -a=ardous waste containers pro$ided with a label as enclosed when transporting

as per (form ; )

Ensure that the -a=ardous disposal is accompanied b" . copies of manifest ( Form 0 )

Submission of transport emergenc" (T(EM) card form ,2 as per motor $ehicle act ,0;0 for

transportation of ha=ardous waste.

ASSOCIATED IMPACTS IN CASE O$ DEVIATION:

Land condemnation

$iolation of the act

-ealth -a=ard.

Potential ris< of accident

CORRECTIVE ACTIONS*

Submission of correcti$e action report to T%P&' regarding the de$iation obser$ed.

Appropriate correcti$e action will be initiated immediatel".

CROSS RE$ERANCE :

Submission (ecords

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC0+

Rev. No.:00

Date: 7/10/02

Pae:1 o! 1

P"RPOSE:To Establish procedure for Safet" belts as per Factor" Act ,05; rule ,0.2 (Sub rule 7, A)

SCOPE: Applicable for Sembium.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS

Ensure the usage of Safet" belts for all the personal wor<ing at a height of more than 1 meters # abo$e

the ground le$el.

Ensure that a competent person from inspectorate of factories shall test thoroughl" 3 e:amine the safet"

belt once in si: months # certificates of such a test and e:amination specif"ing the stabilit" of belt for

compliance.

Ensure that the competent authorit" is ha$ing $alid certificate from inspectorate of factories.

Ensure that safet" belt should be leather shoulder straps of not less than . centimeters in width

and ) ring at the bac< for fastening a rope.

The certificate regards to its suitabilit" must be obtained from the competent person entered in a

register.

The certificates 3 (egister shall be produced before the inspector on demand.

The safet" belts to be condemned in case of noncompliance and must be awa" from the place of use.

ASSOCIATED IMPACTS IN CASE O$ DEVIATION

Accidents due to nonusage of safet" belt.

Leads to $iolation of acts.

CORRECTIVE ACTIONS

)amaged belt to be contemned immediatel".

Proper care to be ta<en when using safet" belts.

CROSS RE$ERANCE :

Test certificates.

Safet" belt register

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC0,

Rev. No.:00

Date: 7/10/02

Pae:1 o! 1

P"RPOSE: To Establish procedure for -oists and Lifting tac<les? E/T? Gib cranes as per the

Factor" Act ,05; (ule ..A Section 10.

SCOPE: Applicable where$er the -oists? Lifting tac<les? &ranes being used.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS

All parts (Lifting tac<les ?&ranes etc) tested thoroughl" 3 e:amined b" a competent person and get the

&ertificates of such a test and e:amination specif"ing the safe wor<ing load 3 loads once in a "ear.

The certificates as per subsection (,) of section 10 of Factories rule <ept a$ailable for inspection b"

inspectorate of factories.

Ensure that the competent authorit" is ha$ing $alid certificate from inspectorate of factories.

%o -oists 3 Lifting tac<les shall ? e:cept for the purpose of test ?be loaded be"ond the safe wor<ing

Load.

Ensure that the passage wa"s for o$er head cranes is of width 12inches (.2cms) and hand rail 4 feet

(02cm) height pro$ided for o$er head cranes.

A self access ladders shall be pro$ided at suitable places.

ASSOCIATED IMPACTS IN CASE O$ DEVIATION

Eill lead to accidents.

Leads to $iolation of Laws.

CORRECTIVE ACTIONS

Suitable >mmediate action to be ta<en when abnormalit" found.

Proper inspection 3 maintenance to be ta<en.

CROSS RE$ERANCE : Test certificates.

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC07

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: To Establish procedure for Pressure $essels as per Factor" act ,05; (ule .7

Tamil nadu Factor" rule ,0.2 (Sub rule 7, A)

SCOPE: Applicable for Sembiam plant.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS

E$er" pressure $essel in ser$ice shall be e:amined thoroughl" b" the )eput" chief inspector of

factories a) /nce in e$er" si: months e:ternall".

b) /nce in two "ears internall".( -"drosatatical test)

c) /nce in four "ears (+ltrasonic test)

-"drosatistical test will be conducted ,.1. times of designed pressure 3 ,.. times of ma:imum

permissible wor<ing pressure which e$er is less.

