Professional Documents

Culture Documents

A Tool For Lap Time Simulation

Uploaded by

Rodrigo Bob0 ratings0% found this document useful (0 votes)

161 views5 pagesA Tool for Lap Time Simulation

Original Title

A Tool for Lap Time Simulation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA Tool for Lap Time Simulation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

161 views5 pagesA Tool For Lap Time Simulation

Uploaded by

Rodrigo BobA Tool for Lap Time Simulation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

962529

A Tool for Lap Time Simulation

Marco Gadola, David Vetturi, Danilo Cambiaghi, and Luca Manzo

University of Brescia

Copyright 1996 Society of Automotive Engineers, Inc.

ABSTRACT

The top Formula 1 and Indycar teams make large use of

computer simulation to improve the performance of their

cars and make the set-up process quicker on the circuit.

The paper aims to present a lap time simulation software

dedicated to racing cars. It is based on the background of

vehicle dynamics research developed at the University of

Brescia, Italy (see [1]).

It should be stated that racecar dynamics is strongly non

linear due to the fact that tyres are always very near the

limit of adhesion. Moreover this makes the effect of lateral

load transfer fundamental for the general balance of the

car.

Therefore Pacejka's Magic Formula has been used for

lateral force/slip while longitudinal force computation is

based on the assumption of a maximum longitudinal

coefficient of friction . This is not only for simplicity but

it is also due to lack of available data. The combined case

is then based on the so-called "traction circle". Lateral and

longitudinal load transfer and downforce as well as their

effects on tyre load are taken into account.

The vehicle model is capable of following a trajectory

acquired with the on-board instrumentation. Also, the use

of genetic algorithms enables the program to find the

optimum cornering line for any given track. Some results

are shown and compared with real world data.

INTRODUCTION

Simulation has become one of the most involving

engineering subjects. Modern computers enable the

transformation of real life into the so-called virtual reality,

which offers many advantages to the development

engineer.

The racing world has always been very keen on simulation

because of high testing costs involved in the development

of a new car. Modern racing cars are complex devices, and

both designers and race engineers can hardly control all

the variables they can play with.

A computer model can help when choosing gear ratios,

aerodynamic configuration, engine power characteristics

and in general where a compromise must be reached to suit

a peculiar circuit morphology. The simulation of a

complete lap on a given circuit is one of the most

interesting possibilities for this purpose. Data acquisition

also enables quick and successful tuning and verification of

the math models.

THE LAP SIMULATION SOFTWARE

Many computer programs have been written in the past for

the above purpose. This paper aims to present a lap

simulation software which goes deep into vehicle dynamics

theory.

A first phase of the work was the accurate study of the

cornering line the drivers commonly follow in the average

corner. At this stage data acquired on various circuits with

different cars were analysed. Subsequently an algorithm

was tested which tries to reproduce the cornering line for

any corner with the help of the genetic method. An

introduction to the genetic method is presented in "Semi

Active Strategies for Racing Car Suspension Control" by

the same authors [2].

The vehicle model allows for aerodynamic forces, non

linear tyre load sensitivity, lateral load transfer distribution

due to roll stiffness as well as spring and tyre stiffnesses.

Chassis rigidity can be taken into account as well.

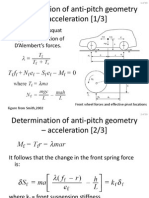

COMPUTATION OF

THE OPTIMUM CORNERING LINE

When pursuing the best performance on a given track the

first step is usually the search for the optimum cornering

line. The subject is very well-known in the racing

Downloaded from SAE International by Coventry University, Monday, September 29, 2014

community, nevertheless the analysis of data acquired on

various circuits with different cars was very helpful to go

"back to basics". The cornering radius is easily computed

from data acquisition with the following math channel:

where R=cornering radius, V=vehicle speed and ay=lateral

acceleration. As a convention R can be set to 0 (and not 8)

in the straightline.

