Professional Documents

Culture Documents

AvK Project Guide

Uploaded by

Vito Digeo0 ratings0% found this document useful (0 votes)

169 views12 pagesAvk Guide

Original Title

AvK Project guide

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAvk Guide

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

169 views12 pagesAvK Project Guide

Uploaded by

Vito DigeoAvk Guide

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Product Guide

There for you

TM

Versatile, robust and reliable brushless

ac generators from 600 to 20,000 kVA

BrushIess AC Generators up to 20,000 kVA

Cummins Generator Technologies offers a range of quality products under the AvK

product brand name from 600 kVA to 20,000 kVA, that meet the critical needs of various

applications - be it in extraction of oil, gas, coal and minerals, or to keep the economy

moving with the freight of commodities by providing critical marine power to tankers and

container vessels, or by providing dependable power with various prime movers like

diesel engines, gas engines, steam turbines, gas turbines or wind turbines in power plant

applications.

We use the experience and knowledge gathered with the large number and diverse

applications of synchronous generator installations worldwide to provide expertise in

offering integrated design solutions that help our customers compete more successfully

throughout the world.

Features and Options

Rated Power: 600 kVA to 20,000 kVA

Rated voltage: 380V - 13.8kV

Rated frequency: 50 and 60 Hz

Speed: 500, 514, 600, 720, 750, 900, 1000,1200,1500,1800 rpm

Protection: P23, P23 with SOLAS, P44, P54, P55

Cooling: C01/C0A1, C81W/C8A1W7

Design: M 1001,M 1101,M 1005, M 1105, M1205, M 1305,

M 2401, M 2001, M 2101 are available on request.

Standards

AvK industrial generators meet the requirements of EC/EN60034, BS5000 and

VDE0530. Our marine generators may be certified to Lloyds, DNV, Bureau Veritas, ABS,

Germanischer-Lloyd, RNA, China Classification Society, Korean Register of Shipping

and Russian Maritime Register of Shipping. Details on conformance to requirements of

other societies can be obtained from our sales offices.

QuaIity Assurance

All generators are designed and manufactured to QA procedures conforming

to SO 9001.

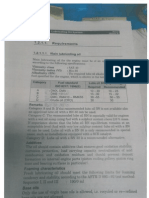

Product Range

Low VoItage Synchronous Generators

380V - 690V

Power Range 600 - 5,900 kVA

Speed rpm

1800

1500

1200

1000

900

750

720

600

750 kVA - 5300 kVA

650 kVA - 4700 kVA

850 kVA - 5900 kVA

700 kVA - 5000 kVA

700 kVA - 4900 kVA

600 kVA - 4030 kVA

1400 kVA - 4850 kVA

1200 kVA - 4050 kVA

Medium / High VoItage Synchronous Generators

2,4 kV - 13,8 kV

Power Range 500 kVA - 20,500 kVA

Speed rpm

1800

1500

1200

1000

900

750

720

600

500

514

900 kVA - 17000 kVA

750 kVA - 17500 kVA

720 kVA - 9900 kVA

500 kVA - 8700 kVA

1500 kVA - 14000 kVA

1100 kVA - 17600 kVA

4150 kVA - 20500 kVA

5000 kVA - 17000 kVA

5000 kVA - 17000 kVA

3800 kVA - 20500 kVA

For higher ratings at specific speeds please check with the factory.

B 3

MB 3

M 1001

EC 34 - 7

DN VDE 0530 - 7

Design

B 20

MB 20

M 1101

B 14 / B 20

MB 24

B 5 / B 20

MB 25

M 2001 / M 1101

B 16

MB 16

M 1305

B 2

MB 2

M 1205

B 3 / B 5

MB 35

M 2001

B 3

MB 3

M 1001

Stator

The stator cores are built from high grade lamination steel. The frame is mechanically

designed to withstand tough applications and ensure that there is ample airflow to cool

the windings. The windings are form wound for higher reliability and braced and

supported to withstand the dynamic stresses generated by the electrodynamic forces

involved.