A report of the test of e$er" e:aminations of test carried out and shall be complied in the prescribed

form no. ;

The report of an" e:amination under this rule specified an" condition for securing the safe wor<ing

of an" pressure $essel. The pressure $essel not to be used unless the condition fulfilled.

E$er" pressure $essel should ha$e pressure relief $al$e ( safet" $al$e) # drain coc<.

Pressure gauges to read the pressure in the $essel and the same to be calibrated periodicall".

%o pressure $essel to be used in the factor" without test certificate.

The certificates as per Factories rule <ept a$ailable for inspection b" inspectorate of factories.

Ensure the formalities to be e:ecuted to deput" chief inspectorate of factories for testing the pressure

$essels before the e:pir" date.

ASSOCIATED IMPACTS IN CASE O$ DEVIATION

Lead to accident

$iolation of the act

CORRECTIVE ACTIONS

&orrecti$e actions to be ta<en immediatel" as per the report.

Proper maintenance to ta<en.

>nformation to be gi$en to )&>F

CROSS RE$ERANCE

Test certificates

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC/10

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: To establish a procedure for monitoring of statutor" re!uirement

&oncerned )6 Set as per Act ,0.7 >E(57

SCOPE: Applicable for )6 Set ,222 H*A? .22H*A? .,.H*A? ,;2H*A 1 %os.

RESPONSI#ILITY: Asst. Manager (Electrical Mint.)

PROCED"RE/ INSTR"CTIONS:

,) Pre$enti$e maintenance of )6 Set will be carried out as per the schedule

1) Permission to obtain when e$er there is an increase in the )6 &apacit"3shifting or installing %ew )6

set3 omission.

4) >nstallation shall be periodicall" inspected and tested at inter$als not e:ceeding fi$e "ears either b" the

inspector or an" officer appointed to assist the inspector.

5) After inspection electrical inspector will sent the detailed report to the supplier concern to rectif" the

mentioned reports.

.) After rectification all the defects? a rectification report will be sent to electrical inspectorate before 4

months after the date of inspection.

7) The fees for such inspection and test shall be determined b" the State 6o$ernment and shall be pa"able

b" the consumer in ad$ance.

9) A super$isor3engineer will be a$ailable at the time of inspection along with super$isor competenc"

certificate ( & License)

;) Electrical >nspection to be conducted once in a "ear as per (ule 57 b" &E>.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

,) *iolation of rules.

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) >nform to Electrical >nspector to conduct the Electrical >nspection incase of de$iation.

CROSS RE$ERENCE I$ ANY:

,) >nspection records.

1) Appro$ed drawing for installation of )6 set.

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC11

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: Procedure established for compliance of Electrical e!uipment as per >ndian Electrical

rules ,0.7 under section 57.

SCOPE: Applicable to all the departments within the premises Sembium plant.

RESPONSI#ILITY: Asst. Manager ( Electrical Maint.)

PROCED"RE / INSTR"CTIONS:

,) Permission letter to be obtained from Electrical >nspector incase of installation of a new Machine (or)

Shifting of machines from one place to another place.

1) >nstallation shall be periodicall" inspected and tested at inter$als not e:ceeding fi$e "ears either

b" the inspector or an" officer appointed to assist the inspector.

4) After inspection electrical inspector will sent the detailed report to the supplier concern to

rectif" the mentioned reports.

5) After rectification all the defects? a rectification report will be sent electrical inspectorate before 4

months after the date of inspection.

.) The fees for such inspection and test shall be determined b" the State 6o$ernment and shall

be pa"able b" the consumer in ad$ance.

7) A super$isor3engineer will be a$ailable at the time of inspection along with super$isor

competenc" certificate ( & License)

9) Electrical >nspection to be conducted once in a "ear as per (ule 57 b" &E>.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

,) *iolation of rules

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) >nform to Electrical >nspector to conduct the Electrical >nspection

CROSS RE$ERENCE I$ ANY:

,. (ecords

1. )rawings

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC12

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: /peration control procedure for compliance as per Passenger Lift Act ,0.7 >E( (Section.7)

SCOPE: Applicable to all Lifts within the premises of Sembium plant.

