Professional Documents

Culture Documents

Ut MT 0428 - RCLF

Uploaded by

gplese00 ratings0% found this document useful (0 votes)

39 views39 pagesTechnical file

Original Title

UT-MT-0428_RCLF

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTechnical file

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views39 pagesUt MT 0428 - RCLF

Uploaded by

gplese0Technical file

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 39

O.C.E.M. S.p.A.

Document UT-MT- 0428 Pagina 1 di 39

Edition 11/11/04

Supersede the edition 01/22/04

QUESTA COPIA NON E FIRMATA PERCHE REGISTRATA E DISTRIBUITA TRAMITE SISTEMA AUTOMATICO DI GESTIONE DEL PATRIMONIO INFORMATIVO (PUO ESSERE FIRMATA A RICHIESTA)

THIS COPY IS NOT SIGNED SINCE IT IS FILED AND DELIVERED BY MEANS OF THE AUTOMATIC KNOWLEDGE MANAGEMENT SYSTEM (IT CAN BE SIGNED ON REQUEST)

QUESTO DOCUMENTO E DI PROPRIETA DELLA O.C.E.M. S.p.A. IL SUO CONTENUTO NON PUO ESSERE DIVULGATO NE MODIFICATO SENZA IL CONSENSO SCRITTO DELLA O.C.E.M. S.p.A.

THIS DOCUMENT BELONGS TO O.C.E.M. S.p.A. ITS CONTENT CANNOT BE DIVULGED OR MODIFIED WITHOUT WRITTEN APPROVAL OF O.C.E.M. S.p.A.

SEMI-FLUSH

RUNWAY CENTRELINE LIGHT

RCLF

INSTRUCTION MANUAL FOR USE,

INSTALLATION AND MAINTENANCE

Compiled by: N. Marabini Approved by: Ing. P. Scaramagli

Via 2 Agosto 1980 n11

40016 SAN GIORGIO DI PIANO

BOLOGNA ITALY

N appendices

Copia N

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 2 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

R E V I S I O N S

REV DESCRIPTION DATE COMP APP

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 3 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

L I S T O F E F F E C T I V E P A G E S

PAGE REV PAGE REV

1 23

2 24

3 25

4 26

5 27

6 28

7 29

8 30

9 31

10 32

11 33

12 34

13 35

14 36

15 37

16 38

17 39

18

19

20

21

22

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 4 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

LIMITED PRODUCT WARRANTY

THE FOLLOWING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT

NOT BY WAY OF LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE.

OCEM warrants to each original Buyer of Products manufactured by the Company that

such Products are, at the time of delivery to the Buyer, free of material and workmanship

defects, provided that no warranty is made with respect to:

(a) any Product which has been repaired or altered in such a way, in Companys

judgement, as to affect the Product adversely;

(b) any Product which has, in Companys judgement, been subject to negligence, accident

or improper storage;

(c) any Product which has not been operated and maintained in accordance with normal

practice and in conformity with recommendations and published specification of Company;

and,

(d) any Product, component parts or accessories manufactured by others but supplied by

Company (any claims should be submitted directly to the manufacturer thereof).

OCEMs obligation under this warranty is limited to use reasonable efforts to repair or, at

its option, replace, during normal business hours at the facility of the Company, any

Product which in its judgement proved not to be as warranted within the applicable

warranty period. All costs of transportation of Products claimed not to be warranted and of

repaired or replacement Products to or from the facility of the Company shall be borne by

Purchaser. Company may require the return of any Product claimed not to be as

warranted to its facility, transportation prepaid by Purchaser, to establish a claim under this

warranty. The cost of labour for installing a repaired or replacement Product shall be borne

by Purchaser. Replacement parts provided under the terms of this warranty are warranted

for the remainder of the warranty period of the Products upon which they are installed to

the same extent as if such parts were original components thereof. Warranty services

provided under the Agreement do not assure uninterrupted operations of Products;

Company does not assume any liability for damages caused by any delays involving

warranty service. The warranty period for the Products is 24 months from date of shipment

or 12 months from date of first use, whichever occurs first.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 5 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

SAFETY NOTICES

This equipment is normally used or connected to circuits that may employ voltages which

are dangerous and may fatal if accidentally contacted by operating or maintenance

personnel. Extreme caution should be exercised when working with this equipment. While

practical safety precautions have been incorporated in this equipment, the following rules

must be strictly observed:

KEEP AWAY FROM LIVE CIRCUITS

Every time operating and maintenance personnel must observe all safety regulations. Do

not perform maintenance on internal components or re-lamp with power ON.

RESUSCITATION

Maintenance personnel should familiarize themselves with the technique for resuscitation

found in widely published manuals of first aid instructions.

CE CERTIFICATE

This equipment complies with the requirements of the EEC directives 73/23/EEC

and 93/68EEC with regard to Electromagnetic Compatibility.

PLACING OUT OF SERVICE

In case of dismantling, placing out of service, scrapping, the user shall follow all the

required precautions for component and material elimination, according to local rules.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 6 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

TABLE OF CONTENTS

Cover 1

Revisions 2

List of Effective Pages 3

Limited Product Warranty 4

Safety Notices 5

Tble of Contents 6

List of Figures 7

1.0 General 9

2.0 Main Features 9

2.1 Removable Light Unit 9

2.2 Shallow Base 18

3.0 Installation 21

3.1 Installing shallow base with thru-feed system (mounting

system B) with cable leads to be laid in wireways 21

3.2 Installing shallow base (suitable for conduit system) with

cable leads to be laid into cable ducts 27

3.3 Installing light unit on L-868 base, size B 30

3.4 Coloured Filter 32

4.0 Maintenance 32

4.1 Removing light unit from the base and opening light unit 32

4.2 Cleaning glass prism and filter 33

4.3 Replacing prism 33

4.4 Relamping 34

4.5 O-ring 35

4.6 Cable lead with plug and bush 35

4.7 Vibration-damping block 36

4.8 Pressure valve 36

4.9 Cleanliness and workmanship 37

4.10 Maintenance program 37

5.0 List of Recommended Spare Parts 39

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 7 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

LIST OF FIGURES

FIGURE 1a - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

REMOVABLE LIGHT UNIT EXPLODED VIEW 10

FIGURE 1b - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

REMOVABLE LIGHT UNIT PARTS LIST 11

FIGURE 2 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

DOME OUTSIDE VIEW 12

FIGURE 3 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH ONE ENTRY AND

INSULATING STRIPS INSIDE VIEW 12

FIGURA 4 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH ONE ENTRY AND

ELECTRONIC RELAYS INSIDE VIEW 13

FIGURE 5 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH TWO ENTRIES AND

INSULATING STRIPS INSIDE VIEW 13

FIGURA 6 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH TWO ENTRIES AND

ELECTRONIC RELAYS INSIDE VIEW 14

FIGURE 7 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER - OUTSIDE VIEW 14

FIGURE 8 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

COMPLITE P/N IDENTIFICATION 17

FIGURE 9 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

STANDARD SHALLOW BASE (MOUNTING SYSTEM B)

ONE ENTRY 19

FIGURE 10 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

STANDARD SHALLOW BASE (MOUNTING SYSTEM B)

