Professional Documents

Culture Documents

Surface Grinding Report

Uploaded by

Nur Muhammad Fitri70%(20)70% found this document useful (20 votes)

15K views12 pagesworkshop report

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentworkshop report

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

70%(20)70% found this document useful (20 votes)

15K views12 pagesSurface Grinding Report

Uploaded by

Nur Muhammad Fitriworkshop report

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 12

1

TITLE: UNIVERSAL SURFACE GRINDING

INTRODUCTION

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used

abrasive machining process in which a spinning wheel covered in rough particles (grinding

wheel) cuts chips of metallic or non-metallic substance from a work piece, making a face of it

flat or smooth.

Surface grinding is the most common of the grinding operations. It is a finishing process that

uses a rotating abrasive wheel to smooth the flat surface of metallic or non-metallic materials

to give them a more refined look or to attain a desired surface for a functional purpose.

The surface grinder is composed of an abrasive wheel, a work holding device known

as a chuck, and a reciprocating or rotary table. The chuck holds the material in place while it

is being worked on. It can do this one of two ways: ferromagnetic pieces are held in place by

a magnetic chuck, while non-ferromagnetic and non-metallic pieces are held in place by

vacuum or mechanical means. A machine vies (made from ferromagnetic steel or cast iron)

placed on the magnetic chuck can be used to hold non-ferromagnetic work pieces if only a

magnetic chuck is available.

Factors to consider in surface grinding are the material of the grinding wheel and the

material of the piece being worked on.

Typical work piece materials include cast iron and mild steel. These two materials

don't tend to clog the grinding wheel while being processed. Other materials are aluminium,

2

stainless steel, brass and some plastics. When grinding at high temperatures, the material

tends to become weakened and is more inclined to corrode. This can also result in a loss of

magnetism in materials where this is applicable.

The grinding wheel is not limited to a cylindrical shape and can have a myriad of

options that are useful in transferring different geometries to the object being worked on.

Straight wheels can be dressed by the operator to produce custom geometries. When surface

grinding an object, one must keep in mind that the shape of the wheel will be transferred to

the material of the object like a mirror image.

Spark out is a term used when precision values are sought and literally means "until

the sparks are out (no more)". It involves passing the work piece under the wheel, without

resetting the depth of cut, more than once and generally multiple times. This ensures that any

inconsistencies in the machine or work piece are eliminated.

TYPES OF SURFACE GRINDERS

1. Horizontal-spindle (peripheral) surface grinders.

2. Vertical-spindle (wheel-face) grinders.

3. Disc grinders and double-disc grinders.

THE BENEFITS OF SURFACE GRINDING ARE

You can grind very hard or abrasive materials

High degree of dimensional accuracy

Produces surface textures of very high finish

Tooling is less expensive

Work holding is easier because of magnetic chuck

Can be done automatically

3

1. Horizontal-spindle (peripheral) surface

Grinders.

The periphery (flat edge) of the wheel is in contact with the work piece, producing the

flat surface. Peripheral grinding is used in high-precision work on simple flat surfaces; tapers

or angled surfaces; slots; flat surfaces next to shoulders; recessed surfaces; and profiles.

2. Vertical-spindle (wheel-face) grinders

The face of a wheel (cup, cylinder, disc, or segmental wheel) is used on the flat surface.

Wheel-face grinding is often used for fast material removal, but some machines can

accomplish high-precision work. The work piece is held on a reciprocating table, which can

be varied according to the task, or a rotary-table machine, with continuous or indexed

4

rotation. Indexing allows loading or unloading one station while grinding operations are

being performed on another.

3. Disc grinders and double-disc grinders

Disc grinding is similar to surface grinding, but with a larger contact area between disc and

work piece. Disc grinders are available in both vertical and horizontal spindle types. Double

disc grinders work both sides of a work piece simultaneously. Disc grinders are capable of

achieving especially fine tolerances.

Aluminium oxide, silicon carbide, diamond, and cubic boron nitride (CBN) are four

commonly used abrasive materials for the surface of the grinding wheels. Of these materials,

aluminium oxide is the most common. Because of cost, diamond and CBN grinding wheels

are generally made with a core of less expensive material surrounded by a layer of diamond

or CBN. Diamond and CBN wheels are very hard and are capable of economically grinding

materials, such as ceramics and carbides, that cannot be ground by aluminium oxide or

silicon carbide wheels.

