Professional Documents

Culture Documents

Potentiometric Level Switch For Dry Run Protection

Uploaded by

Marc Edwards0 ratings0% found this document useful (0 votes)

23 views4 pagesPotentiometric Level Switch for Dry Run Protection

Original Title

Potentiometric Level Switch for Dry Run Protection

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPotentiometric Level Switch for Dry Run Protection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views4 pagesPotentiometric Level Switch For Dry Run Protection

Uploaded by

Marc EdwardsPotentiometric Level Switch for Dry Run Protection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

F OOD 1

NEGELE MESSTECHNIK GMBH

Raieisenweg 7

87743 Egg an der Guenz

Phone +49 (0) 83 33 . 92 04 - 0

Fax +49 (0) 83 33 . 92 04 - 49

sales@anderson-negele.com

Tech. Support:

support@anderson-negele.com

Phone +49 (0) 83 33 . 92 04 - 720

Functional principle

U1

U2

Range of application

Especially for level control of pastes and very adhesive media

Level monitoring in metallic pipes and vessels

Product monitoring in pipes

Minimum conductivity from 1 S/cm (e.g. dest. water)

Application examples

Pump protection/dry run protection of mono pumps

Full/empty detection in metallic pipes and vessels

Level detection in cream cheese production

Hygienic design/Process connection

Flow optimized, hygienic and easy sterilizable installation by sleeve EMZ-132 or

build-in system EHG-.../1/2".

CIP cleanable up to 100 C

High temperature version CIP/SIP cleanable up to 143 C for 30 min max.

FDA conformable sensor materials

Sensor completely made of stainless steel (protection type IP69K)

Available process connections:

Tri-Clamp, diary fange, DRD, APV, Varivent, BioControl

Features

Potentiometric measurement principle

Defned PG-position

Integrated evaluation circuit with 4...20 mA output signal

Defned empty signal

Options/Accessories

High temperature version up to 143 C (with spacer)

Evaluation electronics VGW-E

Electrical connection with M12 plug-in

Pre-assembled connecting cable for M12-plug

Product information NSS-157

Potentiometric level switch NSS

Level switch NSS-157

Function principle

Potentiometric measurement principle measures the change of voltage ratio be-

tween the measurement rod and the metallic pipe or tank wall. Within the media

there is an electric fow feld, based on electric conductivity and capacitive char-

acteristics. The voltage ratio caused by this feld is proportional to the wetted part

of the rod.

Because just voltage amplifcation will be considered, the characteristics of the

media, especially electric conductivity, will have no infuence on the measure-

ment result. A second measurement principle allows the NSL sensor to recognize

a dryrun condition. This eliminates measurement error caused by adhesive media.

Authorizations

TYPE EL

MARCH 2006 74-06

NSS rod Equivalent

Conventional usage

Not suitable for applications in explosive areas.

Not suitable for applications in security-relevant equipment (SIL).

F OOD 2 Specifcation | Dimensional Drawings

Specifcation

Process connection thread

torque

CLEANadapt G1/2" hygienic

max. 10 Nm

Operating pressure max. 16 bar

Materials head

thread connection

isolating part

rod

stainless steel 1.4305

stainless steel 1.4301

PEEK (FDA approval number: 21CFR1772415)

stainless steel 1.4404, R

a

0.8 m

Temperature range ambient

storage

process

CIP/SIP cleaning

0...50 C

-40...85 C

-10...100 C

100 C max. 30 min

143 C max. 30 min with option H (high temperature version)

Resolution < 0.1 % of upper range value (= rod length)

Linearity < 1.0 % of upper range value (= rod length)

Response time < 50 ms

Supply 18...36 V DC

Output signal

burden

empty signal

analog 4...20 mA, 2-wire loop

max. 500

2.4 mA (from conductivity > 1 S/cm)

Electrical connection cable gland

cable connection

M16 x 1.5; 2-pin, 1.5 mm

M12 plug, 1.4301, 4-pin

Protection class with cable connction M12

with cable gland

IP 69 K

IP 67

Weight approx. 1600 g

Dimensional drawing NSS-157 Dimensional drawing NSS-157 / ... / H

I

n

s

e

r

t

i

o

n

l

e

n

g

t

h

E

L

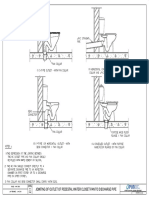

F OOD 3 Mechanical Installation | Electrical Connection | Installation

Mechanical installation

Attention: Do not shorten the rod of the level probe!

