Professional Documents

Culture Documents

Watlow Nozzle Heaters

Uploaded by

EliasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Watlow Nozzle Heaters

Uploaded by

EliasCopyright:

Available Formats

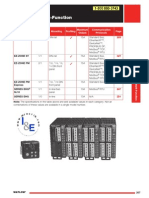

505 WATLOW

Nozzle Heaters

Max. Operating Typical Max.

Temperatures Watt Densities

Nozzle Heaters Sheath Materials F C W/in

2

W/cm

2

Page

Mineral Insulated (MI) Stainless steel 1400 760 230 35.6 507

Pre-Coiled Cable Stainless steel 1200 650 152 23.5 509

N

o

z

z

l

e

H

e

a

t

e

r

s

507 WATLOW

Nozzle Heaters

Mineral Insulated (MI) Nozzle Heaters

The mineral insulated (MI) nozzle heater is a

high-performance heater that incorporates Watlows

exclusive mineral insulation technology. This material

offers much higher thermal conductivity than mica and

hard ceramic insulators used in conventional heaters.

A thin layer of the high thermal conductive MI material

electrically insulates the element wire from the inside

diameter of the heater sheath. A thicker, low thermal

conductivity layer backs up the element wire, directing

the heat inward toward the heated part. The result is

more efficient heat transfera performance solution

that lowers element wire temperatures and increases

heater life.

Performance Capabilities

Heater operating temperatures up to 1400F (760C)

Watt densities up to 230 W/in

2

(35.6 W/cm

2

)

are

available on small diameter nozzle

Maximum voltage up to 240V

Features and Benefits

Operating temperatures up to 1400F (760C)

Melts resins such as PEEK

, Teflon

, Ultem

and Zytel

safely

Higher watt densities

Contributes to faster heat-up and throughput for

increased productivity

High thermal conductivity of MI and low mass

construction

Provides an almost instant response to temperature

control

Eliminates thermal lag and temperature overshoot

Stainless steel cover and side fold design

Resists contamination by overflow of plastic or other

free-flowing materials

Permanently attached clamp bars

Eliminates cumbersome clamping straps to ease

installation

Typical Applications

Extruders

Blown film dies

Injection molding machines

Other cylinder heating applications

For MI nozzle heater part numbers see next page.

For detailed product and technical data,

see the full MI Band Heater product

section located on pages 493 through 502.

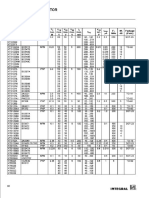

508 WATLOW

Nozzle Heaters

Mineral Insulated (MI) Nozzle Heaters

Heater Part Numbers

RAPID SHIP

RS - Next day shipment

M - Manufacturing lead times

I.D.

in. (mm)

Width

in. (mm) Construction Volts Watts

Watt Density

W/in

2

(W/cm

2

) Termination

Approx. Net Wt.

lbs. (kg) Del.

