Professional Documents

Culture Documents

40 Influence of Additives On Cu Electrodeposition Mechanisms in Acid PDF

Uploaded by

Paz BalladaresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40 Influence of Additives On Cu Electrodeposition Mechanisms in Acid PDF

Uploaded by

Paz BalladaresCopyright:

Available Formats

Inuence of additives on Cu electrodeposition mechanisms in acid

solution: direct current study supported by non-electrochemical

measurements

L. Bonou

a

, M. Eyraud

b,

*, R. Denoyel

b

, Y. Massiani

b

a

Laboratoire de Chimie Physique et dElectrochimie, Universite de Ouagadougou, Ouagadougou 03 BP 7021, Burkina Faso

b

Laboratoire Materiaux Divises et Revetements Electroceramiques (MADIREL), UMR 6121, Universite de Provence-CNRS, case 26, 3 pl. V. Hugo,

13331 Marseille Cedex 03, France

Received 7 March 2002; received in revised form 6 June 2002

Abstract

The effect of polyethylene glycol (PEG) and chloride ions on copper electrodeposits is investigated by electrochemical

measurements (cyclic voltammetry, current and potential pulses) coupled with an ellipsometric study at open circuit. When PEG is

added to the Cu

2

solution, the modifications of the copper electrodeposition mechanism can be explained by a polymer-electrode

interaction instead of a complex formation in solution. Since ellipsometry has shown no PEG adsorption at least at open circuit, that

adsorption is assumed to be potential dependent. Moreover, the efficiency of PEG alone in solution, seems to be decreased when the

deposit grows. With Cl

alone, an activation of copper deposition is performed. The simultaneous addition of the two additives

induces a blocking effect of the copper reduction that continues on with time. X-ray diffraction, optical microscopy and atomic force

microscopy (AFM) carried out complementary results, on bulk deposits obtained from solution with and without these additives. It

has been found that a bright, compact and homogeneous coating is only obtained in presence of both additives. In that case, the

texture of the deposit is modified and the roughness is significantly decreased to 0.5 mm. # 2002 Elsevier Science Ltd. All rights

reserved.

Keywords: Cu electrodeposition; Additives; PEG/Cl

; Synergetic effect

1. Introduction

In modern electroplating practice, it is well known

that the addition of even small amounts of certain

substances in the plating bath leads to significant

changes in the properties and aspect of the deposit.

Recent reviews have tried to summarize their different

effects [1/5]:

/ Levelers have the ability to produce deposits rela-

tively thick in small recesses and relatively thin on

small protusions. They act by adsorption at points

where otherwise there would be a rapid deposition of

the metal.

/ Brighteners allow the microscopic roughness of the

deposit to be lower as the wavelength of the incident

light so that it is reflected rather than scattered. They

act by a modification of the nucleation process and,

therefore, change the Tafel slope.

/ Structure modifiers change the structure of the

deposit and maybe even the preferred orientation of

lattice.

/ Wetting agents accelerate the release of hydrogen gas

bubbles from the surface and avoid hydrogen embrit-

tlement.

/ Among the involved mechanisms, it is known that

many additives are usually capable of adsorption on

the cathodic substrate and even might trap in the

deposit. Some additives also increase the deposition

over-potential. This may be due to either the need for

the electron transfer to occur through the adsorbed

layer or to a complex formation at the electrode

surface. A complexation of the metal cation in

solution is also proposed.

* Corresponding author

E-mail address: m.eyraud@newsup.univ-mrs.fr (M. Eyraud).

Electrochimica Acta 47 (2002) 4139/4148

www.elsevier.com/locate/electacta

0013-4686/02/$ - see front matter # 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 0 1 3 - 4 6 8 6 ( 0 2 ) 0 0 3 5 6 - 0

But, although advances have been made, in many

cases the use of additives is still done in an empirical

way. Indeed, the number of these organic or non-

organic substances is very large. Moreover, their action

could be different in function of the substrate, the ion to

reduce and the electrolytic conditions. For example,

additive re-orientation on the electrode surface [1,2] has

been observed depending on the surface coverage or as a

function of pH. A synergetic effect, often noticed when

several additives are added to the solution even confuses

the issue.

In the case of copper, a very great number of

researches have already been undertaken, because of

the industrial interest. Indeed, electroplated copper has

various applications as contacts and circuitry in the

electronic industry, undercoating for Ni and Cr plating

and the decoration of consumer goods. Each will require

somewhat different properties and hence different bath

formulations or electrolytic conditions. Most copper

baths are made either from cyanide or sulfate salts, but

the first one is gradually given up due to environmental

problems related to the cyanide toxicity.

Addition of some components in the copper electro-

lyte has become quite usual to obtain a uniform deposit

with a high throwing power and a weak roughness. The

most common species added to obtain a bright copper

deposit are: dextrin, gelatin, urea, chloride ions, sulfur-

containing compounds or other organic molecules [6/

18]. Although it has been established that these sub-

stances lead to high changes in the morphology of the

deposit, the knowledge in the mechanism of action of

these additives is very poor. For example, recent years

have shown an increasing use of polyethylene glycol

(PEG) to sulfuric copper electrolytes with or without

Cl

[2,8/18]. This additive appears as brightening or

leveling agent. But, while its influence on the copper

deposition is always observed, it has given rise to

contradictory explanations like:

/ Formation of complexes in solution between ethylene

oxide ligands (/CH

2

/CH

2

/O/)

n

and Cu

or Cu

2

cations [8]. As a result, the transport of copper ions

from the bulk electrolyte is impeded and the work for

the discharge of the copper complex ion increases.