To guarantee a trouble-free function of the measurement point give attention to a good electrical contacting of the

process connection of the level probe to the pipe or vessel.

Do not use any isolating sealing materials like Tefon or similar!

When installing into a pipe the level probe has to be mounted from the bottom side! In this case use the Negele build-

in system type EHG. The length of the rod is optimized for these build-in systems.

When installing into a vessel you can do the mounting from all directions. If you install the level probe from above, give

attention to the note of the installation examples (see above)!

The vessel or pipe has to be made of an electrical conducting material like stainless steel.

Installation example

level control in vessels; e.g. for full-/empty monitoring

Installation example

installation in pipes

e.g. for dry run protection

Attention:

If the level probe will be in-

stalled into the top of a vessel

or horizontally the current out-

put is like the diagram shows:

probe uncovered: 4 mA

probe covered: 20 mA

uncovered covered

level

Electrical connection with cable gland

1: LED probe

2: LED power

3: evaluation device;

e. g. limit switch or PLC

Electrical connection of NSK with M12 plug

1: brown + power supply

2: white + output

4...20 mA

3: blue - output

4: black - power supply

1

2

3

Advice | Installation

Important information: To guarantee a trouble-free

function the power supply cable as well as the signal

cable should be shielded and grounded at the electric

control box.

The device will be shipped exactly calibrated, thus

normally there is no calibration necessary.

Make the electrical connection according to the electri-

cal connecting plan and apply supply voltage.

Set the alarm point of the evaluation unit as required.

Give attention to the following:

A more higher alarm point causes a lower sensitivity

to adhesions.

When installing the sensor in pipes the setting of the

alarm point depends of the flling high that is defned

full.

If it is required to monitor the pipe to completely

flling high we recommend to set the alarm point

between 19 mA and 20 mA.

F OOD 4

NEGELE MESSTECHNIK GMBH

Raifeisenweg 7

87743 Egg an der Guenz

Phone +49 (0) 83 33 . 92 04 - 0

Fax +49 (0) 83 33 . 92 04 - 49

sales@anderson-negele.com

Tech. Support:

support@anderson-negele.com

Phone +49 (0) 83 33 . 92 04 - 720

12.09.14 / 4.0 / MU / at-ac.de

Product information NSS-157

Conditions for a measuring point according to 3-A Sanitary Standard 74-06

The sensors NSS-157 conforming to the 3-A Sanitary Standard.

The sensors are designed for CIP/SIP cleaning. Maximum 143 C for 30 minutes.

Only with the build-in system CLEANadapt (EMZ, EMK, Adapter AMC and AMV) allowed.

Using the weld in sleeve EMZ, EMK the weld must comply to the requirements of the current 3-A Sanitary Standard.

Mounting position, self draining and the position of the leackage hole must be in accordance to current 3-A Sanitary

Standard.

Cleaning/Maintenance

In case of using pressure washers, dontt point nozzle

directly to electrical connections!

Reshipment

Sensors shall be clean and must not be contaminated

with dangerous media and/or heat-conductive paste!

Note the advice for cleaning!

Use suitable transport packaging only to avoid damage

of the equipment!

Standards and Guidelines

You have to comply with applicable regulations and

directives

Advice to EMC

Applicable guidelines:

Electromagnetic compatibility 2004/108/EC

The accordance with applicable EU-guidelines is con-

frmed with CE-labeling of the device.

You have to guarantee the compliance of all guidelines

applicable for the entire equipement.

Disposal

This instrument is not subject to the WEEE directive

2002/96/EC and the respective national laws.

Pass the instrument directly on to a specialised recy-

cling company and do not use the municipal collecting

points.

Transport/Storage

Do not store outside

Store in an area that is dry and dust-free

Do not expose to corrosive media

Protected against solar radiation

Avoid mechanical shock and vibration

Storage temperature -40...85 C

Relative humidity max. 98 %

Order Code

NSS-157 (Potentiometric level switch, process connection G1/2" hygienic)

Rod lenght EL

030

045

060

080

100

130

200

(30 mm, for pipe DN50)

(45 mm, for pipe DN65)

(60 mm, for pipe DN80)

(80 mm, for pipe DN100)

(100 mm, for pipe DN125)

(130 mm, for pipe DN150)

(200 mm, for vessels)

Temperature version

X

H

(standard; for process temperatures up to 100 C)

(high temperature version with spacer: for process temperatures up to 150 C for 30 minutes)

Electrical connection

X

M12

(cable gland M16 x 1,5)

(M12 plug 1.4305)

