Professional Documents

Culture Documents

M

Uploaded by

Warren RiveraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M

Uploaded by

Warren RiveraCopyright:

Available Formats

I

n

t

e

r

n

a

t

i

o

n

a

l

J

o

u

r

n

a

l

o

f

L

e

a

nT

h

i

n

k

i

n

gV

o

l

u

me2

,

I

s

s

u

e1(

J

u

n

e2

0

1

1

)

LeanThi

nki

ng

journalhomepage: www.thi

nki

ngl

ean.com/i

jl

t

Process Cycle Efficiency Improvement Through Lean: A Case Study

D. Rajenthirakumar*

Department of Mechanical Engineering,

PSG College of Technology, Coimbatore,

641 004, India

E-mail Adres: rajentkumar@gmail.com

P.V. Mohanram

Department of Mechanical Engineering,

PSG College of Technology, Coimbatore,

641 004, India

S.G. Harikarthik

Department of Mechanical Engineering,

PSG College of Technology, Coimbatore,

641 004, India

KEYWORDS

ABSTRACT

scientific, objective techniques that cause work tasks in a

Lean Manufacturing,

Value stream mapping,

Cycle time,

Takt time,

Cycle efficiency.

process to be performed with a minimum of non-value

ARTICLE INFO

adding activities resulting in greatly reduced wait time,

Received 23 February 2011

Received in revised form 11 March 2011

Accepted 13 March 2011

Available online 23 March 2011

Lean manufacturing is an applied methodology of

queue time, move time, administrative time, and other

delays. This work addresses the implementation of lean

principles in a construction equipment company. The

prime objective is to evolve and test several strategies to

eliminate waste on the shop floor. This paper describes an

application

of

value

stream

mapping

(VSM).

Consequently, the present and future states of value

stream maps are constructed to improve the production

process by identifying waste and its sources. A noticeable

reduction in cycle time and increase in cycle efficiency is

confirmed. The production flow was optimized thus

minimizing several non-value added activities/times such

as bottlenecking time, waiting time, material handling

time, etc. This case study can be useful in developing a

more generic approach to design lean environment.

________________________________

* Corresponding Author

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

1. Introduction

Lean manufacturing is based on the Toyota Production System developed by Toyota which

focuses on eliminating waste, reducing inventory, improving throughput, and encouraging

employees to bring attention to problems and suggest improvements to fix them (Womack et al.

1991). Lean manufacturing has increasingly been applied by leading manufacturing companies

throughout the world. A core concept of lean manufacturing is pull production in which the flow

on the factory floor is driven by demand from downstream pulling production upstream. Some of

the changes required by lean manufacturing can be disruptive if not implemented correctly and

some aspects of it are not appropriate for all companies (Hobbs, 2004). A lean manufacturing

facility is capable of producing product in only the sum of its value added work content time.

Features of a typical lean manufacturing model include: one unit at a time production, non-value

added time eliminated, production in the work content time only, and relocation of required

resources to the point of usage.

In the present day of manufacturing, assembly line can be formed easily for any industry

whether it is a small-scale or a large-scale industry. When the takt times are calculated for every part

manufactured in the industry through different part movements, then the problem of locating

machines on the shop floor occurs when it is a job type production unit; this problem is the main

reason for reconfiguration of machines and layout design for every demand. To eliminate these

problems, a proper method is required to achieve a rhythm in manufacturing lean assembly line by

identifying value adding, non-value adding, and necessary non-value adding activities through an

optimum feasible takt time.

This paper presents a case study of a large-scale construction equipment manufacturing

industry facing the problems as discussed above. This work addresses the implementation of lean

manufacturing on the construction equipment assembly, with a focus on the activities of paint shop

which should have a proper rhythm of assembly line, minimizing wastages like bottleneck time,

waiting time, material handling time, etc. The prime objective is to develop different strategies to

eliminate waste. The lean tool value stream mapping (VSM) applied as a method to lead the

activities.

47

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

2. Literature Review

Currently, assembly lines are still fundamental to get the smoothing of production system

(Miltenburg, 2001), and they are studied under several operative perspectives seeking its flexibility

(El-Maraghy, 2005; Calvo et al. 2007). Both concepts are subjects of pull systems. In assembly lines,

pull and lean systems are concepts frequently connected, although they pursue different objectives;

pull system toward the reduction of work-in-process (WIP) and lean system toward minimizing the

buffer variability (Hopp and Spearman, 2004). Moreover, with respect to the election of production

control system in a pull system, the alternatives considered are focused on kanban (Monden, 1998)

and constant work in process (CONWIP) (Spearman et al. 1990), both of them focused toward the

reduction of WIP.

