Professional Documents

Culture Documents

Atlas Grade Datasheet 2507 Rev May 2008

Uploaded by

Gaurav NarulaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atlas Grade Datasheet 2507 Rev May 2008

Uploaded by

Gaurav NarulaCopyright:

Available Formats

Grade Data Sheet

2507

2507 is one of a group of "super duplex" becomes embrittled this can only be rectified

grades, combining high strength with by a full solution annealing treatment.

exceptional corrosion resistance.

Heat Treatment

2507 is very highly resistant to general Solution Treatment (Annealing)

corrosion and to pitting and crevice corrosion in Heat to 1040 - 1120°C and cool rapidly in air

high chloride, hot environments. Its duplex or by water quenching.

structure also results in excellent resistance to Duplex and super duplex grades cannot be

stress corrosion cracking. hardened by thermal treatment.

Like other duplex (ferritic/austenitic) grades Welding

the super duplex grades are not suitable for 2507 is weldable by standard methods, without

high or low temperature service. 2507 is not pre-heat. Consumables over-alloyed with

recommended for temperatures below -50°C or nitrogen and nickel are generally

above +300°C, because of reduced toughness recommended such as those with ISO

outside this range. designation “25 9 4 L N”. TIG (GTAW), MIG

(GMAW) and all positional manual (MMAW)

The high strength favours applications in electrodes are available. Heat input should be

pressure vessels and for marine and other within the range 0.5 – 1.5kJ/mm. Post weld

shafts annealing is essential following autogenous

welding, but not otherwise. Nickel-based

Corrosion Resistance consumables (eg Alloy C22) can also be used

2507 has excellent general corrosion to give higher corrosion resisting welds. As for

resistance, superior to virtually all other other duplex stainless steels the coefficient of

stainless steels. It has high resistance to thermal expansion of 2507 is lower than for

intergranular corrosion and very high austenitic grades, reducing distortion and

resistance to stress corrosion cracking in both residual stresses.

chloride and sulphide environments.

Fabrication

A PRE of least 40 indicates that the material 2507 is a high strength steel, so high forming

has good pitting and crevice corrosion forces will be required and high spring-back

resistance to warm sea water and other high should be anticipated. The ductility of the

chloride environments; it is rated as more grade is quite adequate for most operations,

resistant than grade 904L and approximating but heavy deformation, such as cold forging, is

that of the 6% Molybdenum "super austenitic" not possible. If more than about 20% cold

grades. work is carried out an intermediate solution

anneal is required. Hot forging can be carried

2507 is the grade of choice for severe high out in the temperature range 1200 – 1025°C.

temperature marine environments and for Like other duplex grades 2507 has low hot

chemical and petrochemical processing, even strength, so may need support during heat

including some solutions of strong acids. treatment or forging. Hot forging should be

followed by solution treatment.

Consult Atlas Technical Assistance for specific

environmental recommendations. Typical Applications

Oil and gas exploration, processing and support

Heat Resistance systems, pollution control including flue gas

Although super duplex grades have good high desulphurisation, marine and other high

temperature oxidation resistance, like other chloride environments, desalination plants,

duplex stainless steels they suffer from chemical processing, transport and storage,

embrittlement if held for even short times at pulp and paper processing.

temperatures above 300°C. If grade 2507

Revised May 2008 Page 1 of 2

www.atlasmetals.com.au

Grade Data Sheet

2507

Specified Properties

These properties are specified for flat rolled product (plate, sheet and coil) in ASTM A240M and

for pipe in ASTM A790M, as UNS S32750. Similar but not necessarily identical properties are

specified for other products in their respective specifications.

Composition Specification (%)

Grade C Mn Si P S Cr Mo Ni Cu N

min. - - - - - 24.0 3.0 6.0 - 0.24

2507

max. 0.030 1.20 0.80 0.035 0.020 26.0 5.0 8.0 0.50 0.32

Mechanical Property Specification

Grade Tensile Yield Strength Elongation Hardness

Strength 0.2% Proof (% in 50mm) Rockwell B Brinell

(MPa) (MPa) min (HR C) (HB)

min min max max

2507 795 550 15 32 310

Physical Properties (typical values in the annealed condition)

Grade Density Elastic Mean Coefficient of Thermal Thermal Specific Electrical

3 Modulus Expansion Conductivity Heat Resistivity

(kg/m )

(GPa) 0-100°C 0-400°C at 20°C 0-100°C (n.m)

(m/m/°C) (m/m/°C) (W/m.K) ( J/kg.K)

2507 7800 200 13.0 14.5 14.2 460 850

Grade Specification Comparison

Grade UNS Euronorm Swedish Japanese

No No Name SS JIS

2507 S32750 1.4410 X2CrNiMoN25-7-4 2328 -

These comparisons are approximate only. The list is intended as a comparison of functionally similar

materials not as a schedule of contractual equivalents. If exact equivalents are needed original

specifications must be consulted.