Part

Number

1 (25) 1 (25) 1 pc 120 150 92 (14) Type B, C, E, F or H 0.1 (0.05) RS MB1A1AN1

1 (25) 1 pc 120 100 61 (9) Type B, C, E, F or H 0.1 (0.05) RS MB1A1AN2

1 (25) 1 pc 120 200 122 (19) Type B, C, E, F or H 0.1 (0.05) RS MB1A1AN3

1 (25) 1 pc 240 200 122 (19) Type B, C, E, F or H 0.1 (0.05) RS MB1A1AN4

1

1

/2 (38) 1 pc 240 300 106 (16) Type B, C, E, F or H 0.1 (0.05) RS MB1A1JN1

1

1

/2 (38) 1 pc 120 300 106 (16) Type B, C, E, F or H 0.1 (0.05) RS MB1A1JN2

1

1

/2 (38) 1 pc 240 200 70 (11) Type B, C, E, F or H 0.1 (0.05) RS MB1A1JN3

1

1

/2 (38) 1 pc 120 200 70 (11) Type B, C, E, F or H 0.1 (0.05) M MB1A1JN4

1

1

/2 (38) 1 pc 240 400 141 (22) Type B, C, E, F or H 0.1 (0.05) RS MB1A1JN5

1

1

/4 (32) 1 (25) 1 pc 240 250 104 (16) Type B, C, E, F or H 0.1 (0.05) RS MB1E1AN1

1 (25) 1 pc 120 250 104 (16) Type B, C, E, F or H 0.1 (0.05) RS MB1E1AN2

1 (25) 1 pc 240 300 124 (19) Type B, C, E, F or H 0.1 (0.05) M MB1E1AN3

1

1

/2 (38) 1 pc 240 350 87 (13) Type B, C, E, F or H 0.2 (0.09) RS MB1E1JN1

1

1

/2 (38) 1 pc 120 350 87 (13) Type B, C, E, F or H 0.2 (0.09) RS MB1E1JN2

1

1

/2 (38) 1 pc 240 450 112 (17) Type B, C, E, F or H 0.2 (0.09) M MB1E1JN3

1

1

/2 (38) 1 (25) 1 pc 240 300 93 (14) Type B, C, E, F or H 0.1 (0.05) M MB1J1AN1

1 (25) 1 pc 120 300 93 (14) Type B, C, E, F or H 0.1 (0.05) RS MB1J1AN2

1 (25) 1 pc 240 200 62 (10) Type B, C, E, F or H 0.1 (0.05) RS MB1J1AN3

1 (25) 1 pc 120 200 62 (10) Type B, C, E, F or H 0.1 (0.05) RS MB1J1AN4

1 (25) 1 pc 240 400 125 (19) Type B, C, E, F or H 0.1 (0.05) RS MB1J1AN5

1

1

/2 (38) 1 pc 120 300 58 (9) Type B, C, E, F or H 0.2 (0.09) RS MB1J1JN1

1

1

/2 (38) 1 pc 240 450 87 (14) Type B, C, E, F or H 0.2 (0.09) RS MB1J1JN2

1

1

/2 (38) 1 pc 240 300 58 (9.0) Type B, C, E, F or H 0.2 (0.09) RS MB1J1JN3

1

1

/2 (38) 1 pc 240 600 116 (18) Type B, C, E, F or H 0.2 (0.09) M MB1J1JN4

1

1

/2 (38) 1 pc 240 300 64 (10) Post 0.2 (0.09) M MB1J1JP4

1

1

/2 (38) 1 pc 240 450 96 (15) Post 0.2 (0.09) RS MB1J1JP6

2 (51) 1 pc 240 450 57 (9) Type B, C, E, F or H 0.3 (0.14) RS MB1J2AN1

2 (51) 1 pc 240 300 42 (7) Type B, C, E, F or H 0.3 (0.14) RS MB1J2AN2

2 (51) 1 pc 240 900 125 (19) Type B, C, E, F or H 0.3 (0.14) RS MB1J2AN3

3 (76) 1 pc 240 500 45 (7) Type B, C, E, F or H 0.4 (0.18) RS MB1J3AN1

3 (76) 1 pc 240 350 31 (5) Type B, C, E, F or H 0.4 (0.18) M MB1J3AN2

3 (76) 1 pc 240 1000 104 (16) Type B, C, E, F or H 0.4 (0.18) M MB1J3AN3

1

3

/4 (45)

1

3

/8 (35) 1 pc 240 450 83 (13)

36 in. 90 Type B braid

w/HD strain relief

0.2 (0.09) RS MB1N1GX3A

1

1

/2 (38) 1 pc 240 300 47 (7) Type B, C, E, F or H 0.2 (0.09) RS MB1N1JN1

1

1

/2 (38) 1 pc 120 300 50 (8) Type B, C, E, F or H 0.2 (0.09) RS MB1N1JN2

1

1

/2 (38) 1 pc 240 700 110 (17) Type B, C, E, F or H 0.2 (0.09) RS MB1N1JN3

2 (51) 1 pc 240 750 86 (13) Type B, C, E, F or H 0.3 (0.14) M MB1N2AN1

2 (51) 1 (25) 1 pc 240 350 73 (11) Type B, C, E, F or H 0.2 (0.09) RS MB2A1AN1

1 (25) 1 pc 120 350 73 (11) Type B, C, E, F or H 0.2 (0.09) RS MB2A1AN2

1 (25) 1 pc 240 450 94 (15) Type B, C, E, F or H 0.2 (0.09) RS MB2A1AN3

1 (25) 1 pc 240 350 79 (12)

