Professional Documents

Culture Documents

XTEInterfaceServlet PDF

Uploaded by

WalterOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XTEInterfaceServlet PDF

Uploaded by

WalterCopyright:

Available Formats

36-11 CT3-11ET 3c, 15kV, 175 mil EPR (100%), TS, GW, PVC, CT Rated

CT3-11ET

15kV Type MV-105. 3 Copper Conductors.

Thermosetting Conductor and Insulation Shield.

EPR Insulation. Tape Shield. Copper

Ground Wire. PVC Jacket.

RoHS

APPLICATIONS

Southwire CT3-11ET Type MV-105 Cable is for use in aerial installations, direct buried, cable trays, troughs or raceway.

These cables are capable of operating continuously at a maximum conductor temperature of 105C for normal operation,

140C for emergency overload conditions, and 250C for short circuit conditions, and are rated at 15,000V, 100% insulation

level (grounded system). Maximum sidewall pressure is 1000 lbs.

SPECIFICATIONS

Southwire CT3-11ET Type MV-105 Cable is manufactured and tested in accordance with the latest revisions of the following

standards and specification:

UL 1072 and 1685

ICEA S-93-639 (NEMA WC 74)

ICEA S-97-682 (when requested)

IEEE 1202-FT4 Flame Test (70,000 Btu/hr Vertical Tray Test) with CPE and Solonon jacket.

AEIC CS-8

RoHS

CONSTRUCTION

Southwire CT3-11ET Type MV-105 cable offers heavy duty construction and flexible EPR insulation. For use in cable trays

per NEC Article 392. Alternate constructions available. SOLONON low smoke, non halogen polyolefin jackets and CPE

jackets are available upon request.

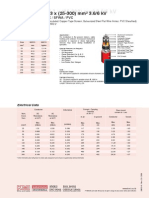

Product

Code

Size Diameter 0.175"

(4.45mm)

Insulation

Diameter

Extruded

Insulation

Shield Diameter

Grd.

Cond.

Size

Min. Point

Jacket

Thickness

Approximate

Overall

Diameter

Approximate

Net Weight

Allowable

Ampacities+

AWG

or

kcmil

inch* mm inch** mm inch*** mm AWG inch mm inch mm lb./Mft. kg/km Duct Conduit

In Air

CT3-11ET-002 2 .283 7.19 .683 17.34 .738 18.73 6 .1 2.54 1.862 47.3 1972 2935 160 165

CT3-11ET-001 1 .322 8.18 .723 18.35 .778 19.75 4 .1 2.54 1.949 49.5 2268 3375 185 185

CT3-11ET-010 1/0 .362 9.19 .763 19.37 .818 20.76 4 .1 2.54 2.035 51.7 2551 3795 210 215

CT3-11ET-020 2/0 .405 10.29 .803 20.38 .858 21.78 4 .1 2.54 2.121 53.9 2928 4358 235 245

CT3-11ET-030 3/0 .456 11.58 .853 21.65 .908 23.05 3 .1 2.54 2.229 56.6 3397 5055 270 280

CT3-11ET-040 4/0 .512 13 .908 23.05 .963 24.45 3 .1 2.54 2.348 59.6 3944 5869 305 320

CT3-11ET-250 250 .558 14.17 .965 24.51 1.02 25.91 2 .1 2.54 2.484 63.1 4473 6655 335 350

CT3-11ET-350 350 .661 16.79 1.068 27.11 1.123 28.51 2 .1 2.54 2.706 68.7 5703 8487 400 430

CT3-11ET-500 500 .79 20.07 1.193 30.29 1.248 31.69 1 .125 3.18 3.029 76.9 7615 11331 485 525

CT3-11ET-750 750 .968 24.59 1.38 35.05 1.435 36.45 1/0 .125 3.18 3.434 87.2 10542 15686 585 635

*Nominal diameter per ASTM Standards. **0.030" ***0.050"

+Ampacities are based on the NEC, 2011 Edition. Duct ampacities are based on Table 310.79 three conductors within an overall covering in one underground duct,

105C conductor, 20C earth ambient temperature. Conduit in air ampacities are based on Table 310.75 three cables within an overall covering in isolated conduit in

air, 105C conductor, 40C ambient temperature.