Although many tools exist, from its origin, VSM has demonstrated its efficacy (Womack and

Jones 1996; Sullivan et al. 2002; Abdulmalek and Rajgopal 2007; Serrano et al. 2008; Sahoo et al.

2008). Following the benchmarking perspective, as well the use of a contrasted tool, facilitates the

interchange of improvements. It is a tool that provides communication solutions for practitioners to

obtain maximum efficiency and definitions of theoretical development points to become a reference

among redesign techniques (Serrano et al. 2008). A detailed description of VSM can be seen in

Rother and Shook (1999). Thus, as improvement tool simplifies the measurement of times without

added value, so the calculation of indexes of lean metrics is easier and it is possible to enhance the

operative actions with strategic results.

This paper unifies several gaps and it shows how value stream transformation actions can

achieve high levels of performance in a short time and in a real industry, inside a context of an

assembly line with a small space and that it requires flexibility.

3. Problem Definition

This work deals with the end to end perspective of reducing waste at an assembly line paint

shop of a construction equipment manufacturing company. The major tasks involved in the paint

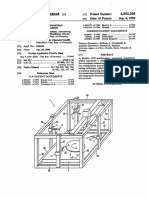

shop are sketched in Figure 1 and the layout is given in Figure 2.

48

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

Figure 1. Major taskks in the asseembly line paiint shop

Figurre 2. Layout of the assembbly line paintt shop

AAfter intense brain stormiing and a thoorough studyy of the paintt shop, it wass observed thhat the

paint shop activitiees contain vaarious forms oof non-value-adding activitties as follow

ws:

Drying whhich takes eigght hours incrreases cycle time

t

Paint shopp floor space insufficient ffor 100 toness

Inadequatte lighting (850 lux)

Paint coaggulation

Ineffectivee blower perfformance

C

Certainly, all of these factors lead to hhigh production lead time. In the existiing conditionns, the

averagge productioon lead time is found to bee around 96888 min and th

he cycle efficieency is foundd to be

3%, w

which is not sufficient.

49

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

4. Leaan Implemeentation

IIn order to implement

i

leean principlees, a task grooup was form

med with peoople from diffferent

parts of the orgaanization, all having richh knowledgee and inform

mation pertaaining to prrocess,

produuction, equippment and plaanning. The oobjectives of the operation

n were (i) to reduce the leevel of

non-vvalue activitiees present in any form byy implementiing the variou

us lean toolss (ii) to reduce the

overaall process tim

me of the asssembly line paint shop through imp

provements iin the water wash,

maskiing, drying processes

p

andd eliminatingg over processsing of final black paint ((iii) to introdduce a

safetyy trolley for masking

m

radiaator cover annd (iii) to increase the cyccle efficiency.. The methoddology

adoptted to achievee the objectivves is given inn Figure 3.

Fiigure 3. Methhodology forr lean implem

mentation

4.1 Cuurrent state value

v

stream

m mapping

TTo constructt the currennt state valuee stream maap, relevant information was collectted by

intervviewing peopple on the paint shop flooor. As a pre-w

work, process and time stuudy was perfoormed

and TTable 1 sum

mmarizes the overall activvities associaated with thee paint shopp along withh their

proceessing time. Data

D relevant to the custom

mer, such as quantity to be

b delivered, delivery timee were

obserrved and infoormation relaated to the asssembly line, such as proccessing time, inventory sttorage,

inspeections, rework loops, number of worrkers and opeerational hou

urs per day w

were collecteed and

docum

mented propperly. To com

mplete the vaalue map, a timeline

t

is ad

dded at the bbottom of thee map

recorrding the leadd-time and thhe value-addeed time. Evenntually, the vaalue stream m

map for the cuurrent

state is constructed as shown inn Figure 4.

50

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

Tablee 1. Current state

s

paint shhop processess and processsing time

Name of the

processs

De-greease

Water wash

Dry offff

Buff

Mask

Yellow

w paint

Dry offff

Mask

Black ppaint

Dryingg

Average proceessing time in

minutes

15

60

55

45

40

120

240

10

20

60

Namee of the processs

De-masking

Paintiing: yellow

Dryinng

De-masking

Paintiing: black

Dryinng

De-masking

Decall

PDI/reectification

Average pprocessing timee in

minutes

10

60

290

26

35

120

15

35

30

Figure

F

4. Thee present valuue stream maap

AAs observed from the vaalue map, vaarious value--added activiities presentt in the flow

w line,

bottleenecks are identified and quantified inn time, as shoown in Figuree 5 and Tablee 2. It is founnd that

aboutt 293.80 min, or 22.85% out

o of 1286 m

min, were vallue added activities, comppared to 992..2 min

or 777.15% of non-value addedd activities. It is concludedd that the drrying processs is the majorr issue

whichh is not withiin the current levels of deemand. If the growing leveels of demannd increases, drying

d

is nott within the taakt time.

