Professional Documents

Culture Documents

270 Ultrabondecos9551k GB

Uploaded by

Floorkit0 ratings0% found this document useful (0 votes)

3K views4 pages270 Ultrabondecos9551k Gb

Original Title

270 Ultrabondecos9551k Gb

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document270 Ultrabondecos9551k Gb

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3K views4 pages270 Ultrabondecos9551k GB

Uploaded by

Floorkit270 Ultrabondecos9551k Gb

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

WHERE TO USE

Bonding wooden parquet and all types and formats

of pre-finished materials.

Some application examples

Ultrabond Eco S955 1K is used for bonding pre-

finished materials, lamparquet, slats, floor-boards and

all types of parquet on: cementitious screeds, screeds

made using Mapecem, Mapecem Pronto, Topcem,

Topcem Pronto and similar products, old wooden

floors, ceramic, marble, terrazzo, etc. and anhydrite

screeds. It is also suitable for heated substrates.

TECHNICAL CHARACTERISTICS

Ultrabond Eco S955 1K is a one-component, sililated

polymer-based adhesive without water, solvents, with

an extremely low emission level of volatile organic

compounds (EMICODE EC1 R Plus). It is manufactured

according to a technology developed in MAPEIs

own research laboratories and has the following

characteristics:

one-component, ready-to-use product; no catalyser

is required, therefore no mixing. If stored correctly,

remaining quantities of the product may be used

again at a later date;

suitable for use by installers who are allergic to

epoxy and epoxy-polyurethane products;

GEV certified, as a product with a very low

emission level of volatile organic compounds

(EMICODE EC1 R Plus);

compatible with Ultracoat and Ultracoat Oil water

based varnishes and undercoats;

no hazard risks and risk and danger symbols;

easy to apply with excellent ridge holding;

20-30% more yield compared with conventional

two-component adhesives, thanks to its low viscosity

and free-flowing properties when applied by trowel;

totally free of solvents;

easy to remove from hands and pre-finished

elements.

RECOMMENDATIONS

Before installation commences, doors and windows

should be installed.

The humidity level in the screed must be compliant

with that prescribed by the current standards for the

installation of wood, and as indicated in the technical

data sheet for the parquet.

If the substrate is not thoroughly dried, or if the

residual humidity is higher than the level

prescribed, we recommend the use of a suitable

waterproofing primer, such as Eco Prim PU 1K,

Primer MF, etc.

If there is a risk of rising damp, a vapour barrier

must be installed before laying the screed.

One-component, solvent-

free, sililated polymer-

based adhesive with a

very low emission level of

volatile organic compounds

(EMICODE EC1 R Plus),

for all types of parquet

U

l

t

r

a

b

o

n

d

E

c

o

S

9

5

5

1

K

U

l

t

r

a

b

o

n

d

E

c

o

S

9

5

5

1

K

TECHNICAL DATA (typical values)

PRODUCT IDENTITY

Consistency: creamy paste

Colour: beige or brown

Density (g/cm): 1.60

Dry solids content (%): 100

Brookfield viscosity (mPas): 37,000

(rotor 7 - 50 rpm)

EMICODE: EC1 R Plus - very low emission

APPLICATION DATA (at +23C and 50% R.H.)

Recommended application temperature range: from +10C to +35C

Open time (formation of surface skin): 50-60 mins

Adjustment time: 1 hour and 45 minutes-2 hours

Set to light foot traffic: approx. 12 hours

Polishing: after 3 days

FINAL PERFORMANCE

Shore A hardness (7 days at +23C): 45

Wood - concrete bond (N/mm): 2

Wood - ceramic bond (N/mm): 2

Elongation at breakage (7 days at +23C) (%): 200

In service temperature range: from -20C to +80C

U

l

t

r

a

b

o

n

d

E

c

o

S

9

5

5

1

K

U

l

t

r

a

b

o

n

d

E

c

o

S

9

5

5

1

K

Easy opening of the

bucket

Easy and fast removal

of the sealing film

Excellent keeping and

stability of the product

Cracks in the substrate must be repaired

beforehand with a product such as Eporip,

Eporip Turbo, Epojet, etc.

