Professional Documents

Culture Documents

Elements of Masonry Design

Uploaded by

dyetCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elements of Masonry Design

Uploaded by

dyetCopyright:

Available Formats

Scranton, Pa.

El ements of

Masonr y Desi gn

PREPARED ESPECIALLY FOR HOME STUDY

By

I. C. S. STAFF

IN COLLABORATION WITH

C. E. OROURKE, C. E.

PROFESSOR OF STRUCTURAL ENGINEERING, CORNELL UNIVERSITY

3404 EDITION 1

Copyright, 1936, by I n t e r n a t i o n a l T e x t b o o k Co m p a n y . Copyright in Great

Britain. All rights reserved

Printed in U. S. A.

3404

ELEMENTS OF MASONRY DESIGN

Serial 3404 Edition 1

STRESSES IN MASONRY

INTRODUCTION

1. Classes of Masonry.A structure that is built either of

stone or of manufactured stone-like materials, such as concrete,

brick, or hollow clay tile, is known as a masonry structure.

Thus, masonry may be classified according to the materials

used as stone masonry, concrete masonry, brick masonry, or

hollow-tile masonry.

In stone masonry, blocks of stone of comparatively large

size are fitted in place and are usually held together by port-

land-cement mortar or cement-lime mortar. Although the

blocks used in stone masonry have a wide variety of shapes

and sizes, all stone masonry may be divided into two general

classes, namely, ashlar and rubble. The masonry is classed

as ashlar when the stones are cut so accurately and are laid so

carefully that the mortar joints are not more than \ inch thick.

The stone blocks in rubble masonry either are of irregular

shape or are not laid with sufficient accuracy to meet the

requirements of ashlar.

Concrete consists of comparatively small particles of crushed

stone, gravel, or blast-furnace slag that are bound together by

cement mortar. Concrete may be either plain or reinforced

with steel bars or other shapes.

Brick masonry, or brickwork, is similar to ashlar masonry,

but the bricks are much smaller than the stone blocks and the

thickness of the mortar joints usually does not exceed J inch.

Also, in brick masonry, lime mortar, as well as portland-

COPYRIGHTED BY I NTERNATIONAL TEXTBOOK COM PA N Y. ALL RIGHTS RESERVED

2 ELEMENTS OF MASONRY DESIGN

cement and cement-lime mortar, is employed. Brick masonry

may be reinforced with steel bars, in which case it is called

reinforced brick masonry.

Concrete blocks or clay-tile blocks laid in mortar are fre

quently used for walls in buildings. Such blocks are made

hollow in order to reduce their weight and to provide an air

space in the walls. The faces of the blocks are essentially

plane and rectangular, but the surfaces may be grooved to

improve the adhesion of the mortar.

2. Comparison of Masonry With Other Structural Mate

rials.It is comparatively easy to give a masonry structure a

pleasing appearance. Masonry structures that are built of

good material, and are properly designed and erected, are very

durable and fairly fireproof. On the other hand, metal struc

tures are subject to rust and timber structures are subject to

decay, and structures of either material are seriously affected

by fire. Masonry, unlike steel and timber, is not suited for

resisting tensile stresses and should preferably be subjected

only to direct compression. Also, to carry a given compressive

stress safely, a masonry member must be considerably larger

than a metal one and somewhat larger than a timber one.

3. Uses of Different Kinds of Masonry.Concrete is

usually the most economical kind of masonry for retaining

walls, bridge piers, foundations, and tunnels. The facility

with which concrete is placed accounts to a large extent for its

extensive usage. Stone masonry is employed where special

architectural treatment is desired or where permanence is of

vital importance. In localities near stone quarries where

suitable material for stone masonry is available, the cost of

preparing and laying large blocks of stone is often less than the

cost of making and placing concrete. Brickwork is used

extensively for the walls of buildings and for special purposes,

such as the lining of large sewers. Concrete blocks and terra

cotta blocks are especially adapted to wall and floor construc

tion.

ELEMENTS OF MASONRY DESIGN 3

WORKING STRESSES FOR MASONRY

4. Introductory Remarks.In the design of any masonry

member, it is assumed that the masonry is monolithic; that is,

the entire member is treated as a single piece of homogeneous

material. The same general method of procedure is followed

for all classes of masonry without reinforcement. Except for

the explanations dealing with reinforced brick masonry at the

end of this text, the general principles that are here presented

apply to plain concrete, stone masonry, unreinforced brick

work, and concrete-block and terra-cotta masonry. Rein-

forced-concrete design is taken up in separate texts.

5. General Characteristics of Masonry.Masonry is fairly

strong in compression, but is weak in shear and has practically

no strength in tension. Nevertheless, masonry is sometimes

used in walls subjected to horizontal thrust and has to resist

shear, or it is employed to span an opening and is subjected to

both flexural and shearing stresses. When masonry is to

resist flexural stresses, it should be laid with special care. It

should not be subjected to direct tension.

The strength of masonry depends on the quality of the

materials used and on the workmanship, or the care with which

the materials are handled and placed. Ordinarily, the blocks in

masonryincluding the coarse aggregate in concretehave

more strength than the mortar, and therefore the strength of

the mortar and the adhesion between the blocks and the mortar

are important factors. The quality of concrete is generally

specified by its ultimate compressive strength at the age of 28

days. For example, concrete which has a crushing strength of

2,000 pounds per square inch at the age of 28 days is called

2,000-pound concrete.

6. Allowable Compressive Strength of Masonry.Average

values of the strength of masonry under various kinds of stress

are merely rough approximations and may differ considerably

from the values obtained in a test of a particular specimen.

In most of the larger cities in the United States, the allowable

pressures on masonry are specified by the local building laws,

4

ELEMENTS OF MASONRY DESIGN

the values differing widely in the various cities. When the

design is not governed by any law and there are no definite

specifications concerning the strength of the masonry to be

used, the working unit pressures given in Table I may be

employed. These values will be used in all problems in this

text.

TABLE I

WEIGHTS AND ALLOWABLE PRESSURES FOR MASONRY

Type of Masonry

Allowable Pressure, in Pounds

per Square Inch Weight

in

Pounds

per

Cubic

Foot

Portland-

Cement

Mortar

Cement-

Lime

Mortar

Lime

Mortar

Brickwork....................................... 175 140 75

120

Ashlar stonework:

Granite........................................ 800 640 400

168

Limestone................................... 500 400 250

168

Sandstone................................... 400 320 160

144

Rubble stonework:

Granite........................................ 140 100 156

Limestone................................... 140 100 156

Sandstone................................... 140 100 132

Hollow blocks or tiles:

Concrete...................................... 80 70 72

Terra-cotta................................. 80 70 . - . 60

Concrete, 2,000-pound at

28 days........................................ 500 144

7. Allowable Shearing and Tensile Strength of Masonry.

For shear without diagonal tension, the allowable shearing unit

stress in stone masonry may be assumed to be about one-

quarter of the allowable compressive unit stress. The safe

strength of concrete in shear is generally taken as about 6 per

cent of the ultimate compressive strength at the age of 28 days.

In determining the resistance to diagonal tension, the safe shear

ing strength of stone masonry may be assumed as about 30

pounds per square inch, and that of concrete as 2 per cent of

the ultimate 28-day compressive strength.

ELEMENTS OF MASONRY DESIGN 5

The tensile strength of stone masonry should not be taken

as more than 15 pounds per square inch when portland-cement

mortar is used nor more than 5 pounds when lime mortar is

employed. However, many engineers disregard entirely the

tensile strength of stone masonry, and use a solid block of

stone or concrete whenever transverse stresses are to be resisted,

as in spanning openings. The tensile strength of 2,000-pound

concrete may be taken as 40 pounds per square inch.

TABLE II

ALLOWABLE STRESSES IN STONE BLOCKS

Allowable Stresses, in Pounds per Square Inch

Material

Bearing Flexure Shear

Granite........... 1,000 150 200

Limestone___ 700 125 150

Sandstone.. . . 400 75 150

8. Allowable Stresses for Solid Blocks of Stone.A

masonry member that is subjected primarily to flexural stresses

generally consists of a single block of stone or concrete. In

some cases, the bearing strength of the block is also important.