/ Complex formation on the copper electrode surface

[9]: the adsorption of PEG on the Cu electrode during

electrorefining, involved by polarization curves, gives

rise to surface bonds between the ether oxygen of the

macromolecules and the Cu

2

, Cu

or Cu species.

In that case, the current is decreased and the potential

of copper oxidation becomes more positive. The same

authors have shown that, with Cl

species alone in

solution, the current is also decreased due to a

passivation of the surface related to the presence of

a copper chloride film. Nevertheless, in that case, the

potential of copper oxidation is shift toward a more

negative range. In presence of both PEG and Cl

,

the strongest effect is observed, showing a synergy

between the two additives.

/ Adsorbed glycol film that represents an uniform

barrier to electron transfer, which contributes to a

more uniform deposit [2,10,11].

Generally speaking, adsorption of PEG is often

involved but in different manners and in different forms

(film, monolayer, adsorption of rod-like PEG molecules,

adsorption of spherical PEG molecules. . .) [12/18]. For

example, different forms of adsorption as a function of

the potential range are involved [12,13]. It has been

established by Raman spectroscopy that PEG is ad-

sorbed on the copper surface in the potential range for

copper deposition, but not at the open circuit potential.

However, by comparison of the electrochemical and the

Raman results, the same authors concluded that quite

different PEG species are adsorbed on the surface at

open potential (not detected by Raman method) and in

the potential range where copper deposition occurred. It

is believed that a simple neutral PEG is adsorbed in the

most negative potential area, and a copper chloride

complex with PEG as a ligand close to the open circuit.

On the other hand, differential capacitance measure-

ments in H

2

SO

4

electrolyte have shown [14] that PEG is

very slightly adsorbed on the copper surface, and that

this additive on its own is not able to produce bright

coatings. Hope et al. [15], also involves the weak

adsorption of PEG on steel during copper deposition.

The macromolecules, being slightly adsorbed, are suffi-

ciently mobile and are entrapped in the deposit by

approaching atomic layer, leading to incorporation of

aggregates rather than individual molecules. A decrease

in the PEG concentration is in part due to its inclusion

during the copper deposition. West et al. [17,18] also

indicated a small effect on the electrode kinetics when

PEG is alone in solution, while Cl

only promotes the

copper deposition reaction. Using a quartz crystal

microbalance and electrochemical impedance spectro-

scopy, they suggested the adsorption of a monolayer of

PEG molecules that collapse into spheres provided Cl

is present. That adsorption leads to a blocking of

available surface sites for charge transfer. In contrary,

without Cl

there is a little PEG adsorption.

The employment of ellipsometry for the study of in

situ electrode process as oxidation of metals dates from

the sixties [19]. A few years later, ellipsometry was also

used in the measurement of adsorption of several species

on noble metal [20/22]. Such metals are often required

due to the need of the high stability of the surface: the

changes in optical parameters have not arisen from an

electrode oxidation. More recently, this method was

used to understand the effect of nicotinic acid on copper

layers electrodeposited on Pt [21].

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4140

Here, both electrochemical methods (cyclic voltam-

metry, potentiostatic and galvanostatic experiments) as

well as ellipsometric study at open potential have been

used to have a better insight in the role of PEG and Cl

during copper electrodeposition. This work was done

for each additive separately and together, to show the

evidence of a possible synergetic effect between the two

additives. Optic and atomic force microscopy (AFM) as

well as X-ray diffraction was carried out on the bulk

deposits obtained with or without additives, to support

the electrochemical study and for complementary results

(morphology, roughness, structure and preferential

orientation).

2. Experimental

A classic three-electrode cell was used for all electro-

chemistry experiments. The working electrode consisted

of a 0.28 cm

2

pure copper rod (99.999% purity). It was

prepared by extensive polishing using emery paper to a

grade of 1200, followed by a diamond paste polishing on

a polishing cloth. The counter electrode was a platinum

grid and all potentials were recorded with respect to a

saturated calomel electrode (SCE).

The study of the influence of PEG (CH

2

OH(CH

2

-

OCH

2

)

n

CH

2

OH average molar mass 10 000, supplied by

Merck) and chloride ions (added by using NaCl salt)

was carried out by introducing them in the common

formulation bath (pH 0): CuSO

4

/H

2

SO

4

. In the aim to

determine the influence of each additive, several solu-

tions were prepared with water treated by a millipore

system.

Blank experiments were carried out in electrolytes

referenced as followed:

S

o

: pure H

2

SO

4

2.2 M solution.

S

p

: S

o

/PEG1 g l

1

.

S

c

: S

o

/Cl

50 ppm.

S

pc

: S

o

/PEG1 g l

1

/Cl

50 ppm.

It is obvious that the weak concentration of additives

in solution do not lead to a change of pH. The copper

solutions are listed below:

Cu

o

: S

o

/CuSO

4

/5H

2

O 0.3 M.

Cu

p

: Cu

o

/PEG1 g l

1

.

Cu

c

: Cu

o

/Cl

50 ppm.

Cu

pc

: Cu

o

/PEG1 g l

1

/Cl

50 ppm.