Excessively rough or uneven surfaces should

be levelled using a smoothing compound

with high mechanical properties, such as

Fiberplan, Ultraplan, Ultraplan Maxi,

Nivorapid, etc., chosen according to the

thickness to be installed. Installation may

be carried out once it has cured (see

the relative product technical data sheet).

To install rapid-drying, controlled-shrinkage

screeds, use a special MAPEI hydraulic

binder: Mapecem, which allows for

installation after 24 hours, or Topcem for

installation after 4 days.

Topcem Pronto or Mapecem Pronto

pre-blended, ready-to-use mortar may be

used as an alternative, and wood may be laid

after 4 days and 24 hours, respectively.

In the presence of lightening layers or

insulation, or in the case of screeds installed

directly on the ground, a vapour barrier must

be installed to avoid rising damp.

Do not use Ultrabond Eco S955 1K if the

temperature is lower than +10C or higher

than +35C.

Only carry out the installation if the walls

and ceiling are thoroughly dried.

APPLICATION PROCEDURE

Preparation of the substrate

The substrate must be checked carefully to

assess its condition, and to prepare it for

laying parquet.

Cementitious screeds: must be well cured,

dry, flat and mechanically strong.

The surface must be free of dust, loose parts,

oil, paint, etc.

The level of humidity in the screed must be

measured using a carbide hygrometer. To

solve problems of residual humidity levels

higher than those prescribed for laying, wait

until the screed is dry, or apply a suitable

waterproofing primer, such as Eco Prim PU 1K,

Primer MF, Primer EP, Primer PU60,

Triblock P, etc.

mixtures. It is however recommended to use

gloves, eyes protection and to take the usual

precaution taken when handling chemical

products.

For further and complete information about

the safe use of our product please refer to

our latest version of the Material Safety

Data Sheet.

PRODUCT FOR PROFESSIONAL USE.

WARNING

Although the technical details and

recommendations contained in this product

data sheet correspond to the best of our

knowledge and experience, all the above

information must, in every case, be taken as

merely indicative and subject to confirmation

after long-term practical application; for

this reason, anyone who intends to use the

product must ensure beforehand that it is

suitable for the envisaged application. In

every case, the user alone is fully responsible

for any consequences deriving from the use

of the product.

Please refer to the current version of the

Technical Data Sheet, available from our

website www.mapei.com

Old floors in ceramic, marble, etc. must be

carefully cleaned and degreased before

bonding. The adhesive may only be applied

once the surface is dry.

Wooden floors: make sure wooden

floorboards are rigidly fixed to the substrate.

Remove old paint or wax with sandpaper

down to the bear wood, and remove all dust.

The adhesive may then be applied.

Anhydrite substrates: after sanding down and

removal of all residual dust, apply Eco Prim

PU 1K, Primer MF or Primer EP.

Spreading the adhesive

Spread the adhesive on the substrate using a

MAPEI notched trowel for wood.

Wood has to be laid within approximately

50-60 minutes under normal temperature

conditions (at +23C and 50% R.H.). If left-

over adhesive from previous applications is

to be used, open the drum, remove the skin

formed on the surface of the adhesive and

proceed as above. The layer of skin helps to

preserve the left-over adhesive.

SET TO LIGHT FOOT TRAFFIC

Floors may be walked on after approximately

12 hours.

POLISHING

The floor may be polished after 3 days.

Residual adhesive on the surface of the floor

may be easily removed by using Cleaner L.

Cleaning

Ultrabond Eco S955 1K may be removed

using Cleaner L or other special cleaning

solutions while still fresh. Once hardened,

it must be removed mechanically or with

Pulicol 2000.

CONSUMPTION

800-1200 g/m.

PACKAGING

15 kg plastic drums.

STORAGE

12 months in its original, well-sealed

container stored under normal conditions.

SAFETY INSTRUCTIONS FOR

PREPARATION AND APPLICATION

Ultrabond Eco S955 is not considered

dangerous according to the current

regulations regarding the classification of

Cleaning large format

of pre-finished parquet

with Cleaner L

Excellent workability

and rib stability

This symbol is used to identify Mapei products

which give off a low level of volatile organic

compounds (VOC) as certified by GEV (Gemein-

schaft Emissionskontrollierte Verlegewerkstoffe,

Klebstoffe und Bauprodukte e.V.), an international

organisation for controlling the level of emissions

from products used for floors.