Average values of the allowable stresses for single blocks of

stone are given in Table II; those for concrete have been

specified in the preceding articles.

MASONRY PIERS

PRACTICAL CONSIDERATIONS

9. Limitations of Masonry Piers.Brickwork, stone

masonry, plain concrete, or hollow-block masonry, or a com

bination of two or more of these materials, is frequently used

for the construction of short masonry piers that carry central

loads. When the load on a masonry pier has considerable

eccentricity or the height of the pier is comparatively great,

reinforced masonry should preferably be used.

Brick is the material that is generally used in buildings for

masonry piers where metal reinforcement is not required.

6 ELEMENTS OF MASONRY DESIGN

Concrete is just as satisfactory as brick from the standpoint of

service, but the cost of forms often makes the use of plain con

crete uneconomical for piers. It is commonly specified that

isolated piers in the interior of a building should not be built

of stone masonry, because of the tendency of natural stone to

Spall under great heat; and that in fireproof or semi-fireproof

construction isolated piers should not be built of hollow-block

masonry.

The provisions of the various codes in regard to the design

of masonry piers differ greatly, but the recommendations in the

following articles may be considered to represent good practice.

10. Causes of Failure of Masonry Piers.If a very short

block of plain concrete is subjected to sufficient pressure, it may

fail by crushing, but a plain-concrete pier whose height exceeds

its width usually fails by shearing along an inclined plane. A

brick pier generally fails by longitudinal splitting and sidewise

bulging of the masonry, as a result of failure of the individual

bricks either in tension or in flexure and the pulling apart of

the joints; neither the brick nor the mortar is crushed. For

best results, the mortar joints should be as thin as possible and

of uniform thickness. Also, the bricks should preferably be

laid on edge and the vertical joints should be continuous

through several courses instead of being staggered in each two

adjacent courses. No experimental data are available on the

crushing strength of stone masonry under the conditions

existing in an actual structure. However, the mortar is known

to be the weakest element in good ashlar masonry, and the

strongest stonework is obtained by using large blocks and thin

joints.

11. Brick Piers.A brick pier whose height is not more

than six times its least width may be considered a short post;

therefore, no reduction in the allowable compressive unit

stress, given in Table I, need be made because of the effect of

the height. For piers whose height exceeds six times the

width, the allowable unit stress should be reduced. A good

formula for determining the reduced unit stress is

ELEMENTS OF MASONRY DESIGN 7

f - f ' ( 125- T o V

in which / = allowable unit stress for high pier, in pounds per

square inch;

/ i = allowable unit stress for masonry, as given in

Table I, in pounds per square inch;

h = height of pier, in inches;

6= least width of pier, in inches.

The least width of a brick pier should never be less than

one-twelfth of the height; in the case of an isolated pier, it

should not be less than one-tenth

of the height. Also, no pier over

8 feet high should be less than

12 inches square in cross-section.

Standard bricks are 8 inches long

and 3f inches wide and the mortar

joints between bricks are generally

about \ inch thick, but the width

of brickwork varies somewhat. In

estimating the strength of brick

work, it is best to assume that the width is a multiple of 4 inches.

But, in considering the weight of brickwork or the space occu

pied by it, the actual width should be determined as closely

as possible.

Basemen? F l oor

Fi g . 1

Ex a mpl e .If a pier constructed of brick laid in portland-cement

mortar is to be 20 inches square in cross-section and is to have a height

of 12 feet, what allowable unit stress should be used?

h 12X12

So l u t i o n .The ratio of the height to the width is - = , = 7.2.

Since this is greater than 6, the allowable unit stress should be less than

the value 175 lb. per sq. in. given in Table I for this class of masonry.

Thus,

/ = / i ( l . 2 5 gg|) =175X ( l. 25^ X 7 . 2 ) =156 lb. per sq. in. Ans.

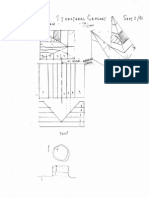

12. Plain-Concrete Piers.In Fig. 1 is illustrated a con

dition in building construction for which a plain-concrete pier

is commonly used. Here, the footing is some distance below

the basement floor, and the plain-concrete pier, or pedestal, p

8 ELEMENTS OF MASONRY DESIGN

is introduced between the footing and the reinforced-concrete

column that is above the floor. The least width of such a

pedestal should not be less than one-third of its depth or height,

because the pedestal transfers the total column load to the

footing and is therefore heavily loaded.

Where a plain-concrete pier is used for any other purpose,

the least width should not be less than one-quarter of the

height.

13. Stone Piers.Stone piers are satisfactory for the sup

port of heavy loads when good strong stone is laid in courses

covering the entire cross-section. The top and bottom courses

should be bedded true and even, the thickness of the joints

should not be more than inch, and the mortar should be kept

back 1 inch from the face of the pier to prevent spalling, or

breaking off, of the edges of the blocks.

The least width of a pier of ashlar masonry should not be

less than one-tenth of the height; and, where the height exceeds

six times the width, the allowable unit stress should be deter

mined by the formula of Art. 11. The width of a rubble pier

should be not less than one-fifth of its height nor less than 20

inches.

PIERS WITH CENTRAL LOADS

14. Unit Stress for Central Load.When the resultant load

on a pier is applied centrally, the stress in the pier is assumed

to be uniformly distributed over the area of the cross-section.

Thus, p

H r (I)

in which/=unit stress, in pounds per square inch;

P = resultant load on pier, in pounds;

A = cross-sectional area of pier, in square inches.

Piers of brick, stone, or hollow-block masonry are usually

square or rectangular in section, and plain-concrete piers are

square, rectangular, or circular. If the section of the pier is a

rectangle whose dimensions in inches are denoted by b and d,

the area is bd and p

ELEMENTS OF MASONRY DESIGN 9

When the actual unit stress in a pier is less than the allow

able value for the material, the pier is considered to be safe.

Ex a mpl e .A vertical load of 350,000 pounds, in addition to the

weight of the pier itself, is to be applied at the center of a 20" X24" rectan

gular pier 8 feet high that is built of granite ashlar laid in portland-cement

mortar. If the allowable unit stress is as given in Table I, is the pier

satisfactory?

So l u t i o n .The unit stress due to the load of 350,000 lb. is, by

formula 2,

* P 350,000 0 1U

20X24 = 729lb- perSq- m'

The unit stress, in lb. per sq. in., produced at the base of the pier by its

own weight is the weight of a prism of masonry 1 sq. in., or sq. ft., in

cross-section and 8 ft. high. This stress is

-j-gX8X168 = 9 lb. per sq. in.

and the total stress is 729+9 = 738 lb. per sq. in.

8X12

The ratio of the height to the least width is =4. 8, which is less

than 6, and the safe unit stress is as given in Table I, or 800 lb. per

sq. in. Since this is greater than the actual unit stress, the pier is satis

factory. Ans.

15. Safe Central Load on Pier.The total central load

that can be supported safely by a pier is equal to the product

of the allowable unit stress for the material and the cross-

sectional area of the pier. If / represents the allowable unit

stress, and the other letters have the same meanings as in the

preceding article,

P=fA (1)

or, for a rectangular section,

P=fbd (2)

Ex a mpl e .A pier built of brick laid in lime mortar is 16 inches square

and 10 feet high. What central load can the pier safely support, in

addition to its own weight, if the allowable stress for brickwork is as

specified in Table I?

h 10 VI2

So l u t i o n .The ratio of the height to the width is ^ =7.5,

and the allowable unit stress should be found by the formula of Art. 11.

From Table I, the value o f / i for brick in lime mortar is 75 lb. per sq. in.

10 ELEMENTS OF MASONRY DESIGN

Hence,

/ = / i ( 1 - 2 5 - ^ f ) =75X ( l . 2 6 - ^ X 7 . 5 ) =66 lb. per sq. in.

The unit stress produced by the weight of the pier itself is j ^ - X 10

X120 = 8 lb. per sq. in., and the remaining unit stress is 66 8 = 58 lb.

per sq. in.

