Professional Documents

Culture Documents

Dry Bean Production Guide PDF

Uploaded by

José Inés Bazán Mota0 ratings0% found this document useful (0 votes)

738 views53 pagesDry edible bean (phaseolus vulgaris) is a human food high in protein, phosphorus, iron, vitamin B 1, fiber, with no cholesterol. Dry bean is a relatively new crop to the North Dakota-Minnesota region. Two classes of dry bean (navy and pinto) encompass the major commercial acreage.

Original Description:

Original Title

Dry Bean Production Guide.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDry edible bean (phaseolus vulgaris) is a human food high in protein, phosphorus, iron, vitamin B 1, fiber, with no cholesterol. Dry bean is a relatively new crop to the North Dakota-Minnesota region. Two classes of dry bean (navy and pinto) encompass the major commercial acreage.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

738 views53 pagesDry Bean Production Guide PDF

Uploaded by

José Inés Bazán MotaDry edible bean (phaseolus vulgaris) is a human food high in protein, phosphorus, iron, vitamin B 1, fiber, with no cholesterol. Dry bean is a relatively new crop to the North Dakota-Minnesota region. Two classes of dry bean (navy and pinto) encompass the major commercial acreage.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 53

Dry Bean Production Guide

A-1133, July 1997. NORTH DAKOTA STATE UNIVERSITY.

Published in cooperation with Northarvest Bean Growers Association

Introduction

Dry edible bean (Phaseolus vulgaris) is a human food high in protein, phosphorus, iron, vitamin B

1

,

fiber, with no cholesterol. Dry bean is an imported staple in many areas of the world, especially

Central and South American and Africa. Different cultures have developed a multitude of end

products made with dry edible bean.

Dry bean is a relatively new crop to the North Dakota-Minnesota region. They have been grown on

a large scale since the 1970s. Two classes of dry bean (navy and pinto) encompass the major

commercial acreage. In addition, black turtle, red kidney, cranberry, pinks, and small red bean

classes are also grown on limited acres. Dry bean are generally grown under contract with a

processing firm. These firms are located throughout the eastern half of North Dakota and west

central Minnesota counties.

The North Dakota Dry Edible Bean Council, the Minnesota Dry Bean Council and the Northarvest

Bean Growers Association are organizations which promote and assist in marketing of dry bean.

The North Dakota Dry Edible Bean Seed Association is organized to grow and promote dry-bean

seed for planting.

Dry bean is a crop that requires special cultural management and attention by the producer. Proper

management is essential from field selection and planting through harvest and marketing for

maximum profitability.

The primary objective of this guide is to help dry bean growers and related industry personnel to be

proficient and successful.

Variety Descriptions

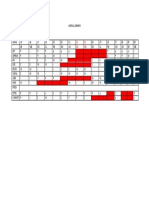

Class and Plant -- Blight -- -- BCMV -- Fusarium White

Cultivar Mat

3

Type

2

Common Halo Type NY15 Root Rot Mold Rust

1

-------------------------------------------------------------------------

PINTO

Agassiz E B S R R S S

Apache M V S R

Arapaho M V S R R S S

Aztec E UV S S S S S

Bill-Z M V S R R S MR

Chase L V R R S S T R

Elizabeth M V S R

Fargo E V S-MS

Fiesta E V S T R R S S S

Focus M UV S R

Hatton E V S R R S S-MR

Maverick ME V S S S R

Othello E V S T R R S S

Remington M UV R

RS-101 E USV S S

Topaz E V T R R S S-MS

Winchester ME UV R

-------------------------------------------------------------------------

NAVY

Agri-1 M B S T R R S S-MR

Aspen M USV R R R

Avanti M USV R R R-MS

Envoy M B R R S R

Fleetwood L B S T R R S S S-MR

Huron M USV R R T R

Mayflower ML USV T R R T T R

Navigator M USV R R T R

Newport E B R R S R

Norstar ME USV S T R R T R

Prize M B R R R

Schooner ML USV R R S R

Seafarer E B S T R R S S S

Snowbunting E B S T R S S S S

Upland ME B S T R S S S S-MR

Vista ML USV R R T R

Voyager ME V R R S S-MS

-------------------------------------------------------------------------

CRANBERRY

Cran-09 M B R R S S R

Mich. Imp L V S R

Taylor Hort E B S S R

UI-50 M B R R

UI686 M V R R R

-------------------------------------------------------------------------

SMALL RED

Cajun E UV MR

Garnet M V R R S S

NW59 ML V S T R R T S S

NW63 ML V S T R R T S S

UI-239 ME V S S

-------------------------------------------------------------------------

BLACK

Blackhawk L USV S T R R T T R

Blackjack ML USV R R R

Black Magic L USV S T R R T T R

Domino L USV S T R R T T R

Midnight L USV S S R R T T R

Panther M USV R R T R

Raven ME R R S R

Shadow ME USV R R T R

T-39 M USV S T R R T T R

UI-911 M V R R R

-------------------------------------------------------------------------

PINK

Flamingo E V S S

UI537 E V R R S S

Viva M V R S S

-------------------------------------------------------------------------

LT. RED KIDNEY

California E B S S S S

Early

Chinook M B T R R R

Foxfire ME B T R R R T T R

Sacramento E B S S S S S S S

-------------------------------------------------------------------------

DK. RED KIDNEY

Drake M B S S R R S T R

Isles M B T R R T T R

Montcalm ML B S T R R S T R

-------------------------------------------------------------------------

GREAT NORTHERN

Alpine M UV S T R R S R

Beryl M V S

Starlight ME V T T T T MR

-------------------------------------------------------------------------

Some cultivar disease reactions adapted from North Central Regional

Extension Publication 198.

1

Reaction based upon field observation of rust obtained in North

Dakota, 1995-1996 and field collections, 1996

S = Susceptible; MS = Moderately Susceptible;

T = Tolerant; MR = Moderately Resistant.

R = Resistant;

2

V = Vine; UV = Upright Vine;

B = Bush; USV = Upright Short Vine.

3

RM = Relative Maturity; E = Early;

M = Medium; ME = Medium Early;

ML = Medium Late; L = Late.

Seed Certification

The purpose of seed certification is to maintain and make available to the public high quality seed of

crop varieties that are produced, conditioned, and distributed as to insure proper identity and

genetic purity. This process of maintaining genetic purity is done through a nationally recognized

seed certification system. Each state has an authorized agency that establishes minimum standards

for genetic purity and other seed quality factors for each class of certified seed. These minimum

standards must meet or exceed the standards set by the Association of Official Seed Certifying

Agencies.

In the case of dry edible beans other seed quality factors like seed borne diseases are as important

as genetic purity. When seed is label as certified, a buyer can be assured that the seed has been

produced and lab tested to maintain varietal purity, low levels of disease, noxious weeds, inert

matter and other crop seeds. Each seed lot is conditioned and handled as seed and must meet

minimum standards for germination. Seed can not be sold as certified seed until it has passed field

inspection and laboratory testing.

All seed sold as certified seed must bear a certified seed tag on the bag. Those tags will come in

three colors. A white tag that represents Foundation class seed, a purple tag that represents

Registered class seed and a blue tag represents Certified class seed. These are the only color of

tags that are recognized by the Association of Official Seed Certifying Agencies.

The Idaho Department of Agriculture provides a windrow field inspection service to monitor bean

fields for blight symptoms. All seed that passes their windrow inspection is given a Green tag. No

varietal purity check are made during these inspections, nor are there any laboratory tests for seed

borne blight organisms conducted on such seed lots by the Idaho Ag Department.

Plant Variety Protection PVP

Plant variety protection provides owners of a novel variety control over who can produce and

market the variety that they develop. A Certificate of Plant Variety Protection can be issued either

with a requirement that the variety be certified by an official certifying agency (Title V option) or the

certificate of protection can be issued which gives the owner of the variety or his designee the

exclusive right to produce and market the variety as seed.

The Title V option essentially allows anyone to handle the variety providing it has met all of the

certification requirements.

Marketing of protected varieties that don't have the certification requirement is usually restricted to

those that are authorized to handle the variety either through a licensing agreement or through an

established dealer network.

Approximately one-half of the dry bean varieties that have a Certificate of Plant Variety Protection

are protected with the Title V option that requires certification.

