Professional Documents

Culture Documents

Determining Construction Progress-Rev 0

Uploaded by

Nayan MulkiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determining Construction Progress-Rev 0

Uploaded by

Nayan MulkiCopyright:

Available Formats

Understanding Construction Progress and Percent

Complete Reporting

By Les Zinger

Overview

There are many misunderstandings of what % complete actual means and

what it represents on any construction project. This paper will explain the

different methods of reporting progress, what is required to develop and

track the project progress curve, differentiate the differences between

reporting progress by DURATION % Complete and % complete based on

PHYSICAL PROGRESS. The goal of this paper is to help management

understand the following:

What is being reported as progress or % complete and the actual

status of the project may be very different and misleading based on

the methodology being invoked.

The best method is based on physical % complete for the activity. This

is determined by the actual quantity installed vs. the budget quantity

for that activity

The second method would be the actual amount of resources used vs.

the budgeted amount as per the resource loading. This can be very

misleading based on the performance index for that activity. You could

use 100% of the resource and only complete 50% of the work or use

50% of the resources and complete 100% of the work.

The third and most misrepresentative, which is the methodology used

by all versions of MS Projects is duration % complete.

There are only 2 methods in which activities & projects can

relate to each other:

o Monies ( cost value)

o Man-hours

In order to related the activities and projects together to

calculate weighted values they must have either one or the

other, Money or Man-hours, as the common denominator.

In depth analysis of the methodology referenced above.

Physical percent complete In order to use this method you

need 2 of the following items;

o The quantity of the item to be installed based on the units

in the Eskom task order for that contract.

1

o The labor cost of that activity. (Eskom 95% of the time

supplies all the material, thus the amount stated in the

task order has a very high reliability to compose of 98100% total labor). This cost along with the quantities, unit

rates, total cost should be in the Eskom Task orders line

items when they are property completed.

o With a correctly resource loaded schedule the total number

of man-hours for that activity can used in lieu of the

activity cost. Currently there only exists one contractor that

is correctly resource loading the schedule in their propriety

schedule done in PSNET. Unfortunately due to contract

issues these resources are not being exported into P6 when

the conversion from PSNET to P6 is done.

o All the schedules provided to Eskom with resources

included are as follows:

Just thrown in MS_Project to fulfill a request from

Eskom and not really the resources that contractor

will use on the task,

Resources provided on highly level summary

activities such as methodology used by Rotek.

NO resources are included in their Excel, MS Project

Gantt (bar chart) or MS_Project schedule.

o Based on this we are very suspicious to determine any

progress based on resources.

Resources Actual vs. planned

o The problem with this method is that to maintain an SPI

(Schedule performance index) of 1.0 for any sustained

period or multiple craft disciplines is not realistic. The SPI is

typical used for monitoring the schedules performance as a

whole for Actual vs., Planned. A SPI below 1.0 is bad since it

indicates you are not performing as the plan. A SPI above

1.0 indicates that you Are performing better than planned

(Note.- some companies use SPI and CPI which are inverse

of this where less than 1.0 is good and greater than 1.0 is

bad) The Number of resources to do a task/ install a

specific quantity can be determined 1 of 4 ways:

The companies own estimating standards based

many historical data points of actual similar work

performed in the past.

Industry standard estimating books such as R.S.

Means or Richardsons.

2

An estimating software program in which depending

on the program used the resource quantity will vary.

To determine the amount and type of resources

required based on personal experience or the

experiences of others.

o The resource quantity can be used in another way- Earned

Man-Hours. In this method you multiple the activitys %

complete by the activitys total man-hours expended to

date to determine Earned Valve based on man-hours

earned. The issue still remains how to determine the

activitys % complete. The only accurate method is

quantity installed vs. planned quantity.

Duration percent complete

o Duration % complete is the least accurate of any method.

The basis of thinking for this is that the level of effort of

every activity is directly proportional to its duration.

o It simple terms if you have an activity to order a bolt and

the fabrication and shipping time to site has a duration of

20 days. When it arrives you earn the same about of

progress as welders working 20 days and making 400

welds. It is simple to demonstrate how this methodology is

totally erroneous.

o MS Project methodology that ESKOM has been

accepting is Duration % complete. This why the all

the consultants to Eskom have been stating that

currently there exists no realistic or analytical

method of accurately determining the outage %

complete with any reasonable certainty.

o This is one of the reasons why ESKOM is moving to P6

which has several methodologies to determine within a

reasonable level of error the outages % complete.

Currently the best and most accurate method of

calculating the outage actual % complete within an

acceptable level of error is physical % complete.

o For this method to work it requires the outage coordinators

to prepare correct and accurate contracts and task orders

from the contractors estimate and scope documents.

These contracts/task order must contain the following:

A task order which is identical to the scope

documents with every element list as a line item.

Each contract/task order line item must contain:

Quantity to be installed

Unit rates for labor

Total labor cost

From these signed contracts/task orders we have a

basis to quantify and cost the line items so they can

inputted into P6.