In formula 2, / = 58 lb. per sq. in. and b = d16 in.; hence, the safe

superimposed load on the pier is

P = / M = 58X16X16 = 14,850 lb. Ans.

16. Design of Pier Carrying Central Load.The required

cross-sectional area of a pier carrying a central load is found by

dividing the load by the safe unit stress. Thus,

The ratio of the height to the least width of the pier must not

be excessive. Also, for a brick pier, the dimensions must be

multiples of 4 inches. In case the height of a brick or stone

pier is found to exceed six times its width, allowance must be

made for the reduced unit stress. Since the value of / in the

formula of Art. 11 depends on the width b, which is not known

until the required area is established, it is necessary first to

determine the area and dimensions on the assumption that the

ratio of the height to the width is less than 6. However, the

value of / used for the first trial should be taken as the differ

ence between the allowable unit stress for a short pier and the

unit stress produced by the weight of the pier itself. Then, if

h

the ratio 7- exceeds 6, the corrected total allowable unit stress

b

is computed by the formula of Art. 11, and this value is reduced

to allow for the weight of the pier. The area is then deter

mined for the net value thus established and, if necessary, the

section is redesigned. If the least width is changed, the cal

culations for the allowable unit stress / and the required

cross-sectional area A should be repeated.

E x a m p l e 1.A circular pier o f 2,000-pound concrete, 6 feet high, is

to carry a central load of 180,000 pounds. What is the required diameter,

to the next larger inch?

ELEMENTS OF MASONRY DESIGN 11

So l u t i o n .-From Table I, the allowable unit stress is 500 lb. per sq.

in., and the stress due to the weight of the pier is j p -X6X144 = 6 lb. per

sq. in. Then, the first trial area of the cross-section is taken as

, P 180,000

A = - r = - =364 sq. in.

/ 494 n

V

364

jjygg = 21.5, say 22 in. For this size, the

6X12

ratio of the height to the diameter is = 3.3, which is less than 4.

Therefore, the diameter of 22 in. is satisfactory. Ans.

Ex a mpl e 2.A pier of brick laid in portland-cement mortar is to

carry a central load of 32,000 pounds. If the height of the pier is to be

9 feet 6 inches and its cross-section is to be square or nearly square, what

should be the dimensions of the cross-section?

So l u t i o n .First, the approximate cross-sectional area is determined

by assuming that the allowable unit stress is 175 r r j X 9.5X120 = 175

8 = 167 lb. per sq. in. Then,

. P 32,000 lno

A = j = ~ - = lQ2 sq. in.

h 114

A 12"X16" pier has an area of 192 sq. in., but for this size -^= ^ - = 9.5

and, by the formula of Art. 11,

/ = / i ( l . 2 5 - i D =175X ( l . 2 5 - | j X 9 . 5 ) = 136 lb. per sq. in.

A more accurate value of the required area is

. 32,000

^=TM--ir250sq- in-

and a 12"X16" pier is too small. A 16"X16" pier will obviously be

h

satisfactory, as its area is 256 sq. in., and the ratio r will be reduced to

114

-jjr = 7.1 and the tequired area will be much less than 250 sq. in. Hence,

the pier should be 16 in. square. Ans.

EXAMPLES FOR PRACTICE

1. A pedestal of 2,000-pound concrete that is 3 feet high and 24 inches

square in cross-section is required to support a central load of 280,000

pounds in addition to its own weight, (a) What unit stress is produced?

(5) Is the pier safe according to Table I? , f (a) 489 lb. per sq. in.

1(6) Yes

2. What superimposed central load can safely be placed on a 20-inch

square pier of limestone ashlar laid in portland-cement mortar, if the

height of the pier is 12 feet? Ans. 172,400 lb.

12 ELEMENTS OF MASONRY DESIGN

3. A rectangular pier of 2,000-pound concrete is to be 8 feet high and

30 inches wide. What should be its other dimension if it has to support

a central load of 500,000 pounds? Ans. 34 in.

4. A square pier built of brick laid in cement-lime mortar is to carry

a central load of 15,000 pounds. If the height of the pier is to be 8 feet

8 inches, what should be the dimensions of its cross-section?

Ans. 12 in. X 12 in.

PIERS WITH ECCENTRIC VERTICAL LOADS

17. Investigation for Unit Stress.A masonry pier is some

times subjected to an eccentric load, and the stress on the pier

is then not uniform. In Fig. 2 (a) is shown a part elevation,

and in view (b) a cross-section, of a rectangular pier subjected

to a load P that is eccentric in only one direction. As indi

cated in view (b), the load acts along the center line that is

parallel to the face AB of the

pier but has an eccentricity e

with respect to the center line

parallel to AD. The stress

produced in the pier by such

loading is the same that would

be produced by an imaginary

central load P and a bending

moment Pe.

a

a

2 ,

a

2

Fi g . 2

If the dimensions of the pier section are b and d, respectively,

the compressive unit stress due to the imaginary central load

p

would be This stress would be uniformly distributed over

ELEMENTS OF MASONRY DESIGN 13

the section, as represented by the area mnop in view (a). The

assumed bending moment Pe would produce flexural unit

stresses varying at a uniform rate from a maximum compres

sive unit stress at the edge BC to a maximum tensile unit stress

at the edge AD of the cross-section. These flexural unit

stresses are represented by the triangles fgo and hgp in view (a).

Since the section modulus of a rectangle is fed2, the flexural

unit stresses at the edges BC and AD are each equal to Pe-r-

6 Pb

A bd2=-nf- The total unit stress at any point in the section

far

P

is the resultant of the uniformly distributed stress and the

flexural unit stress at that point. Hence, the eccentric load

P produces at the edge BC, which is nearer to the load, a maxi-

Similarly, the minimum resultant stress which occurs at the

edge AD farther from the load, is

In these formulas/ = maximum unit stress, in pounds per

square inch, at edge of pier that is

nearer the load and perpendicular to

the direction of eccentricity;

P = eccentric load, in pounds;

b = dimension of pier section, in inches,

measured at right angles to eccentricity

of load;

d = dimension of pier section, in inches,

measured in direction of eccentricity;

e = eccentricity of load, in inches;

/ ' = minimum unit stress, in pounds per

square inch, at edge of pier that is

farther from the load and perpendicular

to the direction of eccentricity.

14 ELEMENTS OF MASONRY DESIGN

If the value of / ' for a particular loading is positive, the stress

throughout the pier is compressive, and only the stress / is of

interest in considering the strength of the pier. However, if

f is negative, the resultant stress at the edge of the section

farther from the load is tensile and, since masonry is much

stronger in compression than in tension, the stresses at both

edges of the section are important.

E x a m p l e .A masonry pier that is 20 in. X 24 in. in cross-section

supports a total resultant load, including its own weight, of 160,000

pounds, which acts midway between the 24-inch faces and at a distance of

9 inches from one of the 20-inch faces, or with an eccentricity of 3 inches

measured in the direction of the 24-inch dimension. Compute the maxi

mum and minimum unit stresses in the pier.

So l u t i o n .Since the eccentricity is parallel to the 24-inch dimension,

d = 24 in. and 6 = 20 in. Also, P = 160,000 lb. and e = 3 in. Then, by for

mula 1, the maximum unit stress is

, P / , . Ge\ 160,000^ / , . 6X3\ _00., .

f = Vd { 1 + d) = 20X24 X ( 1 + i r ) = 583 lb- per 0nly Sq- m-

By formula 2, the minimum unit stress is

160,000 / 6 X3\

20 X24 X { 24 )

= 83 lb. per sq. in.

Ans.

Ans.

In this case, the value of f is positive and, therefore, the minimum unit

Stress is compressive.

Fi g . 3

18. Under some conditions, the load on a pier may be

eccentric in both directions, as indicated in Fig. 3 (a), where

the rectangle ABCD represents the cross-section of a pier and

the load P has an eccentricity e\with respect to the center line

parallel to the edge AD and an eccentricity e2 with respect to

ELEMENTS OF MASONRY DESIGN 15

the center line parallel to AB. The loading in this case is

equivalent to a central load P, a bending moment Pe 1with

respect to the center line parallel to the face AD of the pier, and

a bending moment Pez with respect to the perpendicular center

line.