Dry Bean Types and Development Stages

Two basic plant types are found in dry edible bean, determinate (bush) or indeterminate (vining or

trailing). Cultivars may be classified according to plant types. For example, navy beans may be

either of the bush or vining type. In the determinate type, stem elongation ceases when the terminal

flower racemes of the main stem or lateral branches have developed. On indeterminate types,

flowering and pod filling will continue simultaneously or alternately as long as temperature and

moisture permits growth to occur.

In addition to the distinction between determinate and indeterminate plant types, four plant growth

habits have been identified. These are: Type I Determinate bush; Type II Upright short vine,

narrow plant profile, three to four stems; Type III Indeterminate, prostrate vine; Type IV

Indeterminate with strong climbing tendencies. These growth habits have become useful in

identification and classification of new upright bean cultivars.

Plant development for both determinate and indeterminate plant types has been divided into

vegetative (V) and reproductive (R) stages as indicated in Table 1. Vegetative stages are

determined by counting the number of nodes on the main stem beginning at the unifoliate leaf node

(V1). Reproductive stages are described with pod and seed characters in addition to nodes. The

first pod developing on the plant is described and followed to full size. At the time of first bloom (R),

secondary branching begins in the axis of lower nodes which will produce secondary groups of

blooms or pods. It is important to follow the main stem, which is readily discernible on both

determinate and indeterminate plants. A node is counted when the edges of the leaflets no longer

touch.

Table 1. Stages of vegetative and reproductive development in determinate bush (Type I) and

indeterminate (Type III) dry bean.

General Description* Days from

Stage No. Vegetative stages planting**

---------------------------------------------------------------------

V1 Completely unfolded leaves at the primary 10

(unifoliolate) leaf node.

V2 First node above primary leaf node. Count 19

when leaf edges no longer touch.

V3 Three nodes on the main stem including the 29

primary leaf node. Secondary branching

begins to show from branch of V1.

V(n) n nodes on the main stem, but with blossom A new node

clusters still not visibly opened. each 3 days

V5 Bush (determinate) plants may begin to 50

exhibit blossom and become stage R1.

V8 Vine (indeterminate) plants may begin to 40

exhibit blossom and become stage R1.

------------------------------------------------------------

Determinate BUSH (Type I)

Reproductive Stages

R1 One blossom open at any node. 50

R2 Pods long at first blossom position. 53

Usually node 2 to 3.

R3 Pods 1 inch long at first blossom position. 56

Secondary branching at all nodes, so plant

is becoming denser but not taller, bloom.

R4 Pods 3 inches long seeds not discernible. 59

Bush types may be shorter.

R5 Pods 3-4 inches. Seed discernible. 64

R6 Seeds at least inch over long axis. 66

R7 Oldest pods have developed seeds. Other parts 72

of plant will have full length pods with

seeds almost as large as first pods. Pods

will be developed over the whole plant.

R8 Leaves yellowing over half of plant very few 90

small pods and these in axils of secondary

branches, small pods may be drying. Point of

maximum production has been reached.

R9 Mature, at least 80% of the pods showing 105

yellow and mostly ripe. Only 40% of leaves

still green color.

------------------------------------------------------------

Indeterminate VINING Plant (Type III)

Reproductive stages

R1 One blossom open at any node. Tendril will 40

begin to slow.

R1 Pods inch long at first blossom position 43

(node 2 to 5 most plants). Blossom would have

just sluffed.

R3 Pods 1 inch long at first blossom position. 46

Pods are showing at higher nodes when blossom

sluffs, bloom.

R4 Pods 2 inches long at first blossom position. 50

R5 Pods 3 plus inches long, seeds discernible 56

by feel.

R6 Pods 4.5 inches long with spurs (maximum 60

length). Seeds at least inch long axis.

R7 Oldest pods have fully developed green seeds. 70

Other parts of plant will have full length

pods with seeds near same size. Pods to the

top and blossom on tendril, nodes 10-13.

R8 Leaves yellowing over half of plant, very few 82

small new pods/blossom developing, small pods

may be drying. Point of maximum production

has been reached.

R9 Mature, at least 80% of the pods showing 94

yellow and mostly ripe. Only 30% of leaves are

still green.

--------------------------------------------------------------------

* Adapted from: Growth stages according to Marshall J. Lebaron

(University of Idaho, College of Agriculture, Current

Information Series No. 228, April 1974).

** Approximate number of days. This will vary from season to

season and variety to variety.

Plant Description

Visual Aid (6KB b&w image)

1. Hypocotyl

2. Radicle

3. Cotyledon (simple leaf)

4. Colydeonary node

5. Tap root

6. Lateral (branch) root

7. First true leaf (unifoliate)

8. Trifoliate leaflet

9. Terminal bud

10. Axillary buds

11. Hypocotyl arch

12. Nodes (point of leaf attachment)

13. Nodules

14. Root hairs

Planting Rates

Planting rates vary from 35 to 65 pounds per acre, depending on row spacing, bean plant type and

percent pure live seed. Navy bean range from 2,200 to 2,500 seeds per pound. Planting rates

suggested for navy beans are 35 to 45 pounds per acre of pure live seed. Studies conducted at

various plant populations do not indicate any significant advantage to having populations greater

than 90,000 plants per acre for Type I navy beans. Slightly higher rates are advised under irrigation.

Pinto beans range from 1,200 to 1,500 seeds per pound. Planting rates suggested for pintos are 50

to 65 pounds per acre of pure live seed. Populations of 70,000 plants per acre for Type III (pinto)

beans have been found to be adequate. In some instances, reduced yields were observed when

plant populations were below these recommendations. Under irrigation, some lodging has been

observed in the Type I cultivars at extremely low plant populations.

Rates should be adjusted for low germination or cool, wet planting conditions. To obtain desired

plant populations, overseed live seed by 10 to 15 percent to compensate for losses during

emergence. The normal planting depth is about 1-2 inches. Seed should not be planted deeper

unless the topsoil is dry. Plant seeds in moist soil if possible. Windbreaks of corn or sunflower can

be planted in fields where winds could become a problem at harvest. Growers should test their

planter on a hard surface and in the field at normal planting speeds to ensure proper depth and

seeding rate.

Growing Requirements

Dry bean are adapted to a wide variety of soils. They are not sensitive to soil type as long as it is

reasonably fertile, well drained and free of conditions that interfere with germination and plant

emergence, such as saline (salt affected) soils.

Saline soils affect germination, emergence and later plant growth. Plants that emerge on saline

soils may become yellow and have stunted growth. The leaf edges of the affected plant will be

brown and dead and often accumulations of salt may be seen on the leaf surface (refer to the

section on fertility).

Dry bean are a warm season crop and usually are not affected by high temperatures if adequate

soil moisture is present. Cool, humid or rainy weather is unfavorable to dry bean, but they are

adapted to a fairly wide range of temperature. The optimum average growing temperature for field

beans is 65 to 75F. Dry bean production is more successful in areas where rainfall is light during

the latter part of the growing season. It is essential that the crop be grown on a well-drained soil

since beans are extremely sensitive to standing water or waterlogged conditions.

Dry bean are not tolerant to frost or to prolonged exposure to near-freezing temperatures at any

stage of plant growth.

Hail Damage

The amount of crop damage caused by hail will depend on the intensity, size of hail stones and

duration, as well as plant type and stage of development. Determinate (Type I) cultivars are likely to

suffer greater losses than the indeterminate (Types II and III) cultivars, because Types II and III can

recover and compensate to a greater degree than can the Type I.

Severe hail damage can delay plant maturity. The earlier the stage of development at which the

injury occurs, the greater the time available for recovery, resulting in less yield reduction. Hail will

not directly affect seed quality unless a strike occurs on the pod.

Planting Guide

-------------------------------------------------------------

NAVY BEANS

-------------------------------------------------------------

Approximate

lbs. Live Seed Plants --------- Row Width -----------

per Acre per Acre Seed spacings within crop row

-------------------------------------------------------------

6" 12" 22" 30"

30 75,000 3.8 2.8

40 100,000 5.2 2.9 2.1

50 125,000 8.4 4.2 2.3 1.7

60 150,000 7.0 3.5 1.9 1.4

70 175,000 6.1 3.0 1.7

80 200,000 5.2 2.6 1.5

-------------------------------------------------------------

PINTO BEANS 12" 22" 30"

-------------------------------------------------------------

50 62,500 8.4 4.6 3.4

60 75,000 7.0 3.8 2.8

70 87,500 6.3 3.3 2.5

80 100,000 5.2 2.9 2.1

-------------------------------------------------------------

Estimation of Dry Bean Yields

You can estimate dry bean yields by knowing the number of seeds per pod, pods per plant and

plants per 1/1000th of an acre. At the time of counting seeds and pods, the maturity status of each

should be determined.