We would like to point out that, usually:

the turn-in point (1, Fig. 1) is on the outer side of the

road (car still braking)

after the brake release point (2) no longitudinal

acceleration is applied to the vehicle

point (3) -where throttle is applied- is placed on the

inside around the mid corner zone.

the corner exit/zero steer angle point (4) is again placed

on the outside

the cornering radius function gets a parabolic shape

(Fig. 2); in detail the radius is larger in exit then in

turn-in to maximize the exit speed.

Due to the nature of the problem an interpolation approach

was fairly straightforward. The restrained cubic splines

have been chosen because:

if compared to polynomials -whose oscillatory

behaviour can not be easily controlled- splines behave

in a smoother way

cubic splines are characterized by the lowest curvature

in the spline family

the restrained cubic splines can be particularly effective

in this case, the slope being known at each end. The

slope is actually given by the straightline direction

before and after the corner.

The optimization is carried out with the use of a genetic

algorithm [2]. Optimization means finding the

combination of the four points -turn-in, brake release,

throttle application, exit- which actually maximize the

minimum cornering radius. This has a direct effect on

cornering speed. Moreover, the spline computation must

always result in a parabolic line shape.

This means that corner geometry characteristics (radius,

angle and track width) are the main factors in computing

the theoretical cornering line. Nevertheless the spline

computation could be tuned to suit the type of car (front or

rear wheel drive, high or low power, high or low

downforce) or a peculiar driving style. Also, it should be

noticed that genetic algorithms do not offer a unique

solution to the problem. Figure 1 shows a 50 m radius, 80

corner. The four typical points are also shown. Figure 3

shows the cornering radius function for the same corner.

Once the theoretical cornering line is computed for every

corner the whole circuit can be written on a file with the

use of relative coordinates.

Downloaded from SAE International by Coventry University, Monday, September 29, 2014

THE TYRE MODEL

According to "The Milliken" [3], "Racing is all about

driving the vehicle at its limits, near the boundary of the g

g diagram". Therefore tyres are -or should be- always

working near the limit of adhesion i.e. where the sideslip

function is strongly non linear and load sensitivity is

extremely marked. This means that a racecar model needs

to run on a comprehensive, non-linear tyre model.

Unfortunately it is very difficult to get up to date tyre test

data from tyre manufacturers, and this is particularly true

for racing tyres. Moreover, even when some data are

available they usually regard sideforce only -no

longitudinal slip and absolutely no combined slip data.

This can be overcome by analysing negative acceleration

data in pure braking. An average coefficient can be

easily computed for the longitudinal slip case, and such

can be assumed as a basis for a pure longitudinal slip

linear model. Any of the most common, non-linear tyre

models can be used for pure sideforce/sideslip, while the

combined slip model can be based on the good old friction

ellipse theory. The classic 1989 Pacejka Magic Formula [4]

was chosen as a sideslip model in our program.

CORNER-TO-CORNER

PERFORMANCE EVALUATION

Engine power curve, transmission ratios and efficiency,

braking power and aerodynamic coefficients (Cx, cross

section area, Cz front, Cz rear) are needed to assess the

performance between corners with traditional dynamics

formulae. Also longitudinal load transfer is taken into

account to determine the longitudinal adhesion limits

either in braking and under power.

For cornering performance the vehicle model (Fig. 4) is

based on the above combined tyre model and on a simple

linear chassis model with springs, anti-roll bars, radial tyre

stiffnesses, and chassis torsion flexibility. The lateral load

transfer distribution (LLTD) due to front and rear roll

stiffnesses and the consequent tyre side forces are

computed to determine the maximum lateral acceleration

in the mid corner point for a given turn.

The whole circuit is then split into sections from a mid

corner point to the following mid-corner point through the

straight line in between. The maximum speed in the

middle of each corner can be assessed as above by

considering pure coasting (no longitudinal acceleration,

i.e. pure tyre sideslip). Hence a section is composed by a

first known-speed point, an acceleration zone, eventually a

top speed zone, a braking zone and a second known-speed

point.