RESPONSI#ILITY: Asst. Manager ( Elec. Maint.) # AM (Mech. Maint) .

PROCED"RE / INSTR"CTIONS

,) (enewal of the license for passenger lift from once a "ear and records to be maintained.

1) Electrical >nspector to inspect the Life of passenger lift once in a "ear .

4) Monitoring # >nspection of Lift once in a month b" Electrical )epartment.

5) As per Tamilnadu Factor" Act ,05; load test will be conducted b" appro$ed agenc" once in a "ear.

.) Submission of Load Test &ertificate to )". &hief >nspector of Factories after inspection.

7) Ensure that the competent authorit" is ha$ing $alid certificate from inspectorate of factories

9) >nform to Electrical >nspector to the concern due month before the e:pir" of the period.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

,) *iolation of the Act.

1) (is< of accidents

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) >nformation to be gi$en to concerned department for the specific correcti$e action in case of de$iation.

CROSS RE$ERENCE I$ ANY:

,) (ecords >nspection &ertificate.

Load Test &ertificate gi$en b" the appro$ed agenc"

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC1%

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: An Act to pro$ide for public liabilit" insurance for the purpose of pro$iding immediate

relief to the persons effected b" accident occurring while handling an" ha=ardous substances and for

matters connected therewith or incidental thereto as per Public Liabilit" >nsurance Act ,00,.

SCOPE: Applicable to Sembiam Plant.

RESPONSI#ILITY: Manager Administration IAccounts departmentJASP 3 Manager personnel 3

Assistant Manager (Mech. Maint) .

PROCED"RE / INSTR"CTIONS:

,) &ompan" shall before handling of an" ha=ardous substance shall ha$e insurance polic" pro$iding for

contracts of insurance where b" he is insured against liabilit" to gi$e relief under subsection (,) of

section of Public liabilit" act ,00,.

1) Monitoring of >nsurance Polic" e:pir" date # renewal so that the insurance policies ma" remain in

force throughout the period during which such handling continued.

4) Ensure proper collection? treatment? storage and disposal of ha=ardous waste

5) Appl" for renewal of (-EM) authori=ation before e:pir" of the $alidit" period as specified in

the granted in the prescribed Form > and upgradation of -a=ardous Easte generation in

the plant.

.) Maintain records of ha=ardous wastes handling at the scrap "ard in the prescribed form.

7) Submit Annual (eturns to the T%P&' regarding disposal of -E in prescribed form.

9) (eport to the T%P&' if an" accident at storage or transportation while handling -E in

prescribed Form *.

;) Ensure that the !uantit" is as per the !uantit" specified b" T%P&'.

0)Ensure dull"filled T(EM card is a$ailable during transporting -E as per Motor *ehicle Act and

form,2 of ha=ardous waste management and handling rules 1221.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

,) *iolating Prohibition or regulation of the handling of an" ha=ardous substance

1) Stoppage or regulation of the suppl" of resources? electricit" # water or an" other ser$ice immediatel"

as per Public Liabilit" >nsurance Act ,00,.

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) The compan" shall get the insurance polic" referred in subsection(,)? renewed from time to

time before the e:pir" of the period of $alidit" thereof so that the insurance policies ma"

remain in force throughout the period during which such handling is continued.

1) (enew the authori=ation letter to -EM b" T%P&'.

CROSS RE$ERENCE I$ ANY:

,) >nsurance record.

1) -EM&onsent.

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC1&

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: An Act pro$iding for the protection? pre$ention and impro$ement of

the En$ironment As per The En$ironmental protection Act ,0;7

amended 1221.