If a seed or pod will not mature, it shouldn't be counted. Then count the total plants per 1/1000th

acre to complete the data collection.

Length of row equal to 1/1000th acre. An accurate estimate of plant population per acre can be

obtained by counting the number of plants in a length of row equal to 1/1000 of an acre. Make at

least three counts in separate sections of the field, calculate the average of these samples, then

multiply this number by one thousand (1,000).

Length of Single Row

Row Width to Equal 1/1000 of an acre

-----------------------------------------

(inches) (feet) (inches)

6 87 1

10 52 3

15 34 10

22 23 9

30 17 5

36 14 6

-----------------------------------------

Within a representative and uniform plant stand, randomly select five plants each from at least five

randomly selected locations in the field.

Keeping all plant data separate, pull and count the pods from each plant and then count the seeds

to determine average seeds per pod for all five replications. These data are combined with the

average number of plants per 1/1000th acre.

Average Number of

Seeds per Pound

--------------------------------------

Kidneys 900-1000

Pintos 1400

Great Northerns 1600-1800

Pinks/Small Reds 1600-2000

Navies/Blacks 3000

--------------------------------------

Seeds per pound can vary 10-20% for different varieties within a bean class. If available, use

reported estimates for seed number per pound for your variety.

The accuracy of yield estimate can be improved by counting seeds and pods from at least 10 plants

per replication.

Calculations

1. (Average seeds per pod) x (average pods per plant) equals average seeds per plant.

2. (Average seeds per plant) x (plants per 1/1000th of an acre) x (1000) divided by seeds per

pound of the variety equals yield in pounds per acre.

Estimates Program

Dry Edible Beans

Consists of acreage and production reports giving total United States and 17 individual state

estimates. The 17 states are California, Colorado, Idaho, Kansas, Michigan, Minnesota, Montana,

Nebraska, New Mexico, New York, North Dakota, Oregon, Texas, Utah, Washington, Wisconsin

and Wyoming.

Reports on acreage and production are released throughout the year. The following gives a

summary by individual reports. Estimates are total of all classes, unless otherwise indicated.

Planting Intentions released end of March each year.

J une Planted Acres released end of June and contains estimates on acres planted and

intended for harvest.

Planted Acres by Commercial Class are included in the August production forecast,

released around August 12.

Production Forecasts are made as of August 1 and October 1. Production forecasts

consist of adjusted acres for harvest, yield per acre and total production. Release dates are

around August 12 and October 12.

Production Estimate by Commercial Class in early December is an estimate of the

current year's planted and harvested acres, yield per acre and production, by commercial

class. The commercial class acreage, yield and production estimate are released around

December 9.

North Dakota County Estimates contain acres planted, acres harvested, yield per acre

and total production by county. County estimates will be available the middle of March

each year for the previous year's estimates. County data by commercial class is not

available.

Minnesota

Ag Statistics Service

8 East Fourth St., Suite 500

St. Paul, MN 55101

Phone: 612-296-2230

North Dakota

Ag Statistics Service

PO Box 3166

Fargo, ND 58108

Phone: 701-239-5306

Crop Rotation and Disease Management

Several disease-producing bean pathogens are either soil borne or borne on bean crop residue. A

three year crop rotation helps reduce carryover of most disease pathogens, including rust, bacterial

blights, most root rots and anthracnose. A four year rotation may be needed if white mold is severe

in a field. Crop rotation, although it helps to reduce disease carryover, is not a "cure-all" since many

pathogens can be air borne and may blow in from nearby fields. This is particularly notable in the

case of white mold and rust.

Some bean pathogens attack only beans; these include the bacterial blights, rust and anthracnose.

Crop rotation reduces populations of these pathogens. Field selection is also important: if possible,

avoid planting next to a field that was severely infected with rust last year.

Other pathogens, such as the Rhizoctonia root rot pathogen and white mold (Sclerotinia), attack

several crops (hosts), and crop rotation must take into account all crops that are host of the

pathogen. Specific considerations follow.

White mold attacks many broad leaved crops. Dry beans, sunflower and canola are among the

most susceptible. Other crops that are slightly less susceptible include soybeans, safflower,

mustard, lentils, and chickpeas (garbanzo beans). Crops which are moderately susceptible include

alfalfa, field peas, and potatoes. Flax and buckwheat are only slightly susceptible, and produce very

few of the survival structures called sclerotia. They are less liable to be severely attacked and less

liable to help maintain a white mold population than most other broad leaved crops. Sugarbeets

have not been attacked by white mold in Minnesota or North Dakota. Members of the grass family,

including small grains, corn and millet are immune to white mold and are good rotational crops for

dry bean disease management.

Rhizoctonia causes a root rot of dry beans. The same strains of Rhizoctonia that attack dry beans

also cause a severe root rot of sugarbeets, and can cause a root rot of soybeans. Including two of

these crops in a rotation is likely to lead to the buildup of Rhizoctonia. One of the Rhizoctonia

strains that attack dry beans, sugarbeets and soybeans also attack flax and lentils.

Dry Bean Fertility

Dry bean is responsive to fertilizer when soil levels are inadequate to support yield levels possible

with existing soil moisture and growing season climatic conditions. Soil testing is recommended to

determine the probability of crop response to fertilizer amendments. If soil levels are less than

adequate, dry bean may respond to nitrogen (N), phosphorus (P), potassium (K) and zinc (Zn) in

many Northern Plains soils. Soil test cores should be taken at 0-6 inch and 6-24 inch depths. N is

analyzed on both core depths, and P,K and Zn are analyzed on the 0-6 inch depth. Salt levels on

both depths may be analyzed if there is reason to suspect a salt problem. Soil pH may be

determined on the surface depth if iron chlorosis problems are anticipated.

Phosphorus

Phosphorus should be applied as recommended in Table 1. Soil test levels indicating medium

levels and lower would be expected to respond to P fertilizer. P fertilizer may be broadcast or

banded. Banded rates of P in the very low or low range may be reduced by one-third from table

recommendations since the broadcast recommendations also include extra buildup fertilizer useful

in long-term fertility programs. Reducing the rates will not result in long-term improvement of soil P

fertility but may increase short-term profitability in the current crop year.

Table 1. Phosphorus recommendations for dry bean.

Soil Test Phosphorus, ppm

--------------------------------

VL L M H VH

Bray Pl 0-5 6-10 11-15 16-20 21+

Olsen 0-3 4-7 8-11 12-15 16+

-----------------------------------------

lb/A -------- lb P

2

O

5

/Acre --------

1200 20 15 10 0 0

1400 25 20 15 0 0

1600 30 25 15 0 0

1800 35 25 15 0 0

2000 45 30 20 10 0

2200 50 35 20 10 0

2400 55 40 25 10 0

-----------------------------------------

Banded P should not be placed in contact with the seed. In fact, no fertilizer should be placed in

contact with the seed. The fertilizer band should be placed with at least 1 inch of complete

separation from the seed. A band 2 inches to the side and 2 inches below the seed is very

commonly used.

Potassium

Potassium is seldom required in most Northern Plains soils; however, a soil test should be analyzed

to determine the probability of response. Medium K level or lower may respond to K fertilizer. Lower

K levels may sometimes be found on sandy ridges within the region. The rate of K recommended at

different K soil test levels is shown in Table 2. K fertilizer may be broadcast or banded. Banded K

should not be placed with the seed. At least 1 inch of seed and fertilizer separation is required.

Table 2. Potassium recommendations for dry bean.

Soil Test Potasium, ppm

-------------------------------------

Yield VL L M H VH

Goal 0-40 41-80 81-120 121-160 161+

----------------------------------------------

lb/A ----------- lb K

2

O/Acre -----------

1200 35 15 0 0 0

1400 35 15 0 0 0

1600 40 15 0 0 0

1800 45 20 0 0 0

2000 50 20 0 0 0

2200 55 25 0 0 0

2400 60 25 0 0 0

----------------------------------------------

Nitrogen

Inoculation

Many legumes have the ability to fix N from the air without the use of commercial fertilizers if

inoculated with a nitrogen-fixing bacteria. The N-fixing bacteria for dry bean is called Rhizobium

phaseoli, and it is specific for dry bean. Inoculant used for soybean or pea are different and will not

infect dry bean. Unfortunately, the relationship between dry bean and Rhizobium phaseoli is not

strong. Dry, hot weather, short periods of soil water saturation, and cold weather, will all result in

sloughing off of nodules, so it may be difficult to achieve high dry bean yields consistently using

inoculation for an N source.