36 in. 90 Type B braid

w/HD strain relief

0.2 (0.09) RS MB2A1AX6B

1

1

/2 (38) 1 pc 240 400 53 (8) Type B, C, E, F or H 0.3 (0.14) RS MB2A1JN1

1

1

/2 (38) 1 pc 240 1000 132 (21) Type B, C, E, F or H 0.3 (0.14) M MB2A1JN2

2 (51) 1 pc 240 750 73 (11) Type B, C, E, F or H 0.4 (0.18) M MB2A2AN1

2 (51) 1 pc 240 1200 125 (19) Type B, C, E, F or H 0.4 (0.18) RS MB2A2AN2

2 (51) 1 pc 240 750 75 (12)

36 in. 90 Type B braid

w/HD strain relief

0.2 (0.09) RS MB2A2AX2A

2

1

/4 (57)

2 (51) 1 pc 240 750 63 (10)

120 in. 180 Type B

braid w/HD strain relief

0.2 (0.09) RS MB2E2AX7

2

1

/2 (64) 1 pc 240 1000 72 (11) Type B, C, E, F or H 0.5 (0.23) RS MB2E2JN1

2

1

/2 (64) 1 (25) 1 pc 240 400 63 (10) Type B, C, E, F or H 0.2 (0.09) RS MB2J1AN1

1

1

/2 (38) 1 pc 240 500 50 (8) Type B, C, E, F or H 0.4 (0.18) RS MB2J1JN1

509 WATLOW

Nozzle Heaters

Pre-Coiled Cable Nozzle Heaters

The Watlow pre-coiled, cable nozzle heater has been

formed into a compact, tightly wound coil to supply

360 degrees of heat. This heater features a 5 in.

(127 mm) long, no-heat tail section, which eliminates

failures in the adapter area due to overheating.

This cable nozzle heater is manufactured with Watlows

swaged compaction process. This process provides a

greater compaction of the MgO insulation than the

competitors rolling process. Compacting MgO insulation

into a solid mass results in excellent heat conductivity and

high dielectric strength.

Performance Capabilities

Watt density up to 100 W/in

2

(15.5 W/cm

2

)

Possible operating temperature up to 1200F (650C)

(Dependent on type of element wire used)

230 and 240V constructions

Features and Benefits

Low-profile construction

Provides easy installation in the tight environment of

multiple-gate molds

No-heat tail section

Reduces temperature at the adapter eliminating

failures due to overheating

Single tail with dual lead

Occupies less space in the wire raceway

360 circumference heat

Provides even heating

Optional externally welded thermocouple to the

sheath

Provides temperature measurement capabilities

Typical Applications

Plastic injection molding equipment

Hot runner molds

Round or

Square Cable

Single Tail

with Dual Lead

430 SS Band Clamp with End

Rollover to Retain Coil

2F Style Lead Orientation

No-Heat Section

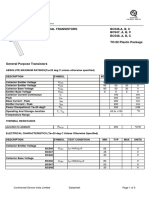

510 WATLOW

Nozzle Heaters

Pre-Coiled Cable Nozzle Heaters

Technical Data

5 in. (127 mm)

No-Heat Section

3

/16 in. (4.67 mm) Dia.

1.25 in.

(32 mm)

1 in.

(25 mm)

0.28 in. (7.1 mm)

B"

A"

0.094 in. (2.39 mm)

Dia. 304 SS Sheath

#6-32 SS Socket

Head Cap Screws

22 Ga. Type E

Teon

Leads

Coiled Nozzle Heaters Mounted on a

64 Cavity Plastic Injection Mold

0.75 (19) 240 268 72 (1829) 1.25 (32) Round Z5969

0.75 (19) 240 149 72 (1829) 1.25 (32) Round Z5968

Note: An optional Type J or Type K thermocouple can be externally brazed to the sheath O.D.

Coil I.D. Lead Length Clamp Width

in. (mm) Volts Watts in. (mm) in. (mm) Cable Type Part No.

0.058 in. Diameter Round Mini-Cable Nozzle Heater

(Coiled nozzle with axial clamp)

(with 5% wattage tolerance)

No-Heat Tail Section

0.058 in.

Round Cable

Axial Access Clamp

Delivery, 1 to 3 working days

a

Units have a 36 in. (914 mm) fiberglass insulated Type J thermocouple externally brazed to the heater sheath O.D.