Rotor

The salient pole rotors have windings secured with wedges and end winding supports to

withstand centrifugal forces. Damper windings are provided to reduce generator

harmonics and absorb the impacts caused by unbalanced load conditions. The solid rotor

acts as a damper in our generators above 6000 kVA. The dampers also reduce the

system oscillations caused during parallel operation.

Bearings

We offer anti-friction and sleeve bearings dependent upon the load, speed, ambient

temperature and application in question. Please refer to factory for details.

For sleeve bearings, self lubrication is standard. Depending on the operating conditions,

water cooling or forced lubrication can be provided. For safety reasons during

transportation, we provide sleeve bearing alternators without oil filling.

Construction

Automatic VoItage ReguIator

Excitation and ReguIation

DM 110 digital AVR is used on AvK AC generators up

to 5000 kVA. This AVR is either fitted or supplied

loose, depending upon the application. For loads

higher than 5000 kVA, the Unitrol 1000-15 AVR is the

standard, and the DECS 200 AVR is available as an

option. Both these AVRs are designed to be fitted into

the control panel. All AVRs are electronic, solid-state,

microprocessor based devices, with a regulation

of +/- 0.5% from no load to full load at steady state.

t is particularly suitable for non-linear load applications. Three phase sensing centres any

voltage imbalance on the nominal voltages caused by load imbalances, and helps to

ensure trouble-free operation under the most demanding loads.

Short Circuit

ndustrial machines will withstand a maximum short circuit of 300% of rated current, under

a 3 phase (L-L-L) short circuit condition. The initial value of the short circuit current will be

higher than 300%. (details can be obtained from the factory). The AVR will support the

sustained short circuit condition for up to 10 seconds, at which point the AVR over-

excitation protection system will de-excite the machine. This feature should not, however,

replace the switchgear protection provided by the customer. Sustained current levels under

2 phase L-L or 1 phase L-N short circuit levels are much higher than the above L-L-L

levels, and must be removed from the generator by breakers within 4 seconds for L-L

faults, and within 2 seconds for L-N faults.

ParaIIeI Operation

All AvK generators are well suited for parallel operation with the mains utility or other

generators. All AVRs have power factor control or reactive power control. For site

conditions where the grid is weak and unstable, please refer to the factory.

Protection and CooIing

Protection and CooIing

Our standard is the open drip-proof enclosure, suitable for clean air environments and

where there are harsh environmental conditions, we can provide a variety of cooling and

protection options.

The standard is P23 and higher types of enclosure protection such as P23 with filters,

P44, P54, and P55 can be supplied on request.

TotaIIy encIosed air to air cooIed ( TEAAC/CACA)

These are suitable for dusty environmental conditions,

as found in mining, textile plants, oil & gas, quarries

and wind applications. There are one or two internal

fans that direct the enclosed air up and through an

array of tubes, which are mounted on top of the

generator. n the outer circuit, an external fan motor

drives air through an outer sheet metal enclosure to

cool the tubes, and the air is then exhausted on the

drive-end side of the generator.

TotaIIy encIosed air to water cooIed (TEWAC/CACW)

These are generally used when the volume of the ambient air available is restricted, as

aboard a ship, or for other applications like steam turbine and CHP power plants where

there is an abundance of water available for cooling.

There are one or two internal fans. Air is forced up

and through air to water radiators within the

generator enclosure. The heated air is cooled by the

water in the tubes and recirculated through the

generator to cool the windings. The radiator consists

of an inner tube, and it may have an optional outer

tube (recommended by AvK) to better protect against

water leakage. A separate system to pump a

continuous supply of cooling water through the

radiator must be supplied on site, and is not in the

scope of AvK.

Marine

The form wound coil designs, along with the impregnation

system and the choice of cooling and protection options have

resulted in AvK machines withstanding harsh and critical

marine power needs. They operate as shaft generators,

PT/PTO/PTH, in auxiliary gensets, or as main propulsion

generators for diesel-electric applications in cruise liners,

tankers, ice-breakers and offshore supply vessels. They

comply with the requirements of most marine classification

societies. AvK alternators with heat exchangers or air filters

fulfil the requirements for local fire-fighting systems (SOLAS).