Dry bean seed is usually inoculated with a chemical used to control bacterial blight. Until recently,

many dry bean producers would not use an inoculation treatment because of the fear that the

chemical would also kill the Rhizobium bacteria. It was recently shown that at least some newer

strains or formulations resisted the seed treatment, and would produce greater nodule numbers

when inoculant was applied to seed immediately prior to planting. However, higher rates of soil N at

planting decreased the number of nodules on the plant. Therefore, the following guidelines are

suggested to determine whether to inoculate or apply fertilizer N instead.

Inoculate when

Yields 2,000 lb/acre represent realistic yield goals, and soil nitrate-N levels are 50 lb/acre or less.

Use fertilizer N only when

Yields greater than 2,000 lb/acre are consistently desired, or when beginning soil nitrate-N levels

are greater than 50 lb/acre.

Commercial N Fertilizer

Because of the inconsistency of inoculation in supplying season long N nutrition, N fertilizer is often

recommended. Table 3 shows the amount of N required for selected yield levels. The general

formula for these recommended levels is:

N recommended = Yield Goal X 0.05 less soil test nitrate-N to 2 ft., previous crop credit from other

legumes in the rotation and a sampling date adjustment if fall sampled before September 15 of lb

N/day.

Table 3. N recommendations for dry bean.

Soil N plus

Yield Goal Fertilizer N Required

---------------------------------------

lb/A lb/Acre 2'

1200 60

1400 70

1600 80

1800 90

2000 100

2200 110

2400 120

---------------------------------------

Some producers are reluctant to apply fertilizer N because of fear of white mold caused by

enhancing robust early growth. However, studies have indicated that higher susceptibility to white

mold is dependent on increased crop growth from either inoculation or N fertilizer. If the crop is

healthy enough to achieve a high yield level, it is susceptible to white mold damage if environmental

conditions are favorable for the disease, regardless of source of N. Recently developed upright

growth varieties, wider rows and crop rotation away from white mold susceptible crops may help to

reduce white mold infection and damage. Certainly, being prepared to apply fungicides at the

proper time is important in a higher yield environment.

Zinc

Dry bean is one of only a few crops in the region to regularly respond to zinc fertilizer in low zinc

soils. Soil test levels below 0.8 ppm may respond to fertilizer zinc application. Zinc deficiency may

be seen as bronzing, browning and death of leaf tissue, stunting, and poor vining. Zinc deficiency

may be treated by foliar sprays of zinc sulfate, zinc chelate or ammoniated zinc solutions. Zinc

deficiency may be prevented with preplant or planter treatments of zinc sulfate, zinc chelates or

ammoniated zinc solutions. A treatment of 3-5 lb/acre actual zinc preplant incorporated as zinc

sulfate may improve soil availability for several years.

Iron Chlorosis

Dry bean is generally more resistant to iron chlorosis than soybean, but it can still be observed in

some fields under certain conditions. Iron chlorosis is the yellowing of upper leaves of dry bean in

response to low soil iron levels, or more commonly, the unavailability of soil iron due to soil

conditions related to high soil pH, high levels of carbonate minerals and possibly high salts. Soil pH

levels higher than 7.0 may be accompanied by high levels of calcium/magnesium carbonates in the

soil. Carbonates dissociate in moist soils to form bicarbonate, which lowers the dry bean plant's

ability to take up soil iron. Wetter soils contain higher levels of soluble bicarbonate than dry soils.

Wetter soils may also contain higher levels of salts due to an increase in soil water table. The

combination of high levels of soil carbonates and salts has been shown to increase the level of iron

chlorosis symptoms in soybean. A similar relationship is also probable for dry bean. Iron chlorosis

may be minimized by planting varieties showing tolerance and having a higher tolerance to salt

damage. Iron sprays have performed inconsistently in the past but if used should be applied early in

the season for best effect. Late season spraying after about the third true leaf would reduce

effectiveness. Iron sprays of ferrous sulfate or iron chelates have been used with limited success.

Salts

Dry bean is very sensitive to salt damage. Levels of salt higher than 2 mmho/cm as a 1-1 soil water

extract begin to reduce yield expectations of dry bean. Salt levels are reduced by lowering water

table levels. This is difficult to do in exceptionally wet years. However, in more normal years, lower

salt levels are achieved by continuous cropping and introducing deep rooting crops into the rotation.

See NDSU Extension circular SF-1087 for more information.

Weed Control

The weed control suggestions in this production guide are based on the assumption that all

herbicides mentioned will have a registered label with the Environmental Protection Agency.

Herbicides should be used which are no longer registered or have not yet received registration for

dry edible bean. Dry beans treated with with a non-registered herbicide may have an illegal residue

which, if detected, could cause condemnation of the crop. Nonregistered herbicide use is illegal and

a user could be subject to a heavy fine even without detectable residue.

Chemical Weed Control Guide for Dry Edible Beans

-----------------------------------------------------------------------

Roundup Ultra, Roundup Ultra RT, Glyphos (glyphosate)

$/A: 3.00-12.00

Rate: 0.5 to 2 pt of a 3 lb ae/gal conc. (0.19 to 0.75)

Weeds: Emerged grass and broadleaf weeds.

Apply: Preplant or anytime prior to crop emergence.

Remarks: A nonselective, translocated, foliar herbicide. No soil

residual activity. Refer to label for adjuvant use.

-----------------------------------------------------------------------

Eptam (EPTC) - Spring Applied

$/A: 12.00-19.00

Rate: 3.5 to 4.5 pt 7E, 15 to 20 lb 20G (3 to 4)

Weeds: Grass and some broadleaf weeds.

Apply: PPI

Remarks: Weak on wild mustard. PPI immediately after application. May

be tank-mixed with trifluralin, Sonalan, Prowl, Lasso, or

Dual to increase spectrum of weeds controlled. Consult label

for rate range for specific tank mix.

-----------------------------------------------------------------------

Eptam (EPTC) - Fall Applied

$/A: 20.00-25.00

Rate: 4.5 to 5.25 pt 7E, 20 to 22.5 lb 20G (4 to 4.5)

Weeds: Grass and some broadleaf weeds.

Apply: Fall: Incorporated after October 15 until freeze-up.

Remarks: Same as Eptam Spring applied.

-----------------------------------------------------------------------

Trifluralin

$/A: 4.00-8.50

Rate: 1 to 2 pt 4E, 5 to 10 lb 10G, 0.83 to 1.67 lb 60DF (0.5 to 1)

Weeds: Grass and some broadleaf weeds.

Apply: PPI: Fall or Spring.

Remarks: No wild mustard control. PPI within 24 hours after

application. May be tank-mixed with Dual, Eptam, Frontier

and Lasso.

-----------------------------------------------------------------------

Sonalan (ethalfluralin)

$/A: 5.00-17.50

Rate: 1.5 to 4.5 pt EC, 5.5 to 17 lb 10G (0.55 to 1.7)

Weeds: Grass and some broadleaf weeds.

Apply: PPI: Fall after October 15 or Spring. Spring incorporated

for EC only.

Remarks: The low rate should be used on coarse textured, sandy soils.

The high rate should be used on fine textured soils for

black nightshade control. Poor wild mustard control.

-----------------------------------------------------------------------

Sonalan (ethalfluralin)

$\A: 8.00-14.00

Rate: 7.5 to 12.5 lb 10G (0.75 to 1.25)

Weeds: Foxtail suppression.

Apply: Fall: Incorporated between October 1 to December 31 or Spring.

Remarks: Use in reduced or conservation tillage systems. Incorporate

twice at 2-3 inches deep using a V-blade undercutter or

rotary hoe at 5 mph. For fall applications, incorporate

once in the fall and once in the spring before planting.

-----------------------------------------------------------------------

Prowl (pendimethalin)

$/A: 8.00-12.50

Rate: 2.4 to 3.6 pt EC, 1.2 to 2.5 lb DG (0.75 to 1.5)

Weeds: Grass and some broadleaf weeds.