51

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

Figure

F

5. Thee present statte VA/NVA tim

me

Tablee 2. Current state

s

VA/NVA time analysiss

Name of the processs

De-greease

Water wash

Dry offff

Buff

Mask

Yellow

w paint

Dry offff

Mask

Black ppaint

Dryingg

De-maasking

Paintinng: yellow

Dryingg

De-maasking

Paintinng: black

Dryingg

De-maasking

Decal

PDI/rectification

%VA

60%

60%

0%

60%

30%

70%

0%

30%

70%

0%

60%

70%

0%

30%

70%

0%

50%

60%

0%

VA time (minn)

9.00

36.00

0.00

27.00

12.00

84.00

0.00

3.00

14.00

0.00

6.00

42.00

0.00

7.80

24.50

0.00

7.50

21.00

0.00

NVA timee (min)

6.00

24.00

55.00

18.00

28.00

36.00

240.00

7.00

6.00

60.00

4.00

18.00

290.00

18.20

10.50

120.00

7.50

14.00

30.00

Aveerage processin

ing time in min

nutes

15

60

55

45

40

1200

2400

10

20

60

10

60

2900

26

35

1200

15

35

30

4.2 Taact time

TTact time cann be defined as the time rrequired prodducing one unit

u of daily ssalable quantiity. To

calcullate tact timee in the conteext of presentt problem, thhe average deemand per tw

wo shifts was found

to bee 3.2 units off componentts under studdy. The comppany runs fo

or two shifts, 500 min peer shift

excluding break tiime. This resuults in a tact time of nearlly 312.5 min.. Therefore, iit is concludeed that

m interval.

one uunit of product must comee out during every 312.5 min

52

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

4.3 Total cycle time and cycle efficiency

Reducing the lead time in any production system is a continuous improvement process. While

addressing the problem, the production lead time for the existing conditions was first calculated.

The various components associated with lead time are identified separately and different practical

strategies are adopted for improvement. In general, the various components associated with the

lead time of any production process are (i) Waiting time before process (ii) Setup time (iii) Process

time (iv) Waiting time after process (v) Transfer time. Considering all the elements involved, a total

cycle time of 9687.50 minutes was calculated.

Also, the total cycle efficiency involved in the process is found to be approximately 3.2%. In

order to reduce the total cycle time and increase the cycle efficiency, various strategies such as

problem identification, data documentation, motion and time study, improvements made,

operation sheet review, and continuous monitoring are adopted.

Initiatives taken to increase the cycle efficiency are:

Standard work sheet is prepared

Warm water is utilized to facilitate quicker drying process

Permanent mask using rubber material designed to facilitate better functioning

Stringent monitoring is done and improvement opportunities are addressed in time

Wherever possible, inefficient operations are eliminated; for example, oven drying process is

developed

To handle higher capacity, construction equipment layout modification was done

To improve operator safety, safety trolley was designed for masking process

4.4 Reducing time for masking process

To Reduce the masking time, permanent mask using rubber material was designed which in

turn reduces the cost of masking. The improvements are shown in Figure 6.

53

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

1 00

Thousands

30

Masking cost (Rs)

Masking time (min)

80

60

40

25

25

Cost of m asking/fiv e units

20

Cost of m asking/u nit

15

10

20

2

0.4

0

0

Pr esen t st a t e m a sk in g Ma sk in g pr ocess w it h

pr ocess

n ew desig n

Pr esen t st a t e

Ma sk in g w it h n ew desig n

Cost for masking process

Time for masking process

Figure 6. Masking process time reduction

4.5 Improvement of drying process

As a part of improved drying process, warm water was used for water washing of the

equipment which results in 58% of time savings. From the current state analysis, it was clear that the

drying process was the major bottleneck. In the present state, drying process was carried out

outside the paint shop by allowing the unit to dry in hot sun which took 16 hours to complete. Also

time amounts to 650 minutes on an average was spent for paint drying operation which included

yellow painting, black painting and final yellow painting. Instead ovens of LPG type were

introduced for drying process and the process time was decreased to 240 minutes. The

improvement is shown in Figure 7.

1 000

Time for drying process (min)

9 00

800

7 00

6 00

% Tim e sav ing : 63 %

500

4 00

3 00

2 00

1 00

0

Present state dry ing process

New im prov ed ov en dry ing

Figure 7. Improved drying process

4.6 Improvement in safety

It was found that the operator masks the unit by standing in the bumper of the construction

equipment which is unsafe as shown in Figure 8. As a part of safety risk assessment, a new trolley

was designed for masking radiator cover, where the operator stands near the corner of the

equipment. By using the newly designed trolley, the operator is able to mask the radiator easily

54

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

w

without any issues

i

as show

wn in Figure 9. Since the trolley was developed

d

usiing scrap matterials,

the laabour cost is the

t only cost element assoociated with the

t new safetty equipmentt.