Der Blaue Engel is a German mark of ecological

quality used to identify products which respect the

environment, contractors and end users. MAPEI

products carrying this logo have been tested

according to strict criteria defined by the German

standard RAL-UZ 113 and, because they are all

solvent-free with very low emission of volatile

organic compounds, also offer advantages for the

environment and public wellbeing.

All relevant references

for the product are available

upon request and from

www.mapei.com

Our Commitment To The Environment

MAPEI products assist Project Designers

and Contractors create innovative LEED

(The Leadership in Energy and Environmental

Design) certified projects,

in compliance with the U.S. Green

Building Council.

U

l

t

r

a

b

o

n

d

E

c

o

S

9

5

5

1

K

U

l

t

r

a

b

o

n

d

E

c

o

S

9

5

5

1

K

A

n

y

r

e

p

r

o

d

u

c

t

i

o

n

o

f

t

e

x

t

s

,

p

h

o

t

o

s

a

n

d

i

l

l

u

s

t

r

a

t

i

o

n

s

p

u

b

l

i

s

h

e

d

h

e

r

e

i

s

p

r

o

h

i

b

i

t

e

d

a

n

d

s

u

b

j

e

c

t

t

o

p

r

o

s

e

c

u

t

i

o

n

(

G

B

)

A

.

G

.

B

E

T

A

BUILDING THE FUTURE

2

7

0

-

6

-

2

0

1

4

(

G

B

)

You might also like

- 2504 Ultrabond Eco s945 1k GBDocument4 pages2504 Ultrabond Eco s945 1k GBFloorkitNo ratings yet

- Eco Pim TDocument4 pagesEco Pim TFloorkitNo ratings yet

- 2918 Mapeproof 1k Turbo UkDocument4 pages2918 Mapeproof 1k Turbo UkFloorkitNo ratings yet

- Mapei Eco Prim TDocument4 pagesMapei Eco Prim TFloorkitNo ratings yet

- A Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionDocument4 pagesA Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionFloorkitNo ratings yet

- 220 Ultrabond Eco 170 UkDocument4 pages220 Ultrabond Eco 170 UkFloorkitNo ratings yet

- Mapei ECO Prim GripDocument4 pagesMapei ECO Prim GripFloorkitNo ratings yet

- 219 Ultrabond Eco Fix UkDocument4 pages219 Ultrabond Eco Fix UkFloorkitNo ratings yet

- 4007 Ultraplan Renovation Screed Uk NoRestrictionDocument2 pages4007 Ultraplan Renovation Screed Uk NoRestrictionFloorkitNo ratings yet

- 232 Ultrabond Eco 380 UkDocument4 pages232 Ultrabond Eco 380 UkFloorkitNo ratings yet

- Mastertop 1120tDocument3 pagesMastertop 1120themajsuryaNo ratings yet

- 4005 Ultraplan Eco 20 UaeDocument0 pages4005 Ultraplan Eco 20 UaeJohn SarthouNo ratings yet

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringDocument4 pagesUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitNo ratings yet

- MASTERTOP 1110 - v1Document2 pagesMASTERTOP 1110 - v1Sumit KiratNo ratings yet

- 279 Ultrabondp9901k GBDocument4 pages279 Ultrabondp9901k GBMarko GagroNo ratings yet

- 209 Topcem Pronto GB NoRestrictionDocument4 pages209 Topcem Pronto GB NoRestrictionFloorkitNo ratings yet

- 231 Ultrabond Eco Vs90 UkDocument4 pages231 Ultrabond Eco Vs90 UkFloorkitNo ratings yet

- Conbextra EP Data SheetDocument4 pagesConbextra EP Data Sheetprabhu81No ratings yet

- Non toxic epoxy coatingDocument4 pagesNon toxic epoxy coatingVenkata RaoNo ratings yet