Electrochemical experiments consisted of cyclic vol-

tammetry or linear sweep polarization, potential /time

and current /time transients. The equipment consisted

of a EG&G-PAR model 273 potentiostat /galvanostat.

The potential sweeps or steps started from the rest

potential of the substrate in the solution and continued

in the cathodic direction.

Ellipsometric measurements were made with a Ru-

dolph apparatus type 43603-200E, which has been

described in numerous papers [23,24]. It is a null

ellipsometer in a horizontal polarizer, compensatory,

sample analyzer (PCSA) arrangement. All details on

null procedure can be found in [25]. The sample was

maintained vertically in a trapezoid quartz cell (Thuet et

Bichelin, Strasbourg) allowing experiments at an inci-

dence angle of 688. The wavelength was 632.8 nm. The

optical parameters, D and C, were measured by the four

zones method.

The measurements were made on a copper sample,

glued on an isolated conductive sheet. Special care was

taken on polishing to obtain a flat, reproducible, and

mirror like surface. For that, the same polish procedure

as described before was employed, but it was pursued to

a 1 mm grade. To know if there is a PEG adsorption on

the copper surface, ellipsometric results obtained from

solution with or without PEG, were compared. The

blank electrolyte consisted on the S

o

bath, previously de-

aerated under an argon flow, to avoid the oxidation of

the copper surface with time. De-aeration was main-

tained during the experiment. To verify the ageing of the

surface with time in the blank solution, the time stability

of D and C values were controlled before the first

injection. Then, injections of a concentrate PEG solu-

tion were made so as to increase the PEG concentration

of about 1 g l

1

after each addition. The measurements

of the optical parameters were made twice immediately

and 20 min after each injection.

Bulk deposits were obtained under galvanostatic

conditions, from copper solutions with and without

the additives. In that case, the substrate consisted in a 2

cm

2

pure copper sample (99.9% purity), soldered on a

conductive sheet isolated from the solution by an

araldite film. In this way, the substrates were easily

released from the support to be analyzed. Morphology,

roughness and structure of the deposits were determined

by optical microscopy, AFM (CP Autoprobe provided

by Park Scientific Instruments) and X-rays diffraction

(Siemens D-5000).

3. Results and discussion

3.1. Blank experiments without Cu

2

in solution

Since the modification of the hydrogen evolution

reaction (HER) is dependent of an adsorbed layer, the

first experiments were made on blank solutions without

Cu

2

, containing or not the additives. Since the pH-

value is unchanged whatever the solution used, if a

change of HER. (E

eq,H

/H

2

//0.24 V per ECS) is

performed, that cannot be due to a complex formation

with the proton but rather to an adsorbed layer on the

electrode surface.

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4141

Fig. 1 reports the linear sweep polarization carried

out on copper at 20 mV s

1

, from open circuit to /1 V,

in S

o

, S

p

, S

c

, S

pc

solutions. For S

o

, no significant current

is performed until the potential reaches /700 mV,

corresponding to the HER. The over potential for the

proton reduction on the copper substrate is then about

450 mV. From the other solutions, it can be noticed

that:

/ No supplementary current is observed until the HER;

the PEG and Cl

additives are not electroactive, at

least in this potential range.

/ When the additives are added to the S

o

solution, a

supplementary over voltage for the HER is obtained

on the curves S

p

, S

c

and S

pc

in comparison to S

o

. This

increase in the over potential is more effective with

both additives in solution, as can be seen in Table 1.

It can be concluded that these two additives can

adsorb on the copper substrate, at least for the potential

range where the HER occurs.

The ellipsometric D and C data in function of time

are shown in Fig. 2. At first, to control the copper

surface stability with the immersion time, the D and C

parameters were monitored during 45 min before the

first PEG injection. That corresponds to the two first

points on the curves. A weak but significant decrease of

both the D and C values can be noticed, probably due to

a slow surface oxidation. Then, four Injections of PEG

were made during the 3 h of the experiment. These

injections are identified by i on the curves. The

measurements of the optical parameters were made

immediately and 20 min after each injection. It can be

seen from the curves, that no supplementary deviation

of the optical parameters was performed, neither shortly

after the injection nor after 20 min. This result seems to

point out that there is no PEG adsorption on the copper

surface.

At first sight, this conclusion might be considered as a

total contradiction to the first electrochemical experi-

ments described above. But, if the electrochemical and

the optical results are interpreted together, then the

conclusion must be that the PEG adsorption does not

occur at open circuit but at a more cathodic potential.

3.2. From Cu

2

solutions

3.2.1. Additive-free Cu

2

solution

Fig. 3 shows two cycles of the voltammograms from

the additive-free copper bath Cu

o

. The first cycle

corresponds to the copper deposition on polished

copper substrate and the second cycle to the copper

deposition on electrodeposited copper. On polished

substrate, no current is performed until Er//100

mV, that corresponds to the reduction of Cu

2

. From

that, there is an increase in the cathodic current, due to

the copper crystallization, followed by a current plateau,

at about 32 mA cm

2

, indicating a mass transfer control

of the process. By reversing the sweep, a cross-over is

observed between the cathodic and the anodic current,

that is characteristic of a mechanism of nucleation [26].