NSS-157 / 030 / X / M12 /

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Topic 4 Radar System Jun2020Document87 pagesTopic 4 Radar System Jun2020Nabilah DaudNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Finding Stocks The Warren Buffett Way by John BajkowskiDocument10 pagesFinding Stocks The Warren Buffett Way by John Bajkowskiapi-3794576100% (2)

- Emcp 4.2Document72 pagesEmcp 4.2RakibNo ratings yet

- Ata 42 Ima & AdcnDocument8 pagesAta 42 Ima & AdcnJagbir Singh100% (1)

- Trading Journal TemplateDocument8 pagesTrading Journal TemplateMarc EdwardsNo ratings yet

- Training Course_5G RAN3.0 Massive MIMODocument41 pagesTraining Course_5G RAN3.0 Massive MIMOVVLNo ratings yet

- Agitated Vessel Heat Transfer Design PDFDocument3 pagesAgitated Vessel Heat Transfer Design PDFmrariffNo ratings yet

- Centrifugal PumpDocument11 pagesCentrifugal PumpMarc EdwardsNo ratings yet

- Telegram Channel @nettrainDocument52 pagesTelegram Channel @nettrainSurajit Pal100% (1)

- Simulation of Paint Manufacturing ProcessDocument17 pagesSimulation of Paint Manufacturing ProcessMarc Edwards100% (1)

- VectorsDocument5 pagesVectorsMarc EdwardsNo ratings yet

- Scalar, Vector, MatrixDocument3 pagesScalar, Vector, MatrixMarc EdwardsNo ratings yet

- Systems of Linear and Quadratic EquationsDocument5 pagesSystems of Linear and Quadratic EquationsMarc EdwardsNo ratings yet

- Solving Systems of Linear Equations Using MatricesDocument3 pagesSolving Systems of Linear Equations Using MatricesMarc EdwardsNo ratings yet

- PSP Analog Stick FixDocument3 pagesPSP Analog Stick FixMarc EdwardsNo ratings yet

- Chemical ResistanceDocument36 pagesChemical ResistanceÉricaTirelliNo ratings yet

- SanDrgNo3 23aDocument1 pageSanDrgNo3 23aMarc EdwardsNo ratings yet

- SP Solar Power - GeneratorsDocument15 pagesSP Solar Power - GeneratorsMarc EdwardsNo ratings yet

- Phosphorous Removal From Waste WaterDocument5 pagesPhosphorous Removal From Waste WaterJanice OmadtoNo ratings yet

- Inverse of A Matrix Using Minors, Cofactors and AdjugateDocument3 pagesInverse of A Matrix Using Minors, Cofactors and AdjugateMarc EdwardsNo ratings yet

- 26 Aug 2013 ECM Review Panel Review of Earth Control Measures Plan Provided by QecpDocument3 pages26 Aug 2013 ECM Review Panel Review of Earth Control Measures Plan Provided by QecpSơn Nguyễn-LêNo ratings yet

- Submission Requirements For Flood Protection MeasuresDocument1 pageSubmission Requirements For Flood Protection MeasuresfrancisalbanNo ratings yet

- Introduction and Sizing Valves For Liquids: ANSI/ISA/IEC Valve SizingDocument38 pagesIntroduction and Sizing Valves For Liquids: ANSI/ISA/IEC Valve SizingMarc EdwardsNo ratings yet

- Hare and The Tortoise RulesDocument8 pagesHare and The Tortoise RulesMarc EdwardsNo ratings yet

- Crystal Reports - A4PackReportDocument1 pageCrystal Reports - A4PackReportMarc EdwardsNo ratings yet

- NPT Thread Chart - NPT & NPS Fittings Dimensions & SizesDocument2 pagesNPT Thread Chart - NPT & NPS Fittings Dimensions & SizesMarc EdwardsNo ratings yet

- Ticker Price Change % PE 52wklow 52wkhigh: IBM KO Aapl UVE JPM Intc Ezpw COHDocument2 pagesTicker Price Change % PE 52wklow 52wkhigh: IBM KO Aapl UVE JPM Intc Ezpw COHMarc EdwardsNo ratings yet

- MEGAMAN Luminaire Catalogue 2015 16 Indoor Track Lighting MOSAICDocument2 pagesMEGAMAN Luminaire Catalogue 2015 16 Indoor Track Lighting MOSAICMarc EdwardsNo ratings yet

- L&C Card Manifest 1.2Document3 pagesL&C Card Manifest 1.2Marc EdwardsNo ratings yet

- Critical-Subcritical Pressure (GAS CHOKED FLOW)Document4 pagesCritical-Subcritical Pressure (GAS CHOKED FLOW)Marc EdwardsNo ratings yet

