Professional Documents

Culture Documents

Vibration Analysis of Centrifugal Blower Impeller For Various Materials Using Fea

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vibration Analysis of Centrifugal Blower Impeller For Various Materials Using Fea

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

VIBRATION ANALYSIS OF CENTRIFUGAL BLOWER IMPELLER

FOR VARIOUS MATERIALS USING FEA

Adgale Tushar Balkrishna1, P.D.Darade2, Govind Raiphale3

1

M.E. Design, Alard College of Engineering & Management, Pune, India

2

Asst. Professor, SITS, Narhe Pune, India

3

M.E. Design, Pune, India

Abstract

It is important to recognize that the design of any machine is an interdisciplinary process, involving aerodynamics,

thermodynamics, fluid dynamics, stress analysis, vibration analysis, the selection of materials, and the requirements for

manufacturing. The operation of any mechanical system will always produce some vibration. Our goal is to minimize the effect of

these vibrations, because while it is undesirable, vibration is unavoidable. The result of excess vibration can vary from nuisance

disturbance to a catastrophic failure. All fans must generate some vibration. They continuously rotate and since nothing is perfect,

cyclic forces must be generated. Its only when vibration reaches a certain amplitude that we call it bad. Vibration may just be an

indicator of some problem with a mechanism, or it may be a cause of other problems. Finally, vibration can transmit into adjacent

areas and interfere with precision processes, or create an annoyance for people. Hence the objective of this study is to present

vibration analysis of centrifugal blower for materials such as steel, aluminium and composite (glass/epoxy).

Keywords - Centrifugal Blower, Impeller, Static, Modal and Harmonic Response, CATIA V5 R19, ANSYS 14.5.7

-------------------------------------------------------------------***------------------------------------------------------------------1. INTRODUCTION

Fans and blowers provide air for ventilation and industrial

process requirements. Fans generate a pressure to move air (or

gases) against a resistance caused by ducts, dampers, or other

components in a fan system. The fan rotor receives energy

from a rotating shaft and transmits it to the air. Blowers are

one of the important component used regularly in Boiler

operation. High efficient fans can increase Boiler efficiency.

They are used to supply air for combustion of fuel in boiler

furnace using Forced Draught (FD) fan, installed in front side

of furnace supplying air either at normal temperature or at

elevated temperature, if air is supplied using air-pre heater.

The fans must have a pressure capability high enough to

overcome the total resistance of inlet silencers, air preheat

coils, air ducts, air heaters, wind boxes, burner registers, and

any other resistance between the air intake of the fan and the

furnace. The flue gases generated after combustion of fuel can

be drawn out using Induced Draught (ID) fans. They maintain

furnace pressure slightly below atmospheric. Primary Air

(PA) fans are used to supply combustion air for atomization of

pulverized fuel. Secondary Air (SA) fans are used to convey

pulverized fuel through duct conveying system. Generally FD,

SA, and PA are direct-drive fans whereas ID fan is belt-driven

fan.

2.

LOADING

CONDITION

AND

CASE

DESCRIPTION

There are three types of loading that actually act on the

centrifugal fan impeller. The first one is the centrifugal force

caused because of impeller rotation that results in centrifugal

acceleration of the impeller body. The second is that resulted

from thermal expansion caused by temperature rising. The last

one is the aerodynamic force arising from pressure conversion

between the blade and the air.

The impeller considered for case study has OD 660 mm, ID

200 mm, Width of blade at leading edge is 45mm, Width of

blade at trailing edge is 30mm, thickness of back plate is 6

mm, thickness of blades is 5 mm, and shroud is 4 mm.

Number of blades are 12. Rotational speed of impeller is 2900

rpm.

Steps in Project Work

A. Modeling by Using CATIA V5 R19: Modeling of

Impeller is done using 3D software CATIA V5 R19. .

B. Meshing and Analysis Using ANSYS14.5.7: Meshing

and analysis of centrifugal blower has been carried out by

using ANSYS 14.5.7 general purpose FEM software.