Scope: This specification covers three conductor EPR (ethylene propylene rubber) insulated, shielded, thermoplastic jacketed power cables with grounding conductor

for use in aerial installations, direct buried, cable trays, troughs, or raceways. These cables are capable of operating continuously at a temperature of 105C for normal

operations, 140C for emergency overload conditions, and 250C for short circuit conditions, and are rated at 15,000V, 100% (grounded system) insulation level.

Standards: The following standards shall form part of this specification - UL Standard 1072 for Medium Voltage Power Cable and ICEA S-93-639 (NEMA WC 74) 5-46

kV Shielded Power Cable for Use in the Transmission & Distribution of Electric Energy.

Conductor: The conductor shall be Class B compressed concentric stranded bare copper in accordance with ASTM B3 and B8 and ICEA Part 2, Section 2.1 and 2.5.

Conductor Shield: The conductor shall be shielded with an extruded semi-conducting thermosetting polymeric layer, which shall be firmly bonded to the insulation.

The thickness shall be in accordance with the referenced standards.

Insulation: The insulation shall be EPR (ethylene propylene rubber) meeting the requirements of the referenced standards. The nominal thickness shall be 0.175".

Insulation Shield: The insulation shall be shielded with an extruded semi-conducting thermosetting polymeric layer which shall be identified as semi-conducting. Over

this layer shall be applied a helically wrapped 5-mil copper tape with 25% overlap. The method of phase identification will be similar to ICEA Method 3, using printed

circuit numbers and colors (1-BLACK, 2-RED, 3-BLUE).

Grounding Conductor: The ground conductor shall be Class B compressed concentric stranded bare copper in accordance with ASTM B3 and B8.

Assembly: The insulated and shielded power conductors shall be cabled round with fillers and with a grounding conductor in one outer interstice and covered with a

binder tape.

Jacket: The cable shall be covered with a black PVC jacket conforming to the requirements specified for polyvinyl chloride in ICEA. The average thickness shall be in

accordance with the referenced standards. The jacket will be sunlight resistant and will meet the requirements of UL 1685 - UL Flame Exposure Test. Optional

SOLONON low smoke, non halogen polyolefin jackets and CPE jackets are available upon request.

Tests: Qualification tests shall be conducted in accordance with the requirements of AEIC.

CT3-11ET 3c, 15kV, 175mil EPR(100%), TS, GW, PVC, CT Rated

You might also like

- N2XSYDocument5 pagesN2XSYRinda_RaynaNo ratings yet

- Okoguard - Okoseal Type MV-105: Compact Strand ConstructionDocument2 pagesOkoguard - Okoseal Type MV-105: Compact Strand ConstructionHong TrungNo ratings yet

- N2XCYDocument5 pagesN2XCYRinda_RaynaNo ratings yet

- PHELPS DODGE Superflex Pdic01214Document5 pagesPHELPS DODGE Superflex Pdic01214unividenteNo ratings yet

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFDocument2 pages15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezNo ratings yet

- Loxarmor Type MV-105 or MC: 3 Okopact (Compact Stranded) Copper Conductors/105°C Rating 100% Insulation LevelDocument2 pagesLoxarmor Type MV-105 or MC: 3 Okopact (Compact Stranded) Copper Conductors/105°C Rating 100% Insulation Leveldaalca26No ratings yet

- 33kV 3 Core XLPE SWA Stranded Copper Conductor HV CableDocument3 pages33kV 3 Core XLPE SWA Stranded Copper Conductor HV Cableerkamlakar2234No ratings yet

- 2.4 KV GENERAL CABLE PDFDocument2 pages2.4 KV GENERAL CABLE PDFjhernandezelNo ratings yet

- p7326 SPDocument2 pagesp7326 SPchazz29hkNo ratings yet

- 11kV 3 Core PILC SWA BS6480 Cable SpecificationDocument3 pages11kV 3 Core PILC SWA BS6480 Cable SpecificationMuhammad TaufiqNo ratings yet

- N2 XFGB YDocument4 pagesN2 XFGB YRinda_RaynaNo ratings yet

- Na2Xsefgby 3 X (25-300) MM 3.6/6 KVDocument5 pagesNa2Xsefgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- NA2XSEKRY 3 X (25-300) MM 3.6/6 KVDocument5 pagesNA2XSEKRY 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- Control Bus CablesDocument2 pagesControl Bus CablesVeronica Jeldes PonceNo ratings yet