This shape of voltammogram was already obtained

from sulfuric acid solution, but on vitreous carbon

and not on coppers that is the substrate used for this

study [27]. The copper nucleation mechanism is more

surprising on copper substrate, where an epitaxial

growth seems to be more normal. Copper epitaxial

growth was obtained on electrodeposited copper, as it is

shown by the second cycle of the Fig. 3. In that case, the

nucleation loop has disappeared. That results emphasize

the importance of the surface state, its purity, pretreat-

ment conditions. . . on the deposition mechanisms.

Fig. 4 deals with a set of i /t transients for various

potential pulses, from Cu

o

solution, on polished copper

substrate. The shape of the transients depends on the

applied potential. For the highest over-potentials, they

present a maximum current i

m

which occurs at time t

m

,

related to the time at which full coalescence of the

crystallites occurs [28] indicating that a nucleation

mechanism is involved. After the ascending part, the

transients show a decrease followed by stabilization in

current at about 35 mA cm

2

.

The region of the rising part of the peak can be used

to determine the kinetics of nucleus growth [29]. In the

case of a mechanism controlled by mass-transfer, two

types of nucleation can occur: instantaneous nucleation

in which the nuclei are formed at the beginning of the

Fig. 1. Inuence of additives on the linear sweep polarizations for H

reduction from: (S

o

): 2.2 M H

2

SO

4

; (S

p

) is S

o

/1 g l

1

PEG; (S

c

) is

S

o

/50 ppm Cl

; (S

pc

) is S

o

/1 g l

1

PEG/50 ppm Cl

.

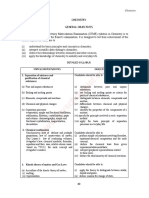

Table 1

Supplementary overpotential for the HER induced by PEG and/or

Cl

in comparison with the blank solution

Solutions S

p

S

c

S

pc

Supplementary overvoltage for HER per S

o

(mV) 82 60 105

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4142

pulse (i #kt

1/2

) and progressive nucleation in which the

formation of the nuclei goes on with the growth

(i #kt

3/2

). By plotting log i /f (log t) the slope can allow

to determine the nucleation and growth model. How-

ever, in our case, the ascending part of the transients

does not fit with a classical model.

Even if no classical nucleation and growth could be

determined, the shape of the transients confirms the

nucleation of copper deposit on copper substrate and

the mass-transfer control, in agreement with the voltam-

metric experiments.

3.2.2. Cu

2

in presence of additives

Fig. 5 presents the voltammograms obtained in

presence of the various additives, from Cu

p

, Cu

Cl

and

Cu

pc

solutions, on the copper substrate. For compar-

ison, the curve Cu

o

is also plotted.

3.2.2.1. With PEG. In the presence of the only PEG

(solution Cu

p

), the shape of the voltammogram ob-

tained is modied with regards to the precedent. A

strong inhibiting effect can be noticed because the

additive promoted a shift of the deposition potential

to more negative values creating an over-voltage of 220

mV. The slope of reduction is not the same as before,

but stronger. In this way, a new kinetic constant is

introduced. It is necessary to note that the limiting

current is the same with or without PEG that removes

the possibility of the complex formation in solution

between PEG and the Cu

2

species. Indeed, in this case

the diffusion coefcient of Cu

2

in solution would have

Fig. 2. Change in the ellipsometric parameters D and C in function of time, from So solution (2.2 M H

2

SO

4

), on copper surface. PEG Injections

were identied by i on curves.

Fig. 3. Successive voltammograms performed from Cu

o

bath: CuSO

4

0.3 M/2.2 M H

2

SO

4

. First cycle corresponds to copper deposition on

polished copper substrate. Second cycle corresponds to copper

deposition on electrodeposited copper.

Fig. 4. Potentiostatic i /t transients for Cu

o

bath: CuSO

4

0.3 M/2.2

M H

2

SO

4

.

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4143

been modied, and consequently the limiting current

[30]. Anyway, the complexation of 0.3 M of Cu ions by a

small PEG quantity seems unlikely. By reversing the

scan, it appears that the backward currents with and

without the additive are very close. This result may

suggest that the change at the copper surface due to the

additive adsorption is irreversible: once copper deposi-

tion has begun, PEG lost its ability to inhibit the

deposit. A similar conclusion was already proposed in

[12]. The observations about the other solutions will be

shown in the following page.

To confirm this result, two successive voltammograms

are performed with PEG in solution (Fig. 6). The second

cycle corresponds to copper deposition on electrode-

posited copper. It clearly presents an increase in the

cathodic current in two steps, with a decrease in the

over-voltage and in the slope values initially induced by

PEG. In this case, the increase in current is slower,

getting closer to that obtained without additive in

solution. On the contrary, by stopping the experiment

during a few minutes and starting it again, we find the

first over-voltage again. Even if PEGs finger print is

still visible, there is a release of the effect of PEG during

the growth of the deposit that could be due to a

competition for the sites in surface among PEG and

copper ions.

Fig. 7 deals with the transients obtained with (Cu

p

)

and without (Cu

o

) PEG in solution, for the same

cathodic pulse at /250 mV. Once again, with PEG,

no deposition law could be established. Nevertheless,

the two curves present a rising part that indicates a

nucleation mechanism. Then, the current stabilizes at

the same value: the diffusion of Cu

2

in solution is not

influenced by a PEG addition. The more important

difference between the transients comes from the

coalescence speed of the crystallites, which is decreased

with PEG. This induction time could be related to the

PEG adsorption on the copper surface that hinders the

formation of the first copper nuclei.