C. Material Selection: The materials selected here are

generally used for fabrication purpose of blower viz., steel,

aluminium and glass/epoxy

2.1 Steel:

Material Properties

Density (kg/m3)

Yield Strength (Mpa)

Ultimate tensile Strength (Mpa)

Poisson's ratio

Young's modulus(Gpa)

Bulk modulus (Gpa)

Shear Modulus (Gpa)

7850

250

460

0.3

200

167

76.923

_______________________________________________________________________________________

Volume: 03 Issue: 09 | Sep-2014, Available @ http://www.ijret.org

296

IJRET: International Journal of Research in Engineering and Technology

Fig.1 3D model of blower impeller

eISSN: 2319-1163 | pISSN: 2321-7308

Fig.4 Total deformation of blower impeller (steel)

Fig.2 Meshing of blower impeller

Fig.5 Directional deformation (x-axis) of blower impeller

(steel)

Fig.3 Equivalent (von-mises) stress of blower impeller (steel)

Fig.6 Directional deformation (y-axis) of blower impeller

(steel)

_______________________________________________________________________________________

Volume: 03 Issue: 09 | Sep-2014, Available @ http://www.ijret.org

297

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

Fig. 11 Deformational Amplitude (z axis) V/s Frequency of

steel Impeller

Fig.7 Directional deformation (z-axis) of blower impeller

(steel)

Mode Frequency [Hz]

1.

122.3

2.

122.36

3.

314.95

4.

403.88

5.

414.66

6.

414.73

7.

696.07

Fig.8 Prestressed natural frequency of blower impeller (steel)

Fig. 9 Deformational Amplitude (x axis) V/s Frequency of

steel Impeller

Fig. 10 Deformational Amplitude (y axis) V/s Frequency of

steel Impeller

2.2 Aluminium

Material Properties

Density (kg/m3)

Yield Strength (Mpa)

Ultimate tensile Strength (Mpa)

Poisson's ratio

Young's modulus(Gpa)

Bulk modulus (Gpa)

Shear Modulus (Gpa)

2770

280

310

0.33

71

69.61

26.7

Fig.12 Equivalent (von-mises) stress of blower impeller

(aluminium)

Fig.13 Total deformation of blower impeller (aluminium)

_______________________________________________________________________________________

Volume: 03 Issue: 09 | Sep-2014, Available @ http://www.ijret.org

298

IJRET: International Journal of Research in Engineering and Technology

Fig.14 Directional deformation (x-axis) of blower impeller

(aluminium)

Fig.15 Directional deformation (y-axis) of blower impeller

(aluminium)

eISSN: 2319-1163 | pISSN: 2321-7308

Fig. 18 Deformational Amplitude (x axis) V/s Frequency of

aluminium Impeller

Fig. 19 Deformational Amplitude (y axis) V/s Frequency of

aluminium Impeller

Fig. 20 Deformational Amplitude (z axis) V/s Frequency of

aluminium Impeller

2.3 Composite (Glass/Epoxy):

Fig.16 Directional deformation (z-axis) of blower impeller

(aluminium)

Mode Frequency [Hz]

1.

123.61

2.

123.71

3.

318.36

4.

401.37

5.

415.01

6.

415.09

7.

697.06

Fig.17 Prestressed natural frequency of blower impeller

(aluminium)

Material Properties

Density (kg/m3)

Poisson's ratio (xy)

Poisson's ratio (yz)

Poisson's ratio (zx)

Young's modulus (x) (Gpa)

Young's modulus (y) (Gpa)

Young's modulus (z) (Gpa)

Shear modulus (xy) (Gpa)

Shear modulus (yz) (Gpa)

Shear modulus (zx) (Gpa)

Constant damping coefficient

1750

0.13

0.39

0.39

14

14

8.8

4.7

4.2

4.2

0.02

_______________________________________________________________________________________

Volume: 03 Issue: 09 | Sep-2014, Available @ http://www.ijret.org

299

IJRET: International Journal of Research in Engineering and Technology

Fig.21 Equivalent (von-mises) stress of blower impeller

(glass/epoxy)

eISSN: 2319-1163 | pISSN: 2321-7308

Fig.25 Directional deformation (z-axis) of blower impeller

(glass/epoxy)

Mode Frequency [Hz]

1.