Cable Heater Units (Coiled nozzle with clamp strap)

Lead Wire

Coil I.D. Clamp O.D. Clamp Width (Swaged-in)

Volts Watts in. (mm) in. (mm) in. (mm) No-Heat PTFE

Only Part Number

230 125 0.75 (19.0) 0.98 (24.9) 1.25 (32) 5 in. (127 mm) 36 in. (914 mm) 94PC30A1A

230 125 0.75 (19.0) 0.98 (24.9) 1.25 (32) only 72 in. (1829 mm) 94PC30A1D

230 250 0.75 (19.0) 0.98 (24.9) 1.25 (32) 36 in. (914 mm) 94PC30A2A

230 250 0.75 (19.0) 0.98 (24.9) 1.25 (32) 72 in. (1829 mm) 94PC30A2D

230 250 0.75 (19.0) 0.98 (24.9) 1.25 (32) 36 in. (914 mm) 94PC30A4A

a

0.094 in. Diameter Round (with 5% wattage tolerance), no lead protection available.

230 125 0.75 (19.0) 1 (25.0) 1.25 (32) 5 in. (127 mm) 36 in. (914 mm) 102PS28A2B

230 125 0.75 (19.0) 1 (25.0) 1.25 (32) only 72 in. (1829 mm) 102PS28A2A

230 250 0.75 (19.0) 1 (25.0) 1.25 (32) 36 in. (914 mm) 102PS28A1B

230 250 0.75 (19.0) 1 (25.0) 1.25 (32) 72 in. (1829 mm) 102PS28A4A

a

230 250 0.875 (22.2) 1.12 (28.5) 1.25 (32) 36 in. (914 mm) 102PS32A1A

0.102 in. Square Cross-Section (with 5% wattage tolerance), no lead protection available.

Delivery, 1 to 3 working days

You might also like

- Watlow Resistance Temperature SensorsDocument21 pagesWatlow Resistance Temperature SensorsEliasNo ratings yet

- Watlow SERV-RITE WireDocument40 pagesWatlow SERV-RITE WireEliasNo ratings yet

- Watlow AccessoriesDocument30 pagesWatlow AccessoriesEliasNo ratings yet

- Watlow Cartridge HeatersDocument49 pagesWatlow Cartridge HeatersEliasNo ratings yet

- Waltlow Specialty HeatersDocument17 pagesWaltlow Specialty HeatersEliasNo ratings yet

- Watlow Mineral InsulatedDocument13 pagesWatlow Mineral InsulatedEliasNo ratings yet

- Watlow Thermocouple SDocument62 pagesWatlow Thermocouple SEliasNo ratings yet

- Watlow Heater Selection MatrixDocument4 pagesWatlow Heater Selection MatrixEliasNo ratings yet

- Watlow Circulation HeatersDocument54 pagesWatlow Circulation HeatersEliasNo ratings yet

- Watlow Strip Clamp On HeatersDocument15 pagesWatlow Strip Clamp On HeatersEliasNo ratings yet

- Watlow Immersion HeatersDocument163 pagesWatlow Immersion HeatersEliasNo ratings yet

- Watlow Reference DataDocument19 pagesWatlow Reference DataEliasNo ratings yet

- Watlow Flexible HeatersDocument46 pagesWatlow Flexible HeatersEliasNo ratings yet

- Watlow Thermostats and AccessoriesDocument10 pagesWatlow Thermostats and AccessoriesEliasNo ratings yet

- Watlow Tubular HeatersDocument55 pagesWatlow Tubular HeatersEliasNo ratings yet

- Watlow Data LoggersDocument10 pagesWatlow Data LoggersEliasNo ratings yet

- Watlow Radiant HeatersDocument16 pagesWatlow Radiant HeatersEliasNo ratings yet

- Watlow High Temperature HeatersDocument33 pagesWatlow High Temperature HeatersEliasNo ratings yet

- Watlow Power Switching DevicesDocument38 pagesWatlow Power Switching DevicesEliasNo ratings yet

- Watlow Air HeatersDocument32 pagesWatlow Air HeatersEliasNo ratings yet

- Watlow Agency Heaters CertificationsDocument6 pagesWatlow Agency Heaters CertificationsEliasNo ratings yet

- Watlow Band Barrel HeatersDocument13 pagesWatlow Band Barrel HeatersEliasNo ratings yet

- Watlow Fluid Delivery HeatersDocument5 pagesWatlow Fluid Delivery HeatersEliasNo ratings yet

- Watlow Operator InterfacesDocument11 pagesWatlow Operator InterfacesEliasNo ratings yet

- Watlow Temperature and ProcessDocument24 pagesWatlow Temperature and ProcessEliasNo ratings yet

- Watlow Controller AccessoriesDocument12 pagesWatlow Controller AccessoriesEliasNo ratings yet