3.2.2.2. With Cl

. Fig. 5 also shows the inuence of

Cl

(solution Cu

Cl

) on the copper reduction mechan-

ism. In that case, the reaction of Cu

2

reduction is

moved towards more positive potential. An inverse

effect is thus obtained with Cl

with regard to that

obtained with PEG, already underlined in references

[9,17]. On the other hand the shape of the curves Cu

Cl

and Cu

o

with and without Cl

, remains unchanged:

they keep the same slope. It can be concluded that the

presence of Cl

leads to an acceleration of the copper

reduction but without modication of the mechanism.

Besides this, Cl

is known for its high adsorption power

[20,31,32], the formation of a cuprous chloride layer

adsorbed on the copper surface was already involved [9].

Fig. 5. Inuence of additives on voltammograms from several solu-

tions: (Cu

o

): CuSO

4

0.3 M/2.2 M H

2

SO

4

; (Cu

p

) is Cu

o

/1 g l

1

PEG;

(Cu

Cl

) is Cu

o

/50 ppm Cl

; (Cu

pc

) is Cu

o

/1 g l

1

PEG/50 ppm

Cl

.

Fig. 6. Successive voltammograms performed from Cu

p

bath: CuSO

4

0.3 M/2.2 M H

2

SO

4

/1 g l

1

PEG. First cycle corresponds to copper

deposition on polished copper substrate. Second cycle corresponds to

copper deposition on electrodeposited copper.

Fig. 7. PEG effect on the i /t transients obtained at /250 mV, from

Cu

o

and Cu

p

bath: (Cu

o

): CuSO

4

0.3 M/2.2 M H

2

SO

4

; (Cu

p

) is Cu

o

/

1 g l

1

PEG.

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4144

The mechanism of ion bridging was introduced by T.C.

Franklin [4,33]. It consists of the ability of a complexed

ion to accelerate the rate of ow of electrons through the

additive from the electrode to the metal ion. Indeed,

there is no electron transfer through the primary water

molecules bound to the ion. Thus, reduction of aqueous

complexes requires either partial desolvatation during

the adsorption process or substitution of the water with

an ion bridge as Cl

.

3.2.2.3. With PEG/Cl

. On Fig. 5, the curve Cu

pc

is

performed from the bath containing the both additives

PEG/Cl

. It seems that Cl

s addition in the PEG

solution leads to the same over-voltage than PEG alone

(curve Cu

p

) but with a slowing down of the deposition

speed of the copper. One nds the same reduction slope

than for copper alone (curve Cu

o

) and in the presence of

Cl

(curve Cu

Cl

). Besides, the current limit remains

always the same with or without additive. That conrms

that the mechanism of reduction stays under mass-

transfer control and that the effect of additives does not

intervene through a complex formation of copper in

solution.

An important difference is recorded on the backward

scan of the curve Cu

pc

, where in that case the backward

current is smaller than the forward current, without

nucleation loop. This is the finger print that the

influence of the two additives continues during the

growth of the copper deposit while, with only PEG in

solution, there is a release of the PEG effect during the

thickening of the deposit. Therefore, it may be con-

cluded that PEG and Cl

can act in a synergistic way,

leading to a strong inhibition of the deposit with the

change in deposition mechanism.

Fig. 8 deals with potential step experiments were

realized from the solution Cu

pc

in presence of the two

additives. In that case, the i /t transients present a

monotonous decrease in current followed by a stabiliza-

tion, which confirms that the copper deposit is made

without nucleation. This figure can be compared with

Fig. 7 obtained with Cu

o

and Cu

p

, where the rising part

indicated a copper nucleation step. With PEG/Cl

the

mechanism of copper deposition is thus different than

that obtained with PEG alone or without additive.

3.2.3. Bulk deposits characterization

To support the electrochemical and ellipsometric

study, bulk copper coatings were obtained on a 2 cm

2

copper substrate under galvanostatic conditions (j /10

mA cm

2

), with a theoretical thickness of 10 mm.

Depending on the Cu

2

bath used, Cu

o

without any

additive, Cu

p

with PEG only or Cu

pc

with PEG and

Cl

, these deposits are, respectively, identified by I

o

, I

p

and I

pc

.

To determine the influence of the additives under

galvanostatic conditions, the E/t curves obtained from

the three solutions at 10 mA cm

2

were brought

together on Fig. 9. Without additive, the potential

rapidly stabilizes at /120 mV. Addition of additives

in the bath induces a more negative potential, showing

again the blocking effect of additives. Nevertheless, with

PEG alone in solution, the potential quickly evolves

towards that obtained without additive underlining the

release of the effect of PEG during the growth of the

deposit. On the other hand, in the presence of two

additives, the initial over-potential is preserved, con-

firming the efficiency of additives with time. Therefore,

the conclusions relative to the effects of the additives are

the same under potential or under current polarization.

Morphological examination of the deposits was

achieved by optical microscopy and AFM. In the case

of the additive-free solution, the sample I

o

appears like a

dull and powdery coating, with a poor aspect and coarse

grains (Fig. 10). AFM observations were not possible

because of the too high roughness of I

o

. The presence of

Fig. 8. Potentiostatic i /t transients for Cu

pc

bath: CuSO

4

0.3 M/2.2

M H

2

SO

4

/1 g l

1

PEG/50 ppm Cl

.

