Professional Documents

Culture Documents

Scale-Free Reheating PDF

Uploaded by

Agustine SetiawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scale-Free Reheating PDF

Uploaded by

Agustine SetiawanCopyright:

Available Formats

. .

INDUSTRIALTECHNOLOGIESPROGRAM

Nation

By

quality of the steel .

reheating.

Scale-Free Steel Reheating

abnormalities that require reprocessing.

downtime.

Boosting the productivity and competitiveness of U.S. industry through improvements and environmental performance

Benets for Our Industry and Our

Scale-free reheating improves productivity

by reducing downtime and manpower to

collect and remove scale. Scale-free reheating

increases energy and cost effciency of steel

reheating and reduces the amount of energy

needed to replenish steel lost as oxides.

reducing the amount of steel lost to scale

formation, this system improves the surface

Applications in Our Nations

Industry

Reducing scale formation during steel reheating

will improve cost and energy effciency in

mini-mills and integrated mills, along with

forging and other industries that use steel

Next Generation Heating System for

Reducing Scale Formation Will Improve Steel

Surface Quality and Furnace Productivity

A reheated steel slab exits a reheat furnace. The slab temperature can reach 2,100F.

Steel reheating is an important, yet energy-

intensive process that mills and fnishers use

prior to rolling or forging. The steel slabs are

heated to approximately 2,100F in reheat

furnaces that often use natural gas or by-

product fuels. During this process, 1-2% of

the steel is typically lost to oxidation, resulting

in scale accumulation on the steel surface and

on the furnace foor.

Scale compromises steel quality because

it adheres to the surface and is diffcult to

remove. If scale is present in the rolled

product, it can result in defects or metallurgical

Scale formation also poses problems for the

reheating furnaces when it accumulates on

the furnace foor. It must be collected and

removed frequently because it impedes gas

fow and heat transfer. In addition, the lifetime

of furnace components can be negatively

affected by scale presence. Finally, removing

scale interrupts production and results in costly

INDUSTRIALTECHNOLOGIESPROGRAM

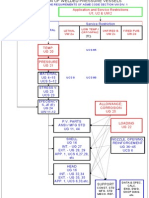

Project Description

The primary objective of this project is to

develop and test a heating system that reduces

scale formation during the steel reheating

process. Successful completion of this project

will improve furnace productivity by reducing

downtime and will reduce scale-associated

energy consumption and reprocessing.

Barriers

Some technical hurdles this project seeks to

overcome are:

Required atmospheric composition for the

heating system

Effects of time and temperature on scale-

free heating.

Lack of knowledge on which burner would

be most appropriate to use for a typical

walking beam furnace.

Pathways

The objectives of this effort will be achieved

through (1) developing and analyzing concepts

for scale-free reheating systems, (2) the

study of the effect of time and temperature

on scale formation, and (3) the verifcation

of process conditions in terms of atmosphere

composition.

Milestones

Phase I

Conduct literature search and analyze

options needed to create a process

atmosphere required for scale-free

reheating (Complete)

Defne furnace operating parameters

required to generate scale-free heating

process atmosphere and conduct economic

and technical analyses (Complete)

Phase II

Pilot-scale furnace heating tests on scale-

free heating using commonly used steel

processing parameters and verifying that

steel samples meet steel industry standards

Defning heating system conditions to meet

scale-free heating requirements for critical

components

Design and validate scale-free heating

system for typical applications

Energy, economic, and environmental

analysis and modeling; evaluation of

options

Commercialization

The scale-free heating burner will be tested

for functionality in furnaces used for both

conventional heating and scale-free heating.

The project team, consisting of steel industry

experts, researchers, and trade associations will

use the results of the economic and technical

analyses to transition the technology for

industrial use upon successful demonstration

of the technology.

Project Partners

E3M, Inc.

North Potomac, MD

Principal Investigator:

Arvind Thekdi (athekdi@e3minc.com)

ACL-NWO, Inc.