Figu

ure 8. Presennt state maskiing-operator risk involvedd

Figure 9.

9 Masking w

with safety trolley-operatorr risk eliminatted

4.7 Fuuture state vaalue stream mapping

m

FFinally, the fuuture state vaalue stream m

map is construucted as show

wn in Figure 110, which repported

a connsiderable deppletion in noon-value-addeed time. A drrastic reductio

on in time foor drying process is

also oobserved. Furrthermore, thhe process leaad time is redduced to 725 min as illusttrated in Figuure 11.

Tablee 3 outlines thhe value streaam analysis reeport for the future state. It is found thhat about 5544 min,

or 766.4% out of 725 min, weree value-addedd activities coompared to 171

1 min or 2 3.6% of non--valueaddedd activities. Comparing

C

the value mapss, it can be cooncluded that a 821.2-minn reduction inn nonvalue--added activvities is achhieved. Figurre 12 depiccts the vario

ous benefitss made afteer the

impleementation of lean.

55

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

Tablee 3. Future sttate VA/NVA time analysis

%VA

80%

80%

100%

80%

80%

70%

100%

80%

70%

50%

70%

70%

50%

50%

100%

50%

VA time (minn)

12.00

48.00

60.00

36.00

12.00

84.00

120.00

4.00

14.00

30.00

7.00

42.00

30.00

5.00

35.00

15.00

NVA tim

me (min)

3.000

12..00

0.000

9.000

3.000

36..00

0.000

1.000

6.000

30..00

3.000

18..00

30..00

5.000

0.000

15..00

Avverage processsing time in miinutes

15

60

60

45

15

120

120

5

20

60

10

60

60

10

35

30

Figure 10. The ffuture state value

v

stream map

m

1 2 00

Process lead time (min)

Namee of the processs

De-grease

Water wash

Dry off

Buff

Mask

YYellow paint

Dry off

Mask

Black paint

Drying

De-masking

Paainting: yellow

Drying

De-masking

Decal

PD

DI/rectification

9 00

% im prrov em ent : 45%

6 00

3 00

0

Preesent state

Future state

Fiigure 11. Redduction of prrocess lead tim

me

56

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

2 00

1 80

153.13

1 60

1 40

1 20

1 00

88.56

80

60

40

29.03

29.03

20

0

% WIP reduction

% Total cy cle tim e % im prov em ent in

reduction

v alue added tim e

Cy cle efficiency

im prov em ent (%)

Figure 12. Improvement after lean approach

5. Conclusion

This present work provides a case study of the improvement of a construction equipment

company non value added activities by means of lean tools. It focuses the revamp of operations by

eliminating non value-added time and improving cycle efficiency through VSM. It can be concluded

that VSM is an effective tool for identifying the processing wastes.

References

Abdulmalek F.A. and Rajgopal J. Analyzing the benefits of lean manufacturing and value stream

mapping via simulation: a process sector case study, Int J Prod Econ, 2007, 107 (1): 223

236.

Calvo R. Domingo R. and Sebastin M.A. Operational flexibility quantification in a make-to-order

assembly system. Int Journal of Flex Manuf Syst, 2007, 19 (3): 247263.

El-Maraghy H.A. Flexible and reconfigurable manufacturing systems paradigms. Int J Flex Manuf

Syst, 2005, 17 (4): 261276.

Hobbs D.P. Lean manufacturing implementation: a complete execution manual for any size

manufacturer. J. Ross Publishing, Boca Raton, 2004.

Hopp W.J. and Spearman M.L. To pull or not to pull: what is the question?, Manuf Serv Oper

Manag, 2004, 6 (2): 133148.

Miltenburg J. One-piece flow manufacturing on U-shaped production lines: a tutorial, IIE Trans,

2001, 33 (4): 303321.

Monden Y. Toyota production system: an integrated approach to just-in-time, 3rd edn. Engineering

and Management Press, Norcross, GA, 1998.

Rother M. and Shook J. Learning to see: value stream mapping to add value and eliminate MUDA,

The Lean Enterprise Institute, Brookline, MA, 1999.

57

D. RAJENTHIRAKUMAR, P. V. MOHANRAM,S. G. HARIKARTHIK /International Journal of Lean Thinking Volume 2, Issue 1 (June 2011)

Sahoo A.K. Singh N.K. Shankar R. and Tiwari M.K. Lean philosophy: implementation in a forging

company, Int J Adv Manuf Technol, 2008, 36 (56): 451462.

Serrano I., Ochoa C., and de Castro R. Evaluation of value stream mapping in manufacturing system

redesign, Int J Prod Res, 2008, 46 (16): 44094430.