Fig. 9. Galvanostatic E /t transients obtained at 10 mA cm

2

from

several solutions: (Cu

o

): CuSO

4

0.3 M/2.2 M H

2

SO

4

; (Cu

p

) is Cu

o

/1

g l

1

PEG; (Cu

pc

) is Cu

o

/1 g l

1

PEG/50 ppm Cl

.

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4145

PEGS in the bath smoothes the deposit (Figs. 11 and

12). The quality of the I

p

and I

pc

samples is improved,

with a comparable grain size between these deposits but

reduced in comparison to I

o

. However, The I

p

deposit is

not uniform and presents some big protuberances on the

surface (fuzzy area in Fig. 11). We do not know the

reason for the presence of these protuberances, but they

are always on the surface when PEG is alone in solution

and they disappear in the presence of the two additives

(Fig. 12). In our opinion, they can represent the finger

print of the release effect of the additive with the

deposition time, already mentioned, when PEG is alone

in solution. Some analyses have been made by AFM.

For I

p

, the size of crystallites varies from 1 to 6 mm, in

function of the analyzed zone. The roughness of the

surface is almost 0.6 mm. In the case of I

pc

, the AFM

result is shown in Fig. 12b. The micro-structure of the

coating is obvious with large grains (3/6 mm), put on a

compact and thin under-layer (crystallite size about 1

mm). In comparison to the results obtained from Cu

p

solution, the mean roughness is closed but reduced in a

significant way to 0.5 mm. The protuberances obtained

on I

p

represent the major difference between I

p

and I

pc

deposits, respectively, obtained with PEG or PEG/

Cl

, while the roughness of the two deposits is

approximately the same (only slightly smaller for I

pc

).

To characterize the influence of the additives on the

crystallographic structure of the deposits, XRD patterns

were made. Fig. 13 presents the diffractograms obtained

for the bare copper substrate and for the three deposits.

The experimental diffractograms were compared with

the powder standard file JCPDS (vertical line on the

figure) to display preferential orientations. All the

patterns are characteristics for a pure crystalline fcc

copper, with sharp peaks. However, there are some

noticeable differences in intensity with regards to the

powder spectrum. Without additive, the I

o

sample

Fig. 10. Optic micrograph of the sample I

o

(g/600). I

o

is obtained on

Cu substrate, at 10 mA cm

2

from Cu

o

solution: CuSO

4

0.3 M/2.2 M

H

2

SO

4

.

Fig. 11. Optic micrograph of the sample I

p

(g/600). I

p

is obtained on

Cu substrate, at 10 mA cm

2

from Cu

p

solution: CuSO

4

0.3/2.2 M

H

2

SO

4

/1 g l

1

PEG.

Fig. 12. (a) Optic micrograph of the sample I

pc

(g/600), obtained at

10 mA cm

2

from Cu

pc

bath: CuSO

4

0.3/2.2 M H

2

SO

4

/1 g l

1

PEG/50 ppm Cl

. (b) AFM 3D image of the sample I

pc

(10/10

mm). I

pc

is obtained on Cu substrate, at 10 mA cm

2

from Cu

pc

solution: CuSO

4

0.3/2.2 M H

2

SO

4

/1 g l

1

PEG/50 ppm Cl

.

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4146

presents the same (220) preferential orientation as the

bare substrate that differs from the more intense (111)

peak of the powder spectrum. In this case, the coating

seems to follow the substrate texture. With PEG, there is

a decrease of the (220) peak on behalf of the (111) peak.

This phenomenon is even more marked when both

additives are present in solution. All the patterns keep

their textural aspect.

4. Conclusion

Electrochemical methods supplied by non-electroche-

mical investigations were used to have an insight in the

mechanism of action of PEG and Cl

/PEG during

copper electrodeposition. The electrochemical evalua-

tion made on the proton reduction showed an adsorp-

tion of the additives on the copper surface. However,

ellipsometric and electrochemical results suggested that

this adsorption was obvious under cathodic polariza-

tion. These additives promoted a shift of deposition

potential to more negative values during copper deposi-

tion. The copper reduction process was then hindered

and a decrease in potential value was required.

PEG on its own, was not able to produce a bright

coating, owing to the release effect during the copper

growth. The addition of small amounts of Cl

to the

copper/PEG electrolyte had a substantial effect on the

polarization curves, with changes in deposition mechan-

ism. The nucleation mechanism of Cu

2

on the copper

substrate was no more involved, probably due to a

bridging effect of Cl

. In that case, the influence kept

on with time, showing a synergetic effect between the

two additives. This resulted in a quite good compact

copper deposit, with disappearing of large grains

obtained from the additive-free bath, and protuberances

obtained with PEG alone in solution. The additive

effects were also shown by XRD experiments, the

structure of the coating being modified in presence of

additives.

Complementary results obtained by alternative cur-

rent methods should improve the knowledge in the

action of these additives mechanism.

Acknowledgements

We thank Professor J. Crousier, who initiated this

work, for various and helpful discussions.

References

[1] J. Lipkowski, P.N. Ross, Adsorption of Molecules at Metal

Electrodes, VCH Publishers, New York, Weinheim, Cambridge,

1992.

[2] W. Plieth, Electrochim. Acta 37 (1992) 2115.