Sylvania, OH

Bloom Engineering Corporation

Pittsburgh, PA

Steel Dynamics, Inc.

Fort Wayne, IN

Air Products & Chemical

Allentown, PA

Steel Manufacturers Association (SMA)

Washington, DC

Forging Industry Association (FIA)

Cleveland, OH

A Strong Energy Portfolio for a

Strong America

Energy effciency and clean, renewable energy

will mean a stronger economy, a cleaner

environment, and greater energy independence

for America. Working with a wide array of state,

community, industry, and university partners, the

U.S. Department of Energys Offce of Energy

Effciency and Renewable Energy invests in a

diverse portfolio of energy technologies.

September 2007

For more information, visit www.eere.energy.gov/industry or call 1-877-337-3463

You might also like

- End Splitting During Long Products Rolling - Billet Quality of Rolling ProcessDocument27 pagesEnd Splitting During Long Products Rolling - Billet Quality of Rolling ProcessJorge MadiasNo ratings yet

- Billet Defects - Pinhole and Blowhole Formation, Prevention and Evolution PDFDocument10 pagesBillet Defects - Pinhole and Blowhole Formation, Prevention and Evolution PDFSebastian KrdnasNo ratings yet

- Metallurgy of Continiuous Casting Technology PDFDocument20 pagesMetallurgy of Continiuous Casting Technology PDFRadi GoharNo ratings yet

- Tramp Elements and Billet CarckingDocument7 pagesTramp Elements and Billet CarckingOmar TahaNo ratings yet

- Topic Page No.: IndexDocument56 pagesTopic Page No.: Indexvikashranjan1987No ratings yet

- Are View of The Rhomboid It y Problem in Billet CastingDocument11 pagesAre View of The Rhomboid It y Problem in Billet CastingSuhaib AshrafNo ratings yet

- Automated Coil Trimming System For Wire Rod Mills in The Digital EraDocument10 pagesAutomated Coil Trimming System For Wire Rod Mills in The Digital EraJJNo ratings yet

- Presentation BSWDocument75 pagesPresentation BSWBharath100% (1)

- Optimisation of Reheat Furnace - Air PreheaterDocument6 pagesOptimisation of Reheat Furnace - Air PreheaterLTE002No ratings yet

- Bhushan Traioning Report 786Document53 pagesBhushan Traioning Report 786Deepak Giri50% (2)

- Posco WirerodDocument17 pagesPosco WirerodNina LazuardiNo ratings yet

- Feb 2014 PDFDocument72 pagesFeb 2014 PDFsatish_trivediNo ratings yet

- Maintaining Water Cooling in Finishing MillDocument52 pagesMaintaining Water Cooling in Finishing MillRoshan Joe MathewNo ratings yet

- Steel Cleanliness PaperDocument34 pagesSteel Cleanliness PaperyanuarNo ratings yet

- Endless Casting and Rolling of Long Products: The Competitive Substitute of Conventional Mini-MillsDocument8 pagesEndless Casting and Rolling of Long Products: The Competitive Substitute of Conventional Mini-MillsJJNo ratings yet

- Metallurgical Defects of Cast Steel: SeminarDocument26 pagesMetallurgical Defects of Cast Steel: SeminarAndré RibeiroNo ratings yet

- Sulphur in SteelsDocument3 pagesSulphur in Steelsnarayan kaushikNo ratings yet

- Monitoring metallurgical processes during hot rollingDocument25 pagesMonitoring metallurgical processes during hot rollingFrancesco PaternosterNo ratings yet

- Roll Breakage DetectionDocument7 pagesRoll Breakage Detectionzubair ahmadNo ratings yet

- Casting Defects in SteelsDocument4 pagesCasting Defects in SteelsShamsur Rahman Russell100% (1)

- CONTINUOUS CASTING ColloquiumDocument18 pagesCONTINUOUS CASTING ColloquiumakritiNo ratings yet