TWO ENTRIES 20

FIGURE 11a - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

EXAMPLE OF LIGHT CONFIGURATION (ONE

TRANSFORMER PER EACH LIGHT) 22

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 8 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 11b - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

RETILS CONFIGURATION 23

FIGURE 12 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

PAVEMENT BORING, SAWCUTTING AND J OINT

INTERSECTION DETAILS 24

FIGURE 13 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

SHALLOW BASE MOUTING DETAILS 26

FIGURE 14 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

SHALLOW BASE FOR SIDE CONDUIT -

MOUNTIG DETAILS 29

FIGURE 15 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

SHALLOW BASE FOR BOTTOM CONDUIT

MOUNTING DETAILS 30

FIGURE 16 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LIGHT UNIT WITH ADAPTOR RING

(MOUTING SYSTEM R) 31

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 9 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

1.0 GENERAL

RCLF semi-flush runway centreline light is high intensity, bidirectional, inset, steady

burning type; and provide photometric performances in compliace with ICAO Specs -

Annex 14, STANAG 3316, IEC TS 61827 (style 4) and FAA AC 150/5345-46 specification.

Fixtures described in this manual are manufactured to be powered through isolating

transformers by series circuits, fed by constant current regulators.

Characteristics and location of the fixtures shall be in compliance with ICAO Specs -

Annex 14, STANAG 3316 and FAA.

2.0 MAIN FEATURES

Each light assembly mainly consists of a removable light unit and a shallow base

receptacle (mounting system B). The light assembly is waterproof and designed to

withstand aircraft impact and roll-over loads without damage.

On request, a suitable adaptor ring (base mounted, option R) is available to allow the

installation on shallow base, 12 diameter, or on deep base, type L-868, size B, as per

FAA AC 150/5345-42, thereby permitting replacement of any inset fixture without removing

the deep base from the pavement.

2.1 REMOVABLE LIGHT UNIT

The removable light unit mainly consists of a dome, a lower cover and the optical

assembly (fig. 1a-b/2/3/4/5/6/7).

The dome is made by treated drop-forged aluminium and includes two windows to seat

the prisms. In correspondence of the windows, the dome is outside provided with

identification letters A and B.

The dome is provided with two through holes for fastening the light unit to the base and

two dead holes for matching two studs mounted on the base, so to prevent the rotation of

the light unit due to aircraft wheel impact/roll over.

It is also provided with two suitable slots, in opposite position, to make easy the light unit

removal by using suitable lifting tools (available on request, P/N 332.4140 or P/N

332.4230). As alternative, two screwdrivers can be used.

An O-ring (separately supplied) shall be mounted outside around the dome, to avoid dirt

deposits between dome and shallow base.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 10 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

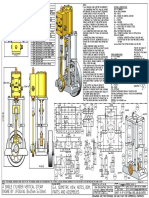

FIGURE 1a - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

REMOVABLE LIGHT UNIT EXPLODED VIEW

12

11

27

13

10

9

7

6

25

1

3

21

26

24

23

12

22

8

4

5

2

24

17

19 18

14

20

16

15

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 11 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

N Description Qt.

1 Complete lower cover see also Fig. 3/4/5/6 1

2 RCLF dome 1

3 HSFH M5x12 inox screw 3

4 O-Ring 4600 silicone 1

5 O-Ring 4775 silicone 1

6 O-Ring 4625 silicone 1

7 Lampholder 1

8 Lamp 2

9 Spacer 4

10 Vibration-damping block 4

11 HSCH M5x16 inox screw 4

12 Dia. 5 inox grower washer 4

13 Dia.5,3x13x1,5 teflon washer 8

14 Optical assembly mounting plate 2

15 Filter-holder box 2

16 Filter 1

17 HSFH M5x12 inox screw 3

18 Teflon prism-holder 2

19 Prism 2

20 Prism gasket 2

21 Cable lead with plug L-823 and terminal bush (*)

22 Grounding cable L=250mm 1

23 Dia.5x10x1 inox washer 1

24 CH M5x10 inox screw 3

25 Fuse cutout (*)

26 O-Ring 2056 Viton (*)

27 Dia. 7x14x1,6 inox washer 4

(*) 1 or 2 depending on the power supply mode

FIGURE 1b - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

REMOVABLE LIGHT UNIT PARTS LIST

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 12 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 2 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

DOME OUTSIDE VIEW

FIGURE 3 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH ONE ENTRY AND INSULATING STRIPS

INSIDE VIEW

1 - Bush of the cable

leads with plug and

bush

2 - Plug-insulating

strips cables

3 - Insulating strip-

insulating strip

cable

4 - Insulating strip

5 - Insulating strip

fastening screws

6 - Leak test valve

7 - Letter A for

cable lead

identification

1 - Dome

2 - Slot for dome removal

3 - Letter "A" to identify the

beam

4 - Through hole for light unit

fastening

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 13 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURA 4 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH ONE ENTRY AND

ELECTRONIC RELAYS INSIDE VIEW 13

FIGURE 5 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH TWO ENTRIES AND INSULATING STRIPS

INSIDE VIEW

1 - Cable lead with

plug and bush

2 - Plug-relay wire

3 Relay-relay wire

4 - Electronic cutout

relay

5 - Relay fastening

screws

6 - Leak test valve

7 - Letter A for cable

lead identification

1 - Cable leads

with plug and

bush

2 - Bush-isulatin

strip wires

3 - Insulating trips

4 - Insulatin strips

screws

5 - Leak test valve

6 - Letter A and

B for cable

leads

identification

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 14 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 6 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER WITH TWO ENTRIES AND ELECTRONIC RELAYS

INSIDE VIEW

FIGURE 7 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LOWER COVER OUTSIDE VIEW

1 - Lower cover

2 - Identification label

3 - Grounding cable hole

4 - Letter A and B for

cable leads indication

5 - Seat for cable leads

bush

7 - Cable leads

with plug and

bush

8 - Bush-relay

wires

9 - Electronic

relays

10 - Electronic

relays screws

11 - Leak test valve

12 - Letter A and

B for cable

leads

identification

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 15 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

The lower cover consists of a treated aluminium casting; it is fastened to the dome by

means of three screws HSFH M5x12 (Fig. 1 - n 3). An O-ring is provided between dome

and lower cover too.

Inside the lower cover the lamps, on the lampholders, are connected to the insulating

strips or the electronic relays.

The cover is outside provided with one or two cable leads with plug L-823 and bush, a

grounding screw with yellow-green cable lead (with male faston terminal) and a valve (with

removable cap) for leak test.

The optical assembly consists of two prisms, two lamp and two coloured filters.

The prisms are mechanically clamped into the light dome by means of a mounting plate

with a gasket; the mounting plate is fixed by means of three screws HSFH M5x12 (Fig. 1 -

n 17). An additional teflon gasket is placed between the mounting plate and the prisms, to

avoid glass-metal direct contact. The prisms replacement is quick and easy and doesnt

require any sealing.