As with any grinding operation, the condition of the wheel is extremely important. Grinding

dressers are used to maintain the condition of the wheel, these may be table mounted or

mounted in the wheel head where they can be readily applied.

5

OBJECTIVE

1. Know how to grind the surface of a metal object.

2. Know about the function of the universal surface grinding machine.

3. Understand the functioned the type of tools used in the universal surface grinding

machine.

4. Knowing method about how the work

SAFETY PRECAUTION

1. Wear a goggle before start the works.

2. Wear safety shoes.

3. Avoid wear jewellery while using this surface grinding machine.

4. Make sure the machine is safe before use.

5. Use appropriate machine speed.

6. Switching off the machine after use.

7. Make sure the machine is used with safety switch and another switch lock.

SAFETY PRECAUTIONS DURING RUN MACHINE

Wear appropriate safety glasses. In addition, use the eye shield on the grinder, when

provided.

Ensure that the grinder has a start/stop button within easy reach of the operator.

Check the grinding wheel before mounting it. Make sure it is properly maintained and

in good working order.

Follow the manufacturer's instructions for mounting grinding wheels.

Keep face of the wheel evenly dressed.

Ensure that the wheel guard covers at least one half of the grinding wheel.

File off any burrs on the surface of work that is placed on the magnetic chuck.

Clean the magnetic chuck with a cloth and then wipe with the palm of your hand.

6

Place a piece of paper slightly larger than workpiece in the centre of chuck.

Position work on the paper and turn on the power to the magnetic chuck.

Check that the magnetic chuck has been turned on by trying to remove work from the

chuck.

Check that the wheel clears the work before starting the grinder.

Run a new grinding wheel for about one minute before engaging the wheel into the

work.

Stand to one side of the wheel before starting the grinder.

Turn off coolant before stopping the wheel to avoid creating an out-of-balance

condition.

Keep the working surface clear of scraps, tools and materials.

Keep the floor around the grinder clean and free of oil and grease.

7

Universal surface grinding

machine

- Used to produce the

smooth finish and flat

surface of the work piece.

VernierCalliper

- Used to measure the

diameter and the length

of work piece.

Goggle

- To protect the eyes from

dust, including iron.

PROCEDURE:

1. Surface grinding machine was started

2. The speed, angle of rotation, height of table and etc has been setting.

3. The work piece has been clamp tightly to avoid it flew away.

4. The movement of the magnetize table was set.

5. The machine started to feed the work piece.

6. The grinded shouldnt very big or else the work piece will be damaged.

7. Make sure the surface object doesnt had any rust strain after it has been grinded

8

EQUIPMENT

A surface grinder is a machine tool used to provide precision ground surfaces, either

to a critical size or for the surface finish.

The typical precision of a surface grinder depends on the type and usage, however +/-

0.002 mm (+/- 0.0001") should be achievable on most surface grinders.

The machine consists of a table that traverses both longitudinally and across the face

of the wheel. The longitudinal feed is usually powered by hydraulics, as may the cross feed,

however any mixture of hand, electrical or hydraulic may be used depending on the ultimate

usage of the machine (i.e.: production, workshop, cost). The grinding wheel rotates in the

spindle head and is also adjustable for height, by any of the methods described previously.

Modern surface grinders are semi-automated, depth of cut and spark-out may be preset as to

the number of passes and, once set up, the machining process requires very little operator

intervention.

Depending on the workpiece material, the work is generally held by the use of a

magnetic chuck. This may be either an electromagnetic chuck, or a manually operated,

permanent magnet type chuck; both types are shown in the first image.

The machine has provision for the application of coolant as well as the extraction of metal

dust (metal and grinding particles).

9

PROCEDURE FOR USE SURFACE GRINDER

The first step in using the surface grinder, is to make sure that the material you wish

to shape can be used in the grinder. Soft materials such as aluminum or brass will clop up the

abrasive wheel and stop it from performing effectively, and it will then have to be cleaned.

