Professional Documents

Culture Documents

Risk Assessment

Uploaded by

SAYEDOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment

Uploaded by

SAYEDCopyright:

Available Formats

منتديات سالمتك

RISK ASSESSMENT

GENERAL INFORMATION

SAYED SALLAM

1/15/2010

معلومات خاصة العضاء منتديات سالمتك – مه ينقلها حق علية ان يذكز المصدر

What is a risk assessment?

Why is risk assessment important?

What is the goal of risk assessment?

How do you do a risk assessment?

How are the hazards identified?

How do you know if the hazard is serious (poses a risk)?

How do you rank or prioritize the risks?

What options exist to rank or prioritize risks?

What are methods of hazard control?

Why is it important to review and monitor your assessment?

What documentation should be done for a risk assessment?

What is a risk assessment?

Risk assessment is the process where you:

identify hazards,

analyze or evaluate the risk associated with that hazard, and

determine appropriate ways to eliminate or control the hazard.

In practical terms, a risk assessment is a thorough look at your workplace to identify

those things, situations, processes, etc that may cause harm, particularly to people.

After identification is made, you evaluate how likely and severe the risk is, and then

decide what measures should be in place to effectively prevent or control the harm

from happening.

For definitions and more information about what hazards and risks are, please see

the OSH Answers document "Hazard and Risk".

Why is risk assessment important?

Risk assessments are very important as they form an integral part of a good

occupational health and safety management plan. They help to:

create awareness of hazards and risks,

identify who may be at risk (employees, cleaners, visitors, contractors, the public,

etc),

determine if existing control measures are adequate or if more should be done,

prevent injuries or illnesses when done at the design or planning stage, and

prioritize hazards and control measures.

What is the goal of risk assessment?

The aim of the risk assessment process is to remove a hazard or reduce the level of

its risk by adding precautions or control measures, as necessary. By doing so, you

have created a safer and healthier workplace.

Salamtc Forum Page 2

How do you do a risk assessment?

Assessments should be done by a competent team of individuals who have a good

working knowledge of the workplace. Staff should be involved always include

supervisors and workers who work with the process under review as they are the

most familiar with the operation.

In general, to do an assessment, you should:

identify hazards,

evaluate the likelihood of an injury or illness occurring, and its severity,

consider normal operational situations as well as non-standard events such as

shutdowns, power outages, emergencies, etc.,

review all available heath and safety information about the hazard such as MSDSs,

manufacturers literature, information from reputable organizations, results of

testing, etc.,

identify actions necessary to eliminate or control the risk,

monitor and evaluate to confirm the risk is controlled,

keep any documentation or records that may be necessary. Documentation may

include detailing the process used to assess the risk, outlining any evaluations, or

detailing how conclusions were made.

When doing an assessment, you must take into account:

the methods and procedures used in the processing, use, handling or storage of

the substance, etc..

the actual and the potential exposure of workers,

the measures and procedures necessary to control such exposure by means of

engineering controls, work practices, and hygiene practices and facilities.

By determining the level of risk associated with the hazard, the employer and the

joint health and safety committee can decide whether a control program is required.

It is important to remember that the assessment must take into account not only the

current state of the workplace but any potential situations as well.

Click here to see a sample risk assessment form.

How are the hazards identified?

Overall, the goal is to find and record possible hazards that may be present in your

workplace. As mentioned, it may help to work as a team and include both people

familiar with the work area, as well as people who are not - this way you have both

the "experienced" and "fresh" eye to conduct the inspection.

To be sure that all hazards are found:

look at all aspects of the work,

include non-routine activities such as maintenance, repair, or cleaning,

look at accident / incident / near-miss records,

Salamtc Forum Page 3

include people who work "off site" either at home, on other job sites, drivers,

teleworkers, with clients, etc.,

look at the way the work is organised or "done" (include experience and age of

people doing the work, systems being used, etc),

look at foreseeable unusual conditions (for example: possible impact on hazard

control procedures that may be unavailable in an emergency situation, power

outage, etc.),

examine risks to visitors or the public,

include an assessment of groups that may have a different level of risk such as

young or inexperienced workers, persons with disabilities, or new or expectant

mothers.