The central load would cause a uniformly distributed com-

P

pressive unit stress equal to . Because of the bending

moment Pei, there is a compressive unit stress of -r-jr- at the

bal

edge BC and a tensile unit stress of equal amount at the edge

AD. Similarly, the bending moment Pe2produces a compres-

sive unit stress of ,,2at the edge AB and a tensile unit stress

dtr

of like amount at the edge CD. The maximum resultant unit

stress in the section evidently occurs at the comer B, where

the stresses due to both bending moments are compressive.

The value of this resultant unit stress is or

in which / = maximum unit stress, in pounds per square inch,

at corner of pier that is nearest to load;

P = eccentric load, in pounds;

5 = one dimension of pier cross-section, in inches;

d = other dimension of pier cross-section, in inches;

ei = eccentricity of load, in inches, measured in direc

tion of dimension d;

ei = eccentricity of load, in inches, measured in direc

tion of dimension b.

The minimum resultant unit stress f occurs at the corner

A, where both bending moments produce tension, and this

stress may be computed by the formula

E x a m p l e .A 30-inch square pier supports a total load of 200,000

pounds applied 9 inches from one face and 14 inches from an adjacent

face. Determine the maximum and minimum unit stresses in the pier.

(1)

(2)

16 ELEMENTS OF MASONRY DESIGN

So l u t i o n .In formulas 1 and 2, P is 200,000 lb. and b and d are each

30 in. The distance from any face of the pier to the parallel center line

of the cross-section is 15 in., and the eccentricities of the load in directions

parallel to the faces of the pier are el = 15 9 = 6 in. and es=15 14 = 1

in. Therefore, the maximum unit stress is

The minimum unit stress is

P / 1_ 6 e , _ 6 f ?\ 200,000 / 6X6 6X1\

1 bd \ d b ) 30X30 X \ 30 30 /

= 89 lb. per sq. in.

and this stress is 89 lb. per sq. in., tension. Ans.

19. Principle of Middle Third.Whenever the eccentricity

e in formula 2, Art. 17, is less than the value of is less than

o a

unity and the minimum unit stress f is then positive. Con

versely, when e is greater than the value of ^ is greater than

unity and f is negative. Thus, where the load on a pier is

eccentric in only one direction, the pier will be entirely in com

pression if the eccentricity is less than and will be partly in

d

tension if the eccentricity is greater than A point that is at

d ^

a distance of 7-. from the center line of the cross-section is at the

o

edge of the middle third of the section, and the principle just

developed may be expressed as follows:

When a load on a rectangular pier is eccentric in only one

direction and lies within the middle third of the cross-section, the

stresses are entirely compressive; if the load is applied outside the

middle third, there is tension near the face of the pier that is

farther from the load and perpendicular to the direction of the

eccentricity.

= 533 lb. per sq. in., compression. Ans.

20. Kern.In case the load on a pier is eccentric in both

directions, there will be no tension in the pier if the load lies

ELEMENTS OF MASONRY DESIGN 17

within the so-called kern of the section, which is a certain area

near the axis. For the rectangular section A BCD in Fig. 3

(6), the kern is the shaded rhombus EFGH, whose vertexes E

and G are at the ends of the middle third of the center line that

is parallel to the face AB, and whose vertexes F and H are at

the ends of the middle third of the perpendicular center line.

If the load acting on the section is applied at any point within

the kern, the entire section will be in compression; but, if the

load is applied outside the kern, there will be tension in some

parts of the section.

21. Limitation of Tensile Stress.The tensile strength of

the masonry is usually neglected in the design of masonry

members, such as piers, that are intended primarily to resist

compressive stresses. Therefore, it is usually considered good

practice to have the resultant load on a masonry pier lie within

the kern of the cross-section.

In the case of a rectangular pier carrying a load that is

eccentric in only one direction, the load should preferably be

applied within the middle third of the cross-section. When

such a load is applied exactly at the edge of the middle third,

the eccentricity e is equal to J d. If this value for e is substi

tuted in formula 2, Art. 17, it is found that the minimum unit

stress / ' is equal to zero; also, from formula 1, Art. 17, the

maximum unit stress is

Hence, the maximum unit stress for a load acting at the edge

of the middle third is just twice as great as the stress ior an

equal central load.

22. Design of Eccentrically Loaded Pier.The usual pro

cedure in the design of a masonry pier that is to carry an eccen

tric load is to assume a probable section and then to investigate

its suitability and, if necessary, to make the required changes

in the assumed dimensions. If it is desired to avoid tension in

the pier, the load should lie within the middle third of the

section, and the dimension that is in the direction of the eccen

tricity should not be less than six times the eccentricity. Experi

18 ELEMENTS OF MASONRY DESIGN

ence in masonry design and familiarity with designs used under

similar conditions are valuable aids in selecting the first section

to be investigated. However, when information is not avail

able as a guide, it is best to compute first the required area

for a central load and to assume for the first investigation a

section of somewhat larger area, as illustrated in the following

examples.

Ex a mpl e 1.A square pier of limestone ashlar laid in portland-

cement mortar is 12 feet high and is to support a superimposed load of

200,000 pounds applied 4 inches from the axis of the pier and on a center

line perpendicular to one face of the pier. Determine the required width,

so that there will be no tension in the masonry.

So l u t i o n .As stated in Art. 13, the width of an ashlar pier should

not be less than one-tenth of the height, or ~ X 1 2 = 1.2 ft., say 15 in.

Also, to avoid tension in the masonry, the width should not be less than

six times the eccentricity, or 6X4 = 24 in.

The allowable unit stress, exclusive of that due to the weight of the

pier, is 500^j j X 12X168 = 480 lb. per sq. in. and the required area

for a central load of 200,000 lb. is

A

P

f

200,000

486

= 412 sq. in.

For a load applied at the edge of the middle third of the section, the

maximum unit stress is twice the average value; therefore, in the limiting

case for no tension in the pier, the required area is 2X412 = 824 sq. in.,

which can be provided by a 29"X29" section. As the 29-in. width of this

section is somewhat greater than the width of 24 in., for which the load

would be applied at the edge of the middle third, the required area will

be a little less than 824 sq. in. and a 28"X28" pier will be tried. From

formula 1, Art. 17, the maximum unit stress for this section would be

, f 6e\ 200,000 / 1 . 6X4\

f ~bd ( 1 + j ) = T8X28 X ( 1 + ^ 8 - ) = 474 lb< per Sq- m-

h 12X12

Also, -r=jrs = 5.1, which is less than 6, and no reduction in the allow-

b 28

able unit stress of 486 lb. per sq. in. need be made. It will be found that

a pier with a section 27 in. square is too small, and a 28-in. square pier

would be used. Ans.

Ex a mpl e 2.A pier of brick laid in cement-lime mortar is to be 16

feet high and 32 inches wide. If it is to carry a vertical load of 60,000

pounds applied 2 inches from its axis, the eccentricity being measured at

ELEMENTS OF MASONRY DESIGN 19

right angles to the 32-inch dimension, what should be the other dimension,

or thickness, of the pier?

So l u t i o n .The reduced allowable unit stress in this case is 140r^

X16X120 = 14013 = 127 lb. per sq. in. For a central load of 60,000 lb.

and a pier for which ^ is less than 6, the required cross-sectional area of

the pier would be p

A = 7 = ' X27~ = 472 sq. in.

If 50 per cent is added as an allowance for the eccentricity of the load

and the probable reduction in the allowable unit stress because the height

may exceed six times the least width, the estimated area would be 1.5X472

= 708 sq. in. The thickness corresponding to this area is 708-^32=22.1,

and a tentative dimension of 24 in. will be tried. For this dimension,

h 16X12

^ = =8, or more than 6; hence, the allowable unit stress should be

reduced in accordance with the formula of Art. 11. Thus,

/ = / , ( l . 2 5 - i 0 =140X ( l . 2 5 - ^ X 8 ) =119 lb. per sq. in.

and the safe unit stress, exclusive of the stress due to the weight of the

pier, is 11913 = 106 lb. per sq. in. Also, by formula 1, Art. 17, in which

P = 60,000 lb., 6 = 32 in., d = 24 in., and e=2 in., the actual unit stress due

to the superimposed load is

, F / . , 6 e \ _60,000^ / , , 6 X 2 \

* bd \1 + d ) 32X24X ( 1 + 24 / 117 lb- Per s<3-ln-

Since this stress exceeds the allowable value of 106 lb., a larger pier

is needed. A 32"X28" section will obviously be satisfactory. Ans.