[3] L. Oniciu, L. Muresan, J. Appl. Electrochem. 21 (1991) 565.

[4] T.C. Franklin, Plat. Surf. Finish. 4 (1994) 62.

[5] S. Trasatti, Electrochim. Acta 37 (1992) 2137.

[6] US Patents: 3 267 010 (1966); 3 328 273 (1967); 3 288 690 (1966).

[7] E. Yung, L. Romankiw, J. Electrochem. Soc. 136 (1989) 756.

[8] D. Stoychev, C. Tsvetanov, J. Appl. Electrochem. 26 (1996) 741.

[9] L. Mirkova, S. Rashkov, J. Appl. Electrochem. 24 (1994) 420.

[10] J.D. Reid, A.P. David, Plat. Surf. Finish. 74 (1987) 66.

[11] J. Steppan, L. Hall, J. Roth, J. Electrochem. Soc. 138 (1991) 2635.

[12] J. Healy, D. Pletcher, M. Goodenough, J. Electroanal. Chem. 338

(1992) 155.

[13] J. Healy, D. Pletcher, M. Goodenough, J. Electroanal. Chem. 338

(1992) 167.

[14] D. Stoychev, I. Vitanova, S. Rashkov, T. Vitanov, Surf. Technol.

7 (1978) 427.

[15] G. Hope, G. Brown, D. Schweinsberg, K. Shimizu, K. Kobayashi,

J. Appl. Electrochem. 25 (1995) 890.

Fig. 13. XRD patterns for the bare Cu substrate and the Cu deposits (I

o

, I

p

, I

pc

) obtained at 10 mA cm

2

from several baths: I

o

is from Cu

o

bath:

CuSO

4

0.3/2.2 M H

2

SO

4

. I

p

is from Cu

p

bath: CuSO

4

0.3/2.2 M H

2

SO

4

/1 g l

1

PEG. I

pc

is from Cu

pc

bath: CuSO

4

0.3/2.2 M H

2

SO

4

/1 g l

1

PEG/50 ppm Cl

.

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4147

[16] J. Kelly, C. Tian, A. West, J. Electrochem. Soc. 146 (1999) 2540.

[17] J. Kelly, A. West, J. Electrochem. Soc. 145 (1998) 3472.

[18] J. Kelly, A. West, J. Electrochem. Soc. 145 (1998) 3477.

[19] A.K.N. Reddy, J.OM. Bockris, in: E. Passaglia, R.R. Stromberg,

J. Kruger (Eds.), Ellipsometry in the Measurement of Surfaces

and Thin Films, Symposium Proceedings, Whashington, 1963, US

Department of Commerce, National Bureau of Standards Mis-

cellaneous Publication 256, US Government Printing Ofce,

Washington, DC, 1964.

[20] W. Paik, M.A. Genshaw, J.O.M. Bockris, J. Phys. Rew. 74 (1970)

4266.

[21] D. Geaglehole, B. Webser, S. Werner, J. Colloids Interf. Sci. 202

(1998) 541.

[22] G. Sandmann, W. Plieth, G.I. Lacconi, M. Lopez Teijelo, Mater.

Sci. Forum Vols. 289/292 (1998) 465.

[23] T. Arnebrant, K. Backstro m, B. Jo nsson, T. Nylander, J. Colliods

Interf. Sci. 128 (1989) 303.

[24] F. Tiberg, M. Landgren, Langmuir 9 (1993) 927.

[25] R.M.A. Azzam, N.M. Bashara, Ellipsometry and Polarized Light,

Elsevier, Amsterdam, 1989.

[26] G. Gunawardena, G. Hills, I. Montenegro, J. Electroanal. Chem.

184 (1985) 357.

[27] I. Bimagrha, J. Crousier, Mater. Chem. Phys. 21 (1989) 109.

[28] J. Amblard, M. Froment, G. Maurin, D. Mercier, E. Trevisan-

Pikacz, J. Electroanal. Chem. 134 (1982) 345.

[29] S. Fletcher, C.S. Halliday, D. Gates, M. Wetcott, T. Lwin, G.

Nelson, J. Electroanal. Chem. 159 (1983) 267.

[30] A.J. Bard, L.R. Faulkner, Electrochimie, Principes, Methodes et

Applications, Masson, Paris, New York, Barcelona, 1983.

[31] L. Vracar, D.M. Drazic, J. Electroanal. Chem. 339 (1992) 269.

[32] T. Murakawa, S. Nagura, N. Hackerman, Corros. Sci. 7 (1967)

79.

[33] T.C. Franklin, Surf. Coat. Technol. 30 (1987) 415.