SCOPE: Applicable for Sembiam Plant.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTION:

,) Submission of en$ironmental audit statement (Form*) of pre$ious financial "ear to T%P&' before

42

Th

September. The statement must contain the following details

a) Ambient Air Kualit" anal"sis report

b) Stac< monitoring reports

c) Eater anal"sis report

d) -a=ardous waste management authori=ation list # !uantit"

e) (aw materials !uantit"

f) Solid waste !uantit"

g) Eater consumption

1) /btain prior En$ironmental clearance from T%P&'? in case of %ew proLect?

Modernisation and e:pansion of the e:isting proLect.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

,) %on monitoring of parameters? specification ma" lead to noncompliance statutor"

re!uirement of T%P&'.

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) >f de$iation obser$ed b" T%P&'? appropriate suitable correcti$e action will be initiated immediatel".

1) Anal"sis are to be used as e$idence in legal proceedings.

CROSS RE$ERENCE I$ ANY:

,) T%P&' &onsent orders Air? Eater. -EM? &ess Pa"ment.

1) Monitoring (ecord ETP? STP? AAK? STA&H Monitoring # >nhouse noise monitoring record.

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC1+

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: To establish procedure for Standard for pollution control # mo$ement of

*ehicles as per Motor *ehicle Act ,05;? Amended ,0;0.

SCOPE: Applicable to Sembiam Plant

RESPONSI#ILITY: Securit" /fficer 3 Assistant Manager Maintenance Mechanical.

PROCED"RE / INSTR"CTIONS:

,) All factor" owned $ehicles # personal $ehicles shall ha$e emission test report dul"

appro$ed3authori=ed agenc" b" T%P&' as per Motor *ehicle (ule ,41( 1 # 5 )

1) All $endor $ehicles entering inside the factor" premises shall ha$e emission test report dul"

appro$ed3authori=ed agenc" b" T%P&' as per M* (ule ,41 (1 # 5)

4) Speed limit inside the premises to be maintained as per the motor $ehicle act

5) Ehile transporting ha=ardous waste? T(EM card shall be a$ailable in the $ehicle as per Section ,41

(1) as per Mo$er *ehicles Act ,0;0.

.) %o air horn shall be used inside the factor" premises.

7) Emission test report shall be <ept with Securit" /fficer for Factor" $ehicles # personal

/wned $ehicles and for $endor $ehicle emission test report shall be shown to securit"

personnel on demand.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

,) Air Pollution

1) %oise Pollution

4) -ealth ha=ard.

5) >nLuries to human being

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) T(EM card shall be ensured b" securit" personnel.

1) )ispla" board to be pro$ided to create awareness of the abo$e acts mentioned.

CROSS RE$ERENCE I$ ANY:

,) (ecords Monitoring

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC1,

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: To e-ta./0-1 a 23oce453e !o3 6o70to307 7o0-e a- 2e3

T1e No0-e Po//5t0o7 8 Re5/at0o7 a74 Co7t3o/9 2000 R5/e- a6e74e4 2002.

SCOPE: Applicable for inhouse noise and ambient noise monitoring within the

premises in Sembiam Plant.

RESPONSI#ILITY: Assistant Manager Maintenance Mechanical.

PROCED"RE/INSTR"CTION:

,) Proper maintenance of all the machines and )6 set to be carried out as per the pre$enti$e

maintenance schedule to control noise at source (02d').

1) %oise monitoring to be carried out nears the )6 area to compl" with the standards.

4) A suitable enclosure to be pro$ided for )6 Set to reduce the noise le$el as per the rule.

5) Ambient noise le$el to be monitored at a fre!uenc" of one month and reports to be submitted to

T%P&' before ,2

th

of e$er" month.

.) Ambient # inhouse noise monitoring to be done at the points indicated in the la"out and records to be

maintained.

7) Ambient noise le$el to compl" with the standards prescribed in industrial area.

)a" time : 9. d'

%ight time : 92 d'

9) Safet" protecti$e e!uipment li<e earplug and ear muffs to be used near the source of noise generation.

ASSOCIATED IMPACT CASE O$ DEVIATION:

,) *iolation against the T%P&' regulations

1) Effects on human health and ps"chological well being of the wor<men.

4) Sleep disturbance? stress reaction and increased blood pressure.