This process is explained in the Maintenance section. The maximum size of a material that

the grinder can machine is 18 long by 8 wide by 6 high. The next step is to make sure the

material is secured. This is done by use of a vice, and then by engaging the magnetic clamp.

Once the material is secure, it must be manually positioned under the abrasive wheel. This is

done by turning the longitude and latitude wheels located on the front of the grinder. The

abrasive wheel itself can be moved slightly to get the material in the perfect position. Then

the machine may be started. It should reach maximum speed before you try to use it for the

safety reasons mentioned before. If the wheel is working properly, then the hydraulic table

can be activated which will then begin to oscillate under the wheel, cross-feeding towards or

away from you as required. The automated speed and direction of the tables oscillations can

be set as required, or manually used when very precise work needs to be done. If needed, a

lubricant may be used to speed up or facilitate the grinding process. For this machine

Cutwell 45 is used. It is delivered via a tube beside the wheel, and falls onto the material

being used. The excess fluid is then drained into the reservoir.

CLEANING

A wire wheel mounted to a utility grinding machine is used for cleaning operations

such as removing rust, paint, or dirt from metal objects. If the utility grinding machine on

which the wire wheel is to be mounted is equipped with wheel guards and tool rests, these

parts should be removed or swung out of the way so that the objects to be cleaned can be

brought against the wheel without interference.

To clean objects with a wire wheel, place the object firmly against the wire wheel.

Work the object back and forth across the face of the wheel until all traces of rust, paint, or

10

dirt are removed. Avoid excessive pressure against the face of the wire wheel to prevent

spreading the steel wires. Keep the point of contact below the center of the wheel to avoid

kickback of the workpiece.

LUBRICATION

Lubricants are sometimes used to cool the workpiece and wheel, lubricate the

interface, and remove swarf (chips). It must be applied directly to the cutting area to ensure

that the fluid is not carried away by the grinding wheel. Common lubricants include water-

soluble chemical fluids, water soluble oils, synthetic oils, and petroleum-based oils. The type

of lubrication used depends on the workpiece material and is outlined in the table below.

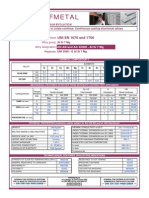

Types of lubricants used for grinding based on workpiece material

Workpiece material Lubricant

Aluminium heavy duty oil

Brass Light duty oil

Cast iron Heavy duty emulsifiable oil, light duty chemical and synthetic oil

Mild steel Heavy duty water-soluble oil

Stainless steel Heavy duty emulsifiable oil, heavy duty chemical and synthetic oil

Plastics Water-soluble oil, dry, heavy duty emulsifiable oil, light duty chemical and

synthetic oil

EFFECTS ON WORK MATERIAL PORPERTIES

The high temperatures encountered at the ground surface create residual stresses and a

thin martensitic layer may form on the part surface; this decreases the fatigue strength. In

ferromagnetic materials, if the temperature of the surface is raised beyond the Curie

temperature then it may lose some magnetic properties. Finally, the surface may be more

susceptible to corrosion.

11

THINGS YOU SHOULD AVOID DOING

Do not run a grinding wheel faster than the speed recommended on the wheel.

Do not clean the magnetic chuck or mount or remove work until the wheel has

completely stopped.

Do not grind material for which wheel is not designed.

Do not grind without proper ventilation.

Do not start the machine until the wheel guard is in place.

Do not stand directly in front of a grinding wheel when starting a grinder.

Do not apply work too quickly to a cold wheel or disk.

Do not jam work into the wheel.

Do not reach above or around a moving wheel.

EXAMPLES OF FINISHED PRODUCT OF SURFACE GRINDER

12

DISCUSSION

Surface finish is an important index of machinability or grind ability because the

performance and the service life of the ground component are often affected by its surface

finish, nature and extent of residual stresses and presence of superficial or sub superficial

micro cracks. The roughness of a ground component is mainly influenced by size of abrasive

grain, dressing conditions, feed rate, spark-out time and cooling conditions. The analysis of

the results obtained with the conventional cutting fluid application system and with the MQL

technique indicates that the application of cutting fluid by MQL technique led to satisfactory

results in comparison to the conventional system, due to the more efficient penetration of the

fluid into the cutting region.

