Professional Documents

Culture Documents

SAE J404 2000 Chemical Compositions of SAE Alloy Steels PDF

Uploaded by

Madirley PimentaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAE J404 2000 Chemical Compositions of SAE Alloy Steels PDF

Uploaded by

Madirley PimentaCopyright:

Available Formats

400 Commonwealth Drive, Warrendale, PA 15096-0001

SURFACE

VEHICLE

STANDARD

REV.

JUN2000

J404

Issued

Revised

Submitted for recognition as an American National Standard

1911-06

2000-06

Superseding J404 APR1994

Chemical Compositions of SAE Alloy Steels

1.

ScopeIn 1941, the SAE Iron and Steel Division in collaboration with the American Iron and Steel Institute

(AISI) made a major change in the method of expressing composition ranges for the SAE steels. The plan, as

now applied, is based in general on narrower ladle analysis ranges plus certain product (check) analysis

allowances on individual samples, in place of the fixed ranges and limits without tolerances formerly provided

for carbon and other elements in SAE steels (reference SAE J408).

ISTC Divison 1 has developed a procedure which allows for the maintenance of the grade list in this SAE

Standard. This will involve conducting an industry-wide survey to solicit input. This survey will be conducted

at a frequency deemed necessary by the technical committee. Criteria have been established for the addition

to or deletion of grades from the grade table. A new grade will be considered if it meets standard SAE grade

ranges, has a minimum usage or production of 225 tonnes/year (250 tons/year), and has the endorsement of

at least two users or producers. New steel compositions will still be considered as Potential Standard (PS)

steels, based on the guidelines provided in SAE J1081, until such time as production of the new steel achieves

a level of production or usage qualifying it for consideration as a standard steel.

The deletion of a grade from the grade table will be by consensus based on the grade survey results. Deleted

grades will be archived in SAE J1249 for future reference.

The compositions in this document may apply to open hearth and basic oxygen, or electric furnace steels.

Grades shown in Table 1 with prefix letter E are normally made by the electric furnace process with maximum

limits of 0.025% phosphorus and 0.025% sulfur. The nominal chemical limits or ranges in the compositions

given in Table 1 are subject to standard variations in check analysis given in SAE J409. Since AISI is no

longer issuing steel grade designations, all grades listed in this document are SAE grades.

Table 1 is applicable to billets, blooms, slabs, plates, wire rods, and hot-rolled and cold-finished bars.

SAE J404 is not applicable to the following product forms:

a. Structural shapesNot normally furnished to alloy chemistries

b. Sheet and strip, hot-rolled and cold-rolledRefer to ASTM A 506 and A 507

c. Seamless and welded mechanical tubingRefer to ASTM A 513 and A 519

SAE Technical Standards Board Rules provide that: This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely

voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.

SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.

TO PLACE A DOCUMENT ORDER; (724) 776-4970

FAX:

SAE WEB ADDRESS http://www.sae.org

Copyright 2000 Society of Automotive Engineers, Inc.

All rights reserved.

(724) 776-0790

Printed in U.S.A.

SAE J404 Revised JUN2000

2.

References

2.1

Applicable PublicationsThe following publications form a part of this specification to the extent specified

herein. Unless otherwise indicated, the latest issue of SAE publications shall apply.

2.1.1

AE PUBLICATIONSAvailable from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

SAE J408Methods of Sampling Steel for Chemical Analysis

SAE J409Product AnalysisPermissible Variations from Specified Chemical Analysis of a Heat or Cast

of Steel

SAE J1081Potential Standard Steels

SAE J1249Former SAE Standard and Former SAE EX-Steels

SAE Aerospace Material Specifications (AMS) Index

2.1.2

ASTM PUBLICATIONSAvailable from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.

ASTM A 506Specification for Steel Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, Regular Quality

ASTM A 507Specification for Steel Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, Drawing Quality

ASTM A 513Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

ASTM A 519Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

3.