- Watlow Integrated Multi-FunctionDocument45 pagesWatlow Integrated Multi-FunctionEliasNo ratings yet

- Watlow SoftwareDocument10 pagesWatlow SoftwareEliasNo ratings yet

- Watlow Limits ScannersDocument24 pagesWatlow Limits ScannersEliasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NNST663SCUHDocument41 pagesNNST663SCUHPatrice PaulNo ratings yet

- Safety RelayDocument28 pagesSafety Relayeric_sauvageau1804No ratings yet

- CSTberger ALDocument4 pagesCSTberger ALbbutros_317684077No ratings yet

- Samsung MM-B3 SchemaDocument26 pagesSamsung MM-B3 Schemauniverso69No ratings yet

- Ap7173 35627Document16 pagesAp7173 35627Jose Barroso GuerraNo ratings yet

- System Sensor PSP1 Data SheetDocument2 pagesSystem Sensor PSP1 Data SheetJMAC SupplyNo ratings yet

- Led TV LG 32ls3500Document48 pagesLed TV LG 32ls3500Aditya AdityaNo ratings yet

- Soft-Start Circuits For LDO Linear RegulatorsDocument4 pagesSoft-Start Circuits For LDO Linear RegulatorsCharles FarhleyNo ratings yet

- Orosz-Ussr Russian Semiconductor Cross-ReferenceDocument8 pagesOrosz-Ussr Russian Semiconductor Cross-ReferenceNikolett GyalogNo ratings yet

- Weidmuller Indicating Fuse Terminal Blocks PDFDocument2 pagesWeidmuller Indicating Fuse Terminal Blocks PDFchard serdenNo ratings yet

- Xerox WorkCentre 3210 - 3220 SMDocument416 pagesXerox WorkCentre 3210 - 3220 SMjanusz198No ratings yet

- Line ProtectionDocument91 pagesLine Protectionhafiz_hazreen100% (1)

- 2019 Book MicrowaveActiveDevicesAndCircuDocument700 pages2019 Book MicrowaveActiveDevicesAndCircuLaila Fighera MarzallNo ratings yet

- ARM11Document8 pagesARM11Joseph JohnNo ratings yet

- Big Ideas - Electromagnetism and ElectronicsDocument26 pagesBig Ideas - Electromagnetism and ElectronicsKhushal Gupta100% (1)

- Datasheet FDP7N50Document10 pagesDatasheet FDP7N50Anonymous fAL3CNtUiNo ratings yet

- Petrovoltaic Clock PDFDocument1 pagePetrovoltaic Clock PDFwroueaweNo ratings yet

- Ground Sense Comparator: DatasheetDocument56 pagesGround Sense Comparator: DatasheetEdipoNo ratings yet

- Analyze small signal parameters of CC amplifierDocument5 pagesAnalyze small signal parameters of CC amplifierAafaqIqbalNo ratings yet

- IRS2106/IRS21064 high and low side driver datasheetDocument25 pagesIRS2106/IRS21064 high and low side driver datasheetmohamedNo ratings yet

- EDA Open Source Tools WikiDocument13 pagesEDA Open Source Tools WikiNitin PatelNo ratings yet

- ISO 9002 Certified NPN Transistors DatasheetDocument6 pagesISO 9002 Certified NPN Transistors Datasheettabassam7801No ratings yet

- EE4504 - Week 12Document11 pagesEE4504 - Week 12Daniel ChaiNo ratings yet

- E3FA Photoelectric Sensor With Adjustable Distance - 英Document2 pagesE3FA Photoelectric Sensor With Adjustable Distance - 英zheng zhengNo ratings yet

- s3c2450 Datasheet 200901Document2 pagess3c2450 Datasheet 200901jerometim33No ratings yet

- E12.1 The Emitter Current Is Given by The Shockley EquationDocument19 pagesE12.1 The Emitter Current Is Given by The Shockley EquationBengt HörbergNo ratings yet

- Crystal Oscillators CatalogueDocument314 pagesCrystal Oscillators CatalogueC S KumarNo ratings yet

- Schneider Altivar ATV71 90kW ManualDocument49 pagesSchneider Altivar ATV71 90kW Manualrikrdo827296No ratings yet

- Ug Vlsi Design LabDocument2 pagesUg Vlsi Design LabvlsijpNo ratings yet

- MB3773Document28 pagesMB3773Morteza BaratzadehNo ratings yet