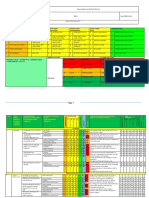

It may help to create a chart or table such as the following:

Table 1

Example of Risk Assessment

Task Hazard Risk Priority Control

Delivering Drivers work alone May be unable to call

product to for help if needed

customers

Drivers have to Fatigue, short rest

occasionally work long time between shifts

hours

Drivers are often in Increased chance of

very congested traffic collision

Longer working hours

Drivers have to lift Injury to back from

boxes when deliverying lifting, reaching,

product carrying, etc.

How do you know if the hazard is serious (poses a risk)?

Each hazard should be studied to determine its' level of risk. To research the hazard,

you can look at:

product information / manufacturer documentation,

past experience (workers, etc),

legislated requirements and/or applicable standards,

industry codes of practice / best practices,

health and safety material about the hazard such as material safety data sheets

(MSDSs), or other manufacturer information,

information from reputable organizations,

results of testing (atmospheric, air sampling of workplace, biological, etc),

the expertise of a occupational health and safety professional,

information about previous injuries, illnesses, "near misses", accident reports, etc.

Remember to include factors that contribute to the level of risk such as the:

Salamtc Forum Page 4

work environment (layout, condition, etc.),

capability, skill, experience of workers who do the work,

systems of work being used, or

range of foreseeable conditions.

How do you rank or prioritize the risks?

Ranking or prioritizing hazards is one way to help determine which hazard is the

most serious and thus which hazard to control first. Priority is usually established by

taking into account the employee exposure and the potential for accident, injury or

illness. By assigning a priority to the hazards, you are creating a ranking or an action

list. The following factors play an important role:

percentage of workforce exposed,

frequency of exposure,

degree of harm likely to result from the exposure,

probability of occurrence.

There is no one simple or single way to determine the level of risk. Ranking hazards

requires the knowledge of the workplace activities, urgency of situations, and most

importantly, objective judgement.

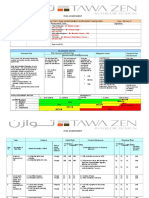

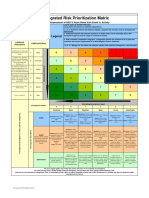

What options exist to rank or prioritize risks?

One option is to use a table similar to the following as established by the British

Standards Organization:

Table 2

Risk Assessment by the British Standards Organization

Severity of Harm

Likelihood of Harm

Slight Harm Moderate Harm Extreme Harm

Very unlikely Very low risk Very low risk High risk

Unlikely Very low risk Medium risk Very high risk

Likely Low risk High risk Very high risk

Very likely Low risk Very high risk Very high risk

Note: These categorizations and the resulting asymmetry of the matrix arise from the

examples of harm and likelihood illustrated within the British Standard. Organizations

should adjust the design and size of the matrix to suit their needs.

Salamtc Forum Page 5

Definitions for Likelihood of Harm

Very Likely - Typically experienced at least once every six months by an individual.

Likely - Typically experienced once every five years by an individual.

Unlikely - Typically experienced once during the working lifetime of an individual.

Very unlikely - Less than 1% chance of being experienced by an individual during

their working lifetime.

Definitions for Severity of Harm

Potential severity of harm - When establishing potential severity of harm,

information about the relevant work activity should be considered, together with:

a) part(s) of the body likely to be affected;

b) nature of the harm, ranging from slight to extremely harmful:

1. slightly harmful (e.g., superficial injuries; minor cuts and bruises; eye irritation

from dust; nuisance and irritation; ill-health leading to temporary discomfort)

2. harmful (e.g., lacerations; burns; concussion; serious sprains; minor fractures;

deafness; dermatitis; asthma; work-related upper limb disorders; ill-health)

3. extremely harmful (e.g., amputations; major fractures; poisonings; multiple

injuries; fatal injuries; occupational cancer; other severely life shortening diseases;

acute fatal diseases)

Definition for Risk Level - Tolerability Guidance on necessary action and timescale

Very low - These risks are considered acceptable. No further action is necessary

other than to ensure that the controls are maintained.