- High Carbon Steel Rolling DMHDocument10 pagesHigh Carbon Steel Rolling DMHimtiyaz aliNo ratings yet

- Quality Problems in Continuous Cast ProductsDocument47 pagesQuality Problems in Continuous Cast Productsmanas burmaNo ratings yet

- Nmd-Atm-2018r-00405 - Arghya Majumder - RinlDocument18 pagesNmd-Atm-2018r-00405 - Arghya Majumder - RinlArghya MajumderNo ratings yet

- Ferritic Hot Rolling for Low Carbon SteelsDocument10 pagesFerritic Hot Rolling for Low Carbon SteelsKetnipha SukwannawitNo ratings yet

- Operation and Maintenance Regulation For Finishing MillDocument67 pagesOperation and Maintenance Regulation For Finishing MillAbhijitkar89No ratings yet

- CVS RM - Company Presentation OverviewDocument102 pagesCVS RM - Company Presentation Overviewrazen_inNo ratings yet

- Continuous Casting Solidification PhenomenaDocument20 pagesContinuous Casting Solidification PhenomenaSyed HasniNo ratings yet

- Multi SlittingDocument6 pagesMulti Slittingeng_ahmedkassemNo ratings yet

- Reheating Furnace.3Document8 pagesReheating Furnace.3Zulfa Ilham BasyarahilNo ratings yet

- Quenched and Tempered BarDocument7 pagesQuenched and Tempered Barpulilatha100% (1)

- Defects On Al Billets PDFDocument7 pagesDefects On Al Billets PDFnanbetonamoNo ratings yet

- Steel Dynamics Bar Book Rev 2 New CoverDocument194 pagesSteel Dynamics Bar Book Rev 2 New CoverNina LazuardiNo ratings yet

- Continuous Casting of Steel PDFDocument10 pagesContinuous Casting of Steel PDFStefan MihalacheNo ratings yet

- Loop Laying HeadDocument21 pagesLoop Laying HeadHarsha Reddy100% (4)

- Mould Fluxes in The Steel Continuous Casting ProcessDocument30 pagesMould Fluxes in The Steel Continuous Casting ProcessUgur KayaNo ratings yet

- Continuous Casting TheoryDocument12 pagesContinuous Casting Theoryyash_ganatra100% (1)

- Slit RollingDocument16 pagesSlit RollingreichfuhrerNo ratings yet

- Advanced Loop Laying Head for Perfect Coil ProductionDocument10 pagesAdvanced Loop Laying Head for Perfect Coil ProductionFrancesco PaternosterNo ratings yet

- Understanding The Properties of Oxide Scales On Hot Rolled Steel StripDocument6 pagesUnderstanding The Properties of Oxide Scales On Hot Rolled Steel Stripradinasr100% (1)

- FUCHS Shaft Furnaces: The Power, The Performance, The ProfitDocument13 pagesFUCHS Shaft Furnaces: The Power, The Performance, The ProfitDhirender Kapoor100% (1)

- Defects 2 PDFDocument37 pagesDefects 2 PDFFongJeremyNo ratings yet

- About Initial Solidification of Steel in Continuous CastingDocument9 pagesAbout Initial Solidification of Steel in Continuous CastingSoumya VaranasiNo ratings yet

- Accelerated CoolingDocument7 pagesAccelerated CoolingHarikrishnan N SivaprasadNo ratings yet

- Improve Desulphurisation Process by Slag ControlDocument66 pagesImprove Desulphurisation Process by Slag ControlRAULYEPEZSANCHEZNo ratings yet

- L2: Sensors & TransducersDocument77 pagesL2: Sensors & TransducersMaheshNo ratings yet

- Improvement of Surface Quality of Continuously Cast Steel Control PDFDocument130 pagesImprovement of Surface Quality of Continuously Cast Steel Control PDFChrist ChristiNo ratings yet