Apply: PPI only.

Remarks: Use higher rates on fine textured soils. Preplant

incorporation is required to provide more consistent results.

Refer to label for rotational restrictions. Can be tank-

mixed and applied PPI with Dual, Eptam, Frontier, Lasso,

Micro-Tech, and Partner.

-----------------------------------------------------------------------

Eptam (EPTC) + Sonalan (ethalfluralin)

$/A: 21.00-32.00

Rate: 2.5 to 3.5 pt 7E, 11 to 20 lb 20G + 3 to 4.25 pt EC,

11.25 to 16 lb 10G (2.2 to 3 + 1.125 to 1.6)

Weeds: Grass and some broadleaf weeds including eastern

black nightshade.

Apply: PPI

Remarks: Use low rate on coarse textured soils. Use high rate on fine

textured soils. PPI immediately after application. Weak on

wild mustard.

-----------------------------------------------------------------------

Dual II (metolachlor)

$\A: 17.00-26.00

Rate: 2 to 3 pt (2 to 3)

Weeds: Grass and some broadleaf weeds including eastern

black nightshade.

Apply: PPI or PRE

Remarks: Weak on wild mustard. Use low rate on coarse textured soils.

Use higher rate on fine textured soils high in organic

matter. Incorporation improves consistency of weed control.

Can be tank-mixed with Eptam, Prowl, Sonalan, and Treflan.

-----------------------------------------------------------------------

Frontier (dimethenamid)

$\A: 13.00-26.00

Rate: 16 to 32 fl oz (0.75 to 1.5)

Weeds: Grass and some broadleaf weeds including eastern

black nightshade.

Apply: PPI, PRE, or POST to third trifoliate.

Remarks: Same as Dual. Can be applied POST with Basagran and Pursuit.

-----------------------------------------------------------------------

Lasso (alachlor) RUP

$/A: 13.00-20.00

Rate: 2 to 3 qt (2 to 3)

Weeds: Grass and some broadleaf weeds including eastern

black nightshade.

Apply: PPI

Remarks: Same as Dual.

-----------------------------------------------------------------------

Basagran (bentazon)

$/A: 8.50-17.00

Rate: 1 to 2 pt (0.5 to 1)

Weeds: Wild mustard, cocklebur, Canada thistle, wild and volunteer

sunflower.

Apply: POST: Crop: Cotyledon stage or larger.

Broadleaf weeds: small seedlings.

Remarks: Thorough spray coverage is essential. Addition of oil

concentrate at 1 qt/A improves weed control. Canada thistle

control requires a second application 7 to 10 days later.

-----------------------------------------------------------------------

Basagran (bentazon)

$/A: 8.50/8.50

Rate: 1 pt/1 pt (0.5/0.5)

Weeds: Wild mustard, cocklebur, common lambsquarters, common ragweed,

Venice mallow, sunflower and suppression of kochia, annual

smartweed and pigweed.

Apply: POST: Apply as a split application. Apply the first

application at recommended growth stage of weeds followed by

the second application 7 to 10 days later.

Remarks: Basagran applied in a split application results in greater

weed control compared to single application. Refer to

narrative for recommended growth stage of weeds at first

application. Dry bean should be at unifoliate or first

trifoliate stage at application. Basagran should be applied

with oil additive at 1 to 2 pt/A or DASH HC at 0.5 to 1 pt/A.

-----------------------------------------------------------------------

Pursuit, Pursuit DG (imazethapyr)

$/A: 10.00

Rate: 2 fl oz 2S, 0.72 oz or 10 A/packet DG (0.5 oz)

Weeds: Wild mustard and control or suppression of black nightshade

and other weeds.

Apply: POST: Crop: After first trifoliate but before flowering.

Remarks: Reduced crop growth, quality, yield and/or delayed maturity

may result. Do not apply when stress such as cold and/or wet

conditions exist or are predicted with one week of

application. Crop damage disclaimer and liability waiver

from company representitve must be signed before use. Refer

to narrative for additional information.

-----------------------------------------------------------------------

Assure II (quizalofop)

$/A: 5.50-9.00

Rate: 6 to 10 fl oz (0.6 to 1 oz)

Weeds: Annual grasses and quackgrass.

Apply: Crop: 30 days or more prior to harvest.

Grass: 2 to 6 inches.

Remarks: Apply with oil additive at 1 qt/A to actively growing

grasses. Do not apply with vegetable oil additive. Can be

tank-mixed with Basagran. Grass control is reduced by

tank-mixtures or applications of Basagran in close interval.

The antagonism generally can be avoided by applying Assure II

1 or more days before or 5 to 7 days after Bansagran. Lack

of yellow foxtail control may result if Assure II is applied

at reduced rates or with Basagran.

Rates required for different grass species are:

Green foxtail 2 to 4 inches 7 fl oz

Yellow foxtail 2 to 4 inches 8 fl oz

Wild oat 2 to 6 inches 7 fl oz

Field sandbur 2 to 6 inches 7 fl oz

Wild proso millet 2 to 6 inches 5 fl oz

Volunteer small grains 2 to 6 inches 7 fl oz

Quackgrass 6 to 10 inches 10/7 fl oz

-----------------------------------------------------------------------

Ultima 160 (sethoxydim)

$/A: 4.50-13.50

Rate: 10 to 30 fl oz Ultima (0.1 to 0.3)

Weeds: Annual and suppression of wild oat, volunteer cereals and

quackgrass.

Apply: Crop: 30 days or more prior to harvest.

Grass: 2 to 4 inches.

Remarks: See Assure II for use of oil additive and grass antagonism

from tank-mixing with broadleaf herbicides.

Rates required for different grass species are:

Green foxtail 1 to 8 inches 20 fl oz

Yellow foxtail 1 to 8 inches 20 fl oz

Wild oat 1 to 4 inches 20 fl oz

Field sandbur 1 to 3 inches 30 fl oz

Wild proso millet 4 to 10 inches 10 fl oz

Volunteer small grains 1 to 4 inches 30 fl oz

Quackgrass 6 to 8 inches 30/20 fl oz

-----------------------------------------------------------------------

Gramoxone Extra (paraquat) RUP

$/A: 3.50-6.00

Rate: 1 to 1.5 pt (0.31 to 0.47)

Weeds: Desiccant

Apply: 7 days or more prior to harvest.

Remarks: Apply when at least 80% of the pods are yellowing and mostly

ripe with no more than 40% (bush type beans) or 30%

(vine type) of the leaves still green.

-----------------------------------------------------------------------

Leafex-3, Defol (sodium chlorate)

$/A: 12.00

Rate: 2 gal of a 3 lb/gal conc. (6)

Weeds: Desiccant

Apply: 7 to 10 days prior to harvest, after pods are brown.

Remarks: Thorough coverage of plant is essential. Apply in 5 to 10 gpa

by air or 20 to 30 gpa by ground.

-----------------------------------------------------------------------

Chemical Names, Formulations and Manufacturers

Trade Name Common Name Conc. Manufacturer

--------------------------------------------------------------

Assure II quizalofop 0.8 E DuPont

Basagran bentazon 4 S BASF

Defol sodium chlorate 6 S Drexel

Dual II metolachlor 7.8 E Novartis

Eptam EPTC 7E, 20G Zeneca

Frontier dimethenamid 6 E BASF

Gramoxone Ext. paraquat 2.5 S Zeneca

Lasso/others alachlor 4E, 15G Monsanto

Prowl pendimethalin 3.3 E Am. Cyanamid

Pursuit imazethapyr 2E, 70DG Am. Cyanamid

Roundup Ultra glyphosate 3 S Monsanto

Sonalan ethalfuralin 3 E DowElanco

Treflan/others trifluralin 4 E DowElanco/others

Ultima 160 sethoxydim 1.3 E BASF

--------------------------------------------------------------

Herbicide Comments

Eptam (EPTC) at 2.3 to 3.4 pt plus either Prowl at 1.2 to 3.6 pt 3.3E or 0.83 to 2.5 lb DG, trifluralin

at 1 pt/A of a 4 lb/gal concentrate or Sonalan at 1.5 to 4.5 pt EC/A or 5.5 to 17 lb/A 10G controls a

broader spectrum of weeds than either herbicide used separately, especially wild oat, common

lambsquarters, and eastern black nightshade. Eptam plus Prowl must be incorporated thoroughly

immediately after application by setting the implement at a 4 to 6 inch depth. The mixture allows

lower rates and reduces the chance of carryover from any dinitroaniline herbicide.