The combined tyre model is used to keep the car on the

boundary of the g-g diagram between points 1 and 2

(cornering under braking) and between points 3 and 4

(cornering under power). If the straight is too short to

reach the top speed an iterative process is used to match

the speed at the end of the acceleration zone i.e. the

beginning of the braking zone.

The model is quasi-static, hence transient effects on lateral

load transfer distribution due to dampers are neglected.

Also, a driver model was not built into the program, the

aim being to assess the best possible lap time for a given

car on a given circuit.

Downloaded from SAE International by Coventry University, Monday, September 29, 2014

VALIDATION

The results of a lap simulation on the Hockenheimring

(short circuit) are shown ; the car is a FWD, D2 Super

Touring saloon.

As one could expect, actually the simulation is slightly

quicker than the real car when running on the real

cornering line (i.e. the line computed with the help of data

acquisition, see Fig. 6 and case b) while the line computed

with the use of the genetic algorithm makes the simulation

slower (case c)

Case b is compared with reality in Fig. 7 (speed), Fig. 8

(lateral acceleration), Fig. 9 (longitudinal acceleration),

Fig. 10 (gear position) and Fig. 11 (time difference).

The computation of an "optimum line" with the use of the

genetic algorithms needs further developments.

THE INTERFACE

The program was then completed with a user-friendly

windows interface which provides easy data input and

processing as shown in Figs. 12 and 13. No built-in post

processing is provided yet.

CONCLUSION

A lap simulation software has been presented. It is based

on a simplified vehicle model and on a non-linear tyre

model. The program is aimed to be a tool for the race

engineer when optimising the car setup. It can be

particularly useful where a compromise is needed: choice

of gear ratios, aerodynamics, and so on.

The results show that the model is reliable at least with the

type of car considered in this example. Improvements

should be made to the gearshift strategy and also when two

corners are separated by a very short straight (or not

separated at all).

The genetic algorithm computation for the optimum

cornering line needs to be tested further and improved;

also, the model should be tested with different types of cars

(e.g. a RWD car with lots of downforce) and a post

processing module should be added.

Many thanks to Riccardo Bonetti & Marco Rossato

Downloaded from SAE International by Coventry University, Monday, September 29, 2014

REFERENCES AND BIBLIOGRAPHY

[1] Cambiaghi D., Gadola M.:"Computer-aided racing car

research and development at the University of Brescia,

Italy". SAE paper n. 942507. 1st Motorsports Engineering

Conference and Exposition. Dearborn (USA). December

1994.

[2] Cambiaghi D., Gadola M., Manzo L., Vetturi D.:

"Semi-Active Strategies for Racing Car Suspension

Control". SAE paper n. 962553. 2nd Motorsports

Engineering Conference and Exposition. Dearborn (USA).

December 1996.

[3] Milliken W.F., Milliken D.L. : "Race Car Vehicle

Dynamics". SAE, 1994.

[4] E. Bakker, L. Lidner, H.B. Pacejka. "A New Tyre

Model with an Application in Vehicle Dynamics Studies".

SAE Paper No. 890087. 1989.

RSp. Sharp. "Vehicle Dynamics Lecture Notes". MSc

lecture notes. Cranfield University, 1992.

C.R.F. (FIAT Research Centre). Vehicle Dynamics

Lectures - module A. 1994.

C.R.F. (FIAT Research Centre). Vehicle Dynamics

C.R.F. (FIAT Research Centre). Vehicle Dynamics

Ellis J.R. : "Road Vehicle Dynamics", published by

John R. Ellis, Akron (Ohio, USA), 1989.

Bastow D., Howard G. : "Car Suspension and Handling

- Third Edition". Pentech Press - SAE, 1993

Cambiaghi D., Gadola M.: "Racecar suspension

kinematics design: a report on the tool developed at the

University of Brescia". Internal paper, University of

Brescia, Italy, January 1994.