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) >dentif" the root cause and suitable action will be ta<en.

CROSS RE$ERENCE I$ ANY:

,) Places identified and mar<ed in the la"out ( inside # outside Factor") to ta<e noise

le$el once in a month using Sound Le$el Meter and record the reading on the da" itself.

1) Lin< from EMP if an" (ef: SP 3 MM 3 EMP 3 21

P(EPA(E) 'A : APP(/*E) 'A :

ENVIRONMENTAL MANAGEMENT SYSTEM

OPERATIONAL CONTROL

Doc. No.: SP/EMS/L/OC17

Rev. No.:00

Date: 7/10/02

Pae:1 o! 2

P"RPOSE: To establish a procedure for control /=one depleting substance as per

/=one depleting substance rule 1222.

SCOPE: Applicable for Sembiam Plant

RESPONSI#ILITY: Asst. Manager ( Electrical Maint.)

PROCED"RE / INSTR"CTIONS:

,) Pre$enti$e maintenance to be carried out to pre$ent the lea<age of freon gas from the chiller Plant.

and 'rea<down maintenance if an" will be carried out b" a appro$ed contractor with a defined

fre!uenc".

1) >ncase of an" lea<age of freon gas the replacement of the gas must not e:ceed the base line $alue.

4) %o person shall import or cause to import from or e:port to an" countr" specified? an" =one depleting

substance unless he obtain a license b" the authorit".

5) %o person shall either himself or b" an" person on his behalf or enterprise purchase /=one depleting

substances specified in column (4) of schedule >* from an" person for ma<ing stoc< or for using such

/=one depleting substances.

.) %o person shall engage in an" acti$it" specified in using /=one depleting substances specified after

the date of that schedule (12,2).

7) Submission of the completing report to change from /=one depleting substance technolog" to non

/=one depleting substance technolog" and the said date to be registered with the authorit" specified.

ASSOCIATED IMPACT IN CASE O$ DEVIATION:

,) /=one depletion due to lea<age of Freon gas and screen out harmful ultra$iolet radiationMs.

1) >mproper ( less) cooling

4) /=one.

CORRECTIVE ACTION IN CASE O$ DEVIATION:

,) >mmediatel" switch /FF the chilling A3&. Plant.

1) The appro$ed contractor will carr" out brea<down maintenance and also the contractor will carr" out

pre$enti$e maintenance once in 7 months.

CROSS RE$ERENCE I$ ANY:

,) Monitoring of (ecords.

1) Lin< from EMP if an" SP 3 EL 3 EMP 3 21

P(EPA(E) 'A : APP(/*E) 'A :

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 7 - SBI BC ManualDocument24 pages7 - SBI BC ManualVisas SivaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Tank ErectionDocument13 pagesTank Erectionsajay2010No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- PilDocument2 pagesPilVisas SivaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- EmployeeDocument4 pagesEmployeeVisas SivaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ContractorDocument6 pagesContractorVisas SivaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Contractor Plant Machinery Insurance Proposal SummaryDocument5 pagesContractor Plant Machinery Insurance Proposal SummaryVisas SivaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Contractor Plant Machinery Insurance Proposal SummaryDocument5 pagesContractor Plant Machinery Insurance Proposal SummaryVisas SivaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- ABC of DiabetesDocument111 pagesABC of DiabetesCandy E Ri ViNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Conditional FormattingDocument5 pagesConditional FormattingVisas SivaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Proposal and Questionnaire For Contractor'sDocument6 pagesProposal and Questionnaire For Contractor'sVisas SivaNo ratings yet

- PliDocument2 pagesPliVisas SivaNo ratings yet

- Proposal For Standard Fire & Special Perils PolicyDocument6 pagesProposal For Standard Fire & Special Perils PolicyVisas SivaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- WCPDocument4 pagesWCPVisas SivaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ERRECTION ALL RISKS/MARINE INSURANCE PROPOSALDocument5 pagesERRECTION ALL RISKS/MARINE INSURANCE PROPOSALVisas SivaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Weight CalculatorDocument6 pagesWeight CalculatorSaurabhNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Car 1Document6 pagesCar 1Visas SivaNo ratings yet