EXAMPLES FOR PRACTICE

1. Find (a) the maximum and (6) the minimum resultant unit stresses

in a 16"X20" rectangular masonry pier which supports a total load of

67,500 pounds applied midway between the 20-inch faces and 7 inches

from one of the 16-inch faces.

A f (a) 369 lb. per sq. in., comp.

nS' \ (6) 53 lb. per sq. in., comp.

2. The height of a square pier of brick laid in portland-cement mortar

is to be 7 feet 6 inches. What width of pier is required to carry a super

imposed load of 50,000 pounds applied 3 inches from the axis and on a

center line perpendicular to one face of the pier? Ans. 24 in.

3. A square pier 12 feet high, built of granite ashlar laid in portland-

cement mortar, is to carry a superimposed load of 140,000 pounds whose

line of action is 1 inches from the axis of the pier and on a center line

perpendicular to one face of the pier. Determine the required width of

the pier to the next larger even inch, Ans. 18 in.

20 ELEMENTS OF MASONRY DESIGN

MASONRY WALLS

WALLS OF UNIFORM CROSS-SECTION

MINIMUM ALLOWABLE THICKNESSES OF BUILDING WALLS

23. Introduction.The thickness of a masonry wall

should in any case be sufficient to resist safely the stresses due

to the dead and live loads on the structure. The exterior

walls of buildings must also provide resistance to fire and must

not be too thin in proportion to the height. Minimum allow

able thicknesses of masonry walls under various conditions are

specified by the building codes of cities and of organizations

such as the United States Department of Commerce and the

National Board of Fire Underwriters. The requirements of

the various codes are fairly similar, although there are some

notable differences. Under ordinary circumstances, the mini

mum allowable thickness of a wall can be adopted with safety,

but it may sometimes be necessary to use a greater thickness

in order to bring the unit stresses below the permissible limits.

The recommendations in the following articles are based

largely on a report of the Building Code Committee of the

Department of Commerce entitled Recommended Minimum

Requirements for Masonry Wall Construction.

24. Exterior and Party Walls in Skeleton Construction.

From an engineering standpoint, buildings may be divided into

two types, known as the skeleton type and the wall-bearing type.

In skeleton construction, the columns and the floors and roof

form a self-sustaining framework, or skeleton, the floors and

the roof being supported by the columns; and the walls and

other parts of the structure are supported by the skeleton.

Thus, the outside walls serve merely to enclose the building,

and are supported at each floor by beams running between

columns. Where there is a party wall, which is a wall between

two buildings and adapted for the joint use of both, it is like

ELEMENTS OF MASONRY DESIGN 21

wise supported by beams and columns that are common to the

two buildings. Exterior and party walls are generally of solid

brickwork but, in buildings with reinforced-concrete skeletons,

the enclosure walls are sometimes of reinforced concrete.

Exterior walls of unreinforced masonry in skeleton construc

tion should be at least 8 inches thick. In the case of a party

wall, the minimum thickness should be 12 inches.

25. Bearing and Non-Bearing Walls in Wall-Bearing Con

struction.In wall-bearing construction, the walls rest on

suitable foundations, and the floors and roof are supported

either entirely by the walls or by the walls and interior columns.

The walls are usually of brick, but in buildings that are only

one or two stories high, hollow blocks are often used in the

walls. Party walls of brick masonry should be laid in cement

mortar or cement-lime mortar. Wall-bearing construction is

not recommended for buildings of more than ten or twelve

stories.

Even in wall-bearing construction, a distinction must be

made between so-called bearing walls and non-bearing walls.

A bearing wall is one that supports a vertical load in addition

to its own weight. Thus, in dwellings, the floor and roof loads

are generally carried to the side walls by closely-spaced wooden

joists. Also, in structures such as armories and gymnasiums,

the walls frequently support balconies and roof trusses. Non

bearing walls, which support only their own weight, are used

along the ends of buildings. These walls run parallel to the

floor joists and do not receive any load from the joists.

26. Thickness of Exterior and Party Walls in Wall-Bearing

Construction.Recommended minimum thicknesses for high

exterior and party walls of masonry in buildings of the wall

bearing type are indicated in Fig. 4. In view (a) is represented

an outside bearing wall; in view (b), a party wall; and in view

(c), an outside non-bearing wall. As shown in the illustration,

the thickness of a bearing walleither outside or party

should be not less than 12 inches for the uppermost 35 feet of

its height and should be increased by 4 inches for each successive

35 feet or fraction thereof measured downwards from the top

22 ELEMENTS OF MASONRY DESIGN

of the wall. For a non-bearing wall, the thickness may be 4

inches less than the minimum recommended value for a bearing

wall, provided that it is not less than 12 inches.

The thickness of a masonry wall should not be less than one-

twentieth of the height between successive floors or other

substantial lateral supports, unless the wall is reinforced by

Fi g . 4

cross-walls, piers, or buttresses at intervals not exceeding

twenty times the thickness. Where an exterior bearing wall

or a party wall is stiffened, at intervals of not more than 12

feet, by cross-walls or by projections at least 2 feet deep, the

thickness need be only 12 inches for the uppermost 70 feet of

the height and should be increased by 4 inches for each succes

sive 70 feet or fraction thereof.

The preceding recommendations apply to most walls of solid

masonry and, in general, also to walls of hollow masonry.

However, the height of a hollow wall above the top of the

ELEMENTS OF MASONRY DESIGN 23

foundation wall should never exceed 50 feet, and the thickness

of such a wall should not be less than one-eighteenth of the

vertical or horizontal distance between substantial lateral sup

ports. Also, walls of rubble masonry should be 4 inches

thicker than similar walls of other classes of solid masonry and

should never be less than 16 inches thick.

Each change in the thickness of a wall should be made at a

floor level and not between floors. Where a change in wall

thickness would theoretically occur between floor levels, the

greater thickness should be continued to the higher floor.

27. Exterior bearing and non-bearing walls or party walls

in wall-bearing construction may be only 8 inches thick under

the following conditions: (1) When they are in the top story

of a building not exceeding three stories or 40 feet in height or

in a one-story commercial or industrial building, provided the

unsupported height of the 8-inch wall does not exceed 12 feet

and the roof beams are horizontal. (2) When they are in a

one- or two-family dwelling and are either solid walls not more

than 30 feet high or hollow walls not more than 20 feet high.

If such a dwelling has a gable wall, which comes to a point at

the roof, the portion within 5 feet of the peak need not be

included in determining the height.

28. Foundation Walls.The foundation walls support the

vertical loads from the structure resting on them and usually

also resist lateral earth pressure. Thus, they generally act as

both bearing and retaining walls. They must, therefore,

possess adequate strength and stability and must be at least as

thick as the walls they support.

Foundation walls are usually of plain or reinforced concrete,

stone, or brick, but sometimes they are of hollow masonry. A

foundation wall of rubble stone should be not less than 18

inches thick. If the wall is of concrete, brick, coursed stone,

or hollow masonry, its thickness should be not less than 12

inches. However, where the foundation walls are built in

trenches and the material enclosed by them is not excavated

to provide a basement, a minimum thickness of 8 inches may

be used if the entire wall including the foundation wall is

24 ELEMENTS OF MASONRY DESIGN

not over 30 feet high for solid masonry or 20 feet high for hollow

masonry. Foundation walls of masonry should be laid in

cement mortar. Also, all foundation walls should extend

below the level of frost action.