Cambiaghi D., Gadola M.: "MMGB: a computer-based

approach to racing car suspension design". ATA

Journal- Ingegneria Automotoristica, ?. 6/7 - 1994.

Manzo L., Vetturi D., Gadola M., Cambiaghi D.:

"Modelling, simulation and analysis of vehicle

suspension system dynamics". 29th ISATA. Florence,

Italy, June 1996.

DixonJ.C. : "Tvres. Suspension and Handling".

Cambridge University Press, Cambridge, 1991.

Downloaded from SAE International by Coventry University, Monday, September 29, 2014

You might also like

- Simulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactDocument15 pagesSimulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactVyssionNo ratings yet

- ME06 Spoiler With VGsDocument8 pagesME06 Spoiler With VGsariekopriantoNo ratings yet

- The Magic Formula Tyre ModelDocument19 pagesThe Magic Formula Tyre ModelgholmalikNo ratings yet

- How to Measure and Translate Vehicle Slip AngleDocument8 pagesHow to Measure and Translate Vehicle Slip AngleyeshwantambureNo ratings yet

- The Leading Edge by Goro Tamai - Table of ContentsDocument1 pageThe Leading Edge by Goro Tamai - Table of ContentsBentley PublishersNo ratings yet

- Design Developmentofan Aerodynamic Packageforan FSAERace CarDocument137 pagesDesign Developmentofan Aerodynamic Packageforan FSAERace CarMaurício Gomes Marçal100% (1)

- F1 Aerodynamics Study Reveals Wake EffectsDocument25 pagesF1 Aerodynamics Study Reveals Wake EffectsLumpiang Toge100% (1)

- Suspension Analyzer ManualDocument156 pagesSuspension Analyzer ManualSankalp SharmaNo ratings yet

- Parameterization and Modelling of An Offroad Tires and AnalysisDocument9 pagesParameterization and Modelling of An Offroad Tires and AnalysisKranthi P GNo ratings yet

- RCE4Document3 pagesRCE4Ketan JainNo ratings yet

- Handling Cornering Speed: 1) Tire's GripDocument17 pagesHandling Cornering Speed: 1) Tire's GripPushkin SaxenaNo ratings yet

- Aerodynamic Analysis of Drag Reduction Devices On The Underbody For SAABDocument88 pagesAerodynamic Analysis of Drag Reduction Devices On The Underbody For SAABJosé López100% (1)

- Developments of A Method For Lap Time SimulationDocument7 pagesDevelopments of A Method For Lap Time SimulationRodrigo Bob100% (1)

- Structural Analysis of Steering Knuckle For Weight ReductionDocument6 pagesStructural Analysis of Steering Knuckle For Weight ReductionMithun V KulkarniNo ratings yet

- The Aerodynamic Interaction Between An Inverted Wing and A Rotating WheelDocument13 pagesThe Aerodynamic Interaction Between An Inverted Wing and A Rotating WheelVyssionNo ratings yet

- Combined Effect of Ground Presence and Heaving Motion On A Race Car WingDocument86 pagesCombined Effect of Ground Presence and Heaving Motion On A Race Car WingMatteo de'Giovanetti100% (3)

- Ground Effect in Formula One: Oliver Mercer-U1554386 - Communication & Research-NPE0001 - February 16, 2016Document17 pagesGround Effect in Formula One: Oliver Mercer-U1554386 - Communication & Research-NPE0001 - February 16, 2016Oliver MercerNo ratings yet

- BV Spring Rate Calculator V6.4Document16 pagesBV Spring Rate Calculator V6.4Anonymous QiMB2lBCJLNo ratings yet

- FSAE Aero Initial Performance Predictions - MonashDocument10 pagesFSAE Aero Initial Performance Predictions - MonashPedro BarataNo ratings yet