Spearman M.L. Woodruff D.L. and Hopp W.J. CONWIP: a pull alternative to kanban, Int J Prod Res,

1990, 28 (5): 879894.

Sullivan W.G. McDonald T.N. and Van Aken E.M. Equipment emplacement decisions and lean

manufacturing, Robot Comput- Integr Manuf, 2002, 18 (3): 255265.

Womack J.P., Jones D.T. and Roos D. The machine that changed the world. HarperCollins

Publishers, New York, 1991.

Womack J.P. and Jones D.T. Lean thinking: banish waste and create wealth in your corporation.

Simon & Schuster, New York, 1996.

58

You might also like

- Improvement Based On Standardized Work: An Implementation Case StudyDocument14 pagesImprovement Based On Standardized Work: An Implementation Case StudySandy M. MaddaganNo ratings yet

- VSMDocument6 pagesVSMLGUIMARA12No ratings yet

- Lean manufacturing case study improves process cycle efficiencyDocument13 pagesLean manufacturing case study improves process cycle efficiencyசரவணகுமார் மாரியப்பன்No ratings yet

- Material Handling and Process Improvement Using Lean Manufacturing Principles.1-4Document4 pagesMaterial Handling and Process Improvement Using Lean Manufacturing Principles.1-4SitisaifulNo ratings yet

- Implementation of Lean Manufacturing Principles in FoundriesDocument5 pagesImplementation of Lean Manufacturing Principles in FoundriesIJMERNo ratings yet

- Graficos de ControlDocument7 pagesGraficos de ControlAli BadfaceNo ratings yet

- Cycle Time Reduction in Deck Roller Assembly ProductionDocument10 pagesCycle Time Reduction in Deck Roller Assembly ProductionTeshome DengisoNo ratings yet

- Rad o SMED UDocument9 pagesRad o SMED UAmiljkovicviNo ratings yet

- LEC-2010 Value-Stream Mapping The Chemical ProcessesDocument5 pagesLEC-2010 Value-Stream Mapping The Chemical ProcessesMustafa Mert SAMLINo ratings yet

- Value Stream Mapping Reduces Lead Time and Inventory for Fastener ManufacturerDocument5 pagesValue Stream Mapping Reduces Lead Time and Inventory for Fastener ManufacturerDipankar GhoshNo ratings yet

- SmedDocument4 pagesSmedYurdun OrbakNo ratings yet

- Verma Smita PrecisDocument14 pagesVerma Smita PrecisAshwani Kumar VermaNo ratings yet

- Q1. Explain in Brief The Origins of Just in Time. Explain How JIT Is ImplementedDocument39 pagesQ1. Explain in Brief The Origins of Just in Time. Explain How JIT Is ImplementedPushpam NayanNo ratings yet

- Lead Time Reduction Through Lean Technique in An Engine Assembly LineDocument7 pagesLead Time Reduction Through Lean Technique in An Engine Assembly LineVarun KumarNo ratings yet

- JIEMS - Volume 6 - Issue 2 - Pages 147-164Document18 pagesJIEMS - Volume 6 - Issue 2 - Pages 147-164John MendozaNo ratings yet

- Lean Implementation and Its Benefits To Production IndustryDocument13 pagesLean Implementation and Its Benefits To Production IndustryJunando HunterNo ratings yet

- Waste Elimination Using VSM and VALSATDocument9 pagesWaste Elimination Using VSM and VALSATkokoblukNo ratings yet

- Abdulmalek, Rajgopal - 2007 - Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector CaseDocument14 pagesAbdulmalek, Rajgopal - 2007 - Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector CaseDragan DragičevićNo ratings yet

- Development of A Design - Ime Estimation Model For Complex Engineering ProcessesDocument10 pagesDevelopment of A Design - Ime Estimation Model For Complex Engineering ProcessesJosip StjepandicNo ratings yet

- Value Stream Mapping: A Case Study of Fastener IndustryDocument4 pagesValue Stream Mapping: A Case Study of Fastener IndustryIOSRjournal100% (1)

- Critical Study On Vital Factors Influencing Productivity ImprovementDocument8 pagesCritical Study On Vital Factors Influencing Productivity ImprovementIJRASETPublicationsNo ratings yet

- Jurnal Tugas Akhir - Implementasi Lean Manufacturing Dalam Meminimasi Waste Pada Lantai ProduksiDocument16 pagesJurnal Tugas Akhir - Implementasi Lean Manufacturing Dalam Meminimasi Waste Pada Lantai ProduksiRudini Mulya100% (3)

- Value Stream Mapping A Case Study of AutomotiveDocument5 pagesValue Stream Mapping A Case Study of AutomotiveInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Management Accounting and Control Systems: Xxxvi, 3Document29 pagesManagement Accounting and Control Systems: Xxxvi, 3SUHAIRI19084488No ratings yet

