Professional Documents

Culture Documents

AW Transmission Engineering in Plymouth Receives Renewed MIOSHA Recognition For Its Workplace Safety and Health Excellence

Uploaded by

Michigan News0 ratings0% found this document useful (0 votes)

22 views2 pagesAW Transmission Engineering in Plymouth recently received renewal of its prestigious Michigan Safety and Health Achievement Recognition Program (MSHARP) Award certification. MSHARP targets small manufacturers to help them develop, implement and continuously improve their workplace safety and health management system.

Original Description:

Original Title

AW Transmission Engineering in Plymouth Receives Renewed MIOSHA Recognition for Its Workplace Safety and Health Excellence

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAW Transmission Engineering in Plymouth recently received renewal of its prestigious Michigan Safety and Health Achievement Recognition Program (MSHARP) Award certification. MSHARP targets small manufacturers to help them develop, implement and continuously improve their workplace safety and health management system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views2 pagesAW Transmission Engineering in Plymouth Receives Renewed MIOSHA Recognition For Its Workplace Safety and Health Excellence

Uploaded by

Michigan NewsAW Transmission Engineering in Plymouth recently received renewal of its prestigious Michigan Safety and Health Achievement Recognition Program (MSHARP) Award certification. MSHARP targets small manufacturers to help them develop, implement and continuously improve their workplace safety and health management system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

AW Transmission Engineering in Plymouth Receives Renewed MIOSHA

Recognition for its Workplace Safety and Health Excellence

Contact: Tanya Baker 517-373-9280

Agency: Licensing and Regulatory Affairs

October 20, 2014 AW Transmission Engineering USA, Inc. (AWTEC) in Plymouth recently

received renewal of its prestigious Michigan Safety and Health Achievement Recognition Program

(MSHARP) Award certification from the Michigan Occupational Safety and Health Administration

(MIOSHA). MIOSHA established the MSHARP Award to recognize employers that have achieved

workplace safety and health excellence far beyond their peers. The MIOSHA program is part of the

Michigan Department of Licensing and Regulatory Affairs (LARA).

The management and employees of AW Transmission Engineering have once again proven their

commitment to workplace safety and health excellence, said MIOSHA Director Martha Yoder. We

are pleased to recognize them as an MSHARP worksite a designation which they have held since

2011 and look forward to their continued participation in this cooperative program.

MSHARP targets small manufacturers to help them develop, implement and continuously improve

the effectiveness of their workplace safety and health management system. The program provides

an incentive for employers to emphasize accident and illness prevention by anticipating problems,

not reacting to them.

The MIOSHA Onsite Consultation Program within the Consultation Education and Training (CET)

Division operates the MSHARP. MSHARP worksites earn an exemption from "programmed"

MIOSHA inspections on a yearly basis.

Onsite consultants work with employers to help them become self-sufficient in managing

occupational safety and health. The MIOSHA review team consisted of George Zagresky, senior

safety consultant and D.W. Johnson, industrial hygienist. The site manufactures automatic

transmissions and car navigation systems for its parent company, Aisin AW. The North American

Industry Classification System (NAICS) Code for AWTEC is 33635.

"MSHARP requires a comprehensive consultation visit and the correction of all serious workplace

safety and health hazards," said Yoder. "AWTEC has developed an exemplary safety and health

program which provides the utmost protection for its workers."

The facility has an excellent system in place, which incorporates each of the seven required

elements: hazard anticipation and detection; hazard prevention and control; planning and evaluation;

administration and supervision; safety and health training; management leadership; and employee

participation.

Some of AWTECs new improvements include:

Installed safety railings where forklift and pedestrian traffic converge.

Posted new PPE/Emergency Action signs in the work area.

Installed E-Stop cables along all powered conveyors.

For more information on AWTEC, please visit http://www.awtec.com/.

For more information about MIOSHA, please visit http://www.michigan.gov/miosha

Like us on Facebook and follow us on Twitter

For more information about LARA, please visit www.michigan.gov/lara

Follow us on Twitter, Like us on Facebook or find us on YouTube

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Schuette Charges Two in Insurance Fraud Scheme After Joint Investigation With Department of Insurance and Financial ServicesDocument2 pagesSchuette Charges Two in Insurance Fraud Scheme After Joint Investigation With Department of Insurance and Financial ServicesMichigan NewsNo ratings yet

- ShootingsDocument4 pagesShootingsMichigan NewsNo ratings yet

- Schuette Files For Reinstatement of Charges Against CMU Sexual Assault Suspect, New Court Date SetDocument1 pageSchuette Files For Reinstatement of Charges Against CMU Sexual Assault Suspect, New Court Date SetMichigan NewsNo ratings yet

- To Our Customers: DuMouchellesDocument1 pageTo Our Customers: DuMouchellesMichigan NewsNo ratings yet

- MPSC Fines DTE Energy $840,000 For Improper Billing, ShutoffsDocument2 pagesMPSC Fines DTE Energy $840,000 For Improper Billing, ShutoffsMichigan NewsNo ratings yet