- 5-Project Summary and Description TemplateDocument23 pages5-Project Summary and Description TemplateVisas SivaNo ratings yet

- BurglaryDocument5 pagesBurglaryVisas SivaNo ratings yet

- Two Year Calendar 2014 2015 Landscape in ColorDocument1 pageTwo Year Calendar 2014 2015 Landscape in ColorVisas SivaNo ratings yet

- Labour Productivity NormsDocument3 pagesLabour Productivity NormsSharad Kumar67% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Comment Resolution SheetDocument1 pageComment Resolution SheetVisas SivaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- CRNDocument6 pagesCRNVisas SivaNo ratings yet

- Carbon Steel Storage TanksDocument1 pageCarbon Steel Storage TanksVisas SivaNo ratings yet

- Meeting AgendaDocument3 pagesMeeting AgendaVisas SivaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MD PV ASME v0.1Document35 pagesMD PV ASME v0.1Visas SivaNo ratings yet

- Tank Erection ProcedureDocument29 pagesTank Erection ProcedureVisas Siva100% (3)

- Comment Resolution SheetDocument1 pageComment Resolution SheetVisas SivaNo ratings yet

- 5-Project Summary and Description TemplateDocument23 pages5-Project Summary and Description TemplateVisas SivaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Level of Schedule in PlanningDocument5 pagesLevel of Schedule in PlanningVisas SivaNo ratings yet

- PlanningDocument67 pagesPlanningVisas SivaNo ratings yet

- Vega Atlantic CrossingDocument6 pagesVega Atlantic Crossingjoswas100% (2)

- OHCHR Discussion Paper - The Rights of Those Disproportionately Impacted by Climate Change - 30 Sept 2016Document9 pagesOHCHR Discussion Paper - The Rights of Those Disproportionately Impacted by Climate Change - 30 Sept 2016Seni NabouNo ratings yet

- Rossby and Kelvin WaveDocument18 pagesRossby and Kelvin Waveayu_28488No ratings yet

- L A S - S Ci: Research 7 Activity Sheet Quarter 1 - MELC 7 Week 6Document9 pagesL A S - S Ci: Research 7 Activity Sheet Quarter 1 - MELC 7 Week 6Clifford Jay Lachica100% (4)

- Gopaims To Blocksyrian Refugee Plan: Clawing Their Way BackDocument84 pagesGopaims To Blocksyrian Refugee Plan: Clawing Their Way BackstefanoNo ratings yet

- Springside Bitz N Bytes Summer 2012Document22 pagesSpringside Bitz N Bytes Summer 2012Deb KeyowskiNo ratings yet

- Enhancing Photoelectric Conversion Efficiency of Solar Panel by WatercoolingDocument5 pagesEnhancing Photoelectric Conversion Efficiency of Solar Panel by WatercoolingskrtamilNo ratings yet

- PMD News Bulletin: Promotion of Mr. Arif Mahmood As Director General of Pakistan Meteorological DepartmentDocument7 pagesPMD News Bulletin: Promotion of Mr. Arif Mahmood As Director General of Pakistan Meteorological DepartmentFahad NizamaniNo ratings yet

- CatalogDocument108 pagesCatalogMargaret DaughertyNo ratings yet

- Periodical Test 2NDDocument2 pagesPeriodical Test 2NDMilagros FernandezNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Teme Speaking Cu ModelDocument8 pagesTeme Speaking Cu ModelclaudiaNo ratings yet

- Sunriver March 30Document3 pagesSunriver March 30Alvaro ScorzaNo ratings yet

- Dear Esther ScriptDocument23 pagesDear Esther Scriptmc1062No ratings yet

- Evidence of Global Warming in Nigeria: Ukponmwan. H. Nosakhare and Ajibade, F. BrightDocument9 pagesEvidence of Global Warming in Nigeria: Ukponmwan. H. Nosakhare and Ajibade, F. BrightEditor IJRITCCNo ratings yet

- Environment Lighting MayaDocument70 pagesEnvironment Lighting MayaChristopher ForraiNo ratings yet

