Professional Documents

Culture Documents

Fact-Data: Manufacturer

Uploaded by

sandrapat45Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fact-Data: Manufacturer

Uploaded by

sandrapat45Copyright:

Available Formats

FACT-DATA

MANUFACTURER

FORTA CORPORATION, 100 Forta Drive, Grove City, PA, U.S.A., 16127-6399

TELEPHONE: 1-800-245-0306, (724) 458-5221; FAX: (724) 458-8331; www.fortacorp.com

GENERAL DESCRIPTION

FORTA-FERRO is an easy to finish, color blended fiber, made of 100% virgin copolymer/

polypropylene consisting of a twisted bundle non-fibrillating monofilament and a fibrillating network

fiber, yielding a high-performance concrete reinforcement system. FORTA-FERRO is used to reduce

plastic and hardened concrete shrinkage, improve impact strength, and increase fatigue resistance and

concrete toughness. This extra heavy-duty fiber offers maximum long-term durability, structural

enhancements, and effective secondary/temperature crack control by incorporating a truly unique

synergistic fiber system of long length design. FORTA-FERRO is non-corrosive, non-magnetic,

and 100% alkali proof!

APPLICATIONS

FORTA-FERRO is mainly used with performance concrete applications such as industrial floors,

bridge decks, shotcrete, loading docks, precast products anywhere that steel reinforcement reduction

or replacement is the objective. Contact FORTA Corporation for design assistance.

INSTALLATION

Recommended dosage rate of FORTA-FERRO is 0.2% to 2.0% by volume of concrete (3 to 30 lbs.

per cubic yard) added directly to the concrete mixing system during, or after, the batching of the other

ingredients and mixed at the time and speed recommended by the mixer manufacturer (usually four to

five minutes).

PHYSICAL PROPERTIES

Materials..Virgin Copolymer/Polypropylene

Form.Monofilament/Fibrillated Fiber System

Specific Gravity..0.91

Tensile Strength.83-96 ksi. (570-660 MPa)

Length.....2.25 (54mm), 1.5 (38mm)

Color..Gray

Acid/Alkali Resistance.Excellent

Absorption Nil

ComplianceA.S.T.M. C-1116

AVAILABILITY

FORTA-FERRO can be purchased from FORTA Corporation or an authorized FORTA products

distributor, dealer or representative. Orders are shipped within 24 hours by small package services,

commercial carrier, or air freight.

PACKAGING

Convenient incremental pound or kilogram mixer-ready bag packaging.

WARRANTY

FORTA products are warranted to be free of defects in material and meet all quality control standards set by the

manufacturer. FORTA Corporation specifically disclaims all other warranties, express or implied. The exclusive remedy for

defective product shall be to replace the product or refund the purchase price. No agent or employee of this company is

authorized to vary the terms of this warranty notice. FORTA Corporation has no control over the design, production,

placement, or testing of the concrete products in which FORTA products are incorporated, and therefore FORTA Corporation

disclaims liability for the end product.

U. S. Patent No. 6,753,081. Additional patents pending.

FORTA Specification

FORTA Corporations technical recommendations regarding synthetic fiber characteristics are

based on years of engineering research and scores of concrete projects. FORTA has developed

a simple 4-Cs formula to help the specifier choose the right fiber for any concrete project

application. By making a decision with each of the FORTA 4-Cs categories Configuration,

Chemistry, Contents, and Correct Lengthspecifiers are assured of obtaining the desired fiber

performance level for a given project. The following 4-Cs Formula Specification has been

prepared to accommodate the stated reinforcement objective for this FORTA product grade.

REINFORCEMENT OBJECTIVE: To inhibit plastic and settlement shrinkage cracking prior to the

initial set, and to reduce hardened concrete shrinkage cracking, improve impact strength, and

enhance concrete toughness and durability as an alternate secondary/temperature/structural

reinforcement.

DIVISION CONCRETE

SECTION CONCRETE REINFORCEMENT

SUB-SECTION SYNTHETIC FIBROUS REINFORCEMENT

Synthetic fibrous reinforcement shall be used in the areas denoted in plans, and shall

comply with the following fiber characteristics:

1. Configuration Fiber shall be a synergistic combination of a twisted-bundle nonfibrillating monofilament and a fibrillating network fiber system.

2. Chemistry Fiber shall be made of 100% virgin materials in the form of fully-oriented

copolymer/polypropylene, gray in color.