Low - No additional controls are required unless they can be implemented at very

low cost (in terms of time, money, and effort). Actions to further reduce these risks

are assigned low priority. Arrangements should be made to ensure that the controls

are maintained.

Medium - Consideration should be as to whether the risks can be lowered, where

applicable, to a tolerable level and preferably to an acceptable level, but the costs of

additional risk reduction measures should be taken into account. The risk reduction

measures should be implemented within a defined time period. Arrangements should

be made to ensure that controls are maintained, particularly if the risk levels area

associated with harmful consequences.

High - Substantial efforts should be made to reduce the risk. Risk reduction

measures should be implemented urgently within a defined time period and it might

be necessary to consider suspending or restricting the activity, or to apply interim

risk control measures, until this has been completed. Considerable resources might

have to be allocated to additional control measures. Arrangements should be made

Salamtc Forum Page 6

to ensure that controls are maintained, particularly if the risk levels are associated

with extremely harmful consequences and very harmful consequences.

Very high - These risk are unacceptable. Substantial improvements in risk control

measures are necessary so that the risk is reduced to a tolerable or acceptable level.

The work activity should be halted until risk controls are implemented that reduces

the risk so that it is no longer very high. If it is not possible to reduce the risk, the

work should remain prohibited.

Note: Where the risk is associated with extremely harmful consequences, further

assessment is necessary to increase confidence in the likelihood of harm.

Adapted From:

Occupational health and safety management systems - Guide: British Standard, BS

8800, BSI 2004; and Managing Safety the Systems Way: Implementing OHSAS

18001 using BS 8800, BSI 2004.

Other options include using tables such as Table 3 below.

Table 3

Hazard Control Strategy: A Sample Worksheet

% Employees Frequency of Hazard Priority

Hazard Priority

Affected Occurrence Potential Rank

Ergonomics 60 H H 60-HH 1 (?)

Back pain 80 H H 80-HH 2 (?)

Noise 30 L H 30-LH 3

Heat 50 L L 50-LL 5

Lasers 2 L H 2-HL 4

H = High, L = Low

* from: "Health and Safety Committees Reference Guide", CCOHS, 2003

Salamtc Forum Page 7

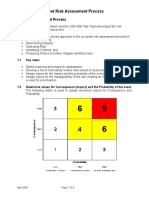

Or, Table 4, where 1 = extremely important to do something as soon as possible, 6

= hazard may not need immediate attention.

Table 4

Example of Hazard Priority Setting

Very likely - Unlikely - Very unlikely -

Likely - could

could could happen could happen

happen

happen at but very but probably

sometime

any time rarely never will

Kill or cause

permanent

1 1 2 3

disability or ill

health

Long term illness

1 2 3 4

or serious injury

Medical attention

and several days 2 3 4 5

off work

First aid needed 3 4 5 6

From: "Hazpak: Making your workplace safer. A practical guide to basic risk

management" by WorkCover New South Wales, Australia.[n.d.] .

What are methods of hazard control?

Once you have established your top priorities, you can decide on ways to control

each specific hazard. Hazard control methods are often grouped into the following

categories:

elimination (including substitution),

engineering controls,

administrative controls,

personal protective equipment.

For more details, please see the OSH Answers "Hazard Control".

Why is it important to review and monitor your assessment?

It is important to know if your risk assessment was complete and accurate. It is also

essential to be sure that changes in the workplace have not introduced new hazards

or changed hazards that were once ranked as lower priority to a higher priority.