- EP-MS-P4-S3-050 - XLPE Insulated Pilot Cables - (KM Material Spec)Document8 pagesEP-MS-P4-S3-050 - XLPE Insulated Pilot Cables - (KM Material Spec)dimaomarNo ratings yet

- Sound Generated AerodynamicallyDocument33 pagesSound Generated AerodynamicallyAbraham Benjamin Britto100% (1)

- Was The Serial Killer They Had Been Looking ForDocument4 pagesWas The Serial Killer They Had Been Looking ForMila AllisonNo ratings yet

- Airbus Helicopters Brochure AS365N3Document20 pagesAirbus Helicopters Brochure AS365N3ZZTOP100% (1)

- Official SSC CHSL Question Paper 19th Jan 2017 Tier I With Answer KeyDocument24 pagesOfficial SSC CHSL Question Paper 19th Jan 2017 Tier I With Answer Keynidhi tripathiNo ratings yet

- List of cable nomenclature and ratingsDocument4 pagesList of cable nomenclature and ratingssmcsamindaNo ratings yet

- Lab 5 Heat ExchangerDocument13 pagesLab 5 Heat ExchangerNur Syuhaidah100% (1)

- Close Reading Annotations of The ShawlDocument3 pagesClose Reading Annotations of The ShawlmissstsaiNo ratings yet

- Conceptual Design For The Breakwater SystemDocument16 pagesConceptual Design For The Breakwater SystemKremen Mitov100% (1)

- Coasts PPT For Year 11Document62 pagesCoasts PPT For Year 11ife100% (1)

- Sportswear TECH.Document12 pagesSportswear TECH.Kushagradhi DebnathNo ratings yet

- 5225 (Rain Gauge)Document10 pages5225 (Rain Gauge)Ajit P. SinghNo ratings yet

- CGE23218Document6 pagesCGE23218Aloha LaparNo ratings yet

- SmartPly VapAirTight DATA SHEET Final 2015Document4 pagesSmartPly VapAirTight DATA SHEET Final 2015WPenrithNo ratings yet

- Azimuth Angle of PhotovoltaicDocument4 pagesAzimuth Angle of PhotovoltaicPetrescu VasyNo ratings yet

- The Russia Hoax: The Illicit Scheme to Clear Hillary Clinton and Frame Donald TrumpFrom EverandThe Russia Hoax: The Illicit Scheme to Clear Hillary Clinton and Frame Donald TrumpRating: 4.5 out of 5 stars4.5/5 (11)

- Power Grab: The Liberal Scheme to Undermine Trump, the GOP, and Our RepublicFrom EverandPower Grab: The Liberal Scheme to Undermine Trump, the GOP, and Our RepublicNo ratings yet

- Crimes and Cover-ups in American Politics: 1776-1963From EverandCrimes and Cover-ups in American Politics: 1776-1963Rating: 4.5 out of 5 stars4.5/5 (26)

- Stonewalled: My Fight for Truth Against the Forces of Obstruction, Intimidation, and Harassment in Obama's WashingtonFrom EverandStonewalled: My Fight for Truth Against the Forces of Obstruction, Intimidation, and Harassment in Obama's WashingtonRating: 4.5 out of 5 stars4.5/5 (21)

- The Red and the Blue: The 1990s and the Birth of Political TribalismFrom EverandThe Red and the Blue: The 1990s and the Birth of Political TribalismRating: 4 out of 5 stars4/5 (29)

- Modern Warriors: Real Stories from Real HeroesFrom EverandModern Warriors: Real Stories from Real HeroesRating: 3.5 out of 5 stars3.5/5 (3)

- The Courage to Be Free: Florida's Blueprint for America's RevivalFrom EverandThe Courage to Be Free: Florida's Blueprint for America's RevivalNo ratings yet

- Game Change: Obama and the Clintons, McCain and Palin, and the Race of a LifetimeFrom EverandGame Change: Obama and the Clintons, McCain and Palin, and the Race of a LifetimeRating: 4 out of 5 stars4/5 (572)