29. Fire Walls and Partitions.A fire wall is a wall that

subdivides a building in order to restrict the spread of fire and

that extends continuously from the foundation to and above

the roof. Such walls should preferably be of solid brick

masonry, laid in cement mortar or cement-lime mortar, or of

reinforced concrete. When a fire wall is constructed of brick,

the requirements in regard to minimum thickness are the same

as those for party walls in wall-bearing construction, except

that in residential buildings a brick fire wall may be 8 inches

thick for the uppermost 20 feet of its height. Fire walls of

hollow masonry, other than hollow brick walls, should be not

less than 16 inches thick in any part, but a minimum thickness

of 12 inches may be used for all such walls in a residential

building or for hollow walls of brick in all buildings.

Partitions may be used in the various stories of a building

merely to subdivide the floor space. Often they are provided

to restrict the spread of fire, and are then called fire partitions

or fire division walls. The thickness of fire partitions of solid

brick should not be less than 8 inches. If such partitions are

of hollow masonry, they should never be less than 12 inches

thick. In buildings used for heavy manufacturing, the mini

mum thickness of fire partitions should be 12 inches if of hollow

brick construction and 16 inches if of other types of hollow

masonry.

A partition that serves as a bearing wall, but not as a fire

division wall, should have a thickness of at least one-eighteenth

of the height between floors or floor beams. Non-bearing

partitions that do not serve as fire division walls are usually

made of hollow masonry. The thickness, exclusive of plaster,

should be not less than 2 inches for an unsupported height up

to 8 feet, 3 inches for a height of 12 feet, 4 inches for a height

of 15 feet, 6 inches for a height of 20 feet, and 8 inches for a

height of 25 feet.

ELEMENTS OP MASONRY DESIGN 25

30. Parapets.Exterior walls, party walls, and fire walls

of masonry should be carried above the roof wherever the roof

is not of fireproof construction and the building is within about

50 feet of other buildings. The portion of the wall projecting

above the roof is known as a parapet. In buildings in which

8-inch walls are permitted, the parapet should be at least 8

inches thick and 2 feet high. In other buildings, the parapet

should be not less than 12 inches thick and 3 feet high.

INVESTIGATION AND DESIGN

Roof

400

600

600% jeL

600* - j / g f

6,080

600^-c

3,ZOO

31. Walls of Uniform Section With Uniform Vertical Loads.

If masonry walls are built in conformity with the minimum

requirements specified in

the preceding articles, the

maximum compressive unit

stresses produced by the

actual loads will usually be

well within the allowable

limits. However, in some

cases, it may be necessary

to investigate the stresses

developed in a wall or to

design a wall to withstand

a certain loading.

The simplest type of wall

is one that is of uniform

cross-section and carries

uniformly-distributed loads.

Since all portions of the

wall are then alike, a foot

length of the wall is usually

considered in investigation

or design. In solving a

particular problem, it is first

necessary to determine the amount and position of the resultant

load and then to proceed as described for a pier.

In order that a wall may be considered safe, the unit stress

at any point must not exceed the allowable value for the kind

t

!6

0>)

Fi g . 5

26 ELEMENTS OF MASONRY DESIGN

of masonry used in the wall. Also, if tension in the masonry

is not permitted, the resultant of the loads must lie within the

middle third of the wall. For the purpose of investigation or

design, the load from closely spaced joists may be assumed

to be uniformly distributed.

Ex a mpl e .In Fig. 5 (a) is shown a proposed section of an outside

bearing wall of a dwelling. The wall is to be of brick laid in portland-

cement'mortar and is to support its own weight and joists from five floors

and a roof; the basement floor is to rest directly on the soil. The load

per linear foot from each floor, which may be considered uniform for the

entire length of the wall, is 600 pounds, and from the roof 400 pounds.

Each of these loads is applied 4 inches from the inside face of the wall.

If the wind and earth pressures are disregarded, is the wall thick enough

just above the footing?

So l u t i o n .In this case, a linear foot of wall is considered. It is

necessary first to find the weight of the various parts of the wall and then

to determine the amount and the line of action of the resultant of all the

loads. Since the brickwork weighs 120 lb. per cu. ft., the weights of the

parts of the wall per lin. ft. are as follows;

19

12" wall, 2 7 X^X 12 0 = 3,240 lb.

16" wall, 38Xj ^ X 120 = 6,080 lb

20" wall, 16xf^X120 = 3,200 lb.

The positions of the loads acting on the wall are shown in Fig. 5 (6).

The resultant load and its distance from the outside face of the 20-in. wall

are computed in the following manner:

Load

Weight, Arm, Moment,

in Lb. in In. in In.-Lb.

Roof..................................... 400 8 3,200

5th floor.............................. 600 8 4,800

12" wall............................... 3,240 6 19,440

4th, 3d, 2d floors.............. 1,800 12 21,600

16" wall.............................. 6,080 8 48,640

1st floor.............................. 600 16 9,600

20" w a l l ............................. 3,200 10 32,000

Total........................... 15,920 139,280

Hence, the resultant load, which amounts to 15,920 lb., acts at a distance

from the outside face of the wall equal to 139,280+15,920 = 8.75 in. The

ELEMENTS OF MASONRY DESIGN 27

20

eccentricity of the load is 8.75 = 1.25 in. and by formula 1, Art. 17,

the maximum unit pressure is

15,920 / 6X1.25\

12X20* \ + 20 )

= 91.2 lb. per sq. in.

This is well below the allowable value of 175 lb. per sq. in., but the thick

nesses of the wall cannot be reduced because they are the smallest that

are permitted by the requirements in Fig. 4 (a).

32. Effect of Lateral Thrust.When a wall is subjected

to lateral thrust, as from wind or earth pressure, the resultant

load on the wall is inclined. In this case, it is most convenient

to determine first the amount and the line of action of the

resultant of the vertical loads only and

then to combine this resultant with

the horizontal or inclined force repre

senting the lateral pressure. The

resultant of the vertical forces is usu

ally found most easily by calculation,

but the graphic method is convenient

for locating the point where the resul

tant of all the forces cuts the base of

the wall. However, the horizontal

distance from any point on the base

to the resultant may also be found by

dividing the algebraic sum of the

moments of all the forces about that point by the vertical

component of the resultant.

When the resultant force acting on a wall is inclined, the

horizontal component tends to overturn the wall and to cause

the upper part of the wall to slide on the lower part, whereas

the vertical component resists overturning and sliding. The

conditions are indicated diagrammatically in Fig. 6, in which

Pv represents the vertical component of the resultant and Ph

represents the horizontal component. The overturning moment

about the edge a of the base of the wall is PhXab, and the

resisting moment is PvXac. If the resisting moment is greater

than the overturning moment, the wall is stable against over

turning; on the other hand, if the overturning moment exceeds

Fi g . 6

28 ELEMENTS OF MASONRY DESIGN

the resisting moment, the wall is unstable. However, the

factor of safety against overturning should preferably be at

least 2; that is, the quotient obtained by dividing the resisting

moment by the overturning moment should not be less than 2.

33. If a building wall were designed so that the vertical

loads acting on it would provide sufficient resistance to over

turning by wind and earth pressure, an excessive thickness of

wall would be required because the arm of the horizontal wind

pressure about the base of the wall is much greater than the

arm of the vertical load about the outer edge of the base.

However, considerable lateral resistance to wind pressure is

furnished by the floors of the building, and it is customary to

make allowance for this resistance in designing the wall. Since

it is not possible to estimate even roughly the amount of the

resistance supplied by a particular floor, the required thickness

of the wall must be based on experience and empirical rules.

It may be taken for granted that exterior walls built in accord

ance with the requirements in Arts. 23 to 28, inclusive, will be

stable against overturning by external lateral pressure.

34. A wall will not slide if the ratio of the horizontal com

ponent of the resultant force acting on the wall to the vertical

component does not exceed the coefficient of friction for two

blocks of the material of which the wall is composed. The

value of this coefficient for any kind of masonry used in a wall

may be taken as 0.65. However, the factor of safety against

sliding should be about 1.5. Thus, if the product of the verti

cal component of the resultant force and the coefficient of

friction is divided by the horizontal component of the resultant,

the quotient should be at least 1.5. Even if the lateral resist

ance of the floors is neglected, a building wall that meets the

minimum requirements for stability against overturning will

be amply safe against sliding.