- A Framework For Implementing Just in Time in A Valve Manufacturing IndustryDocument5 pagesA Framework For Implementing Just in Time in A Valve Manufacturing IndustryInnovative Research PublicationsNo ratings yet

- Must ReadDocument10 pagesMust ReadJuby JoyNo ratings yet

- Lean Production Principles for Construction ManagementDocument18 pagesLean Production Principles for Construction ManagementRitesh PrajapatiNo ratings yet

- Implementation of Lean Strategies in A Furniture Manufacturing FactoryDocument6 pagesImplementation of Lean Strategies in A Furniture Manufacturing FactoryInternational Organization of Scientific Research (IOSR)No ratings yet

- Operation Management Lean ManagementDocument7 pagesOperation Management Lean ManagementSakshi SharmaNo ratings yet

- Analyzing The Benefits of Lean Tools: A Consumer Durables Manufacturing Company Case StudyDocument5 pagesAnalyzing The Benefits of Lean Tools: A Consumer Durables Manufacturing Company Case StudyPruthviraj DhinganiNo ratings yet

- Simulacion 2Document8 pagesSimulacion 2Victor Barrios AlvarezNo ratings yet

- An Application of SMED MethodologyDocument4 pagesAn Application of SMED MethodologyIng Raul OrozcoNo ratings yet

- Application of SMED Methodology-A Case Study in Small Scale IndustryDocument4 pagesApplication of SMED Methodology-A Case Study in Small Scale IndustryAkshay PatilNo ratings yet

- Amm PDFDocument13 pagesAmm PDFShruti AirenNo ratings yet

- Accelerating furniture factory productivityDocument7 pagesAccelerating furniture factory productivityIam RodriguesNo ratings yet

- Ans - All SubjectDocument3 pagesAns - All SubjectEmad Al-AmadNo ratings yet

- Implementing Lean Tools in Electrical Panel AssemblyDocument8 pagesImplementing Lean Tools in Electrical Panel AssemblyPankajSinghBhatiNo ratings yet

- Methods For Design, Analysis and Improvement of Logistical ProcessesDocument7 pagesMethods For Design, Analysis and Improvement of Logistical ProcessesGradiella MbemNo ratings yet

- Group TechnologyDocument19 pagesGroup TechnologyCem Savaş AydınNo ratings yet

- Facility Layout and DesignDocument9 pagesFacility Layout and DesignAfia Nazmul 1813081630No ratings yet

- Implementation of Industrial Engineering ConceptsDocument7 pagesImplementation of Industrial Engineering ConceptsMudra SinghNo ratings yet

- Smude Mba Sem2 All AssignmentsDocument168 pagesSmude Mba Sem2 All AssignmentsAshok BabuNo ratings yet

- Application of Lean Approaches and Techniques in An Automotive CompanyDocument8 pagesApplication of Lean Approaches and Techniques in An Automotive CompanyAchraf adenasNo ratings yet

- Smart VSM 2Document16 pagesSmart VSM 2JeromeNo ratings yet

- Articulo de SistemasDocument5 pagesArticulo de SistemasMariana PalenciaNo ratings yet

- Value Stream MappingDocument9 pagesValue Stream MappingIAEME PublicationNo ratings yet

- Journal of Manufacturing Systems: Taho Yang, Yiyo Kuo, Chao-Ton Su, Chia-Lin HouDocument8 pagesJournal of Manufacturing Systems: Taho Yang, Yiyo Kuo, Chao-Ton Su, Chia-Lin HoujanellaNo ratings yet

- Artículos Científicos Celdas de Manufactura y Balance de Línea - Grupo 2Document8 pagesArtículos Científicos Celdas de Manufactura y Balance de Línea - Grupo 2Marcos Alonso Castillo QuispeNo ratings yet

- Facility Layout and Design: A Case Study of A Soap Manufacturing Company in NigeriaDocument10 pagesFacility Layout and Design: A Case Study of A Soap Manufacturing Company in Nigeriabiniam meazanehNo ratings yet

- MB0044 Set 1Document12 pagesMB0044 Set 1Bela JadejaNo ratings yet

- Jurnal TA Lean SIx SigmaDocument7 pagesJurnal TA Lean SIx SigmaManuel AllenNo ratings yet

- Lean Manufacturing Implementation Using Value Stream Mapping: A Case Study of Pumps Manufacturing CompanyDocument7 pagesLean Manufacturing Implementation Using Value Stream Mapping: A Case Study of Pumps Manufacturing Companyirfan iruNo ratings yet

- 518-Celotna Knjiga-1167-1-10-20201111Document22 pages518-Celotna Knjiga-1167-1-10-20201111Samuel Getaneh TNo ratings yet