The lamps are of tungsten-halogen type, 48 W, 6,6 A, 1000 hour rated life, with dichroic

reflector and cable leads (with male faston terminals); they are mounted on a suitable plate

surely fastened to a mounting by means of a spring for easy and quick relamping. Plate,

mounting and sping are stainless steel.

J ust one optical assembly is available for this fixture (P/N 152.1700), infact RCLF hasnt

particular beam toes, in compliance with FAA 150/5345-46.

The lamps plate assembly, with a identification label, are always secured in a fixed position

on the lower cover, attached by means of four vibration-damping blocks.

One dichroic filter is placed in the rear side of the prism. The filter holder box is fixed to the

dome by means of two screws CH M5x10 (Fig. 1 - n 24).

Lamps, prisms and coloured filters are factory assembled; they may be field replaced if so

desired (parr. 3.4 - 4.3 - 4.4).

The light unit is supplied with one or two cable lead with plug and bush; it consists of two

single-pole teflon leads, size 2.5 sqmm, 0.500 m long, which end with a threaded bush

including two rounded male faston terminals. The plug is in compliance with FAA L-823 for

very quick coupling with the receptacle mounted on the shallow base.

If light unit is equipped with one cable lead with plug, both the lamps will work

simultaneously; If it is necessary to operate independently the two lamps, then two cable

leads with plug are necessary.

Bidirectional fixtures - one cable lead with plug and bush

The bush of the unique cable lead is screwed to the lower cover in correspondence to the

entry "A" (Figg. 4/6).

Each lamp is connected by means faston terminals to the relevant insulating strip, which is

fixed to the lower cover (one of the lamp male fastons is connected to one of the insulating

strip female ones). The insulating strips are connected to the bush of the unique cable lead

by means a pair of wires (one cable for each insulating strip) equipped at one end with

two female rounded terminals for connection to the bush male fastons and at the other end

with two female terminals for connection to the strip male fastons (Figg. 3/4 - n 2). A

third wire realizes the series connection between the insulating strips (Figg. 4/6 - n 3).

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 16 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

Each strip is suitable to seat a fuse cutout (option F), which on request can be supplied to

allow the series of more light fixtures on the secondary of one isolating transformer .

As alternative each insulated strip can be replaced by an electronic cutout relay (option

E) directly fixed to the lower cover (Fig. 4). In this case the lamp male terminals are

connected to the relay female faston, while the relay male fastons are connected to the

rounded cable lead male faston through the above described pair of wires. The third wire

realizes the series connection between the relays.

Bidirectional fixtures - two cable leads with plug and bush

Both the cable entries of the lower cover are used: the bush of the lamp A cable lead is

screwed to the lower cover in correspondence to the entry "A" and the bush of the lamp

B cable lead is screwed to the lower cover in correspondence to the entry "B" (Figg.

5/6).

Each lamp is connected by means faston terminals to the relevant insulating strip, which is

fixed to the lower cover (the lamp male fastons are connected to the insulating strip female

ones). The insulating strip is connected to the bush of the relevant cable lead by means a

pair of wires equipped at one end with two female rounded terminals for connection to the

bush male fastons and at the other end with two female terminals for connection to the

strip male fastons.

Each strip is suitable to seat a fuse cutout (option F), which on request can be supplied to

allow the series of more light fixtures on the secondary of one isolating transformer .

As alternative each insulated strip can be replaced by an electronic cutout relay (option

E) directly fixed to the lower cover (Fig. 6). In this case the male terminals of each lamp

are connected to the female faston of the relevant relay, while the male fastons of the relay

are connected to the rounded male faston of the relevant cable lead through the above

described pair of wires.

The light assembly unit is 203 mm in diameter and 90 mm (+18,5 mm for plugs) high; the

protrusion above the ground is 6 mm.

An identification data label is externally applied over the lower cover (Fig. 7). Moreover, to

identify quickly the beam colour, the letters A and B of the dome in front of the windows

is painted in the same colour of the filter.

The same colour painting is provided outside on the lower cover.

See Fig. 8 for complete P/N informations.

All hardware is made of stainless steel.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 17 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 8 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

COMPLETE P/N IDENTIFICATION

Type:

Compliance:

F =FAA

I =ICAO Cat. III

S =STANAG and ICAO Cat. I - II

T =Taxiway ("Y" and "G" - ICAO only)

R =RETILs ("Y", unidirectional dome only)

Colour(Side A)/Colour(Side B):

C =Clear

R =Red

Y =Yellow

G =Green

X =Blank

M =Aperture not finished (unidirectional dome)

Lamp:

045 =1x48W 6,6A Reflectorized

090 =2x48W 6,6A Reflectorized

Electrical System:

1P =One Plug

2P =Two Plugs

Mounting Assembly:

B =Standard Shallow Base, 8" dia.

R =Adaptor Ring, 8"-12" dia.

O =No Mounting Assembly

Options:

F =Fuse Cutout

E =Electronic Cutout Relay

R C F L 0 F R C 9 0 P 2 O F

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 18 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

2.2 SHALLOW BASE

The shallow base (mounting system B) (Fig. 7) consists of a treated aluminium casting

containing an electrical feed-thru system to connect the power cables, consisting of one or

two cable leads with receptacle incoming inside the base through one or two cable glands.

The cable lead with receptacle consists of two single-pole teflonleads, size 2.5 sqmm,

0.770 m long, with FAA L-823 receptacle.

The letters "A" and B are printed inside the base for cable leads identification.

The base is equipped with an internal grounding screw with yellow-green cable lead, size

2.5 sqmm, 0.250 m long, with female faston terminal for quick connection to the

corresponding of the light unit. An additional external grounding screw is provided close to

the cable entry.

The shallow base is designed for cementing in place in a hole drilled in the pavement.

The light unit has to be fastened to the base by means of two screws. Each locking screw

is complete with external lockwasher and nylon washer (not to lose the previous one). Two

studs are provided in the base to prevent rotation of the light unit due to aircraft wheel

impact/roll over.

An O-ring (separately supplied) must be placed between base and light unit for

watertightness.

The shallow base is 214 mm in diameter and 125 mm high.

On request, special bases without cable leads can be supplied, provided with holes

suitable for conduit connections.

Inside the base two suitable holders (Fig. 9/10 - n 9) are provided to properly sustain the

secondary power cable, in case of this cable is inside incoming through a conduit.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 19 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

1 - Standard shallow base

2 Cable gland for cable entry

3 - Two-pole receptacle with teflon cables

4 - Grounding cable with female faston

5 - Internal grounding screw

6 - External grounding screw

7 - Threaded inserts for light unit fastening by screws

8 - Stud to prevent light unit rotation

9 - Secondary power cable holder

10 - Letter A for calbe lead identification

FIGURE 9 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

STANDARD SHALLOW BASE (MOUNTING SYSTEM B)

ONE ENTRY -

1

5

4

6

2

10

3

9

8

7

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 20 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

1 - Standard shallow base

2 Cable glands for cable entry

3 - Two-pole receptacle with teflon cables

4 - Grounding cable with female faston

5 - Internal grounding screw

6 - External grounding screw

7 - Threaded inserts for light unit fastening by screws

8 - Stud to prevent light unit rotation

9 - Secondary power cable holder

10 - Letters A and B for calbe leads identification

FIGURE 10 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

STANDARD SHALLOW BASE (MOUNTING SYSTEM B)

TWO ENTRIES -

8

9

7

1

2 6

5

10

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 21 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

3.0 INSTALLATION

3.0.1 Using the scheme as shown in example of light configuration FIGURE 11a/b, drill

each recess in pavement as illustrated in FIGURE 12. Make sure the recess size

and depth are maintained within the specified limits. The recess side walls must be

perpendicular to the pavement surface. The bottom surface must be flat or slightly

concave to assure that the shallow base rest securely and in true position. The

recess can best be drilled using a diamond-faced core drill in a sturdy, stable drill

rig.