Sonalan (ethalfluralin), trifluralin, and Prowl (pendimethalin). Lasso at 2 to 3 qt/A PPI or Dual at 2

to 3 pt/A PPI or PRE controls annual grasses and some broadleaf weeds, including nightshade.

Dual may be tank-mixed with Eptam for wild oat control. Trifluralin, Prowl and Sonalan applied PPI

controls annual grasses and certain broadleaf weeds except wild mustard, common cocklebur, and

sunflower. The low rates should be used on coarse-textured, sandy soils. The high rates should be

used for control of eastern black nightshade. Incorporate in the top 2 to 3 inches of soil within 2

days of application. Trifluralin, Prowl and Sonalan are each registered as a tank-mixture with Lasso,

Dual, and Eptam. Sonalan has less soil residue but is more active than trifluralin.

Sonalan 10G at 7.5 to 12.5 lb/A 10G applied in the fall or spring suppresses foxtail in dry edible

bean and sunflower grown in reduced tillage systems. Apply in the fall between October 10 and

December 31, or in the spring PPI before planting. Apply to tilled land or standing or chopped

stubble. Incorporate twice 2 to 3 inches deep using a V-blade undercutter or with other implements

such as a rotary hoe that leave a maximum amount of crop residue on the soil surface. Operate

implements approximately 5 mph. The first incorporation should be performed within 48 hours after

application. The second incorporation should be performed at an angle to the first incorporation and

must be delayed at least 14 days after the first incorporation. Sonalan 10G applied in the fall should

be incorporated once in the fall and the second time in the spring before planting. Refer to label for

application rate according to soil type. The higher rate in the rate range should be used in high crop

residues and heavy weed populations.

Split Applications of Basagran in Dry Bean. Basagran can be applied as successive sequential

treatments for broadleaf weed control in navy, pinto, kidney and great northern types of dry bean.

The first Basagran application should be made before the weeds are 0.5 to 4 inches tall, depending

the weed species. Refer to label for information on weed sizes at application. Apply Basagran at 1

pt/A plus petroleum oil or Dash HC at 0.5 to 1 pt/A and then repeat the application 7 to 10 days

later.

Basagran applied as a planned split application program will offer improved broadleaf weed control

compared to a single application. Split applications will control common cocklebur, common

lambsquarters, annual smartweed, Venice mallow, and wild mustard. Control or suppression may

be observed on common ragweed, kochia, pigweed, and sunflower. NDSU research has shown

greater control of common lambsquarters, redroot pigweed and kochia by applying Basagran as

split treatments either twice at 1 pt/A, 3 times at 0.67 pt/A, or 4 times at 0.5 pt/A as opposed to one

application at 2 pt/A. Greater control of the above mentioned weeds was observed by using Dash

HC as opposed to a petroleum oil or ammonium sulfate.

Pursuit (imazethapyr) at 2 fl oz/A or Pursuit DG at 0.72 oz/A or 10 acres per water soluble packet

applied POST only controls wild mustard and provides suppression of nightshade in pinto, navy,

great northern, kidney, black turtle, cranberry type dry beans. Reduced crop growth, yield, and/or

delayed maturity may result from application. Do not apply if planting is delayed, or cold and/or wet

weather are present or predicted to occur within one week of application. Do not apply to Domino

variety black turtle bean. Pinto varieties UI-111 and Olathe are more sensitive to injury than other

Pinto varieties. Apply Pursuit with NIS at 0.25% v/v to dry beans having at least one trifolioliate leaf.

DO NOT use oil additives, liquid fertilizer or DASH.

Pursuit may control several grass and broadleaf weeds not listed on the label. Pursuit has

controlled mustard, nightshade, foxtail, pigweed, kochia, marshelder, Russian thistle, common

cocklebur, sunflower, smartweed, wild buckwheat, lanceleaf sage, common lambsquarters, and

common ragweed less than 1 inch tall in NDSU field trials. Soil residual from POST applications

may provide erratic control of subsequent flushes of weeds. Erratic control of eastern black

nightshade may occur from Pursuit reaching the soil during a POST application. However, reduction

in number and intensity of other flushes of weeds may be observed.

The following is the rotational crop guidelines after a Pursuit application: 9.5 months for corn, wheat

and dry bean, 18 months for barley, oat, rye, and sunflower, 40 months for sugarbeet, and 26

months for all other crops not listed.

Grazing restriction for dry beans.

Herbicide Restrictions

-----------------------------------

Pursuit Do not graze or feed

Ultima 160 No restrictions

-----------------------------------

Herbicide Carryover

The persistence of phytotoxic levels of a herbicide for more than 1 year can be a problem with some

of the herbicides used in North Dakota. Herbicide residues are most likely to occur following years

with unusually low rainfall because chemical and microbial activity needed to degrade herbicides

are limited in dry soil. Crop damage from herbicide residues can be minimized by applying the

lowest herbicide rate required for good weed control, by using band rather than broadcast

applications, and by moldboard plowing before planting the next crop. Mold-board plowing reduces

phytotoxicity of some herbicides by diluting the herbicide residue in a large volume of soil.

Moldboard plowing is effective in reducing the residual effects of trifluralin, Sonalan, Prowl, Nortron

SC, atrazine, and Lexone/Sencor.

Rotation restrictions for dry beans.

Herbicide Months after Application

----------------------------------------------

Accent 10

Ally 22a

Amber 22

Assert NCS

Atrazine b

Banvel (<0.25 pt/A) NCS

Banvel (>0.25 pt/A) SCS

Basis 8

Basis Gold 18

Broadstrike + Dual 4

Broadstrike + Treflan 4

Broadstrike Plus 10.5

Buckle NCS

Clarity (<0.25 pt/A) NCS

Curtail 12c

Exceed b

Far-Go NCS

Finesse b

Harness NCS

Hornet 10.5

Lexone 12

Matrix 10

Lighting 9.5

Peak 10

Permit 10

Pursuit 4

Scorpion III 10.5c

Sencor 12

Stinger 10.5c

Surpass NCS

Tordon (<1.5 fl oz/A) SCS

----------------------------------------------

NCS = Next cropping season

SCS = Second cropping season

a = Requires 22 months and 22 inches of annual precipitation

west of ND Highway 1 or 34 months and 34 inches of annual

precipitation east of ND Highway 1.

b = Do not plant until field bioassay indicates it is safe to

plant dry beans. Rotation to dry bean after atrazine is

rate and soil pH dependant.

c = Do not plant dry bean for 18 months after application on

soil with less than 2% organic matter and if less than

15 inches of rainfall during the 12 months following

application OR dry bean may be planted 12 months after

application if risk of injury is acceptable.

Management and Control of Nightshade

Nightshades have become a serious weed problem in ND. Human activity associated with crop

production is the greatest contributor to nightshade seed dissemination. Moving tillage and

harvesting equipment from field to field or planting crop seed contaminated with nightshade seed

easily spreads seed. Three different nightshades are found in North Dakota: eastern black

nightshade, hairy nightshade, and cutleaf nightshade.

Nightshade seed germination occurs in June through September and is influenced strongly by

moisture. Hairy nightshade germinating in early fall may produce viable seed before frost while a

black nightshade plant requires a longer growing season. Nightshade can compete in most crops,

including shaded canopy conditions. However, nightshade is visible after harvest where growth

accelerates from exposure to sunlight. Nightshade seeds become viable shortly after berry

formation and can remain viable in the soil beyond 10 years. NDSU studies show one nightshade

plant can produce 178,000 seeds. A nightshade plant was found to produce over 800,000 seeds.

Nightshades plants are frost tolerant, can remain green through the harvest season and can cause

serious harvest problems. Berries are poisonous and the juice from ruptured berries can stain crop

seed, glue nightshade seed and dirt to bean seed. Nightshade can be spread to other fields if

contaminated seed is used for planting. Dry berries are similar in size to soybean seed and are

difficult to separate from seed.

Rain and late season germination are major factors responsible for increased nightshade in ND.