- CG Height Calculator - Automotive Brake System Calculator - BRAKE POWERDocument2 pagesCG Height Calculator - Automotive Brake System Calculator - BRAKE POWERAnonymous QiMB2lBCJLNo ratings yet

- Report On Pushrod SuspensionDocument33 pagesReport On Pushrod SuspensionAshish Rawat100% (4)

- Analysis of Ground Effect Diffuser On A Race Car To Optimize Aerodynamic PerformanceDocument6 pagesAnalysis of Ground Effect Diffuser On A Race Car To Optimize Aerodynamic PerformanceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Composite Effects On Tire MechanicsDocument22 pagesComposite Effects On Tire MechanicsTomislavMatanićNo ratings yet

- Aerodynamic Optimization of The Opel Calibra ITC Racing Car Using Experiments and Computational Fluid DynamicsDocument12 pagesAerodynamic Optimization of The Opel Calibra ITC Racing Car Using Experiments and Computational Fluid DynamicsVyssionNo ratings yet

- Development of Aerodynamics For A Solar Race CarDocument7 pagesDevelopment of Aerodynamics For A Solar Race CarAmr MagdyNo ratings yet

- The Leading Edge by Goro Tamai - Complete IndexDocument8 pagesThe Leading Edge by Goro Tamai - Complete IndexBentley PublishersNo ratings yet

- The Design Process of An Aerodynamic Package For An FSae CarDocument9 pagesThe Design Process of An Aerodynamic Package For An FSae CarJuantxoGarciaNo ratings yet

- CFD of Clubman Roll CagesDocument18 pagesCFD of Clubman Roll CagesJoel ForbesNo ratings yet

- Spoiler (Car)Document6 pagesSpoiler (Car)phutd09No ratings yet

- Method of Drag ReductionDocument8 pagesMethod of Drag Reductionkapil.scribdNo ratings yet

- Comparison of Feedback Control TechniquesDocument12 pagesComparison of Feedback Control TechniquesKunheechoNo ratings yet

- Aerodynamics of A Wing in Ground Effect in Generic Racing Car Wake FlowsDocument13 pagesAerodynamics of A Wing in Ground Effect in Generic Racing Car Wake FlowsVyssionNo ratings yet

- Ackermann Steering For Performance Race Cars PDFDocument22 pagesAckermann Steering For Performance Race Cars PDFr2d23No ratings yet

- Aerodynamic Design For FSAE CarDocument4 pagesAerodynamic Design For FSAE CarMohamed NaderNo ratings yet

- Aircraft Viscous Drag Reduction Using Riblets - ViswanathDocument30 pagesAircraft Viscous Drag Reduction Using Riblets - ViswanathOSCARDELTANo ratings yet

- Force Based Roll CentersDocument6 pagesForce Based Roll Centersnick944100% (1)

- Selecting Automotive Diffusers To Maximise Underbody DownforceDocument18 pagesSelecting Automotive Diffusers To Maximise Underbody DownforceVyssionNo ratings yet

- Tyre Report SampleDocument5 pagesTyre Report SampleArka PatraNo ratings yet

- Analysing Road Car DragDocument7 pagesAnalysing Road Car DragSirAndroid1984No ratings yet

- 16 Suspension 3Document37 pages16 Suspension 3Sunilkumar ReddyNo ratings yet

- Handling: PrefaceDocument19 pagesHandling: PrefaceRohit Tokas100% (1)

- Aerodynamics of Gurney Flaps On A Wing in Ground EffectDocument9 pagesAerodynamics of Gurney Flaps On A Wing in Ground EffectVyssionNo ratings yet

- Development and Experimental Verification of A Parametric Model of An Automotive DamperDocument126 pagesDevelopment and Experimental Verification of A Parametric Model of An Automotive DamperMrudula Amar WardeNo ratings yet

- Vehicle Roll EstimatorDocument10 pagesVehicle Roll EstimatorRaja Amer AzimNo ratings yet