CONCLUSION

Surface grinding is an abrasive machining process in which the grinding wheel

removes material from the plain flat surfaces of the work piece. In surface grinding, the

spindle position is either horizontal or vertical, and the relative motion of the work piece is

achieved either by reciprocating the work piece past the wheel or by rotating it.

REFERENCES

Tool and Manufacturing Engineers Handbook (TMEH), 4th edition, Volume 1, Machining.

Society of Manufacturing Engineers, 1983

Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994), Manufacturing Processes Reference

Guide.

You might also like

- WRC-1992 Diagram FN Calculator - 2013-08 RevDocument6 pagesWRC-1992 Diagram FN Calculator - 2013-08 RevespectromixNo ratings yet

- Damage Mechanism - AsdDocument66 pagesDamage Mechanism - AsdAcid BurnsNo ratings yet

- ASTM Grade 70-50-05 (ISO 500-7, En-JS 1050) Ductile Cast IronDocument8 pagesASTM Grade 70-50-05 (ISO 500-7, En-JS 1050) Ductile Cast IronNagarjun ReddyNo ratings yet

- Welding SymbolDocument52 pagesWelding SymbolShriram Avasarkar100% (4)

- General Standards (NDT)Document2 pagesGeneral Standards (NDT)agniva dattaNo ratings yet

- Fitting ReportDocument18 pagesFitting ReportAriff Azizi67% (3)

- Grinding Wheels Lab ReportDocument18 pagesGrinding Wheels Lab ReportUsman CheemaNo ratings yet

- Machining Process Lab ReportDocument31 pagesMachining Process Lab ReportHafiz Hamza83% (12)

- Edm Wire Cut ReportDocument15 pagesEdm Wire Cut ReportBawen MuralitharanNo ratings yet

- Milling MachineDocument14 pagesMilling MachineAqib ZamanNo ratings yet

- Fence Fittings: Standard Specification ForDocument5 pagesFence Fittings: Standard Specification ForEnriqueVe100% (1)

- Lathe ReportDocument16 pagesLathe ReportMuhammad Aisamuddin88% (8)

- Construction Materials and Testing ModuleDocument66 pagesConstruction Materials and Testing Moduleacurvz2005No ratings yet

- Milling ReportDocument5 pagesMilling ReportMuhammad Fadhli80% (5)

- MEM460 Milling Full ReportDocument15 pagesMEM460 Milling Full ReportNoor Elisha Zulkifli100% (5)

- Surface Grinding ReportDocument3 pagesSurface Grinding ReportFiqri ProductionNo ratings yet

- DJJ 6162 Case StudyDocument48 pagesDJJ 6162 Case StudyMunisprasad MuniandyNo ratings yet

- JJ 103 Fitting ReportDocument12 pagesJJ 103 Fitting ReportNasrul Haziq Murad55% (20)

- CNC Milling ReportDocument15 pagesCNC Milling ReportStarscream Aisyah78% (37)

- CNC ReportDocument39 pagesCNC Reportrasaiya69% (13)

- Lab Report On CNC MachineDocument5 pagesLab Report On CNC MachineAhmad Syamil100% (1)

- DJJ3032 - Workshop Practice 3 (Lathe Machining)Document8 pagesDJJ3032 - Workshop Practice 3 (Lathe Machining)Afiq Fahmi100% (2)

- Lab Report Edm Wirecut PDFDocument23 pagesLab Report Edm Wirecut PDFeizy andy88% (8)

- Surface GrinderDocument7 pagesSurface Grinderaryariqtariq704100% (1)

- Lathe Machine Project Semester 2Document11 pagesLathe Machine Project Semester 2Ye Chonn79% (34)

- Report Machine Sem3Document8 pagesReport Machine Sem3Fazerin Shah100% (3)

- Arc Weld ReportDocument14 pagesArc Weld ReportAsyraf Razali67% (6)

- DJJ40142- MECHANICAL WORKSHOP PRACTICE 4 (GRINDINGDocument14 pagesDJJ40142- MECHANICAL WORKSHOP PRACTICE 4 (GRINDINGMira Amira100% (1)

- JJ303 Report TigDocument10 pagesJJ303 Report TigAh Tiang67% (9)