- Lincoln Park Man To Pay $45,650 in Restitution For Embezzling Charitable Groups' FundsDocument2 pagesLincoln Park Man To Pay $45,650 in Restitution For Embezzling Charitable Groups' FundsMichigan NewsNo ratings yet

- Shots FiredDocument2 pagesShots FiredMichigan NewsNo ratings yet

- Michigan Liquor Control Commission Suspends Oakland County Gas Station's Liquor License For 102 DaysDocument1 pageMichigan Liquor Control Commission Suspends Oakland County Gas Station's Liquor License For 102 DaysMichigan NewsNo ratings yet

- Detroit Crime Blotter For Thursday, March 21, 2018Document18 pagesDetroit Crime Blotter For Thursday, March 21, 2018Michigan NewsNo ratings yet

- Massage Therapist Summarily Suspended For Criminal Sexual ConductDocument1 pageMassage Therapist Summarily Suspended For Criminal Sexual ConductMichigan NewsNo ratings yet

- West Michigan Physician Summarily Suspended For Alleged Criminal Sexual Conduct With PatientsDocument1 pageWest Michigan Physician Summarily Suspended For Alleged Criminal Sexual Conduct With PatientsMichigan NewsNo ratings yet

- DNR Deer Poaching Investigation Results in Sentencing of Allegan County ManDocument2 pagesDNR Deer Poaching Investigation Results in Sentencing of Allegan County ManMichigan NewsNo ratings yet

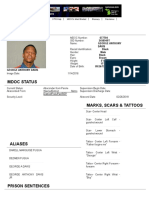

- Offender Tracking Information System (OTIS) - Offender ProfileDocument2 pagesOffender Tracking Information System (OTIS) - Offender ProfileMichigan NewsNo ratings yet

- Tuberculosis Exposure at Three Southeast Michigan Healthcare Facilities Being InvestigatedDocument2 pagesTuberculosis Exposure at Three Southeast Michigan Healthcare Facilities Being InvestigatedMichigan NewsNo ratings yet

- Lt. Gov. Calley: Nearly 5,700 Naloxone Orders Dispensed in Last Six Months 1,800 Through Standing OrderDocument2 pagesLt. Gov. Calley: Nearly 5,700 Naloxone Orders Dispensed in Last Six Months 1,800 Through Standing OrderMichigan NewsNo ratings yet

- $18M in Federal Grants Available To Public and Non-Profit Groups To Provide Services To Crime VictimsDocument2 pages$18M in Federal Grants Available To Public and Non-Profit Groups To Provide Services To Crime VictimsMichigan NewsNo ratings yet

- Schuette Seven Current and Former Police Officers Charged With 101 Felony Counts Related To Fraudulent Auto InspectionsDocument3 pagesSchuette Seven Current and Former Police Officers Charged With 101 Felony Counts Related To Fraudulent Auto InspectionsMichigan NewsNo ratings yet

- Detroit Pharmacist Summarily Suspended For $6 Million Health Care and Wire FraudDocument1 pageDetroit Pharmacist Summarily Suspended For $6 Million Health Care and Wire FraudMichigan NewsNo ratings yet

- Michigan's Statewide Graduation Rate Hits 80 Percent Graduation Rate Increases 0.53 Percent, Dropout Rate DeclinesDocument3 pagesMichigan's Statewide Graduation Rate Hits 80 Percent Graduation Rate Increases 0.53 Percent, Dropout Rate DeclinesMichigan NewsNo ratings yet

- 2018 Lake Sturgeon Season On Black Lake Begins Feb. 3 at 8 A.M.Document3 pages2018 Lake Sturgeon Season On Black Lake Begins Feb. 3 at 8 A.M.Michigan NewsNo ratings yet

- State Police Motor Carrier Officers Join Forces To Fight Human TraffickingDocument1 pageState Police Motor Carrier Officers Join Forces To Fight Human TraffickingMichigan NewsNo ratings yet

- Southfield Physician's Controlled Substance License Summarily Suspended For OverprescribingDocument1 pageSouthfield Physician's Controlled Substance License Summarily Suspended For OverprescribingMichigan NewsNo ratings yet

- Prosecutor Worthy Charges Police Officers With Murder, Misconduct and Other ChargesDocument7 pagesProsecutor Worthy Charges Police Officers With Murder, Misconduct and Other ChargesMichigan NewsNo ratings yet

- Detroit Pharmacy and Pharmacist Summarily Suspended For Over Dispensing Controlled SubstancesDocument1 pageDetroit Pharmacy and Pharmacist Summarily Suspended For Over Dispensing Controlled SubstancesMichigan NewsNo ratings yet

- Livonia Pharmacy and Pharmacist Summarily Suspended For Over Dispensing Controlled SubstancesDocument2 pagesLivonia Pharmacy and Pharmacist Summarily Suspended For Over Dispensing Controlled SubstancesMichigan NewsNo ratings yet