- OptimumT Software for Advanced Tire Data AnalysisDocument6 pagesOptimumT Software for Advanced Tire Data AnalysisPierre LalsingNo ratings yet

- Tire and Rim FundamentalsDocument22 pagesTire and Rim FundamentalswarcellNo ratings yet

- Compression and Rebound Dampening Is The Same When Critically DampenedDocument3 pagesCompression and Rebound Dampening Is The Same When Critically DampenedDiego PesantezNo ratings yet

- CFD Analysis PDFDocument3 pagesCFD Analysis PDFariekoprianto100% (1)

- Chassis Newsletter 2010.8Document3 pagesChassis Newsletter 2010.8Ganesh ShanmugamNo ratings yet

- Analyzing an Oversteering Car's Slip AngleDocument3 pagesAnalyzing an Oversteering Car's Slip AngleLeonardo ColpoNo ratings yet

- A Tool For Lap Time Simulation PDFDocument5 pagesA Tool For Lap Time Simulation PDFRodrigo BobNo ratings yet

- Evolution of AI and Setup for Simulated Race CarsDocument11 pagesEvolution of AI and Setup for Simulated Race CarsAntonio RodriguesNo ratings yet

- ES140205 - Sujit Parmeshwar Narwade 72-80Document9 pagesES140205 - Sujit Parmeshwar Narwade 72-80Kubilay AçıkgözNo ratings yet

- Mame2022 1 6Document6 pagesMame2022 1 6Pujo TrihantoroNo ratings yet

- Ijmet 09 07 045Document13 pagesIjmet 09 07 045shreyashNo ratings yet

- SafetyDocument17 pagesSafetyutkarshNo ratings yet

- OPTIMIZATION OF A CAR SUSPENSION–STEERING LINKAGEDocument8 pagesOPTIMIZATION OF A CAR SUSPENSION–STEERING LINKAGESantiago UrgilesNo ratings yet

- Simplified single track vehicle model evaluationDocument11 pagesSimplified single track vehicle model evaluationnvs1981No ratings yet

- Optimal Kinematic Synthesis of 6-Bar Rack and Pinion Ackerman Steering LinkageDocument10 pagesOptimal Kinematic Synthesis of 6-Bar Rack and Pinion Ackerman Steering LinkageDeb PradhanNo ratings yet

- iRacing Race Schedule with OVAL and ROAD SeriesDocument117 pagesiRacing Race Schedule with OVAL and ROAD SeriesRodrigo BobNo ratings yet

- Assignment 1Document5 pagesAssignment 1Rodrigo BobNo ratings yet

- Mountain Darryl R.. Disrupting Conventional Law0AFirm Business Models Using0ADocument AssemblyDocument22 pagesMountain Darryl R.. Disrupting Conventional Law0AFirm Business Models Using0ADocument AssemblyRodrigo BobNo ratings yet

- Basic ConceptsDocument5 pagesBasic ConceptsRodrigo BobNo ratings yet

- Manual Powerbank PB-6KDocument2 pagesManual Powerbank PB-6KRodrigo BobNo ratings yet

- Developments of A Method For Lap Time SimulationDocument7 pagesDevelopments of A Method For Lap Time SimulationRodrigo Bob100% (1)

- Aerodynamics of Gurney Flaps On A Single-Element High-Lift Wing PDFDocument7 pagesAerodynamics of Gurney Flaps On A Single-Element High-Lift Wing PDFRodrigo Bob100% (1)

- University of Southampton Undergraduate Prospectus 2016 PDFDocument99 pagesUniversity of Southampton Undergraduate Prospectus 2016 PDFRodrigo BobNo ratings yet

- UCEM Accumulator Final ReportDocument40 pagesUCEM Accumulator Final ReportRodrigo BobNo ratings yet

- Eita GiovannaDocument40 pagesEita GiovannaRodrigo Bob100% (1)