- Total Quality ManagementDocument36 pagesTotal Quality Managementfonsekapdl100% (1)

- Reheating Furnaces and Heating TechnologiesDocument12 pagesReheating Furnaces and Heating Technologiesrazen_in100% (2)

- Rod, Wire and Tube Drawing Process GuideDocument51 pagesRod, Wire and Tube Drawing Process GuidegereNo ratings yet

- G. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityDocument7 pagesG. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityMadhusudhan ModemNo ratings yet

- Continuous Casting ProcessDocument12 pagesContinuous Casting ProcessPUSHKARKHANNANo ratings yet

- Electric Arc Furnace Steelmaking by Jeremy A. T. Jones, Nupro CorporationDocument9 pagesElectric Arc Furnace Steelmaking by Jeremy A. T. Jones, Nupro CorporationGilson JuniorNo ratings yet

- Rolling DefectsDocument8 pagesRolling Defectsvelavansu100% (2)

- Proses Manufaktur - Fundamental of Metal FormingDocument35 pagesProses Manufaktur - Fundamental of Metal FormingAnatolium IrgrandeNo ratings yet

- Hot rolled strip metallurgy effectsDocument10 pagesHot rolled strip metallurgy effectspoom2007No ratings yet

- The Iron Puddler My life in the rolling mills and what came of itFrom EverandThe Iron Puddler My life in the rolling mills and what came of itNo ratings yet

- Information Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981From EverandInformation Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981No ratings yet

- N9509-Welding Techniques For Tailored BlanksDocument7 pagesN9509-Welding Techniques For Tailored BlanksAgustine SetiawanNo ratings yet

- Nscguide2012 - e - 61-Flow Production Nippon SteelDocument2 pagesNscguide2012 - e - 61-Flow Production Nippon SteelAgustine SetiawanNo ratings yet

- NSTR101-13 - Tech - Review-2-2-Change and Development of Steelmaking TechnologyDocument6 pagesNSTR101-13 - Tech - Review-2-2-Change and Development of Steelmaking TechnologyAgustine SetiawanNo ratings yet

- DNV Os C401Document44 pagesDNV Os C401Mung Duong XuanNo ratings yet

- NDT-MT TheoryDocument14 pagesNDT-MT TheoryAgustine SetiawanNo ratings yet

- SM - en - Ar - 2003-ANNUAL REPORT-Nippon SteelDocument56 pagesSM - en - Ar - 2003-ANNUAL REPORT-Nippon SteelAgustine SetiawanNo ratings yet

- US4026729-Method of Making A Soft Steel Sheet by Continuous AnnealingDocument6 pagesUS4026729-Method of Making A Soft Steel Sheet by Continuous AnnealingAgustine SetiawanNo ratings yet

- MATERIAL AND NDE CLASSIFICATIONDocument103 pagesMATERIAL AND NDE CLASSIFICATIONAgustine SetiawanNo ratings yet

- Hot-dip coated steel strip with improved drawing qualityDocument5 pagesHot-dip coated steel strip with improved drawing qualityAgustine SetiawanNo ratings yet

- Ductile Iron and Method of Making SameDocument4 pagesDuctile Iron and Method of Making SameAgustine SetiawanNo ratings yet

- Welding-Basic Study Guide 1997Document136 pagesWelding-Basic Study Guide 1997Agustine SetiawanNo ratings yet

- Visual Inspection ModulesDocument6 pagesVisual Inspection ModulesAgustine Setiawan100% (2)

- Trouble Shooting Guide For The Powder CoatingDocument19 pagesTrouble Shooting Guide For The Powder CoatingAgustine SetiawanNo ratings yet

- NDT For BoilersDocument9 pagesNDT For BoilersmjorionNo ratings yet

- NDT-PT TheoryDocument22 pagesNDT-PT TheoryAgustine SetiawanNo ratings yet

- Periodic Table of The ElementsDocument1 pagePeriodic Table of The Elementsm_tagliaNo ratings yet