75.157

2.

76.525

3.

161.71

4.

201.31

5.

218.86

6.

220.93

7.

364.72

Fig.26 Prestressed natural frequency of blower impeller

(glass/epoxy)

Fig.22 Total deformation of blower impeller (glass/epoxy)

Fig. 27 Deformational Amplitude (x axis) V/s Frequency of

glass/epoxy Impeller

Fig.23 Directional deformation (x-axis) of blower impeller

(glass/epoxy)

Fig.24 Directional deformation (y-axis) of blower impeller

(glass/epoxy)

Fig. 28 Deformational Amplitude (y axis) V/s Frequency of

glass/epoxy Impeller

_______________________________________________________________________________________

Volume: 03 Issue: 09 | Sep-2014, Available @ http://www.ijret.org

300

IJRET: International Journal of Research in Engineering and Technology

4.

5.

6.

7.

eISSN: 2319-1163 | pISSN: 2321-7308

Total and directional deformation for glass/epoxy is

more as compared to steel and aluminium.

Prestressed natural frequency for steel and aluminum

is almost similar.

Prestressed natural frequency for glass/epoxy is far

low as compared to steel and aluminum.

Axial (x, y, and z) deformational amplitude versus

frequency is high for glass/epoxy, less for aluminium

and least for steel.

FUTURE SCOPE OF WORK

Fig. 29 Deformational Amplitude (z axis) V/s Frequency of

glass/epoxy Impeller

Table 1 Result from Analysis

Parameter

/

Glass/

Steel

Aluminium

Material

Epoxy

Mass (kg)

31.17

12.06

07.62

Nodes

294869 294675

283951

Elements

147959 147969

142684

Equivalent Stress

107.82

37.51

27.135

(MPa)

Total Deformation

0.0551

0.0532

0.2535

(mm)

x-axis deformation

0.03481 0.03328

0.19947

(mm)

y-axis deformation

0.04171 0.04047

0.14187

(mm)

z-axis deformation

0.04167 0.04048

0.20398

(mm)

Mode number

Prestressed natural frequency

1

122.3

123.61

75.157

2

122.36

123.71

76.525

3

314.95

318.36

161.71

4

403.88

401.37

201.31

5

414.66

415.01

218.86

6

414.73

415.09

220.93

7

696.07

697.06

364.72

x-axis amplitude

v/s

frequency 0.01133 0.03472

0.14873

(mm)

y-axis amplitude

v/s

frequency 0.00498 0.013905

0.03684

(mm)

z-axis amplitude

v/s

frequency 0.00505 0.01405

0.03832

(mm)

3. DISCUSSION AND CONCLUSIONS

1.

2.

3.

Mass of the impeller, keeping same thickness of

impeller components decreases in the sequence of

steel, aluminium and glass/epoxy due to density.

Equivalent stress is least for glass/epoxy, less for

aluminum and high for steel.

Total and directional deformation for aluminum is

slightly less than steel.

In future scope for work, the fan can be simultaneously

designed by simulation checking for both flow and structural

performance. Also now-a- days materials like aluminium and

GRPF (materials) are replacing structural steel as these can

be thought of as alternative, unless proving their reliability.

ACKNOWLEDGMENTS

The satisfaction and exhilaration that accompany the

successful completion of any task would be incomplete

without the mention of the people whose constant guidance

and encouragement aided in its completion. The authors

would like to express the voice of gratitude and respect to all

who had directly or indirectly supported for carrying out this

study and special thanks to Prof.P.D.Darade, Asst. Prof.,

Mechanical Dept., SITS, Narhe, Staff of mechanical

department, Prof.V.R.Bajaj, HOD, Mechanical department

and Dr.S.B.Padwal, Principal, Alard College of Engineering

and Management, Pune.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Engineering Data, Twin City Fan Companies Ltd.,

ED-200,pp.1-6,1999

Asad Said Juma, Al Zadjali and G.R. Rameshkumar."

Condition Monitoring of Centrifugal Blower Using

Vibration Analysis", International Journal of

Multidisciplinary Sciences, and Engineering, vol.4,

no.5, pp.50-59, June 2013.