3. Contents Fiber shall be used at a dosage rate of 0.2% to 2.0% by volume of

concrete (3 to 30 lbs. per cubic yard).

4. Correct Length Fiber Length shall be 2.25 (54mm).

Compliance: Fibers shall comply with A.S.T.M. C-1116 Standard Specification for Fiber

Reinforced Concrete and Shotcrete. The approved product is FORTA-FERRO structural

fiber as manufactured by FORTA Corporation, Grove City, PA, U.S.A. Phone: 1-800-2450306 or 1-724-458-5221; Fax: 1-724-458-8331.

FORTA Corporation

100 Forta Drive, Grove City, PA 16127-6399 U.S.A.

1-800-245-0306 or 1-724-458-5221

Fax: 1-724-458-8331

www.fortacorp.com

FORTA, FORTA-FERRO, and

are registered trademarks of FORTA Corporation

You might also like

- 4.9 MACRO Twisted FibresDocument3 pages4.9 MACRO Twisted FibresmcsomashekaraNo ratings yet

- Sys 00200Document6 pagesSys 00200mutazsalihNo ratings yet

- FD FerroDocument2 pagesFD FerrodhaneshNo ratings yet

- FORTA - Steel-Free Wall Panel ReportDocument13 pagesFORTA - Steel-Free Wall Panel ReportSamiNo ratings yet

- Fosfiber P1Document2 pagesFosfiber P1Balasubramanian AnanthNo ratings yet

- Fosroc PPFDocument2 pagesFosroc PPFNabeel AL-HakeemNo ratings yet

- Forta Ferro PDFDocument2 pagesForta Ferro PDFbeck.26No ratings yet

- Synthetic FibersDocument1 pageSynthetic Fibersapuhapuh_153349No ratings yet

- Enduro 600 (Macrosythetic Fiber)Document0 pagesEnduro 600 (Macrosythetic Fiber)Sunilgiri001No ratings yet

- 3mtm Scotchcasttm Polyolefin Fiber Product DataDocument3 pages3mtm Scotchcasttm Polyolefin Fiber Product Datajack21abNo ratings yet

- Conplast SP480Document2 pagesConplast SP480Tori SmallNo ratings yet

- Fosfiber PPF High Performance Micro Polypropylene FibreDocument2 pagesFosfiber PPF High Performance Micro Polypropylene FibreTori Small100% (1)

- High Performance Concrete SuperplasticiserDocument2 pagesHigh Performance Concrete SuperplasticiserVenkata Raju KalidindiNo ratings yet

- End Uro 600 Data SheetDocument2 pagesEnd Uro 600 Data SheetLissette Rohs Mauricio HerhuayNo ratings yet

- Fiber WrapDocument2 pagesFiber WrapStephen WilberNo ratings yet

- Demand Viton Extreme PerformanceDocument4 pagesDemand Viton Extreme Performancemarcomaciel3061No ratings yet

- Eptfe Innovations PaperDocument16 pagesEptfe Innovations PaperrmnrajanNo ratings yet

- ExpancellDocument2 pagesExpancellshanon33No ratings yet

- Fosroc PPF: High Performance Micro Propylene FibreDocument2 pagesFosroc PPF: High Performance Micro Propylene FibreWahlee SatuNo ratings yet

- Cem Unit 4Document23 pagesCem Unit 4SATVIKNo ratings yet

- General Polyurea Questions (Versaflex)Document6 pagesGeneral Polyurea Questions (Versaflex)thinesNo ratings yet

- Polyaspartics BrochureDocument21 pagesPolyaspartics Brochureколодинский геннадийNo ratings yet

- FiberReinforcedConcrete - Mixage Des FibresDocument2 pagesFiberReinforcedConcrete - Mixage Des Fibresserhrouchni nourelhoudaNo ratings yet

- FRP - Fibre Reinforced PlasticDocument13 pagesFRP - Fibre Reinforced PlasticKIRAN SURESHKUMAR 2061735No ratings yet

- Fibre Reinforced Concrete ThesisDocument6 pagesFibre Reinforced Concrete ThesisHelpMeWriteMyEssayCambridge100% (2)

- 003 FAIRMATE - Construction ChemicalsDocument8 pages003 FAIRMATE - Construction Chemicalsfairmatechemical100% (1)

- HTTP WWW - FibrexDocument6 pagesHTTP WWW - FibrexVinod Varadan SNo ratings yet

- Polyolefins For Pipe and FittingsDocument2 pagesPolyolefins For Pipe and FittingsMd Minhaj100% (1)