- Boiler - DFKI PVBOChartDocument10 pagesBoiler - DFKI PVBOChartAgustine SetiawanNo ratings yet

- Beda Antara Verifikasi & ValidasiDocument18 pagesBeda Antara Verifikasi & ValidasiAgustine SetiawanNo ratings yet

- Cokal Confirms Indonesian Met ResourcesDocument1 pageCokal Confirms Indonesian Met ResourcesAgustine SetiawanNo ratings yet

- Study of Fork Tube Failure in Motorcycle Using Scanning Electron MicroscopeDocument5 pagesStudy of Fork Tube Failure in Motorcycle Using Scanning Electron MicroscopeAgustine SetiawanNo ratings yet

- Hot Dip Galvanizing of Sheet Metal-SpangleDocument6 pagesHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanNo ratings yet

- The Metallurgy of Carbon SteelDocument5 pagesThe Metallurgy of Carbon SteeltsoheilNo ratings yet

- Metallurgy of Iron and SteelmakingDocument13 pagesMetallurgy of Iron and SteelmakingAgustine SetiawanNo ratings yet

- Nickel Alloys Applications and ProcessingDocument16 pagesNickel Alloys Applications and ProcessingAgustine SetiawanNo ratings yet

- Black SteelDocument2 pagesBlack SteelAgustine SetiawanNo ratings yet

- Drilling 01Document1 pageDrilling 01Agustine SetiawanNo ratings yet

- Cold Work EmbrittlementDocument2 pagesCold Work EmbrittlementAgustine SetiawanNo ratings yet

- Standard Test Method For Drop Test of Loaded Containers by Free FallDocument8 pagesStandard Test Method For Drop Test of Loaded Containers by Free FallAgustine SetiawanNo ratings yet

- Metal Ki PehchaanDocument14 pagesMetal Ki PehchaanParteek GandhiNo ratings yet

- Isstech Studies Paper PDFDocument28 pagesIsstech Studies Paper PDFAgustine SetiawanNo ratings yet

- 1979 - Denmark Without Nuclear PowerDocument15 pages1979 - Denmark Without Nuclear PowerZoran OstricNo ratings yet

- Conference Fast Reactors and Related Fuel Cycles Challenges and Opportunities FR09Document410 pagesConference Fast Reactors and Related Fuel Cycles Challenges and Opportunities FR09damp1r100% (1)

- Nanticoke Nuclear Proposal: The Most Important Decision Norfolk Council Will Ever MakeDocument15 pagesNanticoke Nuclear Proposal: The Most Important Decision Norfolk Council Will Ever MakeJim ElveNo ratings yet

- Reprocessing Biotech ProductsDocument14 pagesReprocessing Biotech ProductsawadsonNo ratings yet

- The GNEP Coupled End-to-End (CETE) Research, Development, and Demonstration Project: Overview of The CETE Testbed Capabilities and OperationsDocument5 pagesThe GNEP Coupled End-to-End (CETE) Research, Development, and Demonstration Project: Overview of The CETE Testbed Capabilities and OperationsapolloNo ratings yet

- Te 1250 PRNDocument158 pagesTe 1250 PRNneerajNo ratings yet

- Atomic Energy in India: A PerspectiveDocument64 pagesAtomic Energy in India: A PerspectivemoneshchaturvediNo ratings yet

- Memorial On Behalf of The RespondentDocument17 pagesMemorial On Behalf of The RespondentZahid Hashmi100% (1)

- L Cap 11Document17 pagesL Cap 11elena lopez albaNo ratings yet

- Bridge-Transported Bilateral Master-Slave Servo Manipulator System For Remote Manipulation in Spent Nuclear Fuel Processing PlantDocument23 pagesBridge-Transported Bilateral Master-Slave Servo Manipulator System For Remote Manipulation in Spent Nuclear Fuel Processing PlantPrabhakar JoshiNo ratings yet