Possible Alternative Grades

Grade Why it might be chosen instead of 2507

2205 The lower cost and better availability of 2205 are required, and a lower corrosion resistance

and strength can be accepted.

6% Mo Higher ductility of this austenitic grade is needed, and the much lower strength is acceptable.

Corrosion resistance is similar in many environments, but needs to be considered case by

case.

Ni Alloys A corrosion resistance even higher than 2507 is required, and a higher cost is acceptable.

Limitation of Liability

The information contained in this datasheet is not an exhaustive statement of all relevant information. It is a general

guide for customers to the products and services available from Atlas Specialty Metals and no representation is made or

warranty given in relation to this document or the products or processes it describes.

Revised May 2008 Page 2 of 2

www.atlasmetals.com.au

You might also like

- Casting HandbookDocument18 pagesCasting HandbookGaurav NarulaNo ratings yet

- En 10204Document30 pagesEn 10204Gaurav Narula95% (19)

- LDX2101 Spec SheetDocument2 pagesLDX2101 Spec SheetGaurav NarulaNo ratings yet

- IPL Player Register 2009Document9 pagesIPL Player Register 2009Gaurav Narula100% (1)

- Welcome To Time Management: I Am Damn Sure That You Will Really Like ThisDocument69 pagesWelcome To Time Management: I Am Damn Sure That You Will Really Like ThisGaurav NarulaNo ratings yet

- Corporate Social RespDocument5 pagesCorporate Social RespGaurav NarulaNo ratings yet

- Hanuman Chalisa With Meaning3Document7 pagesHanuman Chalisa With Meaning3oraveen100% (1)

- How Management Works - A StoryDocument25 pagesHow Management Works - A Storyashutoshkj100% (1)

- Will PowerDocument10 pagesWill PowerGaurav Narula0% (1)

- Welcome To Time Management: I Am Damn Sure That You Will Really Like ThisDocument69 pagesWelcome To Time Management: I Am Damn Sure That You Will Really Like ThisGaurav NarulaNo ratings yet

- Welcome To Time Management: I Am Damn Sure That You Will Really Like ThisDocument69 pagesWelcome To Time Management: I Am Damn Sure That You Will Really Like ThisGaurav NarulaNo ratings yet

- MH Dalmia OCL Healthy - LifeDocument25 pagesMH Dalmia OCL Healthy - LifeGaurav Narula100% (1)

- World Business CultureDocument275 pagesWorld Business CultureGaurav Narula100% (8)

- Supply Chain ManagementDocument35 pagesSupply Chain ManagementGaurav Narula100% (1)

- TN3-0506-Properties and Equivalent GradesDocument4 pagesTN3-0506-Properties and Equivalent GradesGaurav Narula100% (1)

- Setting SMARt TargetsDocument3 pagesSetting SMARt TargetsGaurav Narula100% (5)

- Inventory ManagementDocument102 pagesInventory ManagementGaurav Narula100% (7)

- CPK Index - How To Calculate For All Types of TolerancesDocument15 pagesCPK Index - How To Calculate For All Types of TolerancesGaurav Narula100% (6)

- Kings and Queens of England: The Whole BookDocument85 pagesKings and Queens of England: The Whole Bookestudo35No ratings yet

- ISO 9001:2008 EditionDocument25 pagesISO 9001:2008 EditionGaurav Narula100% (15)

- En 10204Document30 pagesEn 10204Gaurav Narula95% (19)

- Quality Manual CalibrationDocument30 pagesQuality Manual CalibrationsaidvaretNo ratings yet

- French For English PeoplesDocument568 pagesFrench For English PeoplesManoj Kumar Jha100% (30)

- Explore The Big Cats PDFDocument65 pagesExplore The Big Cats PDFvarcolacNo ratings yet

- Creative Time - Manage The Mundane - Create The ExtraordinaryDocument32 pagesCreative Time - Manage The Mundane - Create The ExtraordinarySolomon100% (3)