- Advanced Dynamics - TU Delft OnlineDocument1 pageAdvanced Dynamics - TU Delft OnlineRodrigo BobNo ratings yet

- CL Vs AlphaDocument22 pagesCL Vs Alpharahultri333No ratings yet

- Projeto de Pontes de Macarrão PDFDocument8 pagesProjeto de Pontes de Macarrão PDFRodrigo BobNo ratings yet

- Degrees of Freedom ExplainedDocument21 pagesDegrees of Freedom ExplainedRodrigo BobNo ratings yet

- Racing Simulation of A Formula 1 Vehicle With Kinetic Energy Recovery SystemDocument15 pagesRacing Simulation of A Formula 1 Vehicle With Kinetic Energy Recovery SystemRodrigo Bob100% (1)

- USER MANUAL CHASSIS SETUP GUIDEREARmmdegdegdegLb/inmmmmnotchesmm25-2.5°20’ IN13000 turn11B8 R10B10 R6STD<<<<>>>>2Document61 pagesUSER MANUAL CHASSIS SETUP GUIDEREARmmdegdegdegLb/inmmmmnotchesmm25-2.5°20’ IN13000 turn11B8 R10B10 R6STD<<<<>>>>2Rodrigo Bob100% (2)

- A Tool For Lap Time Simulation PDFDocument5 pagesA Tool For Lap Time Simulation PDFRodrigo BobNo ratings yet

- Stress Analysis of Piping SystemsDocument108 pagesStress Analysis of Piping SystemsShijumon KpNo ratings yet

- Data Acquisition System For A Formula SAE Race CarDocument43 pagesData Acquisition System For A Formula SAE Race CarRodrigo Bob100% (1)

- Politecnica - Di - Torino - Specific Qualification PDFDocument3 pagesPolitecnica - Di - Torino - Specific Qualification PDFRodrigo BobNo ratings yet

- NAS120 WS14 Parasolid ModelingDocument34 pagesNAS120 WS14 Parasolid ModelingPieter Van AschNo ratings yet

- Patran 2010 Reference Manual Part 1: Basic FunctionsDocument798 pagesPatran 2010 Reference Manual Part 1: Basic FunctionsDon100% (1)

- Vibration Based Monitoring Applied To The Identification of DefectsDocument10 pagesVibration Based Monitoring Applied To The Identification of DefectsRodrigo BobNo ratings yet

- Application of Computers To Automobile AerodynamicsDocument10 pagesApplication of Computers To Automobile AerodynamicsRodrigo BobNo ratings yet

- Vehicle DynamicsDocument24 pagesVehicle Dynamicssviggnesh_hpNo ratings yet

- Using Modelica Models For Driver-In-The-loop SimulatorsDocument8 pagesUsing Modelica Models For Driver-In-The-loop SimulatorsRodrigo BobNo ratings yet

- Response Surface Methodology (RSM) and Design of Experiments (Doe) Applied To Racecar Vehicle Dynamics Simulation and DevelopmentDocument20 pagesResponse Surface Methodology (RSM) and Design of Experiments (Doe) Applied To Racecar Vehicle Dynamics Simulation and DevelopmentRodrigo BobNo ratings yet

- CIBSE Guide M 2014-Section12 Economic Life FactorsDocument32 pagesCIBSE Guide M 2014-Section12 Economic Life FactorsdamianNo ratings yet

- BPCS - Log-12 Material AllocationDocument4 pagesBPCS - Log-12 Material AllocationgummalamaptiNo ratings yet

- Network Management CourseDocument4 pagesNetwork Management CourseRichard CoronelNo ratings yet

- ACI Concrete Mix Design Guide - Procedure & CalculationsDocument14 pagesACI Concrete Mix Design Guide - Procedure & CalculationsAdi SatriaNo ratings yet

- Fill in The Blanks and True False ComputerDocument3 pagesFill in The Blanks and True False Computerunaas fatimaNo ratings yet