Cross Index to Equivalent Grades and Government SpecificationsAttention is called to the SAE

Aerospace Material Specifications (AMS) Index which is published twice a year. This index gives a cross

reference to AMS grades, SAE grades, AISI grades, and Government Specifications (MIL, QQS, and so on) for

metals, alloys, and nonmetallic materials.

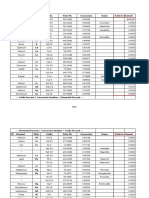

TABLE 1ALLOY STEEL COMPOSITIONS(1)

UNS

No.

SAE

No.

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Composition Composition Composition Composition Composition Composition Composition Composition Composition

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

C

Mn

P

S

Si

Ni

Cr

Mo

V

G13300

1330

0.280.33

1.601.80

0.030

0.040

0.150.35

G13350

1335

0.330.38

1.601.90

0.030

0.040

0.150.35

G13400

1340

0.380.43

1.601.90

0.030

0.040

0.150.35

G13450

1345

0.430.48

1.60-1.90

0.030

0.040

0.15-0.35

G40230

4023

0.200.25

0.700.90

0.030

0.040

0.150.35

0.200.30

G40270

4027

0.250.30

0.700.90

0.030

0.040

0.150.35

0.200.30

G40370

4037

0.350.40

0.700.90

0.030

0.040

0.150.35

0.200.30

G40470

4047

0.450.50

0.700.90

0.030

0.040

0.150.35

0.200.30

G41180

4118

0.180.23

0.700.90

0.030

0.040

0.150.35

0.400.60

0.080.15

G41200

4120

0.180.23

0.901.20

0.030

0.040

0.150.35

0.400.60

0.130.20

G41300

4130

0.280.33

0.400.60

0.030

0.040

0.150.35

0.801.10

0.150.25

G41350

4135

0.330.38

0.700.90

0.030

0.040

0.150.35

0.801.10

0.150.25

G41370

4137

0.350.40

0.700.90

0.030

0.040

0.150.35

0.801.10

0.150.25

G41400

4140

0.380.43

0.751.00

0.030

0.040

0.150.35

0.801.10

0.150.25

G41420

4142

0.400.45

0.751.00

0.030

0.040

0.150.35

0.801.10

0.150.25

G41450

4145

0.430.48

0.751.00

0.030

0.040

0.150.35

0.801.10

0.150.25

G41500

4150

0.480.53

0.751.00

0.030

0.040

0.150.35

0.801.10

0.150.25

G43200

4320

0.170.22

0.450.65

0.030

0.040

0.150.35

1.652.00

0.400.60

0.200.30

-2-

SAE J404 Revised JUN2000

TABLE 1ALLOY STEEL COMPOSITIONS(1)

UNS

No.

SAE

No.

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Ladle

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Chemical

Composition Composition Composition Composition Composition Composition Composition Composition Composition

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

Limits, %

V

Mo

Cr

Ni

Si

S

P

Mn

C

G43400

4340

0.380.43

0.600.80

0.030

0.040

0.150.35

1.652.00

0.700.90

0.200.30

G43406

E4340(2)

0.380.43

0.650.85

0.025

0.025

0.150.35

1.652.00

0.700.90

0.200.30

G46150

4615

0.130.18

0.450.65

0.030

0.040

0.150.35

1.65~2.00

0.200.30

G46170

4617

0.160.21

0.400.65

0.030

0.040

0.150.35

1.652.00

0.200.30

G46200

4620

0.170.22

0.450.65

0.030

0.040

0.150.35

1.652.00

0.200.30

G48200

4820

0.180.23

0.500.70

0.030

0.040

0.150.35

3.253.75

0.200.30

G50461

50B46(3)

0.440.49

0.751.00

0.030

0.040

0.150.35

0.200.35

G51150

5115

0.130.18

0.700 90

0.030

0.040

0.150.35

0.700.90

G51200

5120

0.170.22

0.700.90

0.030

0.040

0.150.35

0.700.90

G51300

5130

0.280.33

0.700.90

0.030

0.040

0.150.35

0.801.10

G51320

5132

0.300.35

0.600.80

0.030

0.040

0.150.35

0.751.00

G51400

5140

0.380.43

0.700.90

0.030

0.040

0.150.35

0.700.90

G51500

5150

0.480.53

0.700.90

0.030

0.040

0.150.35

0.700.90

G51600

5160

0.560.64

0.751.00

0.030

0.040

0.150.35

0.700.90

G51601

51B60(3)