3.0.2. Before installing the shallow base, be sure all surfaces of the recess are clean and

dry. If any of these surfaces is damp, it is desirable that it be dried and blown clean

with a compressed air blast.

3.0.3 Mark on the pavement surface the aiming direction of the light by chalk, nails or

other devices.

NOTE 1: For further information about location and connection circuit of the fixtures see

FAA AC 150/5340-30 specification.

3.1 INSTALLING SHALLOW BASE WITH THRU-FEED SYSTEM (MOUNTING

SYSTEM B) WITH CABLE LEADS TO BE LAID IN WIREWAYS

The wireways should be sawed using a diamond-faced saw, as shown in Figg. 11/12.

When wireways cross construction joints, the sawcuts should extend at least 25 mm below

the existing joint for a distance of 15 cm each side of the joint. In this case, the top 25 mm

of the wireway will have to be filled with an appropriate joint sealing filler. Before installing

the shallow base, be sure all surfaces of the wireways are clean and dry. If any of these

surfaces are damp, it is desirable that they are dried and blown with a compressed air

blast.

ATTENTION: do not handle the fixture by the lead wires.

3.1.1 Remove the light unit from the base, by unscrewing the two locking screws

complete with washers. Raise the light unit, by using the two lifting tools (or two

screwdrivers) inserted in the suitable slots provided on the dome.

3.1.2 Before placing the shallow base in the drilled hole, all external surfaces which will

be bonded to the pavement (except the feed-thru zone) should be slightly

sandblasted and must be cleaned with solvent to assure an adequate bond

between base and sealer. Do not handle the base by the lead wires.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 22 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 11a - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

EXAMPLE OF LIGHT CONFIGURATION (ONE TRANSFORMER

PER EACH LIGHT)

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 23 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 11b - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

RETILS CONFIGURATION

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 24 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 12 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

PAVEMENT BORING, SAWCUTTING AND J OINT

INTERSECTION DETAILS

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 25 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

3.1.3 Connect an insulated grounding wire of suitable length to the grounding screw

externally provided on the wall of the base, close to the feed-thru system.

3.1.4 Unwind the light base leads and splice them to the power cables using solderless

squeeze connectors, crimped with the proper tool. The splices to the light base

leads should be made at staggered locations.

Insulate each splice carefully using either heat shrinkable insulating tubing properly

applied or three layers of plastic electrical insulating tape applied with half overlap.

Connect also the grounding wire to the main grounding network by using a suitable

clamping lug.

3.1.5 A positioning jig (P/N 332.4200). should be used to install and align the base. Mount

the jig on the base by screwing the two spacers in the threaded holes of the base

(Fig. 10); notche in the jig, corresponding to those in the base, is then to be used to

align the fixture with the properly surveyed markings.

3.1.6 Properly arrange the leads in the wireways; if necessary, small wads of plastic

insulating tape may be used to wedge the leads in the bottom of the wireways.

3.1.7 With the jig attached to the base, completely cover the bottom of the base with

sealer material. Apply a thin coat of sealer to the bottom of the drilled hole to assure

a bond between the bottom of the light base and the drilled hole. Use temporary

plugs so as to block the wireways entrances into the drilled hole. The plugs will

retain the sealer while it begins to dry up.

ATTENTION: avoid starting the installation when the ambient temperature is

below 10 C (86F), unless the sealer used is designed for curing at a

lower temperature.

3.1.8 Push the base into the recess until its upper side is at the level of the pavement

surface; during this operation the sealer will be forced upwards in the interstice

between base and recess. Make sure the sealer doesnt flow inside the base.

At the same time align the light base by sighting the two notches of the jig with the

markings on the pavement surface.

.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 26 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 13 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

SHALLOW BASE MOUNTING DETAILS

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 27 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

3.1.9 Place the two linear levels (P/N 738.2001) crosswise on the jig; then level the jig by

operating the four levelling screws. If necessary, a weight may be placed on the jig

to hold the light base in position.

The remainder of the space between the sides of the shallow base and the drilled

hole should be filled with sealer. Fill to a level even with the top of the base or up to

approx 25 mm from the pavement, according to the local needs.

In this last case, fill the remaining 25 mm with a suitable joint sealing filler.

3.1.10 The jig should be left in place until the sealer dries up. But if any voids are present

around the shallow base, just as possible remove the jig for complete visibility and

refill.

3.1.11 When the shallow base installation is finished, install the removable light unit. The

light unit is shipped complete (including the lamp) and ready for installation as

received, except the lower cover outside O-ring and the dome outside O-ring

separately supplied (Fig. 1 - n 5/6). Be sure that inside of the shallow base is dry

and clean. Place properly the first O-ring in the outside groove of the lower cover

and the second one in the outside groove of the dome.

Connect the plugs of the cable leads of the light unit to the receptacle in the shallow

base. Connect the grounding wire of the light unit to the grounding wire of the

shallow base (faston connection). Then press the light unit firmly and evenly by

hand onto the shallow base.

The light unit is subject to mechanical damage and/or optical misalignment if not

properly seated on the base flange.

3.1.12 Secure the inset light fixture to the shallow base using the two locking screws

complete with washers. One drop of anaerobic adhesive, medium type (e.g. Loctite

243) should be applied to the screws before installation; tightening torque is 31 Nm.

3.1.13 Fill the wireways completely with a suitable approved sealer and let cure for at least

24 hours before disturbing, unless otherwise specified.

3.2 INSTALLING SHALLOW BASE (SUITABLE FOR CONDUIT SYSTEM) WITH

CABLE LEADS TO BE LAID INTO CABLE DUCTS

The cable ducts will be laid inside suitable wireways, which should be sawed using a

diamond-faced saw. The realization of the cable duct is depending on the local conditions,

therefore no suggestion are herebelow provided.

ATTENTION: do not handle the fixture by the lead wires.

3.2.1 Remove the light unit from the base, by unscrewing the two locking screws

complete with washers. Raise the light unit by using the two lifting tools (or two

screwdrivers) inserted in the suitable slots provided on the dome.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 28 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

3.2.2 Before placing the shallow base in the drilled hole, all external surfaces which will

be bonded to the pavement should be slightly sandblasted and must be cleaned

with solvent to assure an adequate bond between base and sealer. Do not handle

the base by the lead wires.

3.1.6 A positioning jig (P/N 332.4200). should be used to install and align the base. Mount

the jig on the base by screwing the two spacers in the threaded holes of the base

(Fig. 10); notche in the jig corresponding to those in the base is then to be used to

align the fixture with the properly surveyed markings.