Rain events cause multiple flushes of nightshade and late flushes may develop after normal crop

spraying is completed. Many herbicides used in crop production are applied early, before most

nightshade flushes emerge. Fewer rain events will reduce nightshade flushes. Nightshade can

compete in several environments including in a dense crop under shaded conditions. Nightshades

are immune to shading. Crops that canopy late and cultural methods of early planting, late

cultivation and wide row spacings allow nightshade to grow and develop faster than the crop.

Nightshade is tolerant to many herbicides including sulfonylureas. Herbicides remove other

broadleaf weeds, allowing nightshade to increase by eliminating competition. Residual herbicides

help control continuous nightshade flushes but few effective herbicides have residual activity on

nightshade.

Successful nightshade control requires allowing no seed production. Avoid planting crops

contaminated with nightshade seed. Plan a crop rotation where nightshade can be controlled.

Plant crops, such as small grains or soybean where effective herbicides are labeled for nightshade

control. Herbicides effective on small nightshade in small grains include Tordon, 2,4-D, Banvel,

Buctril, Bronate, and Curtail.

Herbicides used in soybeans and dry bean (only those labeled) for nightshade control are Eptam,

Lasso, Sonalan, Broadstrike + Dual, Broadstrike + Treflan, Cobra, Blazer, and Pursuit. Basagran is

more active on hairy nightshade than eastern black nightshade. Cobra and Blazer are effective only

on small nightshade. Most row crop herbicides, except Puruit and Broadstrike, do not have residual

activity to control continuous flushes of nightshade.

The residue can remain in the soil for more than one year, so long term crop rotation must be

planned if either of these herbicides are used.

Relative Herbicide Effectiveness on Weeds and Persistence in Soil

This table gives a general rating of relative herbicide effectiveness to weeds listed and persistance

of herbicides in soil. Under favorable weather conditions, control may be better than indicated.

Under unfavorable conditions, some herbicides rated as good or fair may give erratic and

unacceptable results. Also, dry and/or cool weather increases herbicide persistence while wet

and/or warm weather reduces herbicide persistence.

Weed control ratings in this section are based on the following scale:

E = Excellent = 90 to 99% Control

P = Poor = 40 to 65% Control

G = Good = 80 to 90% Control

N = None = No Control

F = Fair = 65 to 80% Control

Herbicide persistence ratings are for residues present 12 months after application:

O = Often

S = Seldom

N = None

Soil

Applied

Herbicides

B

a

r

n

y

a

r

d

g

r

a

s

s

F

i

e

l

d

S

a

n

d

b

u

r

F

o

x

t

a

i

l,

G

r

e

e

n

F

o

x

t

a

i

l,

Y

e

l

l

o

w

Q

u

a

c

k

g

r

a

s

s

V

o

l

u

n

t

e

e

r

C

e

r

e

a

l

s

W

i

l

d

O

a

t

W

i

l

d

P

r

o

s

o

M

i

l

l

e

t

H

e

r

b

i

c

i

d

e

P

e

r

s

i

s

t

e

n

c

e

Dual (PRE) G-E P G-E G-E N F-G G P N

Dual (PPI) F-G P G G N F P N N

Eptam (PPI) E G-E E E F-G G-E G-E F-G N

Frontier (PPI) G-E G G-E G-E N G F F N

Frontier (PRE) F-G G G-E G-E N F F F N

Lasso/others (PPI) G-E F G-E G-E N F-G F-G P-F N

Lasso/others (PRE) F-G P G G N F-G P P N

Prowl/Pentagon (PPI) E G E

1

E

1

N G G P-F S

Prowl Pentagon (PRE) E F G-E

1

G-E

1

N F-G P-F PF S

Sonalan (PPI) E G E

1

E

1

N G G P-F S

Trifluralin (PPI) E G E

1

E

1

N N F-G P-F S

PPI = Preplant Incorporated, PRE = Preemergence

1

Except where resistant populations have developed.

Relative Herbicide Effectiveness on Weeds and Persistence in Soil (continued)

Soil

Applied

Herbicides

B

u

c

k

w

h

e

a

t,

W

i

l

d

C

o

c

k

l

e

b

u

r,

C

o

m

m

o

n

F

l

i

x

w

e

e

d

K

o

c

h

i

a

L

a

m

b

s

q

u

a

r

t

e

r

s,

C

o

m

m

o

n

L

a

n

c

e

l

e

a

f

S

a

g

e

M

a

l

l

o

w,

V

e

n

i

c

e

M

a

r

s

h

e

l

d

e

r

M

u

s

t

a

r

d,

W

i

l

d

N

i

g

h

t

s

h

a

d

e,

B

l

a

c

k

P

i

g

w

e

e

d,

R

e

d

r

o

o

t

P

r

i

c

k

l

y

L

e

t

t

u

c

e

R

a

g

w

e

e

d,

C

o

m

m

o

n

S

m

a

r

t

w

e

e

d,

A

n

n

u

a

l

S

u

n

f

l

o

w

e

r

T

h

i

s

t

l

e,

R

u

s

s

i

a

n

T

h

i

s

t

l

e,

C

a

n

a

d

a

Dual (PPI) P N F F N N P G G-E P P-F P N F N

Dual (PRE) P N P-F P-F N N P G F-G P P-F P N P-F N

Eptam (PPI) F P P F F N N P P F-G G P F P N P N

Frontier (PPI) P N F F N P-F G-E E P P N P-F N

Frontier (PRE) P N P-F F N P-F G G-E P P N P N

Lasso/generics (PPI) P N F F N N P G G-E P P P N F N

Lasso/generics (PRE) P N P-F P-F N N P G F-G P P P N P-F N

Prowl/Pentagon (PPI) P-F N P G-E E N F-G N N P E N F P N G N

Prowl/Pentagon (PRE) P N P F-G G N F N N G N P P N F-G N

Sonalan (PPI) P-F P P G-E E N F-G N N F E P P P N G-E N

Trifluralin (PPI) P-F N P G-E G-E N F-G N N P E N P P N G N

PPI = Preplant Incorporated, PRE = Preemergence

1

Except where resistant populations have developed.

Soil

Applied

Herbicides

B

a

r

n

y

a

r

d

g

r

a

s

s

F

i

e

l

d

S

a

n

d

b

u

r

F

o

x

t

a

i

l,

G

r

e

e

n

F

o

x

t

a

i

l,

Y

e

l

l

o

w

Q

u

a

c

k

g

r

a

s

s

V

o

l

u

n

t

e

e

r

C

e

r

e

a

l

s

W

i

l

d

O

a

t

W

i

l

d

P

r

o

s

o

M

i

l

l

e

t

H

e

r

b

i

c

i

d

e

P

e

r

s

i

s

t

e

n

c

e

Assure II E E E G-E G-E E E

1

E N

Basagran N N N N N N N N N

Gramoxone Extra G G G G P F-G G F-G N

Pursuit G P-F G F-G N G F P-F O

Roundup Ultra E E E E E E G-E E N

Ultima 160 E E E E G E G-E

1

E N

1

Herbicides will not control resistant biotypes.

Soil

Applied

Herbicides

B

u

c

k

w

h

e

a

t,

W

i

l

d

C

o

c

k

l

e

b

u

r,

C

o

m

m

o

n

F

l

i

x

w

e

e

d

K

o

c

h

i

a

L

a

m

b

s

q

u

a

r

t

e

r

s,

C

o

m

m

o

n

L

a

n

c

e

l

e

a

f

S

a

g

e

M

a

l

l

o

w,

V

e

n

i

c

e

M

a

r

s

h

e

l

d

e

r

M

u

s

t

a

r

d,

W

i

l

d

N

i

g

h

t

s

h

a

d

e,

B

l

a

c

k

P

i

g

w

e

e

d,

R

e

d

r

o

o

t

P

r

i

c

k

l

y

L

e

t

t

u

c

e

R

a

g

w

e

e

d,

C

o

m

m

o

n

S

m

a

r

t

w

e

e

d,

A

n

n

u

a

l

S

u

n

f

l

o

w

e

r

T

h

i

s

t

l

e,

R

u

s

s

i

a

n

T

h

i

s

t

l

e,

C

a

n

a

d

a

Assure II N N N N N N N N N N N N N N N N N

Basagran F-G G-E E F-G F-G P E G-E E F F E G E E F F-G

Gramoxone Extra F F-G G G-E E E G G E G-E E E G-E E E E P

Pursuit F-G G E E

2

F-G E P E E E E E P-F G G-E G-E N

Roundup Ultra P-F G-E G-E F-E G-E E E G-E G-E F-G G-E E E E G F-G G

Ultima 160 N N N N N N N N N N N N N N N N N

1

Herbicides will not control resistant biotypes.