- Design Process To Reduce Production Cycle Time in Product DevelopmentDocument5 pagesDesign Process To Reduce Production Cycle Time in Product DevelopmentIAES IJAINo ratings yet

- Productivity enhancement through lean manufacturingDocument5 pagesProductivity enhancement through lean manufacturingDiana Marcela RodriguezNo ratings yet

- Just in Time Approach in Inventory Management: Abdul Talib Bon (Corresponding Author)Document9 pagesJust in Time Approach in Inventory Management: Abdul Talib Bon (Corresponding Author)Chad ParkerNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Us 20020091460 A 1Document22 pagesUs 20020091460 A 1Warren RiveraNo ratings yet

- Us 4953306Document15 pagesUs 4953306Warren RiveraNo ratings yet

- Hyd Manual PDFDocument175 pagesHyd Manual PDFWarren RiveraNo ratings yet

- 16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairDocument22 pages16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairPRASAD326100% (4)

- Lean VSMDocument27 pagesLean VSMWarren RiveraNo ratings yet

- Lean01 PDFDocument27 pagesLean01 PDFWarren RiveraNo ratings yet

- vsm09 PDFDocument8 pagesvsm09 PDFWarren RiveraNo ratings yet

- Tariff Revision of Student Special & Roam Free Prepaid PlansDocument1 pageTariff Revision of Student Special & Roam Free Prepaid PlansWarren RiveraNo ratings yet

- Hydraulic CircuitDocument18 pagesHydraulic Circuitshrikant_pesitNo ratings yet

- FundamentalsDocument16 pagesFundamentalsBala SubramanianNo ratings yet

- Hydraulic Cylinder - ReferenceDocument95 pagesHydraulic Cylinder - ReferenceWarren RiveraNo ratings yet

- Kanban Kit PDFDocument11 pagesKanban Kit PDFWarren RiveraNo ratings yet

- Toyota Kanban System Case StudyDocument10 pagesToyota Kanban System Case StudyAman SharmaNo ratings yet

- Optimization LiteratureDocument8 pagesOptimization LiteratureWarren RiveraNo ratings yet

- Vapor Absorption Vs CompressionDocument3 pagesVapor Absorption Vs Compression78kbalajiNo ratings yet

- Apply KanbanDocument13 pagesApply KanbanWarren RiveraNo ratings yet

- Re92060 2014-04Document28 pagesRe92060 2014-04Ibrahim GökmenNo ratings yet

- Development of Kanban System at Local Manufacturing Company in Malaysia - Case StudyDocument6 pagesDevelopment of Kanban System at Local Manufacturing Company in Malaysia - Case StudyAarthy ChandranNo ratings yet

- Fluid MechanicsDocument41 pagesFluid MechanicsRian SteveNo ratings yet

- Varshit Doshi: Mobile: +91 8866514555 Address: D-502, Sahaj Sapphire, Opp APMC MarketDocument2 pagesVarshit Doshi: Mobile: +91 8866514555 Address: D-502, Sahaj Sapphire, Opp APMC MarketWarren RiveraNo ratings yet

- Varshit Doshi: Mobile: +91 8866514555 Address: D-502, Sahaj Sapphire, Opp APMC MarketDocument2 pagesVarshit Doshi: Mobile: +91 8866514555 Address: D-502, Sahaj Sapphire, Opp APMC MarketWarren RiveraNo ratings yet

- IH01Document5 pagesIH01Warren RiveraNo ratings yet

- Stuck in A Range: Punter's CallDocument4 pagesStuck in A Range: Punter's CallWarren RiveraNo ratings yet

- PremiumTechnicals-Nov26 15 GammonDocument2 pagesPremiumTechnicals-Nov26 15 GammonWarren RiveraNo ratings yet

- Varshit Doshi: Mobile: +91 8866514555 Address: D-502, Sahaj Sapphire, Opp APMC MarketDocument2 pagesVarshit Doshi: Mobile: +91 8866514555 Address: D-502, Sahaj Sapphire, Opp APMC MarketWarren RiveraNo ratings yet

- InterView PHPDocument8 pagesInterView PHPWarren RiveraNo ratings yet

- SQL Server InterviewDocument3 pagesSQL Server InterviewWarren RiveraNo ratings yet

- JavaScript Code Snippet EvaluationDocument5 pagesJavaScript Code Snippet EvaluationWarren RiveraNo ratings yet

- Pratap Leela Bhai Odedra Sr. 9662596080 SANJAY HADIYA JRDocument1 pagePratap Leela Bhai Odedra Sr. 9662596080 SANJAY HADIYA JRWarren RiveraNo ratings yet