It is good practice to review your assessment on a regular basis to be sure that

nothing has changed and that your control methods are effective. Triggers for a

review can also include:

Salamtc Forum Page 8

the start of a new project,

a change in the work process or flow,

a change or addition to tools, equipment, machinery (including locations or the

way they are used),

new employees,

moving to a new building or work area,

introduction of new chemicals or substances,

when new information becomes available about a current product.

What documentation should be done for a risk assessment?

Keeping records of your assessment and any control actions taken is very important.

You may be required to store assessments for a specific number of years. Check for

local requirements in your jurisdiction.

The level of documentation or record keeping will depend on:

level of risk involved,

legislated requirements, and/or

requirements of any management systems that may be in place.

Your records should show that you:

conducted a good hazard review,

determined the risks of those hazards,

implemented control measures suitable for the risk,

reviewed and monitored all hazards in the workplace.

Salamtc Forum Page 9

You might also like

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- Sweet Emotion: Bass Line ForDocument2 pagesSweet Emotion: Bass Line ForJames Gale100% (1)

- Step 1. Project / Task Name: Work Area: Org Unit Project / Task Description: Step 2. Step 3. Step 4. Step 5. Step 6. Step 7. Step 8. Step 12Document5 pagesStep 1. Project / Task Name: Work Area: Org Unit Project / Task Description: Step 2. Step 3. Step 4. Step 5. Step 6. Step 7. Step 8. Step 12Julius Habibi100% (1)

- Task Specific Risk AssessmentDocument22 pagesTask Specific Risk Assessmentsimone92% (12)

- Hazard Identification Risk Assessment and Risk ControlDocument7 pagesHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Baseline Risk Assessment for Hitech-Gregfor Port ElizabethDocument32 pagesBaseline Risk Assessment for Hitech-Gregfor Port ElizabethPierre Hayward100% (1)

- 125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتDocument3 pages125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتeng_hma75% (4)

- Risk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderDocument5 pagesRisk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderOvais FarooqNo ratings yet

- Risk Assessment ProcedureDocument9 pagesRisk Assessment Procedurerslapena100% (2)

- Risk AssessmentDocument7 pagesRisk AssessmentMuhammad Ibrahim100% (2)

- All Tyeps Risk Assessment in Construction PDFDocument112 pagesAll Tyeps Risk Assessment in Construction PDFSorin Tec100% (1)

- Sample Risk AssessmentDocument12 pagesSample Risk Assessmentpaansaeng82% (17)

- Risk AssessmentDocument11 pagesRisk AssessmentSanil Kuriakose100% (1)

- Construction Site Management Training Pack Part 2Document41 pagesConstruction Site Management Training Pack Part 2Jaka Sembung GolokNo ratings yet

- Risk Assessment (OSHA)Document9 pagesRisk Assessment (OSHA)Syfull music100% (1)

- HSE Risk Assessment Matrix (2006)Document44 pagesHSE Risk Assessment Matrix (2006)pounding90% (21)

- Baseline Risk Assessment & Hazard Identification With Ohs SpecificationDocument21 pagesBaseline Risk Assessment & Hazard Identification With Ohs SpecificationschoemanNo ratings yet

- Diagnostic Laboratory TestsDocument6 pagesDiagnostic Laboratory TestsKiana Mae Wong Diwag100% (1)

- Risk AssessmentDocument13 pagesRisk AssessmentgaaroncNo ratings yet

- Health Risk AssessmentDocument68 pagesHealth Risk Assessmentkarl_poor100% (4)

- Hazard and Risk AssessmentDocument99 pagesHazard and Risk Assessment최재호83% (6)

- Risk Assessment Form: Hazard ListDocument2 pagesRisk Assessment Form: Hazard ListJulio Alves100% (1)

- The Foreigner Audition Information KitDocument2 pagesThe Foreigner Audition Information KitjnatchNo ratings yet