- Planitop HDM RestauroDocument4 pagesPlanitop HDM RestaurodraganugNo ratings yet

- Purtopeasyt g2Document4 pagesPurtopeasyt g2pankajmandloiNo ratings yet

- Uzin PE 360Document2 pagesUzin PE 360FloorkitNo ratings yet

- FLORGARD SL self-levelling epoxy flooringDocument3 pagesFLORGARD SL self-levelling epoxy flooringcharibackupNo ratings yet

- V5 Ls MSL 5-Steps Guide Aftercare 148x148 0315Document16 pagesV5 Ls MSL 5-Steps Guide Aftercare 148x148 0315Dan George IonescuNo ratings yet

- Penguard PrimerDocument5 pagesPenguard PrimerPutroedidohNo ratings yet

- Penguard Clear Sealer: Technical Data Sheet Application GuideDocument7 pagesPenguard Clear Sealer: Technical Data Sheet Application GuideAnonymous 4SFfEmcHmDNo ratings yet

- Supercast EPT PDFDocument2 pagesSupercast EPT PDFmilanbrasinaNo ratings yet

- TDS - Purtop Easy TDocument4 pagesTDS - Purtop Easy TFerry AnggriawanNo ratings yet

- Fosroc Dekguard PU: Constructive SolutionsDocument4 pagesFosroc Dekguard PU: Constructive SolutionsganmosesNo ratings yet

- Mapei FibreplanDocument4 pagesMapei FibreplanFloorkitNo ratings yet

- TDS 418 GlueDocument3 pagesTDS 418 GlueKhaled OmairiNo ratings yet

- TDS Tankguard Storage GB English ProtectiveDocument5 pagesTDS Tankguard Storage GB English ProtectiveAdverNo ratings yet

- Florgard EsdDocument3 pagesFlorgard Esddox4printNo ratings yet

- Latexplan Latexplan: 2-Part Cement Based Smoothing and Levelling CompoundDocument4 pagesLatexplan Latexplan: 2-Part Cement Based Smoothing and Levelling CompoundFloorkitNo ratings yet

- Nitocote PE135Document2 pagesNitocote PE135Dejan MicicNo ratings yet

- Latexplan Trade NoRestrictionDocument4 pagesLatexplan Trade NoRestrictionFloorkitNo ratings yet

- M4 Ep PDFDocument2 pagesM4 Ep PDFjunaid112No ratings yet

- Eco-friendly protective coatingDocument2 pagesEco-friendly protective coatingRaed Naim KhammashNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901ArieIndrawanNo ratings yet

- Zinsser BrouchureDocument2 pagesZinsser Brouchureislandboy33333No ratings yet

- 2703 UltramasticIIIsuperwhite GB NoRestrictionDocument4 pages2703 UltramasticIIIsuperwhite GB NoRestrictionFloorkitNo ratings yet

- Jotashield Decor TravertineDocument4 pagesJotashield Decor TravertineMazenNo ratings yet

- Rapid Set Tds - NoRestrictionDocument4 pagesRapid Set Tds - NoRestrictionFloorkitNo ratings yet

- G-Ext Catalogue - TrespaDocument25 pagesG-Ext Catalogue - TrespaReahman ColyNo ratings yet

- Primastic UniversalDocument5 pagesPrimastic UniversalaleventNo ratings yet

- Genkem Contact AdhesiveDocument3 pagesGenkem Contact AdhesiveSirGawain9950% (2)

- Marthon Jotun Marine PaintDocument5 pagesMarthon Jotun Marine PaintNishanthNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetajuhaseenNo ratings yet

- Floor Tech FB Primer DataDocument2 pagesFloor Tech FB Primer DatadogankkuNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901kalidindivenkatarajuNo ratings yet

- Elotex TdsDocument2 pagesElotex TdsnanoNo ratings yet

- Nitocote EPW100: Water Dispersed Epoxy Coating and SealerDocument2 pagesNitocote EPW100: Water Dispersed Epoxy Coating and SealerVenkata Raju KalidindiNo ratings yet