- Meijer Joins Growing Group of Retail Pharmacies To Integrate With MAPS To Prevent Opioid AbuseDocument2 pagesMeijer Joins Growing Group of Retail Pharmacies To Integrate With MAPS To Prevent Opioid AbuseMichigan NewsNo ratings yet

- Have You Been The Victim of Sexual Harassment? Consider Filing A Complaint Under Michigan Civil Rights LawDocument3 pagesHave You Been The Victim of Sexual Harassment? Consider Filing A Complaint Under Michigan Civil Rights LawMichigan NewsNo ratings yet

- Schuette: Orchard Lake Restaurant Sushi Samurai Sentenced in Tax Embezzlement Scheme, Owners Will Pay Almost $1 Million in RestitutionDocument2 pagesSchuette: Orchard Lake Restaurant Sushi Samurai Sentenced in Tax Embezzlement Scheme, Owners Will Pay Almost $1 Million in RestitutionMichigan NewsNo ratings yet

- State Police To Participate in Multi-State Commercial Vehicle Enforcement Operation Involving I-94Document2 pagesState Police To Participate in Multi-State Commercial Vehicle Enforcement Operation Involving I-94Michigan NewsNo ratings yet

- West Nile Virus Found in Michigan Ruffed GrouseDocument6 pagesWest Nile Virus Found in Michigan Ruffed GrouseMichigan NewsNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pickelman Opening StatementDocument5 pagesPickelman Opening StatementScott McClallenNo ratings yet

- MIOSHA Guidelines For Employees As People Return To WorkDocument25 pagesMIOSHA Guidelines For Employees As People Return To WorkWXYZ-TV Channel 7 Detroit100% (1)

- Enforcement and Appeals OverviewDocument6 pagesEnforcement and Appeals OverviewJake DraugelisNo ratings yet

- Access Safety: Occupational Safety & Health Training Project MIOSHA CET DivisionDocument41 pagesAccess Safety: Occupational Safety & Health Training Project MIOSHA CET DivisionDitter_frNo ratings yet

- Guide To Michigan Laws & RulesDocument18 pagesGuide To Michigan Laws & RulesrosiesirenNo ratings yet

- General Industry Safety and Health Standard Part 18. Overhead and Gantry CranesDocument22 pagesGeneral Industry Safety and Health Standard Part 18. Overhead and Gantry CranesRubén Cabrera RojasNo ratings yet

- Michigan State University: Personal Protective Equipment GuidelinesDocument40 pagesMichigan State University: Personal Protective Equipment GuidelinessanpkaruNo ratings yet

- Pinch Points 292565 7Document2 pagesPinch Points 292565 7Raj AryanNo ratings yet

- Construction Safety and Health ManualDocument26 pagesConstruction Safety and Health ManualCCT18-20 NMAMITNo ratings yet

- Emergency Rules Coronavirus Disease 2019 (Covid-19) : June 17, 2021Document3 pagesEmergency Rules Coronavirus Disease 2019 (Covid-19) : June 17, 2021Caleb HollowayNo ratings yet

- Tower Crane AccidentDocument37 pagesTower Crane Accidentparawansa muisNo ratings yet

- Employer Sample Program For Heat Illness Prevention - CET 0157Document14 pagesEmployer Sample Program For Heat Illness Prevention - CET 0157WXMINo ratings yet

- Deleg WSH Cetsp01 326406 7Document30 pagesDeleg WSH Cetsp01 326406 7Việt Đặng XuânNo ratings yet

- Powerpoint Presentation MIOSHADocument77 pagesPowerpoint Presentation MIOSHAMD AZHER ULLAH BAIGNo ratings yet

- Sample Ergonomics Program: Safety and Health Resource ManualDocument14 pagesSample Ergonomics Program: Safety and Health Resource ManualJay GolarNo ratings yet

- Order: Life in Lansing Required To Pay Back WagesDocument31 pagesOrder: Life in Lansing Required To Pay Back WagesLansingStateJournalNo ratings yet

- MIOSHA Guidelines For Employers As People Return To WorkDocument36 pagesMIOSHA Guidelines For Employers As People Return To WorkWXYZ-TV Channel 7 DetroitNo ratings yet

- Environmental and SocialDocument9 pagesEnvironmental and SocialTariku BalangoNo ratings yet

- DMC LawsuitDocument13 pagesDMC LawsuitAmber AinsworthNo ratings yet

- Kasco Safety Manual CurrentDocument171 pagesKasco Safety Manual CurrentLea Santos CidNo ratings yet

- Whitmer Administration's General Fund Budget RequestDocument12 pagesWhitmer Administration's General Fund Budget RequestMLive.comNo ratings yet

- STM Turbine Overspeed Failure Investigation-1Document11 pagesSTM Turbine Overspeed Failure Investigation-1Abdulrahman AlkhowaiterNo ratings yet