0.560.64

0.751.00

0.030

0.040

0.150.35

0.700.90

G52986

E52100(2)

0.981.10

0.250.45

0.025

0.025

0.150.35

1.301.60

G61500

6150

0.480.53

0.700.90

0.030

0.040

0.150.35

0.801.10

0.15 min

G86150

8615

0.160.18

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86170

8617

0.150.20

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86200

8620

0.180.23

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86220

8622

0.200.25

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86250

8625

0.230.28

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86270

8627

0.250.30

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86300

8630

0.280.33

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86370

8637

0.380.43

0.751.00

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86400

8640

0.380.43

0.751.00

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86450

8645

0.430.48

0.751.00

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G86550

8655

0.510.59

0.751.00

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G87200

8720

0.180.23

0.700.90

0.030

0.040

0.150.35

0.400.70

0.400.60

0.200.30

G87420

8740

0.400.45

0.751.00

0.030

0.040

0.150.35

0.400.70

0.400.60

0.150.25

G88220

8822

0.200.25

0.751.00

0.030

0.040

0.150.35

0.400.70

0.400.60

0.300.40

G92540

9254

0.510.59

0.600.80

0.030

0.040

1.201.60

0.600.80

G92590

9259

0.560.64

0.751.00

0.030

0.040

0.701.10

0.450.65

G92600

9260

0.560.64

0.751.00

0.030

0.040

1.802.20

1.

For standard variations in composition limits, see Table 4 of SAE J409. Small quantities of certain elements which are not specified or required may be found

in alloy steels. These elements are to be considered as incidental and are acceptable to the following maximum amounts: copper to 0.35%, nickel to 0.25%,

chromium to 0.20%, and molybdenum to 0.06%. Lead - Alloy steels can be produced with a lead additon of 0.15 to 0.35% to improve machinability. Such

steels are identified by inserting the letter L between the second and third numerals of the grade number, for example, 51L40.

The analysis of the following elements shall be reported regardless of whether they are specified:

Aluminum, Titanium, Niobium (Columbium), Vanadium. If the analysis of any of these elements is less than 0.008%, it may be reported as

<0.008%.

2. Electric furnace steel.

3. Boron content is 0.0005 to 0.003%.

-3-

SAE J404 Revised JUN2000

4.

Notes

4.1

Marginal Indicia.The change bar (l) located in the left margine is for the convenience of the user in locating

areas where techncial revisions have been made to the previous issue of the report. An (R) symbol to the left

of the document title indicates a complete revision of the report.

SAE IRON AND STEEL TECHNICAL COMMITTEE DIVISION 1CARBON AND ALLOY STEELS

-4-

SAE J404 Revised JUN2000

Rationale

1. ScopeDetails on new procedure for maintenance.

2. Rename Tables 1A and 1B as Table 1

RationaleBased on the grade survey it was agreed that the tables should be consolidated.

3. SAE PublicationsReference SAE J1081.

4. Table 1Based on the grade survey and consolidation of tables, add 1330, 1345, 4135, 4617, 5046,

5115, 8625, 8627, 8637, 8655, 8742, and 9254.

Relationship of SAE Standard to ISO StandardNot applicable.

ApplicationIn 1941, the SAE Iron and Steel Division in collaboration with the American Iron and Steel

Institute (AISI) made a major change in the method of expressing composition ranges for the SAE steels.

The plan, as now applied, is based in general on narrower ladle analysis ranges plus certain product

(check) analysis allowances on individual samples in place of the fixed ranges and limits without

tolerances formerly provided for carbon and other elements in SAE steels (reference SAE J408).