- Proglaze IIDocument3 pagesProglaze IIMohammad ALTAKINo ratings yet

- Epoxy Resin Mortar for Concrete ProtectionDocument2 pagesEpoxy Resin Mortar for Concrete ProtectionsudhialakkalNo ratings yet

- Nitobond EP : Constructive SolutionsDocument4 pagesNitobond EP : Constructive SolutionsmilanbrasinaNo ratings yet

- FT Forbo 233 EUROSOLDocument3 pagesFT Forbo 233 EUROSOLAndreiNo ratings yet

- Safeguard Universal AGDocument7 pagesSafeguard Universal AGMar PardalesNo ratings yet

- Painting Procedure for Ship MaintenanceDocument7 pagesPainting Procedure for Ship MaintenanceSyaiful Arif WicaksonoNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- No. 110 Inside Cove Corner KitDocument1 pageNo. 110 Inside Cove Corner KitFloorkitNo ratings yet

- Uzin PE 260Document2 pagesUzin PE 260FloorkitNo ratings yet

- Altro Sample Card Altro PVC Weld RodDocument1 pageAltro Sample Card Altro PVC Weld RodFloorkitNo ratings yet

- Mastic Sample BoardDocument1 pageMastic Sample BoardFloorkitNo ratings yet

- Uzin KE 603Document2 pagesUzin KE 603FloorkitNo ratings yet

- Itec Installation GuidelinesDocument3 pagesItec Installation GuidelinesFloorkitNo ratings yet

- Leoline Installation and MaintenanceDocument8 pagesLeoline Installation and MaintenanceFloorkitNo ratings yet

- Crain 247 Multi Purpose Wall TrimmerDocument2 pagesCrain 247 Multi Purpose Wall TrimmerFloorkitNo ratings yet

- Avenue Installation and MaintenanceDocument8 pagesAvenue Installation and MaintenanceFloorkitNo ratings yet

- L3 Gold System Primer GB 01Document2 pagesL3 Gold System Primer GB 01FloorkitNo ratings yet

- Invisiweld Installation GuidelinesDocument2 pagesInvisiweld Installation GuidelinesFloorkitNo ratings yet

- Uzin Ke 2000 S: Product Data SheetDocument4 pagesUzin Ke 2000 S: Product Data SheetFloorkitNo ratings yet

- Camaro Loc BrochureDocument25 pagesCamaro Loc BrochureFloorkitNo ratings yet

- Recommended Adhesives GuideDocument1 pageRecommended Adhesives GuideFloorkitNo ratings yet

- Uzin L 3 Gold: Product Data SheetDocument2 pagesUzin L 3 Gold: Product Data SheetFloorkitNo ratings yet

- Uzin PE 360Document2 pagesUzin PE 360FloorkitNo ratings yet

- Uzin NC 150 New: Product Data SheetDocument2 pagesUzin NC 150 New: Product Data SheetFloorkitNo ratings yet

- Uzin NC 110Document4 pagesUzin NC 110FloorkitNo ratings yet

- Uzin NC 150 New: Product Data SheetDocument2 pagesUzin NC 150 New: Product Data SheetFloorkitNo ratings yet

- Uzin NC 145: Product Data SheetDocument2 pagesUzin NC 145: Product Data SheetFloorkitNo ratings yet

- Uzin KE 2428Document2 pagesUzin KE 2428FloorkitNo ratings yet

- Uzin NC 152Document2 pagesUzin NC 152FloorkitNo ratings yet

- Uzin L 3 Gold: Product Data SheetDocument2 pagesUzin L 3 Gold: Product Data SheetFloorkitNo ratings yet

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringDocument4 pagesUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitNo ratings yet

- 231 Ultrabond Eco Vs90 UkDocument4 pages231 Ultrabond Eco Vs90 UkFloorkitNo ratings yet

- 268 Ultrabond Eco 520 UkDocument4 pages268 Ultrabond Eco 520 UkFloorkitNo ratings yet

- 219 Ultrabond Eco Fix UkDocument4 pages219 Ultrabond Eco Fix UkFloorkitNo ratings yet

- Boiler LogicsDocument42 pagesBoiler LogicsSupratim Pal100% (1)