Shaoping Zhou, Jie Zhang, Yongsheng Su."

Vibration analysis and fault diagnosis of the fan unit

and support structure." Journal of Pressure

Equipment and Systems vol.6, pp.45-48, 2008.

Donald R. Smith, Harold R.Simmons." Unique Fan

Vibration Problems: Their Causes and Solutions".

Proceedings of the Ninth Turbomachinery

Symposium, pp.33-43.

Frantisek L. Eisinger, Robert E. Sullivan." Vibration

Fatigue OF Centrifugal Fan Impeller Due TO

Structural-Acoustic Coupling and Its Prevention: A

CASE Study". Journal of Pressure Vessel

Technology, Vol.129, pp.771- 774, November2007.

Robert J. Sayer, "Structural Dynamics of Centrifugal

Fans". Proceedings of the National Technical

Training Symposium and 34th Annual Meeting of the

Vibration Institute, Oak Brook, IL, June 2010.

Robert J. Sayer, "Dynamic Testing Of Centrifugal

Fan Wheels ". Proceedings of the National Technical

Training Symposium and 34th Annual Meeting of the

_______________________________________________________________________________________

Volume: 03 Issue: 09 | Sep-2014, Available @ http://www.ijret.org

301

IJRET: International Journal of Research in Engineering and Technology

[8]

[9]

[10]

[11]

[12]

[13]

[14]

eISSN: 2319-1163 | pISSN: 2321-7308

Vibration Institute, Oak Brook, IL, June 2010.

Juan Gabriel Monge Gapper." Centrifugal Fan

Impeller Failure Analysis Using Finite Elements".

Ingeniera 16 (2): ISSN: 1409-2441; San Jos, Costa

Rica, pp.55-62, 2006.

Veeranjaneyulu Itha, T.B.S.Rao, "Static And

Dynamic Analysis Of A Centrifugal Blower Using

FEA". International Journal Of Engineering Research

And

Technology

(IJERT)

ISSN:

22780181.vol.1,issue.8,pp.1-11,October2012

Mohd

Zubair,

Ramavath Suman,

M.Guru

Bramhananda Reddy." Evaluation of Static and

Dynamic Analysis Of a Centrifugal Blower Using

FEA". International Journal of Advanced Trends in

Computer Science and Engineering ISSN: 22783091, .vol.2, no.8, pp.316- 321, January 2013.

S.T. (Ted) Myrick. W.Barry Crawford, Gerald L.

Schumpert., "Changing and Controlling the First

Critical Speed of Overhung Centrifugal Fans".

Proceedings of the Ninth Turbomachinery

Symposium, pp.33-40.2004.

P.Mazeika, J.Grigonience, A.Senulis." Influence of

Foundation Stiffness on Vibrations Of rotor

Systems", Ultragarsas ISSN1392-2114, vol.64, no.2,

pp.27-31.2009.

A. El-Shafei." Fan Diagnosis in the Field", RITEC,

Cairo, Egypt 2008

Frank

P.

Bleier,"Fan

Handbook-Selection,

Application,

and

Design"ISBN

0-07005933.McGraw-Hill publication.1998.

_______________________________________________________________________________________

Volume: 03 Issue: 09 | Sep-2014, Available @ http://www.ijret.org

302

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Oil Tanker Construction RulesDocument84 pagesOil Tanker Construction Rulessasikumarmarine100% (4)

- HB-T E990-1112-03Document147 pagesHB-T E990-1112-03maninder_khasria50% (2)

- IHKA Heating Air Conditioning ManualDocument37 pagesIHKA Heating Air Conditioning ManualJohn M. SmithNo ratings yet

- Db-60 Manual 120811 PrintDocument60 pagesDb-60 Manual 120811 PrintRoberto Cedillo100% (1)

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Analytical Solutions For Square Shape PressureDocument4 pagesAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNo ratings yet

- CFD AnalysisDocument8 pagesCFD AnalysisMuhammad Fahrurrazi100% (1)

- Turbine Heat Rate and EfficiecyDocument48 pagesTurbine Heat Rate and EfficiecyPralay Raut100% (6)