- Cable Technical SpecificationDocument66 pagesCable Technical SpecificationKurama_MinatoNo ratings yet

- N2XSEKBYDocument5 pagesN2XSEKBYRinda_RaynaNo ratings yet

- NYSYDocument5 pagesNYSYRinda_RaynaNo ratings yet

- N2XSEBYDocument5 pagesN2XSEBYRinda_RaynaNo ratings yet

- 09 Technical TablesDocument8 pages09 Technical TablesRuban Vijaya SinghNo ratings yet

- N2XYDocument5 pagesN2XYRinda_RaynaNo ratings yet

- N2XSERYDocument5 pagesN2XSERYRinda_RaynaNo ratings yet

- Single Core Cables Xlpe Insulated Cables Mv-90Document20 pagesSingle Core Cables Xlpe Insulated Cables Mv-90AWG AMGCNo ratings yet

- N2XSEKRY 3 X (25-300) MM 3.6/6 KVDocument5 pagesN2XSEKRY 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- Unishield - Uniblend 5kvDocument2 pagesUnishield - Uniblend 5kvfmillan5018No ratings yet

- LG Bus Duct System Guide - Leader in Electrics & AutomationDocument51 pagesLG Bus Duct System Guide - Leader in Electrics & AutomationRajneesh KatochNo ratings yet

- THHN TC FuerzaDocument2 pagesTHHN TC Fuerzajuan pablo castro gallegoNo ratings yet

- Armor-X 600v (4) SouthwireDocument3 pagesArmor-X 600v (4) SouthwireLuis RamirezNo ratings yet

- Fire Resistant CablesDocument11 pagesFire Resistant CablesDEADMANNo ratings yet

- B Span 330m Silec Technical Offer Ref 5890636827terDocument9 pagesB Span 330m Silec Technical Offer Ref 5890636827terUdriste DanielNo ratings yet

- 1 Core 33kv CC NewDocument3 pages1 Core 33kv CC NewAnandvikash SinghNo ratings yet

- NA2XSKB (AL) Y 1 X (25-630) MM 3.6/6 KVDocument5 pagesNA2XSKB (AL) Y 1 X (25-630) MM 3.6/6 KVRinda_RaynaNo ratings yet

- Type ST-C Cables: DescriptionDocument51 pagesType ST-C Cables: DescriptiongilmarquijanoNo ratings yet

- Cu/PVC/SFWA/PVC cable specs (1.5-50 mm2, 0.6/1 kVDocument4 pagesCu/PVC/SFWA/PVC cable specs (1.5-50 mm2, 0.6/1 kVRahul DevaNo ratings yet

- Accr Conductor PropertiesDocument8 pagesAccr Conductor Propertiesdeepu_erNo ratings yet

- Ntcs0402E3..... T: Vishay BccomponentsDocument7 pagesNtcs0402E3..... T: Vishay BccomponentskpNo ratings yet

- Csa Hvteck CableDocument2 pagesCsa Hvteck Cablerafa_4_everNo ratings yet

- PVC Cables FinolexDocument8 pagesPVC Cables FinolexMaria DenetNo ratings yet

- N2 XSEKFGb YDocument5 pagesN2 XSEKFGb YRinda_RaynaNo ratings yet

- LSIS Bus Duct System CatalogDocument52 pagesLSIS Bus Duct System CatalogedcooNo ratings yet

- Data Sheet Kabel NA2XSEYDocument5 pagesData Sheet Kabel NA2XSEYGansar KharismawanNo ratings yet

- CIR CatalogDocument12 pagesCIR Catalogchaupha1No ratings yet

- Section Three - Low Voltage 0.6/1 KV Cables: Notes 3 Explanatory Information 4-10Document112 pagesSection Three - Low Voltage 0.6/1 KV Cables: Notes 3 Explanatory Information 4-10Mohammad AmerNo ratings yet

- Na2Xsekfgby 3 X (25-300) MM 3.6/6 KVDocument5 pagesNa2Xsekfgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- Summary Results of North Arm Bridge Cable Model AnalysisDocument7 pagesSummary Results of North Arm Bridge Cable Model Analysisbcdavid100% (1)