Weed Seedling Identification

Wild Buckwheat (46KB color photo)

Buffalo Bur (38KB color photo)

Cocklebur (56KB color photo)

Wild Mustard (28KB color photo)

Kochia (85KB color photo)

Pennsylvania Smartweed (46KB color

photo)

Common Ragweed (43KB color photo)

Black Nightshade (82KB color photo)

Pigweed (40KB color photo)

Velvetleaf (65KB color photo)

Barnyard Grass (57KB color photo)

Large Crabgrass (80KB color photo)

Wild Sunflower (53KB color photo)

Russian Thistle (70KB color photo)

Giant Ragweed (34KB color photo)

Giant Foxtail (22KB color photo)

Green Foxtail (28KB color photo)

Wild Oat (26KB color photo)

Yellow Foxtail (26KB color photo)

Wild Proso Millet (36KB color photo)

Field Bindweed (33KB color photo)

Yellow Nutsedge (19KB color photo)

Fall Panicum (16KB color photo)

Jerusalem Artichoke (47KB color

photo)

Hedge Bindweed (32KB color photo)

Perennial Sowthistle (39KB colorphoto)

Disease Identification and Management

Principles of Disease Management

Fungi, bacteria and viruses cause important diseases of bean. Diseases reduce yield and quality of

harvested bean and add to production costs. Diseases can be difficult to control, but management

practices can reduce their impact. Management practices can be grouped into three principles.

1. Keep Pathogens and Beans Separated. Observe geographic separation. The soybean

cyst nematode, which can also attack dry beans, occurs in central Minnesota. Do not bring

dry beans or soybeans from affected areas into bean growing areas.

Use high quality seed. Certified seed must meet certain quality standards with regard to

seed borne diseases. No seed is disease free, but certified seed produced under carefully

controlled conditions in the West or in the Northarvest growing area is the best way to

minimize the introduction of bean pathogens on the seed.

Use crop rotation. A rotation of three or four years is desirable, and longer rotations may be

required if disease is severe in a field. Avoid planting next to last year's bean field if

diseases were severe.

Avoid cultivating plants when wet. This helps prevent spread of pathogens, especially

bacterial pathogens.

2. Attack the Pathogen. Bury bean crop refuse by deep plowing. Foliar pathogens do not

survive well in the soil.

Scout fields for disease. Use early detection of disease to determine when to use a

fungicide. Records of disease and weed problems help in planning crop rotations.

Foliar fungicides help suppress disease development. Most fungicides protect against

infection but do not cure established infections. They should be used to prevent infection or

at the first sign of disease to prevent additional infections.

Use seed treatments to reduce early season damping off. Some seed treatments, including

streptomycin, captan and PCNB, may severely reduce the survival of Rhizobium nitrogen

fixing bacteria. These seed treatments may not be compatible with inoculation of the seed.

Some new strains of bacteria are less affected by seed treatment products. Another option

is to use an in-furrow inoculant.

3. Strengthen the Bean Plant. Plant disease-resistant varieties. Provide adequate soil

fertility, according to soil tests, and adequate trace minerals such as zinc. Avoid excess

nitrogen levels that stimulate lush plant growth. Control weeds. Plant in wide rows to help

foliage dry quickly, reducing disease potential. Use deep shanking near the planter row if

there is a hardpan. Handle seed carefully. Hill beans to stimulate lateral root development if

root rot is present, but avoid root pruning by close cultivation.

White Mold

Visual Aid (40KB color photo)

White mold is a sporadic disease which is most serious when wet weather occurs at flowering.

When the surface soil is wet, the hard black survival structures, called sclerotia, germinate to form

tiny mushroom-like bodies that liberate millions of wind-borne spores. These spores colonize dead

bean tissue, particularly the dead blossoms, then the fungus invades green tissues, causing a

watery soft rot. In wet weather infected tissues are tan colored and soft, with tufts of fluffy white

fungal growth. These tufts of "white mold" develop into hard black bodies, the sclerotia, some of

which survive many years in the soil. Leaves of infected plants turn yellow and wilt. In dry weather

affected stems have a bleached or whitish appearance. Infected seed is discolored, chalky and

lightweight.

White mold is favored by rainy weather before and at flowering, moderate temperatures and long

periods of high humidity, and keeping the lower canopy of plants wet more or less continuously for

up to two days.

Management. Crop rotation is important but of only modest value in areas of intensive bean

production, since the spores may blow in from nearby infested fields. Benlate and Topsin M are

registered for white mold control. They are more effective when applied before infection occurs.

Early bloom is the best time to apply these fungicides. Good canopy penetration is required so that

the blossoms and lower stems are covered with fungicide. The most economical method is band

application using drop nozzles, high pressure and high gallonage. High pressure broadcast

application is not quite as effective but can also be used when band application is impractical. Aerial

application using 7-10 gpa also can be effective. Widely spaced rows may help enhance drying in

the canopy. Upright varieties dry more quickly and may escape severe infection in years with

conditions that are marginal for white mold development. Deep plow infected bean crop refuse and

clean harvest equipment between fields. Avoid short rotations or rotation with other susceptible

crops, especially beans, sunflower, canola, lentils and soybeans.

Rust

Visual Aid (44KB color photo)

Rust is a very common disease and can lead to partial or complete crop failure. The rust fungus

forms pustules on the leaves and other plant parts. These pustules release a rusty-colored powder,

the summer spores, that are responsible for disease spread. These spores may be wind blown for

many miles. Infection occurs when the temperatures are moderate (60-75F) and the plant parts stay

wet for 10-15 hours. The infection cycle repeats every 10-14 days. Pustules break through the leaf

surface, opening up the interior of the plant to desiccation. Large numbers of pustules result in

plants drying out and dying even when there is good soil moisture.

Late in the season the rusty powder in the pustules is replaced with a black powder, the winter

spores. Both summer and winter spores overwinter on bean debris and can lead to infections next

spring. The winter spores produce an inconspicuous sexual stage that can lead to the development

of new rust races. The sexual stage often occurs on volunteer beans. The number of races has

been increasing in recent years, and varieties and classes of beans previously showing field

resistance may no longer be field resistant.

Management. Destroy volunteer bean plants in last year's bean fields to reduce early season rust

pressure and to retard the development of new rust races. Monitor fields carefully for rust,

particularly classes of beans known to be susceptible, such as pintos, pinks, small reds, and great

northerns. Other classes, however, may be attacked by new races, so all beans should be

monitored carefully. Protectant fungicides should be used as soon as there are two pustules per

leaf on susceptible varieties or there are a couple of "hot spots" in the field. Once rust is present in

an area, all susceptible varieties should be sprayed, even in fields where rust has not been

detected yet. No fungicide is needed once the lower pods of pinto beans begin striping. Fungicides

currently registered for rust control include chlorothalonil and maneb. Plow down infected crop

refuse shortly after harvest. Use crop rotation and avoid planting next to a field that was severely

diseased last year.

Root Rots

Visual Aid (37KB color photo)

Several fungi cause root rots, including Fusarium, Rhizoctonia and Pythium. Fusarium is the most

common, particularly in drought years. Fusarium produces a dry rot with indistinct brown lesions,

and occasionally a more general browning of the roots. Rhizoctonia is most common in warm moist

soils when beans are grown in rotation with sugar-beets or soybeans. Rhizoctonia causes more

distinct lesions that are chocolate-colored to dark red. Pythium develops in wet soils, causing a soft

brown rot that results in a hollow tap root. Plants with root rot may be stunted with yellowed leaves.

Infected plants form fewer pods and smaller seeds.

Management. Extend crop rotations beyond four years. Root rot is less severe following wheat. If

Rhizoctonia is present, avoid sugarbeets in close rotation. Some varieties are tolerant. Plant high-

quality seed. Deep shanking adjacent to the planter row can reduce damage. Cultivating soil to hill

up around stems can encourage lateral root development, but close cultivation may trim shallow

roots.

Bacterial Blights

Bacterial blights cause leaf and pod lesions, defoliation and shrunken discolored seed. All are seed

borne, can be spread by splashing rain and their spread is aided by storms that cause small