L. Bonou et al. / Electrochimica Acta 47 (2002) 4139/4148 4148

You might also like

- Effecto AdditivesDocument7 pagesEffecto AdditivesPaz BalladaresNo ratings yet

- Cifuentes LDocument9 pagesCifuentes LPaz BalladaresNo ratings yet

- Effecto AdditivesDocument7 pagesEffecto AdditivesPaz BalladaresNo ratings yet

- 20 Effect of Plating Mode, Thiourea and Chloride On The Morphology of PDFDocument13 pages20 Effect of Plating Mode, Thiourea and Chloride On The Morphology of PDFPaz BalladaresNo ratings yet

- 160 Functions of Chloride in Copper-Refining Electrolyte PDFDocument12 pages160 Functions of Chloride in Copper-Refining Electrolyte PDFPaz BalladaresNo ratings yet

- 7 Application of Atomic Force Microscopy and Scaling AnalysisDocument6 pages7 Application of Atomic Force Microscopy and Scaling AnalysisEugenia Araneda HernandezNo ratings yet

- 175 Additive Behavior During Copper ElectrodepositionDocument6 pages175 Additive Behavior During Copper ElectrodepositionPaz BalladaresNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Organic Mind MapDocument37 pagesOrganic Mind Mapkamalia8980% (5)

- 18 NTU TE 0060 - PDFDocument10 pages18 NTU TE 0060 - PDFFahad HussainNo ratings yet

- 0653 m18 QP 22Document16 pages0653 m18 QP 22Thao TrinhNo ratings yet

- Determination of Electron AffinitiesDocument35 pagesDetermination of Electron Affinitiesnena100% (1)

- Disha Class 12 Chemistry Sample Paper For Term 1Document145 pagesDisha Class 12 Chemistry Sample Paper For Term 1Shivansh Singh0% (1)

- WP Measuring Nitration, Oxidation and Sulfation 2017Document3 pagesWP Measuring Nitration, Oxidation and Sulfation 2017HARVY19No ratings yet

- Photoelectrochemical Cell Design, Efficiency, Definitions, Standards, and ProtocolsDocument35 pagesPhotoelectrochemical Cell Design, Efficiency, Definitions, Standards, and ProtocolsLê Văn TrungNo ratings yet

- XI Chemistry Chapterwise Advanced Study MaterialDocument537 pagesXI Chemistry Chapterwise Advanced Study MaterialregisNo ratings yet

- Ascorbic Acid Radical ScavengingDocument16 pagesAscorbic Acid Radical ScavengingJacek KoziorowskiNo ratings yet

- Redox Equilibria: K. DonaldsonDocument83 pagesRedox Equilibria: K. DonaldsonEmily ZhengNo ratings yet

- Corrosion Inhibition of Mild Steel in Hydrochloric Acid and Sodium Lauuryl SulphateDocument7 pagesCorrosion Inhibition of Mild Steel in Hydrochloric Acid and Sodium Lauuryl Sulphatebkpadhi815No ratings yet

- Mid Term Examination November 2014 II Puc ChemistryDocument2 pagesMid Term Examination November 2014 II Puc ChemistryRahul PNo ratings yet

- Lekha Chemistry Pyqs Jee 2021Document634 pagesLekha Chemistry Pyqs Jee 2021LEKHANo ratings yet

- Food Microbiology and Parasito - Mrs - Dorothy Bundi - 15156Document172 pagesFood Microbiology and Parasito - Mrs - Dorothy Bundi - 15156Edward MakemboNo ratings yet

- Formulae and Oxidation NumbersDocument14 pagesFormulae and Oxidation NumbersDoc_CrocNo ratings yet

- General and Inorganic ChemistryhandoutDocument25 pagesGeneral and Inorganic ChemistryhandoutleapapayNo ratings yet

- Basic Concepts of Corrosion Part 1Document75 pagesBasic Concepts of Corrosion Part 1Araasu EgambaramNo ratings yet

- 0705-Enthusiast Score-II - (TEAS, T-AS, TOAS, TNAS, TRAS & TMAS) - Hs.Document19 pages0705-Enthusiast Score-II - (TEAS, T-AS, TOAS, TNAS, TRAS & TMAS) - Hs.Prashant BhattNo ratings yet

- 4.uses of Metals - 1-32 For StudentsDocument13 pages4.uses of Metals - 1-32 For StudentsnergisalihpasaogluNo ratings yet

- Hapter: RedoxDocument5 pagesHapter: RedoxGaryNo ratings yet

- PDF DocumentDocument4 pagesPDF DocumentCHENFEI LIUNo ratings yet

- 2011 Chemistry ExamDocument24 pages2011 Chemistry Examduy_ScdNo ratings yet

- Engineering Chemistry 2019-20 Study MaterialDocument125 pagesEngineering Chemistry 2019-20 Study MaterialG23 nagaleekar nikithaNo ratings yet

- Unit 1 ElectrochemistryDocument25 pagesUnit 1 ElectrochemistrymaheshkancherlajobNo ratings yet

- Electrochem. Solid State Lett. 2002 Chae C64 6Document3 pagesElectrochem. Solid State Lett. 2002 Chae C64 6Anonymous SIG8xwx9ANo ratings yet

- Laporan SYNTHESIS OF TERTAAMINE COPPER (II)Document9 pagesLaporan SYNTHESIS OF TERTAAMINE COPPER (II)Lies LestariningtiasNo ratings yet

- Herbicide Mechanism of Action Summary by HRAC and WSSADocument6 pagesHerbicide Mechanism of Action Summary by HRAC and WSSAMatheus NogueraNo ratings yet

- Chemistry General Objectives: 1. Separation of Mixtures and Purification of Chemical SubstancesDocument13 pagesChemistry General Objectives: 1. Separation of Mixtures and Purification of Chemical SubstancesSara alnaserNo ratings yet

- Drug DegradationDocument42 pagesDrug DegradationVarsha Shende Khobragade100% (6)

- Abundances of The IsotopesDocument9 pagesAbundances of The IsotopesNeah DizonNo ratings yet