3.2.4 With the jig attached to the base, completely cover the bottom of the base with

sealer material. Apply a thin coat of sealer to the bottom of the drilled hole to assure

a bond between the bottom of the light base and the drilled hole. It may be

necessary to place temporary plugs so as to block the wireways entrances into the

drilled hole. The plugs will retain the sealer while it begins to dry up.

ATTENTION: avoid starting the installation when the ambient temperature is

below 10C (86F), unless the sealer used is designed to dry up at a

lower temperature.

3.2.5 Push the base into the recess until its upper side is at the level of the pavement

surface; during this operation the sealer will be forced up the side of the light base:

take care no sealer flowing inside the base.

At the same time align the light base by sighting the two notches of the jig with the

markings on the pavement surface.

3.2.6 Place the two linear levels (P/N 738.2001) crosswise on the jig; then level the jig by

operating the four levelling screws. If necessary, a weight may be placed on the jig

to hold the light base in position.

When the shallow base is in its final position, the conduit(s) must be properly jointed

to the hole(s) provided on the shallow base. This(these) hole(s) can be provided

either on the wall either on the bottom, the number and the dimensions according to

customer requirements (Figg. 14 - 15).

The remainder of the space between the sides of the shallow base and the drilled

hole should be filled with sealer. Fill to a level even with the top of the base or up to

approx 25 mm from the pavement, according to the local needs.

In this last case, fill the remaining 25 mm with a suitable joint sealing filler.

3.2.7 The jig should be left in place until the sealer dries up. But if any voids are present

around the shallow base, just as possible remove the jig for complete visibility and

refill.

3.2.8 Lay the secondary power cable and the grounding wire inside the cable duct from

the isolating transformer to inside the base. The secondary power cable must be

equipped with a suitable two-pole receptacle kit and the grounding wire must be

connected to the grounding screw inside the shallow base.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 29 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

3.2.9 The light unit is shipped complete (including the lamp) and ready for installation as

received, except the lower cover outside O-ring and the dome outside O-ring

separately supplied (Fig. 1 - n 5/6).

Be sure that inside of the shallow base is dry and clean. Place properly the first O-

ring in the outside groove of the lower cover and the second one in the outside

groove of the dome.

Connect the plug of the cable lead of the light unit to the receptacle in the shallow

base. Connect the grounding wire of the light unit to the grounding wire of the

shallow base (faston connection). Then press the light unit firmly and evenly by

hand onto the shallow base.

The light unit is subject to mechanical damage and/or optical misalignment if not

properly seated on the base flange.

3.2.10 Secure the inset light fixture to the shallow base by using the two locking screws

complete with washers. One drop of anaerobic adhesive, medium type (e.g. Loctite

243) should be applied to the screws before installation; tightening torque is 31 Nm.

FIGURE 14 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

SHALLOW BASE FOR SIDE CONDUIT

MOUNTING DETAILS

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 30 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 15 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

SHALLOW BASE FOR BOTTOM CONDUIT

MOUNTING DETAILS

3.3 INSTALLING LIGHT UNIT ON L-868 BASE, SIZE B

Install L-868 light base in compliance with FAA AC 150/5340-30.

The light unit is shipped complete fastened to the adaptor ring (base mounted, option R)

(Fig. 16), including the lamp, and is ready for installation as received.

Be sure the flange on the transformer housing is clean and the O-ring (if used) is in place

in the O-ring groove.

Connect the plug of the light unit to the receptacle of the isolating transformer inside the

deep base. Connect the grounding wire of the light unit to the grounding wire of the deep

base (faston connection). Then press the light unit firmly and evenly by hand onto the base

flange. Secure the light unit to the base by using the six locking screws complete with

washers, supplied with the base. One drop of anaerobic adhesive, medium type (e.g.

Loctite 243) should be applied to the screws before installation; tightening torque is 25 Nm.

For intallation on 12 OCEM shallow base one drop of screw past (e.g. Dow Corning

Molycote 1000) should be applied to the screw before intallation; tightening torque is 25

Nm.

The light unit is subject to optical misalignment and/or mechanical damage if not properly

seated.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 31 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

FIGURE 16 - SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF -

LIGHT UNIT WITH ADAPTOR RING (MOUNTING SYSTEM R)

1 - Adaptor ring (mounting system R)

2 - Removable light unit

3 - Hardware to fasten the light unit to the adaptor ring

4 - Hardware to fasten the adaptor ring to the 12 base

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 32 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

3.4 COLOURED FILTER

Any changes necessary for operational needs must be done after installation acceptance.

If the light unit is open before acceptance, the warranty is void.

If it is necessary to add, remove or replace the filter, operate as follows.

Remove the light unit from the base, by unscrewing the two locking screws complete with

washers. Raise the light unit by using the two lifting tools (or two screwdrivers) inserted in

the suitable slots provided on the dome.

Remove the lower cover assembly by unscrewing the three fixing screws HSFH M5x12

(Fig. 1 - n 3). Remove the filter complete with support by unscrewing the relevant screws.

Before installing new filter, make sure it is clean, of the proper colour and free of

scratches. Install the new filter complete with support, by using the two relevant screws CH

M5x10 (Fig. 1 - n 24). Tightening torque is 3.8 Nm.

Check the O-ring (between dome and lower cover) (Fig. 1 - n 4) is properly placed in the

relevant seat. Re-assembly the lower cover to the dome by using anaerobic adhesive, light

type (e.g. LOXEAL 24-18) on the three fixing screws HSFH M5x12 (Fig. 1 - n 3);

tightening torque is 3.8 Nm.

Check the O-ring (Fig. 1 - n 5) is properly placed outside around the dome.

Check the O-ring (Fig. 1 - n 6) is properly placed outside around the lower cover.

Return the light unit to runway for installation.

CAUTION: the filters are fragile and susceptible to scratches.

4.0 MAINTENANCE

The preferred method of maintaining these lights is to replace each light unit periodically

and systematically and return it to the maintenance shop for renovation.

As an alternative, the light unit can be serviced in the field. However, it is recommended

that field servicing is limited to cleaning the prisms and to replacing the lamp.

4.1 REMOVING LIGHT UNIT FROM THE BASE AND OPENING LIGHT UNIT

Remove the light unit from the base by unscrewing the two locking screws complete with

washers. Raise the light unit by using the two lifting tools (P/N 332.4140 or P/N 332.4230)

inserted in the suitable slots provided on the dome. As an alternative, two screwdrivers

can be used.

Open the light unit by unscrewing the three locking screws HSFH M5x12 (Fig. 1 - n 3).

Every time the light unit is removed from the base receptacle and opened, inspect the

following:

a) prism and filter if clean or damaged and take provision as necessary, as described at

paragraphs 4.2 - 4.3;

b) O-ring between base and light unit and replace it, if necessary, as described at

paragraph 4.5;

c) cable lead with plug for damage and replace it, if necessary, as described at paragraph

4.6.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 33 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

4.2 CLEANING PRISMS AND COLOURED FILTERS

4.2.1 Cleaning prism outside

Removing the light unit is not necessary to clean the outer surface of the prism.