- Risk assessment of microbiology laboratory tasksDocument3 pagesRisk assessment of microbiology laboratory tasksAmira AdilahNo ratings yet

- Technical Report WritingDocument61 pagesTechnical Report WritingShameem Abdul Kadar90% (10)

- Risk AssessmentDocument22 pagesRisk AssessmentIhuhwa Marta TauNo ratings yet

- 1 - ERP - CrisisDocument124 pages1 - ERP - Crisisamira_zainal92No ratings yet

- Risk MatrixDocument1 pageRisk Matrixwadsie100% (2)

- Procedure Conducting Risk AssessmentDocument21 pagesProcedure Conducting Risk Assessmenttheblackalchemist100% (2)

- ThiruppavaiDocument157 pagesThiruppavaiajiva_rts100% (49)

- Risk Assessment ToolsDocument27 pagesRisk Assessment ToolsTAHER AMMARNo ratings yet

- Construction Risk Assesment For Riser Top Ring InstallationsDocument11 pagesConstruction Risk Assesment For Riser Top Ring Installationssaifulnizam86gmailcom100% (1)

- Qualitative V Quantitative Risk AssessmentDocument5 pagesQualitative V Quantitative Risk AssessmentGundeepNo ratings yet

- Phonetics Exercises PDFDocument2 pagesPhonetics Exercises PDFShanti YuliastitiNo ratings yet

- Risk Assessment FormDocument3 pagesRisk Assessment Formazee73100% (2)

- Bill of QuantitiesDocument25 pagesBill of QuantitiesOrnelAsperas100% (2)

- Risk-Based Assessment of Ecobank Ghana LimitedDocument115 pagesRisk-Based Assessment of Ecobank Ghana LimitedGerishom Wafula Manase0% (1)

- Risk AssessmentDocument21 pagesRisk Assessmentledereh1No ratings yet

- Risk Assessment GuidelinesDocument29 pagesRisk Assessment GuidelinesGerald88% (26)

- Risk Assessment GuidesDocument84 pagesRisk Assessment GuidesFrancisco M. RamosNo ratings yet

- Strategic Risk Assessment TemplateDocument2 pagesStrategic Risk Assessment TemplateAnonymous IGs067BpNo ratings yet

- Hazard Identification Risk Assessment and Control Measures For MHFDocument49 pagesHazard Identification Risk Assessment and Control Measures For MHFprav.sarada100% (1)

- Contract Risk Assessment DeliveryDocument8 pagesContract Risk Assessment DeliverySagar BhavsarNo ratings yet

- BP ANZ FVC Level 2 Task Risk AssessmentDocument8 pagesBP ANZ FVC Level 2 Task Risk AssessmentJulian JuliNo ratings yet

- Near MissDocument2 pagesNear MissHafidz Asy'ari AkbarNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- Risk AssessmentDocument2 pagesRisk Assessmentjay baoNo ratings yet

- Radiation Safety ManualDocument80 pagesRadiation Safety ManualSAYEDNo ratings yet

- Risk Assessment Procedures ManualDocument12 pagesRisk Assessment Procedures ManualTony Gallacher60% (5)

- Risk Assesment 2Document1 pageRisk Assesment 2Leon MonsalveNo ratings yet

- Guidance of Risk AssessmentDocument31 pagesGuidance of Risk AssessmentBagus Chandra KurniawanNo ratings yet

- JSA Amp Risk AssessmentDocument19 pagesJSA Amp Risk Assessmentdroffilcz27No ratings yet

- Nebosh Oil & GasDocument30 pagesNebosh Oil & GasSAYED100% (1)

- Cable Fault Location in Power Cables GuideDocument5 pagesCable Fault Location in Power Cables GuideSAYEDNo ratings yet

- RISK ASSESSMENT BSc (hon) Building Construction ManagementDocument34 pagesRISK ASSESSMENT BSc (hon) Building Construction ManagementSujani Maarasinghe75% (4)

- Risk AssessmentDocument8 pagesRisk AssessmentSubhransu Mohapatra50% (2)