35. Distribution of Concentrated Loads.Loads are often

carried to walls by beams, girders, or trusses spaced relatively

far apart. Such loads are gradually distributed over the

masonry below, but the pressure directly under them is much

greater than elsewhere. Where the portion of the bottom of

ELEMENTS OF MASONRY DESIGN 29

the beam or trass which bears on the wall is so small that the

unit pressure on the masonry would exceed the safe strength

of the material, a steel bearing plate must be provided under

the member to spread the load over a larger area of masonry.

In the investigation or design of a wall of

uniform cross-section that carries concen

trated loads, it is necessary to consider a

length of wall equal to the distance between

loads, but otherwise the procedure is similar

to that explained for uniform loads.

Ex a mpl e .A section through a proposed brick

wall for a storage warehouse is shown in Pig. 7.

The floor beams and roof beams are spaced 6 feet

apart horizontally; the load from each roof beam is

4,800 pounds and is assumed to be applied at a dis

tance of 3 inches from the inside face of the wall;

the load from each beam of the sixth, fifth, fourth,

third, and second floors is 18,000 pounds and is

applied 4 inches from the inside face of the wall;

and the load from each first-floor beam is 20,000

pounds and is applied 4 inches from the inside face

of the wall. What is the maximum unit pressure in

the wall just above the footing, for the vertical

loads alone?

So l u t i o n .The calculations for determining

the resultant load for a 6-ft. length of wall and its '<o

distance from the outside face of the wall may be

arranged as follows:

Fi g . 7

Load

Roof ......

6th floor

Weight, in Lb.

. 12.

Arm,

in In.

4,800

18,000

12" wall............................... 30 X 6 X ^ X 1 2 0 = 21,600

5th, 4th floors.

16" wall...........

3d, 2d floors...

.16.

36,000

2 6 X 6 X ^ X 1 2 0 = 24,960

. 20.

36,000

20" wall............................... 2 8 X 6 X ^ X 1 2 0 = 33,600

1st floor

.24.

20,000

24" wall............................... 6X6X^2X120 = 8,640

9

8

6

12

8

16

10

20

12

Total. 203,600

Moment,

in In.-Lb.

43,200

144.000

129,600

432.000

199.700

576.000

336.000

400.000

103.700

2,364,200

30 ELEMENTS OF MASONRY DESIGN

The distance from the outside face of the 24-in. wall to the line of action of

the resultant load is 2,364,200-5-203,600 = 11.6 in., and the distance from

24

the center of the base of that wall to the resultant load is -jp 11.6 = 0.4

in. Hence, by formula 1, Art. 17, the maximum unit pressure is

203,600 w / 6X0.4\

72 X24 X l + 24 )

= 130 lb. per sq. in. Ans.

This is well below the usual allowable value of 175 lb. per sq. in.

EXAMPLES FOR PRACTICE

1. An exterior bearing wall in an apartment house is of brickwork

and has a cross-section similar to the upper 121 feet of the wall shown in

Fig. 4 (a). The 12-inch, 16-inch, and 20-inch thicknesses each extend

for a height of 35 feet, as in the illustration, and the height of the 24-inch

portion is 16 feet. The load from the top tier of joists is treated as a

uniform load of 500 pounds per linear foot, and that from each of the lower

tiers of joists is a uniform load of 800 pounds per linear foot. The loads

from the three upper tiers of joists are applied 4 inches from the inside

face of the 12-inch portion of the wall; the loads from the next three tiers

are applied 4 inches from the inside face of the 16-inch portion; the loads

from the next three tiers, 4 inches from the inside face of the 20-inch

portion; and the load from one tier, 4 inches from the inside face of the

24-inch portion. What is the distance from the outside face of the wall

to the line of action of the resultant of the vertical loads acting on the

wall above the base of the 24-inch portion? Ans. 10.1 in.

2. Compute the maximum unit pressure in the wall of the preceding

example at the base of the 24-inch portion. Ans. 145 lb. per sq. in.

WALLS WITH PROJECTIONS

TYPES OF PROJECTIONS

36. Pilasters.When a concentrated load is applied to a

masonry wall, the thickness of the wall is often increased for

a short distance on each side of the load, as shown in the plan

in Fig. 8 at a. If the load is vertical, the purpose of the addi

tional masonry is merely to increase the bearing area of the

wall directly under the load. These projections, which are

called pilasters, may be placed on the inside of the wall, on the

outside, or on both the inside and outside of the wall at each

load. Brick or stone pilasters should be well bonded to the

wall so that all the masonry will act as a unit in supporting the

ELEMENTS OF MASONRY DESIGN

31

load. The width b of a pilaster should be between one-sixth

and one-third of its length c.

A pilaster and the part of the wall opposite the pilaster are

assumed to act together in supporting the concen

trated load. Thus, in the illustration, the pilaster a

and the portion of the wall between the dotted lines

are treated as a unit in computing the unit stress

produced by a given load or in determining the

dimensions b and c that are required for the support

of a certain load. The method of procedure in

either investigation or design is similar to that for a

masonry pier.

37. Buttresses.When a wall is required to sustain a

horizontal or an inclined load, such as the reaction of a roof

truss exposed to the wind, a heavy masonry projection is

provided to help prevent the wall from overturning. Such a

projection is usually located on the side of the wall toward

which the horizontal component of the load acts. The pro

jection is then subjected to compressive stress and is known as

a buttress. In order that buttresses will act in unison with the

rest of the wall, they must be well bonded into the wall.

38. Counterforts.When a projection that is provided to

help resist a horizontal or an inclined load is placed on the side

of the wall away from which the horizontal component of the

load acts, the masonry in the projection is subjected to tension.

The projection is then called a counterfort. Since plain

masonry is very weak in tension, masonry counterforts must

be reinforced with steel.

STABILITY OF BUTTRESSED WALLS

39. Loads on Buttressed Walls.In Fig. 9 is shown a verti

cal section through a gymnasium, in which the steel roof

trusses rest upon masonry walls. Opposite each truss the

walls a and b are provided with buttresses c and <1. The end

e of each truss is supported on rollers and, therefore, the pres

sure transmitted to the wall b by the truss is always vertical.

The end / of each truss is fastened to the wall a, and the wall

32 ELEMENTS OF MASONRY DESIGN

is subjected to a vertical load from the truss and also to a

horizontal thrust from the wind load on the truss. The wind

also exerts a horizontal pressure on the walls, acting on the

wall a when it is blowing from the left and on the wall b when

it is blowing from the right. Each buttress carries, in addition

to its own weight and the roof load, a vertical load from the

spectators gallery and from each floor.

In order to determine the stability of the walls and but

tresses, it is necessary to consider several conditions. As the

wind may blow against either side, two independent sets of com

putations must be made. First, it should be assumed that

the wind blows from the right-hand side. The reactions from

both the dead loads and the vertical live loads on the floors

tend to resist overturning, but the live loads do not always

act and are disregarded in determining the location of the

resultant of all loads acting on the wall and buttress. How

ever, in determining the maximum compressive unit stress at

the bottom of the buttress, the reactions from the maximum

live loads are included. After both walls a and b have been

investigated with the wind blowing from the right, other sets

of computations are made on the assumption that the wind is

blowing from the left.

ELEMENTS OF MASONRY DESIGN 33

40. Investigation of Walls With Buttresses.In the investi

gation of the stability of a buttressed wall, it is customary to

assume that the buttress and the portion of the wall directly

opposite the buttress act as a unit, and to neglect entirely any

resistance to overturning, sliding, or stress that may be fur

nished by the remainder of the wall. The problem may be

solved entirely by calculation, but it is usually convenient to

adopt the following method, which is partly graphic.

First, a cross-section of the wall and a buttress is drawn to

a convenient scale, the weight of the masonry resisting over

turning is calculated, and the center of gravity of that mass of

masonry is located. On the cross-section are located accu

rately the lines of action of the weight of the masonry, the

reaction from the roof truss, and any other forces that act on

the portion of the masonry under consideration. The position,

in the cross-section, of the line of action of the resultant force

acting on the masonry is then determined by any suitable

graphic method. If this resultant passes well within the base

of the section, the structure will be safe against overturning.