With a compressed air blast or suitable brushes, remove all accumulated debris from the

light channels. Clean the outer surface of the prism with a detergent solution. If the prism

Is coated with a substance impervious to the detergent, a suitable solvent should be

sparingly applied with a wad of cotton or a patch of cloth on the end of a wood splint. After

the solvent has acted, the remaining solvent and softened coating should be removed with

a clean piece of cotton or cloth without scratching the glass. Avoid excessive contact

between the solvent and the prism gasket. Remove all remaining solvent from prism and,

just as possible, from the gasket. A gentle air blast may be used.

4.2.2 Cleaning prism inside and filter

Normallly prisms and coloured filters cleaning operations are not necessary because light

unit is watertight . Whenever it is necessary , remember the following rules.

Remove the light unit from the base and open it following instructions of par. 4.1.

Prism and filter surfaces are now accessible. Remove the filter complete with support by

unscrewing the relevant screws. Polish prism and filter surfaces with propylic alcohol or

similar non abrasive product; dry them carefully. Reinstall the filter complete with support,

by using the two relevant screws CH M5x10 (Fig. 1 - n 24); tightening torque is 3.8 Nm.

Final check before light unit re-assembling.

Verify the correct position of O-ring between dome and lower cover (Fig. 1 - n 4).

Mount the lower cover on the dome and fasten it by means the three screws HSFH M5x12

(Fig. 1 - n 3). One drop of anaerobic adhesive lower type (per esempio LOXEAL 24-18

should be applied to the screws before installation; tightening torque is 3,8 Nm.

Verify the correct positioning of the O-ring around the dome (Fig. 1 - n 5) and of the O-

ring around the lower cover (Fig. 1 - n 6). Return the light unit to taxiway for installation.

Light unit is ready to be field installed.

4.3 REPLACING PRISM

If the prism is broken, leaks, is badly pitted or scarred, it must be replaced. The prism can

be replaced as described below. It is highly recommended to do a complete overhaul of

the light unit. Contact OCEM for any suggestion.

4.3.1 Removing prism

Remove the light unit from the base and open the light unit, as described at paragraph 4.1.

Clean out possible pieces of the old prism and all accumulated debris from the inside.

Unscrew the three screws HSFH M5x12 (Fig. 1 - n 17) which lock the prism retainer.

Remove the retainer and the teflon prism-holder. Then remove the old prism (or the

remaining part of it) and the gasket (or part of it) eventually left in the prism seat.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 34 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

Carefully clean the prism seat by scraping and taking care not to damage the relevant

walls.

4.3.2 Installing new prism

Place a new gasket in the prism cavity on the dome, then position and press by hand the

prism in the relevant seat.

Then mount a new teflon prism-holder. Insert the above assembly completely in the seat

by working with two strong screwdrivers, set in the prism retainer seat. Fasten the retainer

with the three relevant screws HSFH M5x12 (Fig. 1 - n 17); Tightening torque is 3.8 Nm.

Inspect all components inside the light unit for damages or signs of corrosion. Replace all

necessary components.

Reassembly the fixture following instructions of par 4.2.

4.3.3 Pressure test

The assembly should be given a 1,4 atm air pressure test. This can be done by connecting

an external air pressure line to the valve provided on the lower cover. Immerge the

assembly under water, so air loss will be easily viewed if some part is damaged or

assembling is wrong.

If there is no air loss then test is passed succesfully.

Return the light unit to taxiway for installation.Light unit is ready to be field installed.

4.4 RELAMPING

Remove the light unit from the base and open the light unit, as described at paragraph 4.1.

Removal of the lamps from the optical assembly mounting plate is very simple: disconnect

the faston terminals of the lamp wires from the insulating strips or from the electronic

cutout relays and slide each lamp from its seat by forcing the elastic holder.

CAUTION: touching the quartz bulb with bare fingers may seriously shorten the

lamp life. If the quartz bulb has been touched, wipe it clean with a piece

of lens cleaning tissue or similar material moistened with isopropyl

alcohol.

Insert the new lamp in fixed position on its seat (with the UP mark, printed on the lamp,

in upward position), so lock it with the spring. Connect the cable leads of the new lamp to

the insulating strip fixed on the lower cover assembly. Otherwise the lamp cable leads

must be connected to the cable leads of the electronic cutout relay, if provided.

Reassembly the lower cover to the dome; carry out the final check described in par 4.2.

Reassembly the fixture following instructions of par 4.2.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 35 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

4.5 O-RINGS

4.5.1 O-ring examination

Every time an O-ring sealed assembly is taken apart, any O-ring must be closely

examined as described below and replaced if necessary.

Any O-ring that is stretched, torn, has a permanent set or some other defect, which would

prevent it from forming a water-tight seal must be replaced with a new O-ring.

Remove the light unit from the base and open the light unit, as described at paragraph 4.1.

Light assembly is equipped with the following gaskets:

one O-ring in the lower part of the dome (between dome and lower cover)] (Fig. 1 - n

4);

one O-ring externally mounted around the dome (Fig. 1 - n 5)

one O-ring externally mounted around the lower cover (Fig. 1 - n 6)

one prism gasket mounted between prism and the dome (Fig. 1 - n 20). As much as

regards prism gasket replacement see par 4.3.

4.5.2 O-ring replacement

Remove the old O-ring from the groove and clean the flange mating surfaces and the

groove, scraping carefully. Take care not to damage the mating surface and the bottom

and sides of the groove. Position it in the centre of its groove and push it inside.

NOTA 1: Make sure that the proper O-ring is re-inserted into the groove.

NOTA 2: The groove is so designed to provide room for displacement of the O-ring when

compressed between the mating surfaces. Properly tightened screws are

important in obtaining a complete seal.

4.6 CABLE LEAD WITH PLUG AND BUSH

4.6.1 Removing the cable lead with plug and bush

Remove the light unit from the base and open the light unit, as described at paragraph 4.1.

Inside the lower cover, disconnect the pair of wires with faston terminals from the bush of

the damaged cable lead with plug. Outside the lower cover, remove the damaged cable

lead with plug by unscrewing the threaded bush.

Tightening torque:

lower cover HSCH screw: 3.8 Nm

light unit locking screw: 31 Nm (for shallow base)

25 Nm (for L-868 base, size B)

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 36 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

4.6.2 Installing the new cable lead with plug and bush

Be sure that threaded hole surface is perfectly clean. Place the O-Ring (Fig. 1 n 26)

around the bush. Put a drop of anaerobic adhesive lower type (e.g. LOXEAL 24-18) on the

threaded surface of the bush of the new cable lead with plug. Tighten externally the bush

and restore internally the electrical connections.

Verify the correct position of O-ring between dome and lower cover (Fig. 1 - n 4).

Reconnect the faston terminale of the insulating strip to the new bush.

Mount the lower cover on the dome and fasten it by means the three screws HSFH M5x12

(Fig. 1 - n 3). One drop of anaerobic adhesive lower type (e.g. LOXEAL 24-18) should be

applied to the screws before installation; tightening torque is 3,8 Nm.

4.6.3 Pressure test

The assembly should be given a 1.4 atm air pressure test.