- Jotachar Technical Paper - The Mesh MythDocument6 pagesJotachar Technical Paper - The Mesh MythSunil RaneNo ratings yet

- Euroguarco GasketDocument20 pagesEuroguarco Gasketwork.fransgintingNo ratings yet

- TigerTurf Sports Product Brochure 2011Document24 pagesTigerTurf Sports Product Brochure 2011safinditNo ratings yet

- Ptfe Seals Pde3354 enDocument196 pagesPtfe Seals Pde3354 enxuanphuong2710No ratings yet

- Proofex ORG: Loose Laid Reinforced TPO Waterproofing MembraneDocument2 pagesProofex ORG: Loose Laid Reinforced TPO Waterproofing MembranekalidindivenkatarajuNo ratings yet

- Why Use Polymer Data Sheet BallDocument3 pagesWhy Use Polymer Data Sheet BallJuliano. PQMNo ratings yet

- Sikafiber® Force-60: Product Data SheetDocument2 pagesSikafiber® Force-60: Product Data SheetCsillag JanosNo ratings yet

- Baxchem Systems Brochure 20061 PDFDocument6 pagesBaxchem Systems Brochure 20061 PDFA MahmoodNo ratings yet

- Polyurethane ApplicationsDocument6 pagesPolyurethane ApplicationsGabriel DiazNo ratings yet

- Ijciet A Comparative Study of The Retrofitting of Reinforced Concrete Beams Under Flexural LoadingDocument13 pagesIjciet A Comparative Study of The Retrofitting of Reinforced Concrete Beams Under Flexural LoadinggandhiNo ratings yet

- Lip Seal ParkerDocument170 pagesLip Seal Parkersport2008100% (1)

- Parker - PTFE Lip SealsDocument170 pagesParker - PTFE Lip Sealspughreader1100% (1)

- GuritDocument16 pagesGuritKamlesh DalavadiNo ratings yet

- POLYLUBE Design-GuideDocument48 pagesPOLYLUBE Design-GuideDaniel CringusNo ratings yet

- Nonwoven Polypropylene Geotextile: GeosyntheticsDocument6 pagesNonwoven Polypropylene Geotextile: Geosyntheticseasytigeruk15No ratings yet

- Fibrillated Fibre Range Product InformationDocument1 pageFibrillated Fibre Range Product InformationPatricia ClarkNo ratings yet

- Eternit Choosing and Using Profile 6Document12 pagesEternit Choosing and Using Profile 6Vasile BudaNo ratings yet

- Huntsmann Polyurethane CompositesDocument16 pagesHuntsmann Polyurethane CompositesYuriKolobovNo ratings yet

- Masterfiber 154 Spa TdsDocument2 pagesMasterfiber 154 Spa Tdsmohamed nomanNo ratings yet

- XR 1300 English - Ed April - 2020Document2 pagesXR 1300 English - Ed April - 2020Chamakhi AmeurNo ratings yet

- Drip Irrigation Borealis PDFDocument2 pagesDrip Irrigation Borealis PDFchinmoyd1100% (1)

- Sika Fiber T48 - TDSDocument2 pagesSika Fiber T48 - TDSMarko StojanovicNo ratings yet

- E PTFEDocument5 pagesE PTFEAlfa PumpsNo ratings yet

- Conplast SP430Document2 pagesConplast SP430Tori Small100% (1)

- Conplast SP430RDocument2 pagesConplast SP430RTori Small100% (1)

- Fosroc Fibreboard - DtsDocument2 pagesFosroc Fibreboard - Dtsaljhun_1966No ratings yet

- Intraplast: Expanding Grout AdmixtureDocument2 pagesIntraplast: Expanding Grout AdmixtureManoj ChhetriNo ratings yet

- Fosroc Solutions for Structural StrengtheningDocument7 pagesFosroc Solutions for Structural StrengtheningShridhar VaidyaNo ratings yet

- Project Report On Polymer Fibre Reinforced Concrete PavementsDocument41 pagesProject Report On Polymer Fibre Reinforced Concrete PavementsShilankarMurti82% (17)

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- Polymeric Foams Structure-Property-Performance: A Design GuideFrom EverandPolymeric Foams Structure-Property-Performance: A Design GuideRating: 5 out of 5 stars5/5 (2)

- Rehabilitation of Concrete Structures with Fiber-Reinforced PolymerFrom EverandRehabilitation of Concrete Structures with Fiber-Reinforced PolymerNo ratings yet