Reference Section

SAE J408Methods of Sampling Steel for Chemical Analysis

SAE J409Product AnalysisPermissible Variations from Specified Chemical Analysis of a Heat or

Cast of Steel

SAE J1249Former SAE Standard and Former SAE EX-Steels

SAE J1081Potential Standard Steels

SAE Aerospace Material Specifications (AMS) Index

ASTM A 506Specification for Steel Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, Regular

Quality

ASTM A 507Specification for Steel Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, Drawing

Quality

ASTM A 513Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

ASTM A 519Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

Developed by the SAE Iron and Steel Technical CommitteeDivision 1Carbon and Alloy Steels

Sponsored by the SAE Iron and Steel Executive Committee

You might also like

- ASTM A240-20aDocument12 pagesASTM A240-20a杜文欽100% (1)

- Cameron LoadKing Drilling Riser 3.5 ManualDocument277 pagesCameron LoadKing Drilling Riser 3.5 ManualMadirley Pimenta83% (6)

- Y14 43Document1 pageY14 43Adrian JoelNo ratings yet

- Asme B107.17M 1997Document14 pagesAsme B107.17M 1997Roberto Poblete HernandezNo ratings yet

- BS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled BushesDocument14 pagesBS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled Bushesxuanphuong2710No ratings yet

- ASME 889.4.1 b-2001Document101 pagesASME 889.4.1 b-2001Alaeddine Abid100% (1)

- Book Partituras - Richard Clayderman 3 - Piano Solo Best Collection PDFDocument49 pagesBook Partituras - Richard Clayderman 3 - Piano Solo Best Collection PDFMadirley Pimenta100% (1)

- Convert XRF Data Element %Document8 pagesConvert XRF Data Element %manas773No ratings yet

- B564 Plfy402430879val PDFDocument11 pagesB564 Plfy402430879val PDFCarlosIkeda100% (1)

- Surface Vehicle Recommended Practice: Issued OCT1999Document19 pagesSurface Vehicle Recommended Practice: Issued OCT1999Eduardo100% (1)

- SAE J404 V 002Document6 pagesSAE J404 V 002DylkanWingsNo ratings yet

- Din 8140 AmecoilDocument1 pageDin 8140 Amecoiljuanpalomo74No ratings yet

- Asme-B18.7.1m (2007)Document14 pagesAsme-B18.7.1m (2007)Sergio Rodriguez CamberosNo ratings yet

- Unc Thread Ansi b1Document1 pageUnc Thread Ansi b1Shatish KumarNo ratings yet

- Reaffirmed 2001: For Current Committee PersonnelDocument182 pagesReaffirmed 2001: For Current Committee PersonnelCarlitos100% (1)

- Norma ISO 12240-4 Horquillas Articuladas PDFDocument39 pagesNorma ISO 12240-4 Horquillas Articuladas PDFNemoz ZrNo ratings yet

- Asme B1.10MDocument26 pagesAsme B1.10MRicardo ValenciaNo ratings yet

- ASME B1.21M - Metric Screw Threads MJ ProfileDocument68 pagesASME B1.21M - Metric Screw Threads MJ ProfileEnrique SGNo ratings yet

- Surface Vehicle Standard: Rev. JUN1998Document45 pagesSurface Vehicle Standard: Rev. JUN1998Sandeep Goud ChatlaNo ratings yet

- Double Coil Helical Spring Lock Washers For Wood Structures: ASME B18.21.3-2008Document14 pagesDouble Coil Helical Spring Lock Washers For Wood Structures: ASME B18.21.3-2008Joel CieltoNo ratings yet

- Astm F 136 - 02Document6 pagesAstm F 136 - 02Marcos Verissimo Juca de PaulaNo ratings yet

- Asme-B18.5.2.1m (2006)Document18 pagesAsme-B18.5.2.1m (2006)Sergio Rodriguez CamberosNo ratings yet

- A Kinematic Analysis of Meshing Polymer Gear TeethDocument16 pagesA Kinematic Analysis of Meshing Polymer Gear TeethsandeepNo ratings yet

- Mil PRF 8625 Amend02Document20 pagesMil PRF 8625 Amend02dan howsNo ratings yet

- QQ N 290aDocument17 pagesQQ N 290aBryan MartinezNo ratings yet

- ASME B1.20.5 Rosca NPTDocument63 pagesASME B1.20.5 Rosca NPTdopcncNo ratings yet