- NA2XSKYDocument5 pagesNA2XSKYRinda_RaynaNo ratings yet

- 15kv Phelps DodgeDocument4 pages15kv Phelps DodgeJuan E Torres M100% (1)

- Raychem Spec 44Document8 pagesRaychem Spec 44zakariiNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Rechargeable Batteries Applications HandbookFrom EverandRechargeable Batteries Applications HandbookRating: 2 out of 5 stars2/5 (1)

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- 354 eDocument146 pages354 erachitmatNo ratings yet

- NEMA CC 1 2009 Contains 2012Document67 pagesNEMA CC 1 2009 Contains 2012Marco Vassão100% (1)

- Standard bolt dimensions chartDocument2 pagesStandard bolt dimensions chartWalterNo ratings yet

- Dispositivos Switching - SwitchgearDocument198 pagesDispositivos Switching - SwitchgearWalterNo ratings yet

- Ti SPC Ohe Inscom 107Document44 pagesTi SPC Ohe Inscom 107mukeshhNo ratings yet

- Iso 898-2 1992e PDFDocument20 pagesIso 898-2 1992e PDFsuresh kumar100% (1)

- Astm F 519 PDFDocument18 pagesAstm F 519 PDFGaurav100% (1)

- Ieee STD 4 1995 High Voltage TestingpdfDocument138 pagesIeee STD 4 1995 High Voltage TestingpdfWalterNo ratings yet

- Fotoceldas Long JoinDocument2 pagesFotoceldas Long JoinWalterNo ratings yet

- Iec 60609-4Document70 pagesIec 60609-4WalterNo ratings yet

- Test Procedures of The Behaviour of Cables in Case of FireDocument12 pagesTest Procedures of The Behaviour of Cables in Case of FireWalterNo ratings yet

- Tech Serial v1r0c0 PDFDocument15 pagesTech Serial v1r0c0 PDFsalehimohsen13514969100% (1)

- INNOVA OBD2 Manual - RevA - E - Final PDFDocument32 pagesINNOVA OBD2 Manual - RevA - E - Final PDFreachlarryNo ratings yet

- Reglas BaseballDocument32 pagesReglas BaseballHugo Arnoldo Martinez MendezNo ratings yet

- Astm F412-2009Document16 pagesAstm F412-2009WalterNo ratings yet

- ASTM - D1248-04 - Polietileno Plástico Por ExtrucciónDocument9 pagesASTM - D1248-04 - Polietileno Plástico Por ExtrucciónWalterNo ratings yet

- C 1535 - 02Document7 pagesC 1535 - 02WalterNo ratings yet

- Jingle BellsDocument1 pageJingle Bellsxjnx100% (3)

- Documento Sobre Empalmes MTDocument4 pagesDocumento Sobre Empalmes MTWalterNo ratings yet

- Salt Spray TestDocument17 pagesSalt Spray Testavadh87100% (1)

- Ensayo Postes de Madera BrazilDocument8 pagesEnsayo Postes de Madera BrazilWalterNo ratings yet

- Uso Fusible Limitador CooperDocument0 pagesUso Fusible Limitador CooperWalterNo ratings yet

- Excellent Corrosion-Resistant Zn-Al-Mg-Si Alloy Hot-Dip Galvanized Steel Sheet "SUPER DYMA"Document3 pagesExcellent Corrosion-Resistant Zn-Al-Mg-Si Alloy Hot-Dip Galvanized Steel Sheet "SUPER DYMA"WalterNo ratings yet

- PULD-40 - Medidor de Descargas ParcialesDocument3 pagesPULD-40 - Medidor de Descargas ParcialesWalterNo ratings yet

- Excellent Corrosion-Resistant Zn-Al-Mg-Si Alloy Hot-Dip Galvanized Steel Sheet "SUPER DYMA"Document3 pagesExcellent Corrosion-Resistant Zn-Al-Mg-Si Alloy Hot-Dip Galvanized Steel Sheet "SUPER DYMA"WalterNo ratings yet

- Ansi Anslg C82.9-2010Document24 pagesAnsi Anslg C82.9-2010Marco LiguoriNo ratings yet

- ASTM - A722M - Barras de Acero para Concreto PretensadoDocument4 pagesASTM - A722M - Barras de Acero para Concreto PretensadoWalterNo ratings yet