- Inspiring StoriesDocument21 pagesInspiring StoriesGaurav Narula100% (2)

- Solar SystemDocument105 pagesSolar Systemv155r100% (18)

- Vertical PumpsDocument4 pagesVertical PumpsGaurav NarulaNo ratings yet

- Torque Flow PumpsDocument4 pagesTorque Flow PumpsGaurav Narula0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Welding-Process 222Document63 pagesWelding-Process 222Jasm OmranNo ratings yet

- Trailblazer325 MillerDocument8 pagesTrailblazer325 MillerWilfredoNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Module 2 - Welding and Cutting Proccess PDFDocument148 pagesModule 2 - Welding and Cutting Proccess PDFTuhoyito TarahaoNo ratings yet

- WPE2 Course Notes PDFDocument356 pagesWPE2 Course Notes PDFQuoc Vinh100% (2)

- BS en 12070 (2000)Document13 pagesBS en 12070 (2000)vuthuy94No ratings yet

- Analysis of Stainless Steel Welded Joints A Comparison Between Destructive and Non-Destructive TechniquesDocument7 pagesAnalysis of Stainless Steel Welded Joints A Comparison Between Destructive and Non-Destructive TechniquesKhalid M. HafezNo ratings yet

- Analytical Process Model for Wire + Arc Additive ManufactureDocument11 pagesAnalytical Process Model for Wire + Arc Additive ManufactureÄmRít RájNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- WeldDocument52 pagesWeldAlwin Victor Williams100% (1)

- Guide to Welding Types and TechniquesDocument15 pagesGuide to Welding Types and TechniquesArslan100% (1)

- Introduction to Gas Shielded Arc WeldingDocument157 pagesIntroduction to Gas Shielded Arc Weldingrohit mathankerNo ratings yet

- Kobelco Stainless SteelDocument32 pagesKobelco Stainless SteelMiguel BentoNo ratings yet

- Sav 4740Document72 pagesSav 4740tlidiaNo ratings yet

- Electrode For 2015-16Document12 pagesElectrode For 2015-16vp singhNo ratings yet

- Preparation of Stress-Corrosion Test Specimens For WeldmentsDocument8 pagesPreparation of Stress-Corrosion Test Specimens For Weldmentsmohammed karasnehNo ratings yet

- Citoarc 270: Professional Welder For Tough Working ConditionsDocument2 pagesCitoarc 270: Professional Welder For Tough Working ConditionsNIZAM NIZAMNo ratings yet

- Operator'S Manual: Tig-250Pl AcdcDocument33 pagesOperator'S Manual: Tig-250Pl AcdcAntonio MaesoNo ratings yet

- Stainless Steel Pipe and Tube Manufacturing Process: Pearlite Steel Stainless Steel Blog Uncategorized No CommentDocument2 pagesStainless Steel Pipe and Tube Manufacturing Process: Pearlite Steel Stainless Steel Blog Uncategorized No CommentpritiNo ratings yet

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (1)

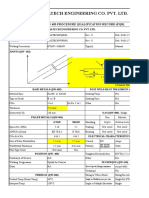

- CALTECH ENGINEERING PQR PROCEDUREDocument8 pagesCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- Keyhole GTAW & GTAW Variants ExplainedDocument2 pagesKeyhole GTAW & GTAW Variants ExplainedThiago Ribeiro da SilvaNo ratings yet

- Syllabus: Craft Instructors Training Scheme (Cits)Document21 pagesSyllabus: Craft Instructors Training Scheme (Cits)Abdul MalikNo ratings yet

- QC Welding Inspector NotesDocument26 pagesQC Welding Inspector NotesSohail Aziz Ahmad MalikNo ratings yet

- Sandvick Stainless Welding Products (S 236 Eng 2006)Document27 pagesSandvick Stainless Welding Products (S 236 Eng 2006)Anonymous yQ7SQrNo ratings yet

- Welding TerminologiesDocument11 pagesWelding TerminologiesPankajabhangNo ratings yet

- Miller XMT 304 Manual de Servicio PDFDocument104 pagesMiller XMT 304 Manual de Servicio PDFNINO100% (1)

- Weldability of Nickel-Base Alloys: December 2014Document31 pagesWeldability of Nickel-Base Alloys: December 2014Silvio ZappinoNo ratings yet

- Assignment Answer WPS HK40Document4 pagesAssignment Answer WPS HK40RahulNo ratings yet