- Sae J49-2018 PDFDocument10 pagesSae J49-2018 PDFNastyNo ratings yet

- Saej 476 Av 001Document47 pagesSaej 476 Av 001Aditi Garg100% (1)

- B89-3-4M R1992 E1985Document47 pagesB89-3-4M R1992 E1985miorNo ratings yet

- M4 Carbine SpecificationDocument56 pagesM4 Carbine SpecificationGary WilliamsNo ratings yet

- Astm A29Document22 pagesAstm A29jangaswathiNo ratings yet

- Mil PRF 81733DDocument34 pagesMil PRF 81733DHenryNo ratings yet

- Asme B1.3-2007 (R2017)Document24 pagesAsme B1.3-2007 (R2017)lucasNo ratings yet

- 3 Surface Roughness SymbolsDocument7 pages3 Surface Roughness SymbolsAMIRHUSAIN MOMINNo ratings yet

- Ansiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFDocument190 pagesAnsiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFrzurabaezaNo ratings yet

- Asme B107.1-2002Document26 pagesAsme B107.1-2002noahb110No ratings yet

- Surface Vehicle Recommended PracticeDocument8 pagesSurface Vehicle Recommended Practicewilian_coelho3309No ratings yet

- Asme 14.36 Surface FinishDocument2 pagesAsme 14.36 Surface FinishASHOK0% (5)

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerNo ratings yet

- RDS User Manual V4.0.0.086 - en PDFDocument185 pagesRDS User Manual V4.0.0.086 - en PDFCesar Arellano100% (3)

- Mil dtl83420Document29 pagesMil dtl83420Jose Miguel Atehortua ArenasNo ratings yet

- Fed STD H28 20BDocument30 pagesFed STD H28 20BL FNo ratings yet

- Heli-Coil Catalog HC2000 Rev12Document40 pagesHeli-Coil Catalog HC2000 Rev12anon_512891835No ratings yet

- Vehicle Information/Test Specifications FMVSS 210: FORM 210Document1 pageVehicle Information/Test Specifications FMVSS 210: FORM 210ArunkumarNo ratings yet

- Mil A 8625FDocument25 pagesMil A 8625FSteveNo ratings yet

- B30 00 PDFDocument12 pagesB30 00 PDFluis_may22No ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseDocument6 pagesSource: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseJoey ThomannNo ratings yet

- ASME - IsO GD&T Standard DifferencesDocument1 pageASME - IsO GD&T Standard Differencesravi7447100% (1)

- MIL-PRF-23377 Rev. KDocument19 pagesMIL-PRF-23377 Rev. KRoban BieberNo ratings yet

- M793Document29 pagesM793Hossam AliNo ratings yet

- ASME Y14.36M Surface Texture Symbols PDFDocument14 pagesASME Y14.36M Surface Texture Symbols PDFjmmshahNo ratings yet

- Small: SolidDocument23 pagesSmall: SolidJoel CieltoNo ratings yet

- Hexagon, Socket Head Shoulder Screws (Metric Series) : An American National StandardDocument22 pagesHexagon, Socket Head Shoulder Screws (Metric Series) : An American National StandardJoel CieltoNo ratings yet

- Unc Thread Ansi - Asme b1.1Document2 pagesUnc Thread Ansi - Asme b1.1Btvnravi TejaNo ratings yet

- Asme B18.18.5M-1998Document27 pagesAsme B18.18.5M-1998IliyaNo ratings yet

- Nitriding 4340 ADocument8 pagesNitriding 4340 AyanuarNo ratings yet

- Manual Servo SGM, SGMP, SgdaDocument429 pagesManual Servo SGM, SGMP, SgdaAndry MisfirNo ratings yet

- Sae J402 (Jul2005)Document8 pagesSae J402 (Jul2005)Diogo100% (1)

- 01 07-2Document954 pages01 07-2bs2002No ratings yet

- SAE J403-EN MS gradesDocument9 pagesSAE J403-EN MS gradesVishal BhanderiNo ratings yet