WARNING: pressure test must be carried out at least 15 minutes after putting

anaerobic adhesive to let it work correctly.

See par 4.3.3.

4.7 VIBRATION-DAMPING BLOCK

If it is necessary to replace the vibration-damping block for aging or damaging , see the

following instructions after removing light unit from the base and after opening it as

described in par. 4.1.

It is recommended to replace all the four vibration-damping blocks.

Remove the lampholder complete with lamp, by unscrewing the four screws HSCH M5x16

(Fig. 1 - n 11).

Remove the brass spacers and then the vibration-damping blocks.

Disconnect the male faston of the lamp from the insulating strip.

Mount the new vibration-damping blocks in their seats and insert the new brass spacers.

Reassembly the lampholder, by tightening the four screws HSCH M5x16 (Fig. 1 - n 11);

tightening torque is 1.9 Nm. Reconnect the male faston of the lamp to the insulating strip.

Reassembly the fixture following instructions of par 4.2.

4.8 PRESSURE VALVE

If a leakage is found through the pressure valve during an air pressure test, check carefully

where the leakage happens. If the leakage is between the valve and the lower cover,

check the tightening of the valve body to the lower cover from the inside of the light unit.

If the leakage is between the valve core and body, remove the valve cap and check the

tightening of the valve core to the body from the outside of the light unit by means of

pointed pliers.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 37 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

In case the pressure valve needs replacing, operate as follows, considering the light unit

already open, as described at paragraph 4.1. Remove the valve cap. Unscrew the valve

body with gasket from the inside of the lower cover by clamping the hexagonal end section

of the valve body. Screw the new valve on the lower cover; tightening torque is 0.35 Nm.

Check the valve core is tightened to the valve body and then screw its cap.

Reassembly the fixture following instructions of par 4.2.

4.9 CLEANING AND WORKMANSHIP

Service life depends upon the entire assembly being waterproof. All surfaces must be

clean, dry and free of all foreign matter if the light fixture is to operate for an extended

period without requiring maintenance.

NOTE: see par 5.0 for recommended spare parts list

4.10 MAINTENANCE PROGRAM

In order to ensure maximum light fixture life, the installed units should be subject to a

maintenance program in accordance with the following instructions and taking as

reference the ICAO suggestions provided by the Airport Services Manual - Part 9 - Airport

Maintenance Practices or by Faa AC 150 5340-30.

4.10.1 Daily operational check

A daily operation check should be made of the light unit. The lights should be energized

and visually inspected. If any lamps are out, the location of the fixture should be recorded

and the lamps replaced at the time when the circuit is de-energized, as described at

paragraph 4.4.

4.10.2 Cleaning

Regular cleaning is necessary in order to ensure that in-pavement lighting fixtures operate

at maximum efficiency. The outside of the polycarbonate ring and channels for beam

output should be cleaned periodically as per paragraph 4.2.1. The regularity and type of

cleaning will be dictated by the weather and the location of the fixtures.

4.10.3 Snowplow operations

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 38 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

Snowplow operators should exercise extra care not to strike the light fixtures with

snowplow blades. After snow removal operations, inspect all light fixtures to locate and

replace, if necessary, any damaged light assemblies.

Passes over the light rows should be made with a power broom only if practical. Whenever

snowplows must traverse in-pavement light fixtures, they should be either travelling at less

than 10 km/h or have the blades lifted clear of the fixtures. Recommended snow removal

techniques are described in Airport Services Manual - Part 9 - Airport Maintenance

Practices or described in Faa AC 150/5200-30.

4.10.4 Monthly inspections

This light unit is designed to exclude both ground and surface water from entering. If the

lights are not properly maintained (e.g. screws not properly tightened and O-rings or

gaskets in bad condition) water may enter inside the fixture and create serious problems.

To prevent this from occurring, it is recommended that each fixture be inspected from the

presence of water at least once a month. More frequent inspection is desirable during and

following rainy season.

4.10.5 Screw tightness

Light unit locking screws should be checked for proper torque at least once every three

months or more frequently during the two-four weeks following the reinstallation of a

serviced light unit.

4.10.6 Leak testing

If any fixture contains water, remove the water and clean and dry the entire fixture.

Pressure test the fixture to find the leak. Inspect the O-ring and gasket grooves and clean.

The O-rings and gaskets should be replaced, the fixture repaired and reinstalled as

specified herein.

O.C.E.M. S.p.A. Document UT-MT-0428 Pagina 39 di 39

Edition 11/11/04

SEMI-FLUSH RUNWAY CENTRELINE LIGHT RCLF

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

Supersede the edition 01/22/04

5.0 LIST OF RECOMMENDED SPARE PARS

Codice

[P/N]

Descrizione FIGURE Numero

303.2440 Bidirectional dome 1 2

152.5300 Lower cover with a cable lead with plug and bush

and internal connections cables

1/3/4 1

152.5305 Lower cover with two cable leads with plug and bush

and internal connections cables

1/5/6 1

152.1500 Complete lamp supporting plate RCLF 35 1 7

152.5320 Vibration-damping block with hardware

760.2191 48 W tungsten-halogen, 6.6 A, with dichroic reflector 1 8

341.0831 Aluminium screen for unidirectional light

318.8165 Dichroic RED filter 1 16

318.3075 Dichroic YELLOW filter 1 16

318.8214 Dichroic GREEN filter 1 16

318.1241 Prism L-850A/B 1 19

318.1290 Prism L-852A/C 1 19

325.0430 Prism gasket 1 20

758.2120 O-Ring 4600 silicone 1 4

758.2014 O-Ring 4775 silicone 1 5

758.2008 O-Ring 4625 silicone 1 6

758.2035 O-Ring 2056 Viton 1 26

000.1466 Fuse cutout 1 25

329.3025 Insulating strip for fuse cutout with hardware 3 3

202.0012 Electronic relay with hardware 5 3

786.7045 Pressare valve 3 5

329.0050 Cable lead with plug L-823 and terminal bush, length

0,500m

3 1

323.2610 Cable lead with receptacle L-823 for shallow base 9/10 3

712.0025 Lower anaerobic adhesive, 50 cc

752.0003 Screw paste, 100 gr

712.0004 Medium anaerobic adhesive, 50 cc

152.6045 Shallow base fixing hardware, dia 8":

700.2228 - screw HH M10x30 stainless steel (2)

706.1106 - elastic washer M10 stainless steel (2 )

706.5206 - washer M10 nylon (2)

152.8060 Shallow base fixing hardware (with adaptor ring), dia 12":

700.2228 - screw HH M10x30 stainless steel (6 )

706.1106 - elastic washer M10 stainless steel (6 )

706.5206 - washer M10 nylon (6 )

You might also like

- Different Types of Drilling FluidschemicalsDocument1 pageDifferent Types of Drilling Fluidschemicalsgplese0No ratings yet

- Ampac SLDocument2 pagesAmpac SLgplese0No ratings yet

- Design of Triplex Plunger Pump for Local ManufacturingDocument56 pagesDesign of Triplex Plunger Pump for Local ManufacturingManatchai BattōsaiNo ratings yet