- 2007 03 08 EUCI - Nuclear RenaissanceDocument44 pages2007 03 08 EUCI - Nuclear RenaissanceEdward KeeNo ratings yet

- Radionuclide Contamination and Remediation Through Plants (PDFDrive)Document315 pagesRadionuclide Contamination and Remediation Through Plants (PDFDrive)Boryana KostovaNo ratings yet

- Thermal-Hydraulics of a Molten Salt Fast ReactorDocument6 pagesThermal-Hydraulics of a Molten Salt Fast ReactorMuhammad AwaisNo ratings yet

- Concept of Molten Salt Fast Reactor, Elsa Merle FranceDocument79 pagesConcept of Molten Salt Fast Reactor, Elsa Merle Franceandreidiana1978No ratings yet

- Nuclear Fuel Reserves - Cherrish Khera, 2060, AECC EVS Assignment 2022Document12 pagesNuclear Fuel Reserves - Cherrish Khera, 2060, AECC EVS Assignment 2022Gautam DohareyNo ratings yet

- Cdna12526enc 001Document170 pagesCdna12526enc 001Anonymous 1hOgJqwZuzNo ratings yet

- Uranium Enrichment Plant Characteristics-A Training Manual For The IAEADocument73 pagesUranium Enrichment Plant Characteristics-A Training Manual For The IAEANafees VakilNo ratings yet

- Unit 3 - Power Plant Engineering - WWW - Rgpvnotes.inDocument12 pagesUnit 3 - Power Plant Engineering - WWW - Rgpvnotes.inSarvjeet ThakreNo ratings yet

- Jeremy Clawson - Rough DraftDocument9 pagesJeremy Clawson - Rough Draftapi-546692450No ratings yet

- Extended Storage Collaboration Program International Subcommittee ReportDocument132 pagesExtended Storage Collaboration Program International Subcommittee ReportBálint GrNo ratings yet

- NUCLEAR ENGINEERING OBJECTIVE AND COURSE CONTENTSDocument4 pagesNUCLEAR ENGINEERING OBJECTIVE AND COURSE CONTENTSBaskarBossYuvanRomeo'zNo ratings yet

- Corrosion Behaviour of Uncoated and Ceramic Coated 9Cr-1Mo Steel in Molten Licl-Kcl-Ucl SaltDocument9 pagesCorrosion Behaviour of Uncoated and Ceramic Coated 9Cr-1Mo Steel in Molten Licl-Kcl-Ucl SaltShameekaNo ratings yet

- NQE Qualifying Exam Problem BankDocument31 pagesNQE Qualifying Exam Problem BankGiovano Camargos0% (1)

- Reprocessing of Nuclear FuelDocument70 pagesReprocessing of Nuclear FuelDharmendraKumarNo ratings yet

- The Next Arms RaceDocument530 pagesThe Next Arms RaceSSI-Strategic Studies Institute-US Army War CollegeNo ratings yet

- Commercial Application of Extracting Reagents 125Document13 pagesCommercial Application of Extracting Reagents 125mtanaydinNo ratings yet

- Air Cleaning Conference: Proceedings of The 22nd DOE/NRC NuclearDocument538 pagesAir Cleaning Conference: Proceedings of The 22nd DOE/NRC NucleargabuelfulNo ratings yet

- Nuclear Waste ManagementDocument14 pagesNuclear Waste ManagementShivam GroverNo ratings yet

- ENERGY AND ENVIRONMENT - 18ME751 Module 4 - Dr. ShashikantDocument31 pagesENERGY AND ENVIRONMENT - 18ME751 Module 4 - Dr. Shashikant17druva MNo ratings yet

- SOLID AND HAZARDOUS WASTES MANAGEMENTDocument114 pagesSOLID AND HAZARDOUS WASTES MANAGEMENTAstra BeckettNo ratings yet