- Djj10022 Fitting ReportDocument7 pagesDjj10022 Fitting ReportTamil passang songNo ratings yet

- Mesin Report SEM 2Document17 pagesMesin Report SEM 2Fiqri Ash RuleNo ratings yet

- Lathe Report Sem 1 DegDocument9 pagesLathe Report Sem 1 DegTarmizi Bahari74% (27)

- Report MesinDocument8 pagesReport MesinWan Muhamad FaizNo ratings yet

- DJM1012 Mechatronic Workshop Practice-Machining ReportDocument16 pagesDJM1012 Mechatronic Workshop Practice-Machining ReportRachel Ramirez100% (7)

- Report Lathe MachineDocument13 pagesReport Lathe Machinehairul akmal0% (1)

- Report CNC MillingDocument16 pagesReport CNC Millingharislukman100% (5)

- Welding Discontinuities and Their CausesDocument2 pagesWelding Discontinuities and Their Causeszarif73% (15)

- Lathe Machine ReportDocument28 pagesLathe Machine ReportFaizal64% (11)

- Inventor ReportDocument7 pagesInventor Report2cekal50% (2)

- Gas Welding ReportDocument17 pagesGas Welding ReportNorasilah Chan67% (3)

- Report Workshop Gas WeldingDocument6 pagesReport Workshop Gas WeldingDzulkhairie DK0% (1)

- Grinding ReportDocument5 pagesGrinding ReportSteady Bunny100% (2)

- Discussion EdmDocument3 pagesDiscussion EdmShamsul Aiman100% (1)

- Djj30082 - Mechanical Workshop Practice 3 (Machining) Report 1 (Part A, Clo 2) 1.0 ObjectivesDocument6 pagesDjj30082 - Mechanical Workshop Practice 3 (Machining) Report 1 (Part A, Clo 2) 1.0 Objectivesshirleyna sara100% (1)

- JJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Document9 pagesJJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Ah Tiang100% (1)

- Milling Report (Indexing)Document23 pagesMilling Report (Indexing)Aiman AlifNo ratings yet

- DJJ1032 Fitting (Hexagon Gauge) : Muhammad Ariff Bin Shukri TeyDocument14 pagesDJJ1032 Fitting (Hexagon Gauge) : Muhammad Ariff Bin Shukri TeyTak ProNo ratings yet

- Report Bengkel Cad CamDocument8 pagesReport Bengkel Cad CamYouDiey33% (3)

- Report FittingDocument1 pageReport FittingNordianaaida Eda67% (3)

- A Lab Report On Fitting Workshop PracticeDocument6 pagesA Lab Report On Fitting Workshop PracticeBilal Mobeen88% (17)

- Lab Report TIGDocument4 pagesLab Report TIGAlimah Azeli50% (2)

- FittingDocument14 pagesFittingMuhd Ashraf67% (3)

- Lathe Machine Lab ReportDocument8 pagesLathe Machine Lab ReportJasmine_lai00No ratings yet

- Edm ReportDocument13 pagesEdm Reportrasaiya57% (7)

- Report CNC Turning LengkapDocument19 pagesReport CNC Turning LengkapFirdaus Shah25% (4)

- DJJ 10033-Chapter 5.GEARDocument34 pagesDJJ 10033-Chapter 5.GEARStepianus JtNo ratings yet

- Report CNC TurningDocument23 pagesReport CNC Turningdkeaumani57% (7)

- Basic Pure Pneumatic Circuit Design: Experiment: 1 Title: Duration: 2 Hours: 1 0F 3Document3 pagesBasic Pure Pneumatic Circuit Design: Experiment: 1 Title: Duration: 2 Hours: 1 0F 3shirleyna saraNo ratings yet

- Report Edm Die SinkerDocument21 pagesReport Edm Die SinkerAwateff Al-Jefry II100% (8)

- Lathe ReportDocument11 pagesLathe ReportWan Syafiq Wan Syamsulbahri100% (2)

- Foundry ReportDocument2 pagesFoundry ReportPreavin Kutty Thamotharan50% (2)

- Surface Grinding ReportDocument12 pagesSurface Grinding ReportyowiskieNo ratings yet