Wind Turbines

Our synchronous wind alternator design, running at

synchronous speed with variable speed gearboxes or

alternatively, with variable speed drives, is designed for high

efficiency and operating voltages up to 13.8 kV, thereby

eliminating the need for local step-up transformers. This, along

with the cooler construction involved, keeps the nacelle weight

down. The subtransient and transient reactances are low to

keep the machine in synchronism as long as possible for Low

Voltage Ride Through (LVRT). The generator has provision for

changing bearings in-situ.

OiI and Gas

The form-wound coil design, robust mechanical design and

tuning of the reactances help meet the power needs of oil rigs.

Our DSG machines with Class H insulation can be derated for

a Class B temperature rise, to ensure a long operating life.

The insulation system is designed to withstand repeated

surges caused by inverter-fed drives. Copper damper winding

is designed to reduce the damper cage heating caused by

non-linear loads on oil rigs.

AppIications

Reciprocating Power PIants

Our high efficiency and integrated design solutions help our

customers deliver the right packages for their power plant

requirements. We work jointly with the set builder to develop a

high degree of standardisation, resulting in shorter

manufacturing times, which allow customers to deliver power

plant packages ever more quickly. We also offer vibration

analysis capabilities for proving the validity of genset designs

or for solving the end users' vibration issues.

Gas Turbines

We work closely with gas turbine manufacturers in sizing the

appropriate AC generator and in developing integrated design

solutions that enable the customer to supply compact

packages necessary for transportable and containerized power

plants.

Steam Turbines

A stiff construction plus sleeve bearings help meet the low

vibration requirements. We can also optionally supply

provisions for vibration monitoring. The bearings are usually

lubricated from the prime mover's oil circuit. We offer a wide

range of cooling options to meet customer needs.

AppIications

TechnicaI Support and After SaIes Service

Cummins Generator Technologies' engineers are available to provide technical information before the

sale to assist in selecting the correct generator specifications that the job demands. We continue our

support through commissioning and into after-sales service and support.

Our engineers are experienced professionals trained in electrical, electronic and mechanical skills.

They in turn are supported by a worldwide spares and service network. You can call +49 841 792 163

during office hours (German Time Zone) and for field support after office hours,

please call +44 1780 484732.

Our global service offers:

Commissioning of generators on site.

On-site insulation integrity checks.

AVR and accessories set up on site

Service parts are stocked in Germany and by our subsidiary

companies, to ensure prompt availability of key parts.

Product Training

Product familiarity will ensure maximum productivity and optimum use of the

generator. Our Customer Support Department offers product training courses

for engineers, operators, and service & support staff. Each course is

individually tailored to suit the needs of the customer, the genset builder and

the end-user.

Product familiarisation courses, with a choice of training modules - including generator control

systems, applications, trouble-shooting, maintenance or other specific requirements are also

available.

Vibration AnaIysis

Generators coupled to reciprocating engines are exposed to engine induced vibrations. We use

design tools to analyse the impact of linear and torsional vibrations, and work with the engine or

genset builder to validate the design of the genset, as well as to solve end-user vibration issues. This

technology is key in enabling customers to improve the innovation and reliability of new and current

product designs.

GIobaI Support

Our Promise

At Oumm|ns Generator Teohno|og|es, |t`s not just the

produots we make that set us apart - |t`s how we engage

our oustomers everyday. The un|que oomb|nat|on of

know|edge, dependab|||ty and |nnovat|on we br|ng to eaoh

oustomer re|at|onsh|p turns everyday serv|oe |nto exoe||ent

oustomer support. As a resu|t we he|p our oustomers

operate w|th greater eff|o|enoy, mak|ng |t poss|b|e for them

to oompete more suooessfu||y throughout the wor|d.

Oumm|ns Generator Teohno|og|es manufaotures

the wor|d`s broadest range of ao generators from

0.5 to 20,000 kvA.