- Risk AssessmentDocument21 pagesRisk AssessmentKaran MehtaNo ratings yet

- Efficient Warehouse Design GuideDocument16 pagesEfficient Warehouse Design GuideAbhinit SinhaNo ratings yet

- دليل المدرب في تدريب المدربينDocument89 pagesدليل المدرب في تدريب المدربينSAYED88% (16)

- Laboratory Safety Inspection ChecklistDocument4 pagesLaboratory Safety Inspection ChecklistSAYEDNo ratings yet

- Positive Performance MeasurementDocument42 pagesPositive Performance MeasurementSAYED100% (4)

- Suntay V CojuancoDocument2 pagesSuntay V CojuancoJushiNo ratings yet

- Nebosh PSM SummaryDocument67 pagesNebosh PSM SummaryAhmed Hamad100% (1)

- Fire Risk AssessmentDocument39 pagesFire Risk AssessmentMutu PalembangNo ratings yet

- FCC TechDocument13 pagesFCC TechNguyen Thanh XuanNo ratings yet

- Exam 2 Study GuideDocument11 pagesExam 2 Study GuideAnonymous ewJy7jyvNNo ratings yet

- Petroleum Risk AssessmentDocument18 pagesPetroleum Risk AssessmentGokul pNo ratings yet

- Margiela Brandzine Mod 01Document37 pagesMargiela Brandzine Mod 01Charlie PrattNo ratings yet

- Crane Safety ManualDocument28 pagesCrane Safety Manualpuneet71% (7)

- Advanced Risk Assessment Techniques CourseDocument4 pagesAdvanced Risk Assessment Techniques CourseMohamed AdamNo ratings yet

- Guide Lines For NSC HSE PlanDocument52 pagesGuide Lines For NSC HSE Planജിനാദ് അബ്ദുസ്സലാംNo ratings yet

- Risk AssesmentDocument23 pagesRisk AssesmentMohamed ReezaNo ratings yet

- Fleet Risk Assessment Process GuideDocument4 pagesFleet Risk Assessment Process GuideHaymanAHMEDNo ratings yet

- Workplace Risk Assessment PDFDocument14 pagesWorkplace Risk Assessment PDFSyarul NizamzNo ratings yet

- Risk Assessment PrioritizationDocument43 pagesRisk Assessment PrioritizationAndre Novent Chenady100% (1)

- Element A1 Principles of Health and Safety ManagementDocument46 pagesElement A1 Principles of Health and Safety ManagementSAYEDNo ratings yet

- 7 Stupid ReasonsDocument24 pages7 Stupid ReasonsSAYED100% (1)

- 7 Stupid ReasonsDocument24 pages7 Stupid ReasonsSAYED100% (1)

- A Guide To Selecting Appropriate Tools To Improve HSE CultureDocument24 pagesA Guide To Selecting Appropriate Tools To Improve HSE CultureSAYED100% (3)

- 7 Stupid ReasonsDocument24 pages7 Stupid ReasonsSAYED100% (1)

- BSA - Construction Equiptment Blindspots 001Document22 pagesBSA - Construction Equiptment Blindspots 001SAYEDNo ratings yet

- Profile FinalDocument21 pagesProfile FinalSAYEDNo ratings yet

- Deepwater Horizon: Rig Type BuilderDocument16 pagesDeepwater Horizon: Rig Type BuilderSAYEDNo ratings yet

- FIFA World Cup South Africa 2010 - Excel File .Document6 pagesFIFA World Cup South Africa 2010 - Excel File .U. Milakovic100% (1)

- الرافعاتDocument5 pagesالرافعاتSAYEDNo ratings yet

- 25 May 2011 Workshop Program - Final EnglishDocument1 page25 May 2011 Workshop Program - Final EnglishSAYEDNo ratings yet