- Astm A105 - 05Document5 pagesAstm A105 - 05Stéphane LevasseurNo ratings yet

- Astm A615Document3 pagesAstm A615Makaryo L. Buensuceso83% (6)

- Deformed and Plain Carbon-Steel Bars For Concrete ReinforcementDocument6 pagesDeformed and Plain Carbon-Steel Bars For Concrete ReinforcementJhon Paul EstopinNo ratings yet

- Steel Wire, Oil-Tempered For Mechanical SpringsDocument1 pageSteel Wire, Oil-Tempered For Mechanical SpringsJunNo ratings yet

- A 228 - A 228M - 00 Qtiyoc0wma - PDFDocument4 pagesA 228 - A 228M - 00 Qtiyoc0wma - PDFRafael GarciaNo ratings yet

- Did You Think To Pray: Arranged by Amber L. Tilley and Naloni LovellDocument6 pagesDid You Think To Pray: Arranged by Amber L. Tilley and Naloni LovellMadirley PimentaNo ratings yet

- API CatalogueDocument20 pagesAPI CatalogueMadirley Pimenta100% (1)

- 8 Perguntas Sobre Alienação Parental - A Construção Do Desamor - Geledés PDFDocument3 pages8 Perguntas Sobre Alienação Parental - A Construção Do Desamor - Geledés PDFMadirley PimentaNo ratings yet

- Catalogo General BOPs (Hydril - GE)Document46 pagesCatalogo General BOPs (Hydril - GE)Ronal Borrero100% (2)

- SAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFDocument5 pagesSAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFMadirley PimentaNo ratings yet

- 6252 8377 1 PB PDFDocument5 pages6252 8377 1 PB PDFMadirley PimentaNo ratings yet

- BOP Catalog vFEB20152 PDFDocument36 pagesBOP Catalog vFEB20152 PDFMadirley Pimenta100% (1)

- Chapter-1: Well ControlDocument25 pagesChapter-1: Well ControlRama KrishnaNo ratings yet

- Material Data Sheets and Element Data Sheets For PipingDocument133 pagesMaterial Data Sheets and Element Data Sheets For PipingJorge Durão100% (1)

- Carbodur Komplett Uk 1 PDFDocument13 pagesCarbodur Komplett Uk 1 PDFMadirley PimentaNo ratings yet

- BOP Operations MaintenanceDocument54 pagesBOP Operations MaintenanceSean Murphy100% (2)

- 4362 en PDFDocument6 pages4362 en PDFMadirley PimentaNo ratings yet

- 1 CR Mo-ARCELORMITTAL - PRESSURE - VESSELDocument12 pages1 CR Mo-ARCELORMITTAL - PRESSURE - VESSELRocky ThomasNo ratings yet

- M CR 601r1Document14 pagesM CR 601r1nazari123No ratings yet

- Bop HydrilDocument1 pageBop HydrilMadirley PimentaNo ratings yet

- Austinitic WeldDocument43 pagesAustinitic WeldJim GrayNo ratings yet

- 3Document4 pages3Madirley PimentaNo ratings yet

- Agenda: of The ASME Boiler and Pressure VesselDocument240 pagesAgenda: of The ASME Boiler and Pressure VesselMadirley PimentaNo ratings yet

- BopDocument37 pagesBopBrahim Letaief100% (1)

- General Welding Fabrication and TestingDocument24 pagesGeneral Welding Fabrication and TestingAhmed FathyNo ratings yet

- ECFR - Code of Federal RegulationsDocument8 pagesECFR - Code of Federal RegulationsMadirley PimentaNo ratings yet

- High Tech Tool CatalogDocument40 pagesHigh Tech Tool CatalogMadirley PimentaNo ratings yet

- RTJDocument5 pagesRTJkdvc18No ratings yet

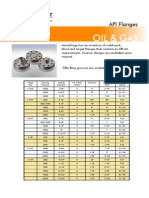

- API FlangesDocument2 pagesAPI FlangesandresaroNo ratings yet

- Flange Api6a Api6b Api6bx BlindDocument4 pagesFlange Api6a Api6b Api6bx BlindMadirley PimentaNo ratings yet