Office

Cummins Generator TechnoIogies

Germany GmbH

Bunsenstrasse 17

D-85053 ngolstadt

Phone: +49 (0) 841 792 0

Fax: +49 (0) 841 792 250

SaIes

Cummins Generator TechnoIogies

Germany GmbH

Dreieich Office

Benzstrasse 47-49

D-63303 Dreieich

Phone: +49 (0) 6103 5039 0

Fax: +49 (0) 6103 5039 40

www.cumminsgeneratortechnologies.com

email: info@cumminsgeneratortechnologies.com

P

G

_

A

v

K

_

0

3

_

0

8

_

1

G

B

Kontakt :

AvK Genertory s.r.o.

ul. 4. Kvtna 175

755 01 Vsetn

tel : +420 571 413 322

fax : +420 571 413 322

e-mail:

info@avk-cummins.cz

avk@avk-cummins.cz

Website:

www.avk-cummins.cz

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hatz 1D Repair ManualDocument193 pagesHatz 1D Repair ManualVito Digeo91% (22)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Coops Nieborg Gantry Crane ManualDocument26 pagesCoops Nieborg Gantry Crane ManualVito Digeo0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Challenge of Stern Tube Bearings and Seals)Document6 pagesChallenge of Stern Tube Bearings and Seals)Vito DigeoNo ratings yet

- Handbook Conical MountingsDocument28 pagesHandbook Conical MountingsVito DigeoNo ratings yet

- Regulations KIEL CANALDocument76 pagesRegulations KIEL CANALdivermarinerNo ratings yet

- Sperry Sun - LWD and LWD ServicesDocument8 pagesSperry Sun - LWD and LWD ServicesBAS100% (1)

- User Interface DesignDocument6 pagesUser Interface DesignpoojaqNo ratings yet

- CNSK - Pocket Fits06-Fits and ClearancesDocument15 pagesCNSK - Pocket Fits06-Fits and Clearancesswamymk100% (1)

- NRF Boxcooler Installation Manual PDFDocument22 pagesNRF Boxcooler Installation Manual PDFVito DigeoNo ratings yet

- Marine Bearing Installation Manual A4Document64 pagesMarine Bearing Installation Manual A4mkm123100% (1)

- HZTL455311P0020 enDocument20 pagesHZTL455311P0020 enVito DigeoNo ratings yet

- Shaft Alignment GN E-Feb14Document122 pagesShaft Alignment GN E-Feb14supriadi90315No ratings yet

- NRF Boxcooler Installation Manual PDFDocument22 pagesNRF Boxcooler Installation Manual PDFVito DigeoNo ratings yet

- Hatz 1D Operators ManualDocument120 pagesHatz 1D Operators ManualVito DigeoNo ratings yet

- Guidelines For Inspection of Hull WeldsDocument110 pagesGuidelines For Inspection of Hull WeldsVito DigeoNo ratings yet

- Coatings Industrial Maintenance GuideDocument11 pagesCoatings Industrial Maintenance GuideVito DigeoNo ratings yet

- Dnvps Line Sampler: (Marpol Annex Vi-Compliant)Document6 pagesDnvps Line Sampler: (Marpol Annex Vi-Compliant)dassi99No ratings yet

- L16-24 Gen Sets 2008 UpgradeDocument4 pagesL16-24 Gen Sets 2008 UpgradeVito DigeoNo ratings yet

- Damen ASD Tug 2810Document36 pagesDamen ASD Tug 2810Vito Digeo100% (2)

- Clean Oil GuideDocument36 pagesClean Oil GuidesppramNo ratings yet

- Clean Oil GuideDocument36 pagesClean Oil GuidesppramNo ratings yet

- Clean Oil GuideDocument36 pagesClean Oil GuidesppramNo ratings yet

- Wartsila SR RT82 Distillate Fuel UseDocument11 pagesWartsila SR RT82 Distillate Fuel UseVito DigeoNo ratings yet

- Bearings For Longer Shaft LifeDocument3 pagesBearings For Longer Shaft LifeVito Digeo100% (1)

- Fuel Oil QualityDocument2 pagesFuel Oil QualityAmit BaruaNo ratings yet

- Towage Guidance NotesDocument8 pagesTowage Guidance NotesVito DigeoNo ratings yet

- Wartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitDocument21 pagesWartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitVito Digeo100% (2)

- MaK M 32 C Low Emission EngineDocument12 pagesMaK M 32 C Low Emission EngineJenniferValleNo ratings yet

- Anchor Handling Manual MSFDocument45 pagesAnchor Handling Manual MSFfeghuolhakim100% (4)