- Lab Session 10Document5 pagesLab Session 10Rahmat aliNo ratings yet

- André Grinding Machine AssemblyDocument4 pagesAndré Grinding Machine AssemblyBruno SpezziNo ratings yet

- Quad Processing MachineDocument6 pagesQuad Processing MachineSulfikkar100% (1)

- Lab 02 - Surface GrindingDocument13 pagesLab 02 - Surface GrindingShahminan ShahNo ratings yet

- Grinding Machine: Abrasive Machining Process Removes MaterialDocument16 pagesGrinding Machine: Abrasive Machining Process Removes MaterialMudassar AkhtarNo ratings yet

- Sae 147626610-Astm-A-576 PDFDocument5 pagesSae 147626610-Astm-A-576 PDFNina LazuardiNo ratings yet

- Curva Conduit Rgs X 90 Deg Ul UniverDocument12 pagesCurva Conduit Rgs X 90 Deg Ul UniveraasfaskjlNo ratings yet

- 7963 Brida Ac WN 6 X 150 SCH STD SWDocument2 pages7963 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- Metallurgy, Corrosion, CP SystemDocument37 pagesMetallurgy, Corrosion, CP Systemsatish04No ratings yet

- Stainless Steel Socket, Square Head, and Slotted Headless-Set ScrewsDocument6 pagesStainless Steel Socket, Square Head, and Slotted Headless-Set ScrewsDanZel Dan100% (1)

- LA02b - Soldering TechniqueDocument24 pagesLA02b - Soldering TechniqueFairolizwan AbdullahNo ratings yet

- Erosion Resistance of Infiltration Brazed Tungsten Carbide CladdingDocument9 pagesErosion Resistance of Infiltration Brazed Tungsten Carbide CladdingjorgeNo ratings yet

- Sltp-Standard Inch Pins UsDocument2 pagesSltp-Standard Inch Pins UsErick Frank Dueñas CudeñaNo ratings yet

- Evaluating Cu-W Composite Powder Metallurgy ProcessesDocument24 pagesEvaluating Cu-W Composite Powder Metallurgy Processesmuthu kumarNo ratings yet

- PugalenthiDocument7 pagesPugalenthiTHANI ORUVANNo ratings yet

- QB Fitter MCQ 1st SemesterDocument78 pagesQB Fitter MCQ 1st SemesterAmit ShahNo ratings yet

- Shielded Metal Arc Welding: Grade 10Document23 pagesShielded Metal Arc Welding: Grade 10Jessel Mejia OnzaNo ratings yet

- Arcelormittal How To WeldDocument21 pagesArcelormittal How To WeldZachNo ratings yet

- Standard Welding Procedure Specification Demonstration FormDocument1 pageStandard Welding Procedure Specification Demonstration FormEmma DNo ratings yet

- Aluminum Alloy EvolutionDocument2 pagesAluminum Alloy Evolutionc4pp3ll410_m4tt0No ratings yet

- Me6403 Emm PDFDocument116 pagesMe6403 Emm PDFRAMESHKUMAR.S MCE-LECT/MECHNo ratings yet

- Forming Questions For Entrance Exams - SanfoundryDocument4 pagesForming Questions For Entrance Exams - SanfoundryrahmaNo ratings yet

- Synthesis and Charecterization of Alfecrni Four Component High Entropy Alloy by Mechanical AlloyingDocument5 pagesSynthesis and Charecterization of Alfecrni Four Component High Entropy Alloy by Mechanical Alloyingvsraju2No ratings yet

- AWS Electrode classifications explainedDocument3 pagesAWS Electrode classifications explainedUsamaIjazNo ratings yet

- PART 100 What Is GMAW - STTDocument5 pagesPART 100 What Is GMAW - STTravindra_jivaniNo ratings yet

- EAA Aluminium Automotive Manual - JoiningDocument25 pagesEAA Aluminium Automotive Manual - JoiningArathoNNo ratings yet

- Moonstar - Air DuctDocument24 pagesMoonstar - Air DuctdenisnonameNo ratings yet

- Permanent Metal - Data - Sheet - AFP 1 209B New PDFDocument1 pagePermanent Metal - Data - Sheet - AFP 1 209B New PDFcham_900No ratings yet