However, in order to avoid tension in the masonry, the resultant

force should cut the base of the section inside the middle third.

The resistance to sliding and to crushing of the masonry

should also be investigated. To determine the factor of safety

against sliding, the product of the vertical component of the

resultant force and the coefficient of friction for the masonry

is divided by the horizontal component of the resultant force.

For safety against crushing, the maximum pressure, as deter

mined by formula 1, Art. 17, must not be greater than the

allowable value for the masonry.

Where the buttress and wall increase in thickness toward the

bottom, and the floor loads are applied at various heights, it

is often necessary to investigate the safety of the wall at each

change in thickness, as well as at the bottom. In investigating

the safety of the wall at any level, only the forces applied to

the wall above that level are considered.

Ex a mpl e .-In Fig. 10 (a) is shown an enlarged section through the

wall a and a buttress c in Fig. 9. The wall and buttress are of limestone

ashlar, and the width of the buttress, measured parallel to the wall, is

34 ELEMENTS OF MASONRY DESIGN

Fig . 10

ELEMENTS OF MASONRY DESIGN 35

4 feet below point p, Fig. 10 (a), and 3 feet above that point. The wind

is assumed to be blowing from the right, and the truss reaction for the

combined dead and wind loads has a vertical component of 54,000 pounds

and a horizontal component of 5,500 pounds. The dead load from the

gallery is carried almost entirely by the. truss, and the amount transmitted

directly to the wall may be neglected. The wall carries a dead load of

19,000 pounds from the first floor and an equal load from the locker-room

floor, each of these loads being applied 8 inches from the inside face of the

wall. The load on the basement floor is carried directly by the soil. Find

the distance from the outside face of the buttress to the point where the

resultant load cuts (a) the top of the footing and (6) the section x-x at the

first-floor line.

So l u t i o n . (a) In order to determine the weight of the masonry and

the position of the center of gravity, the cross-section may be imagined

to be made up of the divisions numbered 1, 2, 3, 4, 5, 6, 7, 8, and 9 in Fig.

10 (a). In this case, the width of the masonry under consideration is not

uniform for the entire height of the buttress, this width being 4 ft. below

point p and 3 ft. above that point. Therefore, in locating the center of

gravity, it is necessary to use the volumes of masonry in the divisions and

not the areas. These volumes, their respective arms from the inside face

of the lower portion of the wall, and the moments about that face are as

follows:

Division Volume, in Cu. Ft. Arm, in Ft. Moment

1 1.5X6.75X3 = 30.4

2

61

2 1X2.25X3.5X3 = 11.8 3.5 41

3 0.25X2X3 1.5 2.63 4

4 2X7.5X3 45.0 1.5 68

5 2.5X8X3 60.0 3.75 225

6 2.5X13X3 97.5 1.25 122

7 4X10.5X3 126.0 4.5 567

8 6.5X2X3 39.0 3.25 127

9 7X23.5X4 658.0 3.5 2,303

1,069.2, say 3,518, say

1,070 3,520

If the masonry is assumed to weigh 168 lb. per cu. ft., the total weight

of the masonry is 1,070X168 = 179,800 lb. The distance from the inside

face of the wall to the center of gravity of the wall and buttress is 3,520-f-

1,070 = 3.28 ft., or 3 ft. 3 in.

The forces acting on the buttress above the footing are shown in Fig.

10 (a). In order to present clearly the graphic method of locating the line

of action of the resultant of these loads, the outline of the cross-section

is here redrawn in view (5), but in practice it would not be necessary to

redraw the section. The first step is to locate the point a. where the

reaction from the truss is applied, and to establish graphically the line of

36 ELEMENTS OF MASONRY DESIGN

action ab of the resultant of the two components of that reaction. This

is done by laying off, to some convenient scale, the length ac vertically

downwards to represent 54,000 lb. and the length cb horizontally toward

the left to represent 5,500 lb., and then joining a and b by a straight line.

The next step is to locate the line of action of the resultant de of the truss

reaction and the vertical loads at the first floor and the locker-room floor.

The line ab is prolonged upwards to intersect at d the vertical line repre

senting the common line of action of the two floor loads. The required

line of action de is determined by laying off from d the vertical distance

df to represent the total load of 38,000 lb. from the two floors, making the

inclined distance fe parallel and equal to ab, and connecting d and e by a

straight line. The last step is to draw a vertical line at a distance of 3.28

ft. from the face of the wall to represent the line of action of the entire

weight of the masonry, which is 179,800 lb., and to extend the line de

until it intersects this vertical line of action at g. The final resultant gh

of all the forces is determined by making the vertical distance gi equal to

179,800 lb., making ill equal and parallel to de, and then drawing the line

from g to h. The resultant gh cuts the base of the buttress at a distance

of 3 ft. 4J in. from the outside face of the buttress, whereas the edge of

the middle third is 1 x 7 ' 0 " = 2 ft. 4 in. from that face. Ans.

(b) In the investigation for the section x-x, Fig. 10 (a), only divisions

1 to 7, inclusive, of the cross-section are included in determining the weight

of masonry that resists the truss reaction. The volume of this part of

the wall is 372.2, or say 372, cu. ft. and the sum of the moments about the

inside face of the wall is 1,088. Hence, the weight of the masonry

is 372X168 = 62,500 lb., and the distance from the inside face of the wall

to the center of gravity is 1,088-r-372 = 2.92 ft., or 2 ft. 11 in.

The resultant of the truss reaction and the weight of the masonry,

which are the only forces acting above the first floor, is then located as in

Fig. 10 (c). The resultant ab of the components of the truss reaction is

determined as in view (b). It is then prolonged to intersect the vertical

line of action of the weight of the masonry at j ; and the resultant jk of

the weight of the masonry and the truss reaction is determined by laying

off j l to represent the weight of 62,500 lb., making Ik parallel and equal

to ab, and joining the points j and k. This final resultant cuts the section

x-x at m. The distance from the outside face of the buttress to the inter

section point m is 2 ft. 11|in., whereas the edge of the middle third is at

a distance of JX6' 6" = 2 ft. 2 in. from that outside face. Ans.

41. Design of Buttressed Walls.The procedure in design

ing a buttressed wall consists in assuming a cross-section for

the wall and buttress, and investigating its stability against

overturning and sliding. Usually, it will be unnecessary to

compute the crushing stress, but under heavy loads that stress

ELEMENTS OF MASONRY DESIGN 37

must also be investigated. In the selection of the trial section,

the required architectural effect will usually govern, but past

experience and good judgment are frequently helpful. If the

trial section is not thick enough, as indicated by the fact that

the resultant of the forces acting on the wall passes outside the

middle third of the base or the maximum unit pressure exceeds

the allowable value, the wall or buttress should be made

heavier and the new section should be investigated. In case

the resultant lies quite near the center of the wall, and the unit

pressure is much lower than the allowable value, it is advis

able to reduce the size of the wall in order to lower the cost.

Several sections may have to be tried and investigated before

the final design is adopted. Thus, in the case of the section

shown in Fig. 10 (a) and investigated in the example of the

preceding article, it is found that the resultant of the forces

acting on the masonry cuts the base of the section very close

to the center, and a smaller buttress would be tried.

EXAMPLE FOR PRACTICE

The buttress shown in section in Fig. 10 (a) and considered in the

example of Art. 40 is altered in the following manner: The thickness of

division 7 is reduced to 3 feet, the thickness of division 8 is made 5 feet 6

inches, and the thickness of division 9 is made 6 feet. Determine the

distance from the outside face of the buttress to the point where the

resultant of all the forces cuts the top of the footing of the new section.

Ans. 2 ft. 7%in.

WALLS WITH OPENINGS

42. Distribution of Pressure.When a wall contains an

opening, as for a window or a door, the weight of the masonry

over the opening and any concentrated or uniform load which

may be applied to that masonry must be carried by the part

of the wall on each side of the opening. Usually, the load

from the masonry over an opening is transmitted to the masonry

alongside the opening by a beam, called a lintel, or by an

arch. Hence, when a wall contains openings, the unit pressure

at a certain level in a portion of the wall alongside an opening