- Tracetek TTFFS Leak DetectionDocument2 pagesTracetek TTFFS Leak DetectionalokinstNo ratings yet

- Fig 21150 Vag Pico PRV Druk ReduceerDocument2 pagesFig 21150 Vag Pico PRV Druk ReduceerAlberto DiazNo ratings yet

- Danby Premiere Dehumidifier User's ManualDocument39 pagesDanby Premiere Dehumidifier User's ManualRick AndersonNo ratings yet

- Tutorial 2 Chapter 2Document2 pagesTutorial 2 Chapter 2Marko IrwinNo ratings yet

- Ruido Suspension Delantera cx-5 PDFDocument7 pagesRuido Suspension Delantera cx-5 PDFAriel SerrateNo ratings yet

- Inject Neutralizer To CDU OVHD Wash WaterDocument1 pageInject Neutralizer To CDU OVHD Wash WaterPhuong LeNo ratings yet

- Webasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedDocument8 pagesWebasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedAlexanderNo ratings yet

- Chapter 3 - Mix DesignDocument16 pagesChapter 3 - Mix DesignAbel MulugetaNo ratings yet

- Proceso: Lummus Application: Improved Technology To Produce Highest Quality Phenol andDocument5 pagesProceso: Lummus Application: Improved Technology To Produce Highest Quality Phenol andAdrian Copa JNo ratings yet

- Waste Segregation Practices Among High School Students of Saint Michael College of CaragaDocument61 pagesWaste Segregation Practices Among High School Students of Saint Michael College of CaragaReinan Ezekiel Llagas100% (1)

- List of Oil ZF PDFDocument16 pagesList of Oil ZF PDFJhon SyalfiandyNo ratings yet

- Plate Theory - Wikipedia, The Free EncyclopediaDocument9 pagesPlate Theory - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Grillage Analogy C.S.surana R.agrawal - For WordDocument283 pagesGrillage Analogy C.S.surana R.agrawal - For WordMohak Nagrani100% (1)

- Vibro CompactionDocument2 pagesVibro CompactionVpln SarmaNo ratings yet

- TRANE Condensor Data SS-PRC003-E4 - RaulDocument32 pagesTRANE Condensor Data SS-PRC003-E4 - Rauldhayalasundaram5689No ratings yet

- 8.1prob Sheet Vapor Power CyclesDocument3 pages8.1prob Sheet Vapor Power CyclesAnonymous mXicTi8hB100% (1)

- Manual 3 Full BrickDocument25 pagesManual 3 Full BrickkeithjonathanNo ratings yet

- Drying Shrinkage of ConcreteDocument6 pagesDrying Shrinkage of Concretecrownguard100% (1)

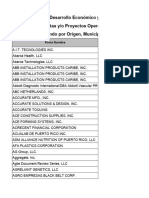

- Directorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubDocument238 pagesDirectorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubnewprojectsNo ratings yet

- Wire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RDocument6 pagesWire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RralishNo ratings yet

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 pagesRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456No ratings yet

- Void Content of Reinforced Plastics: Standard Test Methods ForDocument3 pagesVoid Content of Reinforced Plastics: Standard Test Methods ForStéfany Vier SteffenNo ratings yet

- 31000, 32000 Proximity Probe Housings: DescriptionDocument9 pages31000, 32000 Proximity Probe Housings: Descriptionmehdi227No ratings yet

- Alternators and Starter Motors 2003 PDFDocument106 pagesAlternators and Starter Motors 2003 PDFjovopavlovic100% (4)

- Exploration GeologyDocument36 pagesExploration Geologyفردوس سليمانNo ratings yet

- Katherine Davis, Gary Eddy, Alex Johannigman, Nathan ValdezDocument1 pageKatherine Davis, Gary Eddy, Alex Johannigman, Nathan Valdezanon_760617705No ratings yet

- 10 ElectrochemistryDocument77 pages10 ElectrochemistrySyamil Adzman100% (1)

- Rate Analysis-KalikaDocument35 pagesRate Analysis-KalikaPujan Amit Gurung100% (1)

- Disclaimer Document Supplier ListDocument30 pagesDisclaimer Document Supplier ListAmin AzadNo ratings yet