- dataStyleBX 0 0Document2 pagesdataStyleBX 0 0Madirley PimentaNo ratings yet

- DOUBLE STUDDED ADAPTER FLANGE SPECSDocument1 pageDOUBLE STUDDED ADAPTER FLANGE SPECSMadirley PimentaNo ratings yet

- The Machinability of Nickel-Based Alloys: A Review: E.O. Ezugwu, Z.M. Wang, A.R. MachadoDocument16 pagesThe Machinability of Nickel-Based Alloys: A Review: E.O. Ezugwu, Z.M. Wang, A.R. MachadosenthilNo ratings yet

- Instapdf - in 118 Elements List 216Document5 pagesInstapdf - in 118 Elements List 216HARISH UNo ratings yet

- ESSR Surfacing SolidificationDocument154 pagesESSR Surfacing SolidificationBurag HamparyanNo ratings yet

- Ti Alloys Guide: Properties of Pure Ti & Effects of Alloying ElementsDocument13 pagesTi Alloys Guide: Properties of Pure Ti & Effects of Alloying ElementsEric TaylorNo ratings yet

- Australian Critical Minerals ProspectusDocument68 pagesAustralian Critical Minerals ProspectusBill LiNo ratings yet

- Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General ApplicationDocument4 pagesSteel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Applicationعصام السامرائيNo ratings yet

- Flowforming or Metal Spinning (Spin Forming)Document2 pagesFlowforming or Metal Spinning (Spin Forming)ShivajiNo ratings yet

- Cutting and hardness testing machineDocument4 pagesCutting and hardness testing machineJacques LopezNo ratings yet

- Automotive PDFDocument24 pagesAutomotive PDFbathinsreenivasNo ratings yet

- Astm A29-A29m (2020)Document17 pagesAstm A29-A29m (2020)AHMED SAMIR ALEMDARNo ratings yet

- ETH, DJI, ERI, & SOM (East Africa Mineral 2002Document9 pagesETH, DJI, ERI, & SOM (East Africa Mineral 2002SENAITNo ratings yet

- Astm e 1019 - 03 Leco CS NoDocument21 pagesAstm e 1019 - 03 Leco CS NoPYDNo ratings yet

- General Specification: Welding - MaterialsDocument14 pagesGeneral Specification: Welding - MaterialsGil-Alain EgnakouNo ratings yet

- Asme Sec Ii A Sa-751Document6 pagesAsme Sec Ii A Sa-751ronaldogeNo ratings yet

- Atomic Elements TableDocument4 pagesAtomic Elements TablePaneyNo ratings yet

- Sae Ams2769b (2014)Document19 pagesSae Ams2769b (2014)Yeonggeun LeeNo ratings yet

- Ferro AlloyDocument10 pagesFerro Alloysamba sandykaNo ratings yet

- Afghanistan MineralsDocument101 pagesAfghanistan MineralsKhan MohammadNo ratings yet

- Failure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesDocument21 pagesFailure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesOwais MalikNo ratings yet

- Sulzer Metco - Thermal Spray Materials GuideDocument176 pagesSulzer Metco - Thermal Spray Materials Guidethuron100% (1)

- American Welding Soceity 5.9Document33 pagesAmerican Welding Soceity 5.9Hư VôNo ratings yet

- ASTM A1008 SpecificationDocument7 pagesASTM A1008 SpecificationramorusoNo ratings yet

- ASM-Powder Metallurgy Stainless Steels - Processing, Microstructures, and PropertiesDocument227 pagesASM-Powder Metallurgy Stainless Steels - Processing, Microstructures, and PropertiesAldin Bubic100% (2)

- PVD HardCoating PDFDocument20 pagesPVD HardCoating PDFsatanjrNo ratings yet

- CR39W Alloy Properties and ApplicationsDocument2 pagesCR39W Alloy Properties and ApplicationsJean-Noël LerouxNo ratings yet