- Off JobSafetyBookletDocument59 pagesOff JobSafetyBookletSAYEDNo ratings yet

- Defensive DriveDocument54 pagesDefensive DriveSAYEDNo ratings yet

- Modern Fire CarDocument4 pagesModern Fire CarSAYEDNo ratings yet

- 1Document118 pages1SAYED100% (2)

- مدخل الى السلامة والصحة المهنيةDocument32 pagesمدخل الى السلامة والصحة المهنيةSAYED100% (10)

- Nwa WhitepaperDocument9 pagesNwa WhitepaperSAYEDNo ratings yet

- Road Work SafetyDocument64 pagesRoad Work SafetySAYED100% (1)

- Electrical Equipment in Hazardous LocationsDocument41 pagesElectrical Equipment in Hazardous LocationsSAYEDNo ratings yet

- QRA - FoodDocument27 pagesQRA - FoodSAYEDNo ratings yet

- Live Permit To WorkDocument1 pageLive Permit To WorkSAYED100% (1)

- A Project Report On Working Capital Management of Hindalco For The Last Five YearsDocument83 pagesA Project Report On Working Capital Management of Hindalco For The Last Five YearsBabasab Patil (Karrisatte)0% (1)

- Alan Ross CV Expert Road Safety AdviserDocument4 pagesAlan Ross CV Expert Road Safety AdviserAnna Sophia YorkNo ratings yet

- Old Testament Books Bingo CardsDocument9 pagesOld Testament Books Bingo CardsSiagona LeblancNo ratings yet

- Philippines Disaster Response PlanDocument7 pagesPhilippines Disaster Response PlanJoselle RuizNo ratings yet

- AR118 - MSDS 2023 (Chemlube) - 19.10.2023Document8 pagesAR118 - MSDS 2023 (Chemlube) - 19.10.2023sanichi135No ratings yet

- 41720105Document4 pages41720105renu tomarNo ratings yet

- Planned Parenthood Great NorthWestDocument10 pagesPlanned Parenthood Great NorthWestKate AndersonNo ratings yet

- Joey Cena 2Document1 pageJoey Cena 2api-635313033No ratings yet

- Starch Digestion by Amylase Lab ReportDocument10 pagesStarch Digestion by Amylase Lab Report햇님No ratings yet

- Project Notes PackagingDocument4 pagesProject Notes PackagingAngrej Singh SohalNo ratings yet

- Chapter 2 Phil. HistoryDocument4 pagesChapter 2 Phil. HistoryJaylene AlbayNo ratings yet

- Choosing the Right Organizational Pattern for Your SpeechDocument19 pagesChoosing the Right Organizational Pattern for Your SpeechKyle RicardoNo ratings yet

- Hotel Industry Report Provides Insights on Growth, Costs, and FinancialsDocument12 pagesHotel Industry Report Provides Insights on Growth, Costs, and FinancialssparasavediNo ratings yet

- Khilafat Movement Pakistan Studies (2059)Document5 pagesKhilafat Movement Pakistan Studies (2059)emaz kareem Student0% (1)

- Firewalker Spell and Ability GuideDocument2 pagesFirewalker Spell and Ability GuideRon Van 't VeerNo ratings yet

- Classification of IndustriesDocument17 pagesClassification of IndustriesAdyasha MohapatraNo ratings yet

- CAE-NUST College Aeronautical Engineering AssignmentDocument3 pagesCAE-NUST College Aeronautical Engineering AssignmentBahram TahirNo ratings yet

- Whipping Cream PowderDocument2 pagesWhipping Cream PowderSALCON ConsultancyNo ratings yet

- G.R. No. 190583 - People vs FrontrerasDocument12 pagesG.R. No. 190583 - People vs FrontrerasKaren Faye TorrecampoNo ratings yet

- 3D Model of Steam Engine Using Opengl: Indian Institute of Information Technology, AllahabadDocument18 pages3D Model of Steam Engine Using Opengl: Indian Institute of Information Technology, AllahabadRAJ JAISWALNo ratings yet