- DCF Calculator - V2.0Document4 pagesDCF Calculator - V2.0Marc EdwardsNo ratings yet

- FSTDocument21 pagesFSTMarc EdwardsNo ratings yet

- Small Bore Orifice For Gas FlowDocument4 pagesSmall Bore Orifice For Gas FlowMarc EdwardsNo ratings yet

- !L5R IE BasicRulebook WebDocument76 pages!L5R IE BasicRulebook WebAlvaro Trielli100% (1)

- Blink An LED With Arduino in TinkercadDocument15 pagesBlink An LED With Arduino in TinkercadVirendra GourNo ratings yet

- CNP 3 BisDocument274 pagesCNP 3 Bisomkar1998No ratings yet

- GH 120 GH 200 GH 202 GH 252 GH 300 Instruction - TocDocument4 pagesGH 120 GH 200 GH 202 GH 252 GH 300 Instruction - TocPilar CaleroNo ratings yet

- Baldor-Reliance AC & DC Motor Installation & MaintenanceDocument4 pagesBaldor-Reliance AC & DC Motor Installation & MaintenanceAriawan HasnanNo ratings yet

- Ii B.Tech I Semester (R09) Regular Examination Results Hall Ticket NoDocument2 pagesIi B.Tech I Semester (R09) Regular Examination Results Hall Ticket NoMuramshetty SantoshNo ratings yet

- Luminarias CatalogoDocument362 pagesLuminarias CatalogoAlejandro TelloNo ratings yet

- DTC Reset 2007 HondaDocument2 pagesDTC Reset 2007 HondaMas PoerNo ratings yet

- ECS2z SelfCD Wiring DiagramsDocument3 pagesECS2z SelfCD Wiring DiagramsAby Babu100% (1)

- What Is PCB Busbar or PCB Stiffener Busbar in ElectronicsDocument13 pagesWhat Is PCB Busbar or PCB Stiffener Busbar in ElectronicsjackNo ratings yet

- Noise and Vibration Tester: MVH 90E, MVH 200E MVH 90el, MVH 200elDocument8 pagesNoise and Vibration Tester: MVH 90E, MVH 200E MVH 90el, MVH 200ellaloNo ratings yet

- Contactless Dynamo Bike Wheel LightsDocument6 pagesContactless Dynamo Bike Wheel Lightsmarandan85No ratings yet

- NSN AlaramDocument1 pageNSN AlaramSrikanth MahadevuniNo ratings yet

- BD 249 CDocument5 pagesBD 249 CLucian Traian CojocaruNo ratings yet

- PMSM Speed ControlDocument39 pagesPMSM Speed ControlKushagra KhamesraNo ratings yet

- Sport Lighting Photometric DataDocument1 pageSport Lighting Photometric DataMarkus MatikNo ratings yet

- 4613 SurePOS 100 Pont of Sale TerminalDocument82 pages4613 SurePOS 100 Pont of Sale TerminalRoberto MPNo ratings yet

- Sensors and Actuators: ELEC 483-001Document9 pagesSensors and Actuators: ELEC 483-001Nouman MemonNo ratings yet

- Splicing - Jointing Cable Terminal To Main Aerial and - or Underground Copper CableDocument49 pagesSplicing - Jointing Cable Terminal To Main Aerial and - or Underground Copper CableEdward Allen Manaloto100% (1)

- Interface Generac G Panel ModbusDocument1 pageInterface Generac G Panel Modbusbalajiboss005No ratings yet

- Hoja Tecnica PLC'S VTP 402Document7 pagesHoja Tecnica PLC'S VTP 402Angel Flores RojasNo ratings yet

- Assignment 2 Prelim TermDocument1 pageAssignment 2 Prelim TermNathaniel NimerNo ratings yet

- Frequency Counter 1601Document15 pagesFrequency Counter 1601Miguel Angel Lazarte ChavezNo ratings yet

- High Voltage 2xs FL 2y A2xs FL 2y 110kv Power Cable 1Document3 pagesHigh Voltage 2xs FL 2y A2xs FL 2y 110kv Power Cable 1SanalicaNo ratings yet

- MATLAB Transmission Line Fault AnalysisDocument3 pagesMATLAB Transmission Line Fault AnalysisKALYAN KUMARNo ratings yet

- Infineon TC39xXX - TC39xXP - PB PB v01 - 00 EN PDFDocument2 pagesInfineon TC39xXX - TC39xXP - PB PB v01 - 00 EN PDFmikipejaNo ratings yet