- Rye Patch DrillingDocument11 pagesRye Patch Drillinggplese0No ratings yet

- Quantity Unit Description Item: Brand New Acid Blending PlantDocument4 pagesQuantity Unit Description Item: Brand New Acid Blending Plantgplese0No ratings yet

- Hopper DesignDocument7 pagesHopper DesignRohan Malkar100% (1)

- Garmin ISPI Auto Small 12MLDocument14 pagesGarmin ISPI Auto Small 12MLgplese0No ratings yet

- Losses & Gains Essentials: Well: RigDocument3 pagesLosses & Gains Essentials: Well: Rigallan_lennoxNo ratings yet

- Milestones US Oil HistoryDocument9 pagesMilestones US Oil HistoryvunathanNo ratings yet

- Karst PolDocument3 pagesKarst Polgplese0No ratings yet

- RSS3Document4 pagesRSS3gplese0No ratings yet

- BPM 04two P62-65 Archive Accessible PDFDocument3 pagesBPM 04two P62-65 Archive Accessible PDFgplese0No ratings yet

- Drilling - Engineering - OVERPULLDocument2 pagesDrilling - Engineering - OVERPULLgplese0No ratings yet

- Appendix G HDD Plan PDFDocument13 pagesAppendix G HDD Plan PDFgplese0No ratings yet

- Bentonite Drilling Fluids Grouting Well Rehab Seminar Nov 5Document2 pagesBentonite Drilling Fluids Grouting Well Rehab Seminar Nov 5gplese0No ratings yet

- 21 GreenlandDocument1 page21 Greenlandgplese0No ratings yet

- Conversion Table: Inches Millimeters Inches MillimetersDocument1 pageConversion Table: Inches Millimeters Inches Millimetersseeralan balakrishnanNo ratings yet

- Drill ProDocument1 pageDrill Progplese0No ratings yet

- Intro To HydraulicsDocument16 pagesIntro To HydraulicsKarun NooneyNo ratings yet

- Ironmind Grip ToolsDocument16 pagesIronmind Grip Toolsbeppo33100% (3)

- HSE-Better Alarm Handling PDFDocument4 pagesHSE-Better Alarm Handling PDFAlessio DeOsimoNo ratings yet

- Appendix 1Document12 pagesAppendix 1gplese0No ratings yet

- GD01Document1 pageGD01gplese0No ratings yet

- A 47 A 042Document6 pagesA 47 A 042gplese0No ratings yet

- Downhole Drilling Monitor (DDM) : Advanced Systems For Drilling PerformanceDocument1 pageDownhole Drilling Monitor (DDM) : Advanced Systems For Drilling Performancegplese0No ratings yet

- Index en PDFDocument3 pagesIndex en PDFgplese0No ratings yet

- DWSS04Document5 pagesDWSS04gplese0No ratings yet

- LEB HmsdsDocument2 pagesLEB Hmsdsgplese0No ratings yet

- Preventing Ultra-Deepwater BlowoutsDocument4 pagesPreventing Ultra-Deepwater Blowoutsgplese0No ratings yet

- Desert AwarenessDocument10 pagesDesert AwarenessouestlechatdememeNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ke Masterhose: Metallic and Rubber Flexible HosesDocument40 pagesKe Masterhose: Metallic and Rubber Flexible HosesfcspekNo ratings yet

- Chemical and Petrochemical Statistics at A Glance - 2018Document232 pagesChemical and Petrochemical Statistics at A Glance - 2018Nayan GhoshNo ratings yet

- Compression Molding Machine PriceDocument13 pagesCompression Molding Machine PriceSalma FarooqNo ratings yet

- Material Handling: Tires & WheelsDocument8 pagesMaterial Handling: Tires & WheelsMichael AkhramovichNo ratings yet

- Rubber Band LabDocument4 pagesRubber Band Labapi-201676941No ratings yet

- Parker Industrial Hose Catalog 4800Document258 pagesParker Industrial Hose Catalog 4800MROstop.comNo ratings yet

- Rivo Brochure - WWW - RivoDocument15 pagesRivo Brochure - WWW - RivoAnton PavelNo ratings yet

- Major Footwear's Industry Visit ReportDocument17 pagesMajor Footwear's Industry Visit ReportRadhaChaturvediNo ratings yet

- Epoxy Weld™ Bonding Compound: DescriptionDocument4 pagesEpoxy Weld™ Bonding Compound: DescriptionHasrul HadiNo ratings yet

- Hattersley General ValvesDocument145 pagesHattersley General ValvesSalaheddine ZantoutNo ratings yet

- Realise Your True Potential: Apollo Tyres Annual Report 2010-11Document144 pagesRealise Your True Potential: Apollo Tyres Annual Report 2010-11gardianjoe86No ratings yet

- A Single Cylinder Vertical Steam EngineDocument3 pagesA Single Cylinder Vertical Steam EngineAxel DominiqueNo ratings yet

- Rado - Hydrogenated NBR Elastomer (HNBR), 2021 +Document4 pagesRado - Hydrogenated NBR Elastomer (HNBR), 2021 +oreamigNo ratings yet

- TroubleshootingDocument148 pagesTroubleshootingMarquesDelaManchaNo ratings yet

- VenezuelaDocument12 pagesVenezuelaДафинка ПангароваNo ratings yet

- Toy Project Part 2Document7 pagesToy Project Part 2emily121602No ratings yet

- FT20 Plastic ManualDocument24 pagesFT20 Plastic ManualDavid UlisesNo ratings yet

- Bomba Drump PumpsDocument16 pagesBomba Drump Pumpsjicid100% (1)

- BF V CatalogDocument56 pagesBF V CatalogmaciasrobNo ratings yet

- Himel General CatalogueDocument186 pagesHimel General CatalogueDobre AlexandruNo ratings yet

- Ent Case StudyDocument14 pagesEnt Case StudyAmir Aiman33% (3)

- The Procurement Beige Book Quarterly Category Softness Dashboards 20th September 2018 v2Document148 pagesThe Procurement Beige Book Quarterly Category Softness Dashboards 20th September 2018 v2Huseyn U. d'IslamNo ratings yet

- Warranty Claim Procedure ManualDocument28 pagesWarranty Claim Procedure ManualjorgegachaNo ratings yet

- Zeppelin - Silos and Pneumatic ConveyorsDocument20 pagesZeppelin - Silos and Pneumatic Conveyorsrbrbs7No ratings yet

- Tech International Catalog4-2013Document127 pagesTech International Catalog4-2013Edwin VacaNo ratings yet

- DIPR AlwarDocument23 pagesDIPR AlwarShankar ChowdhuryNo ratings yet

- IUMI Webinar Flat RacksDocument35 pagesIUMI Webinar Flat RacksJackNo ratings yet

- What's The Difference Between EPR and TR-XLP Cable - Border StatesDocument6 pagesWhat's The Difference Between EPR and TR-XLP Cable - Border Statesgari_monsantoNo ratings yet

- Water-Fine Series Filter CartridgesDocument2 pagesWater-Fine Series Filter Cartridgesfernando brasolinNo ratings yet

- Antioxidant 12Document1 pageAntioxidant 12Daniel MartinsNo ratings yet