- Innovheads Design Studio: DT 09/12/15 Sr. No Size Inch SQ - Ft. Glass Work 1 2 3 4 5Document6 pagesInnovheads Design Studio: DT 09/12/15 Sr. No Size Inch SQ - Ft. Glass Work 1 2 3 4 5Warren RiveraNo ratings yet

- Innovation and Entrepreneurship PresentationDocument11 pagesInnovation and Entrepreneurship PresentationGandhi AnugrahNo ratings yet

- Swot Analysis of DoveDocument9 pagesSwot Analysis of DovePrachi NaikNo ratings yet

- MKC1200 Sem2 2007 ExamDocument3 pagesMKC1200 Sem2 2007 ExamAllan ZhangNo ratings yet

- Competitive Advantage Through Innovation: The Case of NespressoDocument16 pagesCompetitive Advantage Through Innovation: The Case of NespressoAna SiqueiraNo ratings yet

- Online Shopping - Wikipedia, The Free Encyclopedia 1Document18 pagesOnline Shopping - Wikipedia, The Free Encyclopedia 1Arnab DeyNo ratings yet

- Accenture Emerging Market EntryDocument16 pagesAccenture Emerging Market EntryPrateek JainNo ratings yet

- Global Market Segmentation TechniquesDocument84 pagesGlobal Market Segmentation TechniquesRica de los SantosNo ratings yet

- Branding: BY: Manich, Chhayhong & Ratanak ReachDocument5 pagesBranding: BY: Manich, Chhayhong & Ratanak ReachSahil MohammadNo ratings yet

- Data2 Dapimage 1409021911 CreditCardApplication1409021911Document4 pagesData2 Dapimage 1409021911 CreditCardApplication1409021911Michel ThompsonNo ratings yet

- What Is Marketing ManagementDocument28 pagesWhat Is Marketing ManagementBidyut Bhusan PandaNo ratings yet

- PURPLE COWDocument5 pagesPURPLE COWRupinder KaurNo ratings yet

- Visual MerchandisingDocument21 pagesVisual MerchandisingrahulranjanjaiswalNo ratings yet

- Marketing Strategy of ParleDocument9 pagesMarketing Strategy of ParleSiddharth MishraNo ratings yet

- Marketing Concepts 2022Document4 pagesMarketing Concepts 2022veqaevNo ratings yet

- Project 4 FinalDocument2 pagesProject 4 Finalapi-307253935No ratings yet

- Ice Fili Analysis: Presented by Group11-Anuraj Antil Ishan Malik Kanishka Singh Sunny Malik Surya DeswalDocument13 pagesIce Fili Analysis: Presented by Group11-Anuraj Antil Ishan Malik Kanishka Singh Sunny Malik Surya DeswalKanishka SinghNo ratings yet

- MBA MARKETING PROFESSIONALDocument1 pageMBA MARKETING PROFESSIONALArpita PriyadarshiniNo ratings yet

- CRM Strategy Coca Cola Sandeep SinghDocument11 pagesCRM Strategy Coca Cola Sandeep SinghShivangi SharmaNo ratings yet

- A Study On Customer Satisfaction in Ceasefire Industries LTDDocument75 pagesA Study On Customer Satisfaction in Ceasefire Industries LTDAjmal Khan0% (1)

- Microeconomics I Assignment 3 optimal pricing and outputDocument4 pagesMicroeconomics I Assignment 3 optimal pricing and outputanirudhjayNo ratings yet

- Answers To Quiz 4 Summer 2013Document2 pagesAnswers To Quiz 4 Summer 2013Melissa Vásquez TrujilloNo ratings yet

- Chapter 20Document2 pagesChapter 20k2a2m2No ratings yet

- Strategic Marketing Questionnaire With AnswersDocument6 pagesStrategic Marketing Questionnaire With AnswersShubhashish100% (1)

- Chinahub 2Document4 pagesChinahub 2Waseem alhlwNo ratings yet

- Perfection Paints: Instructions For ParticipantDocument9 pagesPerfection Paints: Instructions For ParticipantTehone TeketelewNo ratings yet

- Hindustan Unilever Limited FinalDocument22 pagesHindustan Unilever Limited FinalWasim FerozeNo ratings yet

- Consumer Behaviour-IntroductionDocument245 pagesConsumer Behaviour-IntroductionCharu ModiNo ratings yet

- Media Kit Rulomati̇k 2021Document11 pagesMedia Kit Rulomati̇k 2021enesNo ratings yet

- Annual Report 2020 2021Document127 pagesAnnual Report 2020 2021Abhishek SahaNo ratings yet

- Mirpuri Vs CA - 114508 - November 19, 1999 - JDocument17 pagesMirpuri Vs CA - 114508 - November 19, 1999 - JAlexander Julio ValeraNo ratings yet