- Wartsila 26 Lubricating SystemDocument25 pagesWartsila 26 Lubricating SystemVito DigeoNo ratings yet

- 5 Towing Techniques: CRV Crew Training Manual 66 January 2010Document40 pages5 Towing Techniques: CRV Crew Training Manual 66 January 2010Irdam Jono100% (5)

- TNK500P Taneko Industrial Generator (TNK JKT)Document2 pagesTNK500P Taneko Industrial Generator (TNK JKT)Rizki Heru HermawanNo ratings yet

- Contact Centre CapabilityDocument2 pagesContact Centre CapabilityshyamchepurNo ratings yet

- Wae 22462 AuDocument8 pagesWae 22462 AuDaniel ManoleNo ratings yet

- JIMCO Filter Catalog with Products and SpecificationsDocument8 pagesJIMCO Filter Catalog with Products and SpecificationsDedy CjNo ratings yet

- XPol Panel 806–960 65° 0°–14°TDocument3 pagesXPol Panel 806–960 65° 0°–14°TkenansabNo ratings yet

- ANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemDocument42 pagesANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemArzu AkarNo ratings yet

- Phoenix Contact 3247055 enDocument6 pagesPhoenix Contact 3247055 enDGNo ratings yet

- HYDRO VesselsDocument5 pagesHYDRO VesselsMarvinPatricioNarca0% (1)

- Data Acquisition Systems (DAS) in GeneralDocument3 pagesData Acquisition Systems (DAS) in GeneralArjun SinghNo ratings yet

- Joker User Guide 3dlabgang Rev2019 12Document14 pagesJoker User Guide 3dlabgang Rev2019 12HD's RC ChannelNo ratings yet

- Computer Aided Design Course Code: 3341904Document7 pagesComputer Aided Design Course Code: 3341904Dhaval UpadhyayNo ratings yet

- IPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldDocument13 pagesIPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldJean Carlos100% (1)

- Understanding Japanese Management PracticesDocument16 pagesUnderstanding Japanese Management PracticesBusiness Expert Press100% (3)

- 92v Parts List ViperDocument194 pages92v Parts List Viperreltih18No ratings yet

- Sound AttenuatorsDocument24 pagesSound Attenuatorsadeel_akhtarNo ratings yet

- Grade CalculatorDocument1 pageGrade CalculatorKHENN ALDIANONo ratings yet

- GE Lighting Systems Crane Mounted Luminaire Series Spec Sheet 3-81Document2 pagesGE Lighting Systems Crane Mounted Luminaire Series Spec Sheet 3-81Alan MastersNo ratings yet

- Solar Desalination PlantDocument28 pagesSolar Desalination PlantAnonymous TETH310% (1)

- 2011 Equipment Packing InstructionsDocument3 pages2011 Equipment Packing InstructionsNidhi MurthyNo ratings yet

- GE Con Perkins Más StamfordDocument2 pagesGE Con Perkins Más Stamfordjim perdigonNo ratings yet

- Total Internal Reflection and Critical Angle VedioDocument16 pagesTotal Internal Reflection and Critical Angle VedioNor AzizahNo ratings yet

- NOx Control of Kiln and Preheater Complete AnalysisDocument129 pagesNOx Control of Kiln and Preheater Complete AnalysisAnonymous sfY8T3q0100% (2)

- En 808D Commissioning Guide 2013-09Document98 pagesEn 808D Commissioning Guide 2013-09Sam eagle goodNo ratings yet

- John Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)Document16 pagesJohn Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)zhuangfuqian31No ratings yet

- History of JS: From Netscape to Modern WebDocument2 pagesHistory of JS: From Netscape to Modern WebJerraldNo ratings yet

- WM 5.4 CLI Reference Guide PDFDocument1,239 pagesWM 5.4 CLI Reference Guide PDFHermes GuerreroNo ratings yet

- P0562-Battery Voltage LowDocument7 pagesP0562-Battery Voltage Lowguillermoal539100% (1)

- EN 12663-1 - 2010 - IndiceDocument6 pagesEN 12663-1 - 2010 - IndiceOhriol Pons Ribas67% (3)