- Concrete: Muhammad Arslan, Department of Civil Engineering Uet LahoreDocument73 pagesConcrete: Muhammad Arslan, Department of Civil Engineering Uet LahoreMuhammad ArslanNo ratings yet

- Norma Poste Madera M3-81Document5 pagesNorma Poste Madera M3-81WalterNo ratings yet

- Calculus Early Transcendentals 10th Edition Anton Solutions ManualDocument35 pagesCalculus Early Transcendentals 10th Edition Anton Solutions Manualcrenate.bakshish.7ca96100% (16)

- 3 Human Resource ManagementDocument10 pages3 Human Resource ManagementRonaldNo ratings yet

- Toshiba Satellite l645Document2 pagesToshiba Satellite l645pintarbacaNo ratings yet

- Vestige Frequently Asked QuestionsDocument2 pagesVestige Frequently Asked Questionsmadhu77No ratings yet

- G.R. No. 208393, June 15, 2016Document3 pagesG.R. No. 208393, June 15, 2016jeliena-malazarteNo ratings yet

- ZRO List 3.17Document4 pagesZRO List 3.17Com22No ratings yet

- Subcontractor Payment FormDocument2 pagesSubcontractor Payment FormMarcelino SanicoNo ratings yet

- Laporan OjtDocument77 pagesLaporan OjtDimasQiNo ratings yet

- Donate Your Corneas PleaseDocument19 pagesDonate Your Corneas PleaseRahul PinnamaneniNo ratings yet

- الصراع التنظيمي وأثره...Document25 pagesالصراع التنظيمي وأثره...mohmod moohNo ratings yet

- Erasmo WongDocument3 pagesErasmo WongGabriel GutierrezNo ratings yet

- Siemens Technical Paper Life Cycle Value For Combined Cycle Power PlantsDocument48 pagesSiemens Technical Paper Life Cycle Value For Combined Cycle Power Plantsprocurement34No ratings yet

- Apc Materials PropertiesDocument15 pagesApc Materials PropertiesnamyefNo ratings yet

- BAMBUDocument401 pagesBAMBUputulNo ratings yet

- GREEN Manual - 2021Document157 pagesGREEN Manual - 2021Bon Ber Amad Orofeo100% (2)

- Data Structures CompleteDocument255 pagesData Structures Completemovie world50% (2)

- Hydrostatic Test ReportsDocument3 pagesHydrostatic Test ReportsHanuman RaoNo ratings yet

- NGT 1021 8 17 - 2Document10 pagesNGT 1021 8 17 - 2markpestell68No ratings yet

- Pizza Crust Menu in Karachi - Restaurant Online Ordering PakistanDocument2 pagesPizza Crust Menu in Karachi - Restaurant Online Ordering PakistanSyed Rafay HashmiNo ratings yet

- Ilo MLCDocument66 pagesIlo MLCcarmenNo ratings yet

- USPS Tracking # - : Good Faith and Credit OrderDocument3 pagesUSPS Tracking # - : Good Faith and Credit OrderCarolNo ratings yet

- FS Chapter 1Document2 pagesFS Chapter 1Jonarissa BeltranNo ratings yet

- Political Internet Memes On Corruption Issue Surrounding The Philippine Health Insurance CorporationDocument9 pagesPolitical Internet Memes On Corruption Issue Surrounding The Philippine Health Insurance CorporationFeline Joy SarinopiaNo ratings yet

- Approved Term of Payment For Updating Lower LagunaDocument50 pagesApproved Term of Payment For Updating Lower LagunaSadasfd SdsadsaNo ratings yet

- Top 70 CCNA Interview QuestionsDocument10 pagesTop 70 CCNA Interview QuestionsRekha SharmaNo ratings yet

- Safety Breach NoticeDocument3 pagesSafety Breach NoticeMohamed HadjkacemNo ratings yet

- ERP ImplementationDocument47 pagesERP Implementationattarjaved100% (1)

- Tutorial Question 4 TORTDocument2 pagesTutorial Question 4 TORTNBT OONo ratings yet

- Terms and conditions for FLAC 3D licensingDocument2 pagesTerms and conditions for FLAC 3D licensingseif17No ratings yet

- Marguerite Musica, Mezzo Soprano - Upcoming Roles, Training & MoreDocument1 pageMarguerite Musica, Mezzo Soprano - Upcoming Roles, Training & MoreHaley CoxNo ratings yet