- Building PressurizationDocument8 pagesBuilding Pressurizationsajuhere100% (1)

- Service and Maintenance Instructions: 48TC D Nominal 15 To 25 Tons With Puron® (R - 410A) RefrigerantDocument103 pagesService and Maintenance Instructions: 48TC D Nominal 15 To 25 Tons With Puron® (R - 410A) RefrigerantdjtruquitosNo ratings yet

- JCI-GENCAT-2008Document203 pagesJCI-GENCAT-2008Susan LamNo ratings yet

- Pressure Parts Furnace Do's and Dont's GuideDocument4 pagesPressure Parts Furnace Do's and Dont's GuideArun GuptaNo ratings yet

- 11N95 DGT PH2 DSDocument50 pages11N95 DGT PH2 DSSundar RamasamyNo ratings yet

- Clint Cha k726p 36012p Brochure 0325 enDocument2 pagesClint Cha k726p 36012p Brochure 0325 enDorin100% (1)

- Novenco Air Handling Units Provide High Airflow and Customizable FunctionsDocument36 pagesNovenco Air Handling Units Provide High Airflow and Customizable FunctionssugirinNo ratings yet

- NFPA 96 and Building Code Requirements For Commercial Kitchen Hood SystemsDocument49 pagesNFPA 96 and Building Code Requirements For Commercial Kitchen Hood SystemsLuis Gabriel BautistaNo ratings yet

- Utna Platinum 025 4rDocument4 pagesUtna Platinum 025 4rDamian OvidiuNo ratings yet

- Manual de Utilizare Pentru Uscator in Pat Fluidizat TG200 Retsch Necesar in Pregatirea Probelor de LaboratorDocument23 pagesManual de Utilizare Pentru Uscator in Pat Fluidizat TG200 Retsch Necesar in Pregatirea Probelor de LaboratorlucianchiritaNo ratings yet

- EM MultiV IndoorUnits 07 14 - 20140814120226Document440 pagesEM MultiV IndoorUnits 07 14 - 20140814120226Massimo AieseNo ratings yet

- Sie s800 27 Sigma MiniDocument282 pagesSie s800 27 Sigma MiniHải Trần DanhNo ratings yet

- Atlas Copco TH60DH Water Well Drill SpecificationsDocument12 pagesAtlas Copco TH60DH Water Well Drill Specificationsanemoss100% (1)

- Atmospheric Vortex EngineDocument1 pageAtmospheric Vortex EngineGajendra AryaNo ratings yet

- Daikin Indoor Unit Manual FTKS50 60 71 FTXSDocument34 pagesDaikin Indoor Unit Manual FTKS50 60 71 FTXSThais G QuinonesNo ratings yet

- Air-Con PAR-21MAA-JDocument146 pagesAir-Con PAR-21MAA-JJayden DurrantNo ratings yet

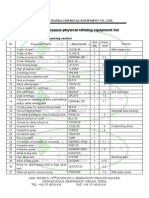

- 50TD Continuous Physical Refining Equipment ListDocument4 pages50TD Continuous Physical Refining Equipment ListWanda OilpressNo ratings yet

- Buser 11 1 WebDocument12 pagesBuser 11 1 WebpavanuNo ratings yet

- Boiler Tuning BasicDocument25 pagesBoiler Tuning Basictrung2iNo ratings yet

- Shaangu For Metalurgical Industry 2013Document49 pagesShaangu For Metalurgical Industry 2013zzgiadinhzzNo ratings yet

- Kaeser Screw Compressors ASD, BSD, CSD SeriesDocument12 pagesKaeser Screw Compressors ASD, BSD, CSD SeriesJoseph Geraci0% (1)

- EUROVENT 6/10 AIR FLOW TESTDocument8 pagesEUROVENT 6/10 AIR FLOW TESTsiva_nagesh_2No ratings yet

- Irc Gov in 090 2010Document96 pagesIrc Gov in 090 2010Elumalai Srinivasan86% (7)

- Rooftop ventilation units with heat recoveryDocument8 pagesRooftop ventilation units with heat recoverychaesar1No ratings yet