- 02 Filtros de Ingreso A CompresorDocument6 pages02 Filtros de Ingreso A CompresorLuis Alonso Dipaz ZeaNo ratings yet

- VacuumDocument7 pagesVacuumMassimilianø Erricø100% (1)

- Dependency of Acidic and Surficial Characteristics of Steamed Y Zeolite.2018Document13 pagesDependency of Acidic and Surficial Characteristics of Steamed Y Zeolite.2018Cecilia ManriqueNo ratings yet

- XII Chemistry CH#11 Notes (Sir Nasim Zulfiqar)Document9 pagesXII Chemistry CH#11 Notes (Sir Nasim Zulfiqar)salmanNo ratings yet

- Nama: Rodiatul Jannah No Absen: 28 Kelas: Xi-Mipa 3 Guru Mapel: Widisuwita Sumadia, M.PDDocument10 pagesNama: Rodiatul Jannah No Absen: 28 Kelas: Xi-Mipa 3 Guru Mapel: Widisuwita Sumadia, M.PDrodiatul jannahNo ratings yet

- Astm E1269 Standard Test Method For CP by DSCDocument6 pagesAstm E1269 Standard Test Method For CP by DSCWMJNo ratings yet

- Lecturer Chemistry Model QuestionDocument11 pagesLecturer Chemistry Model QuestionPrathana Vidya100% (1)

- Chemical Looping of CO2Document23 pagesChemical Looping of CO2shyamNo ratings yet

- Analyzing 1H NMR Spectra of PDMSDocument5 pagesAnalyzing 1H NMR Spectra of PDMSAsrina RoslanNo ratings yet

- CVDocument2 pagesCVyadse100% (1)

- Oal Ed Ethahne: Prof. P. K. SinghDocument67 pagesOal Ed Ethahne: Prof. P. K. SinghViplove RajurkarNo ratings yet

- Circulatum MinusDocument2 pagesCirculatum MinusJoshua Arent100% (1)

- Edicto - Thermodynamics Lab - Heat FusionDocument2 pagesEdicto - Thermodynamics Lab - Heat FusionEdicto, Beatrice CarolineNo ratings yet

- Silo Protection PDFDocument4 pagesSilo Protection PDFjovanivanNo ratings yet

- CONSTRUCTION CHEMISTRY ROOF WATERPROOFINGDocument2 pagesCONSTRUCTION CHEMISTRY ROOF WATERPROOFINGAmar WadoodNo ratings yet

- Trunnion Ball Valves PDFDocument24 pagesTrunnion Ball Valves PDFbenabdallah131No ratings yet

- Chapter 2 Structure, Properties and Behavior of MatterDocument49 pagesChapter 2 Structure, Properties and Behavior of Matteraxeman1nNo ratings yet

- Populations in Ecosystems Summer Holiday Homework QsDocument11 pagesPopulations in Ecosystems Summer Holiday Homework QsSohail AliNo ratings yet

- Pamphlet 152 - Edition 4 - April 2018Document29 pagesPamphlet 152 - Edition 4 - April 2018acidoanimalNo ratings yet

- T06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Document66 pagesT06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Zitouni LamineNo ratings yet

- Lecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaDocument565 pagesLecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaSumanth VarmaNo ratings yet

- Internship Format1Document44 pagesInternship Format1Prajwal ChavanNo ratings yet

- HaarslevDocument12 pagesHaarslevjimdacalano1911No ratings yet

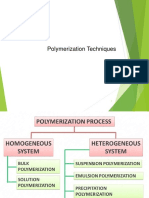

- Polymerisation Practice TEPEDocument39 pagesPolymerisation Practice TEPEDr. Dure Najaf Iqbal100% (3)

- PLAJEX SN Leaflet 2019Document2 pagesPLAJEX SN Leaflet 2019pushpanjali singhNo ratings yet

- Genei: Latex Agglutination Teaching Kit ManualDocument7 pagesGenei: Latex Agglutination Teaching Kit ManualNidhi LashkariNo ratings yet

- Failure TheoryDocument11 pagesFailure TheoryGaurav MallaNo ratings yet

- SP LogDocument28 pagesSP LogVito YogyakartaNo ratings yet

- PLD 105Document8 pagesPLD 105madx44No ratings yet

- Soil Pollution: Causes, Effects and Simple SolutionsDocument7 pagesSoil Pollution: Causes, Effects and Simple SolutionsVon MorenNo ratings yet