- Device Accessories: Device Programmer / Test UnitDocument2 pagesDevice Accessories: Device Programmer / Test UnitRakesh MandalNo ratings yet

- TG862ABS User GuideDocument57 pagesTG862ABS User GuideCamilo RamirezNo ratings yet

- Digital Marketing GlossaryDocument6 pagesDigital Marketing GlossaryAmanMoomdevMahajanNo ratings yet

- Emergency Fire Pump FFV-100DDocument12 pagesEmergency Fire Pump FFV-100DsuranovoleksandrNo ratings yet

- The Toyota Way in Services: The Case of Lean Product DevelopmentDocument18 pagesThe Toyota Way in Services: The Case of Lean Product DevelopmentErnesto GPNo ratings yet

- ISO 3633 2002 (En)Document38 pagesISO 3633 2002 (En)Attef BedawyNo ratings yet

- Experiment No.1: Aim: Case Study of Mis and Its Functional Subsystem TheoryDocument32 pagesExperiment No.1: Aim: Case Study of Mis and Its Functional Subsystem TheoryHarmandeep KaurNo ratings yet

- EElectives SubjectsDocument60 pagesEElectives SubjectsDr. Vivek SrivastavaNo ratings yet

- Hdhomerun HTTP DevelopmentDocument3 pagesHdhomerun HTTP Developmentfrancisca ulloa riveraNo ratings yet

- MATLAB Programming: Functions, Data Analysis, System ResponseDocument3 pagesMATLAB Programming: Functions, Data Analysis, System ResponseShivam YadavNo ratings yet

- Corporate Strategy - Tencent AnalysisDocument9 pagesCorporate Strategy - Tencent AnalysisJosh Forbes100% (2)

- Order Picker/tri-Lateral Stacker (1000 KG)Document4 pagesOrder Picker/tri-Lateral Stacker (1000 KG)陳品宏No ratings yet

- Golf ASV EDC15 121pin - ElsaDocument14 pagesGolf ASV EDC15 121pin - ElsagrzegorzNo ratings yet

- Gsa-Is: Intelligent Ionization Smoke DetectorDocument6 pagesGsa-Is: Intelligent Ionization Smoke DetectormuhammadmujiebNo ratings yet

- Form No.FYP-001 - Dual Power Generation Solar Plus Windmill GeneratorDocument2 pagesForm No.FYP-001 - Dual Power Generation Solar Plus Windmill GeneratorMoazzam IrshadNo ratings yet

- Steel Door MOSDocument6 pagesSteel Door MOSahmed samirNo ratings yet

- Final Year Project Center CoimbatoreDocument15 pagesFinal Year Project Center Coimbatorecoimbatore projectNo ratings yet

- Helping Students Achieve with Online Learning ResourcesDocument12 pagesHelping Students Achieve with Online Learning ResourcesedarankomnasNo ratings yet

- Autonomousvehiclereportv06c 161221232942Document93 pagesAutonomousvehiclereportv06c 161221232942Adarsh AjNo ratings yet

- ACM-8RF Instruction Manual 50362Document48 pagesACM-8RF Instruction Manual 50362Said RomeroNo ratings yet

- Material Estimation Archives - The ConstructorDocument15 pagesMaterial Estimation Archives - The ConstructorEmil Lawrence EspirituNo ratings yet

- RPL Lecture 10Document37 pagesRPL Lecture 10Muqadar AliNo ratings yet

- The Most Complete Starter Kit For UNODocument158 pagesThe Most Complete Starter Kit For UNOShantan KajjamNo ratings yet

- Barcode Recognition System (Second Seminar)Document13 pagesBarcode Recognition System (Second Seminar)Alex WunnaNo ratings yet

- Grashoff's Law and Four Bar InversionsDocument41 pagesGrashoff's Law and Four Bar Inversionsmani88kctNo ratings yet