The budget quantity and total LABOR cost for each

activity corresponding task order line item number

will give the data necessary to determine physical %

complete of that activity by tracking the actual

quantity installed to the budget.

This gives the common denominator, Monies, in

which to relate that activity to all other activities in

the same project and to all the other projects in the

schedule. This is a method of calculating an

accurate weighted value for each activity in

the project and Integrated schedule.

The key to making this successful is to include any

quantity changes due to scope changes. As

additional scope and activities are added or deleted

they must contain both the quantity to be installed

and the total cost of the activity as per the approved

change order.

If scope changes reduce the scope for these activities

the affected quantities and cost must be reduced as

per the approved change order.

This will require both Engineering and the

outage controllers to complete their changes

documentation on time and in accordance with

the PCM for change management.

Several formats exist in P6 for adding the cost and

quantities which will have to be followed along with a

global change to aid in the calculations for deriving at

the performance % complete.

The performance % complete will be valid for every

WBS and Project this will allow rolling up to the total

outage performance % complete to the WBS, Project

and Outage levels.

You might also like

- Beginning Android DevelopmentDocument721 pagesBeginning Android DevelopmentNikola Johnny Popadic67% (3)

- Diamond DA 42 Systems - V12 - 5clases 19 de JunioDocument402 pagesDiamond DA 42 Systems - V12 - 5clases 19 de JunioLiu Antonio Tang100% (1)

- RC2 Series Screw Compressor Maintenance ManualDocument161 pagesRC2 Series Screw Compressor Maintenance ManualMichele CassiniNo ratings yet

- Tutorial On Geometric CalculusDocument16 pagesTutorial On Geometric Calculusschlemihl69No ratings yet

- Using The Leveling Functionality in Primavera P6Document27 pagesUsing The Leveling Functionality in Primavera P6Ahmed SassiNo ratings yet

- Demystifying Earned Value ManagementDocument10 pagesDemystifying Earned Value ManagementHeNo ratings yet

- Keeping Account1 PDFDocument44 pagesKeeping Account1 PDFXavier PokharelNo ratings yet

- Primavera P6 (Fat Client) Understanding Date FieldsDocument5 pagesPrimavera P6 (Fat Client) Understanding Date FieldsKinley ConsultingNo ratings yet

- Chapter 7 - Transient Heat Conduction PDFDocument64 pagesChapter 7 - Transient Heat Conduction PDFhaqjmiNo ratings yet

- Evm Quick GuideDocument7 pagesEvm Quick GuideFarid FaridNo ratings yet

- P6 Primavera Vers.Document748 pagesP6 Primavera Vers.JoseNo ratings yet

- How Does Primavera P6 Calculate Planned Value Cost For Activities Without Linear Distribution (Using Resource Curves or Manual Plan) in Earned Value Management - Do Duy Khuong BlogDocument5 pagesHow Does Primavera P6 Calculate Planned Value Cost For Activities Without Linear Distribution (Using Resource Curves or Manual Plan) in Earned Value Management - Do Duy Khuong BlogKJUNNINo ratings yet

- Ms-Mech-10, Ms Fabrication of PipingDocument13 pagesMs-Mech-10, Ms Fabrication of PipingBabar Manzoor GhauriNo ratings yet

- Integrated Project Plan Template Ver 2 3Document21 pagesIntegrated Project Plan Template Ver 2 3Myname KiplNo ratings yet

- Track Earned ValueDocument18 pagesTrack Earned Valueharish risonthNo ratings yet

- Project underway with global profile and accessDocument17 pagesProject underway with global profile and accessNaeem Uddin KolachiNo ratings yet

- Importing Activity Codes Into P6 Using An XER File and ExcelDocument3 pagesImporting Activity Codes Into P6 Using An XER File and ExcelPeterNo ratings yet

- Project Dates: What Are The Dates in SAP Project System?Document4 pagesProject Dates: What Are The Dates in SAP Project System?Matthew MartinNo ratings yet

- P6 QuestionsDocument70 pagesP6 QuestionsVipul Mistry100% (1)

- Basic Top 10 Primavera Interview Questions With Answers. - EngrDocument5 pagesBasic Top 10 Primavera Interview Questions With Answers. - EngrDebadityachatterjeeNo ratings yet

- Article #110 Using Earned Value Management To Monitor, Evaluate and Report Resources Efficiency Involved in Delivering Capital ProjectsDocument6 pagesArticle #110 Using Earned Value Management To Monitor, Evaluate and Report Resources Efficiency Involved in Delivering Capital Projectsshajbaby100% (1)

- Project Delivery ModelDocument3 pagesProject Delivery ModelAnonymous ciKyr0tNo ratings yet

- Guide Lines For Projects Control ImplementationDocument18 pagesGuide Lines For Projects Control ImplementationSM_Ing.No ratings yet

- FUJI FRONTIER 340E - PartslistDocument172 pagesFUJI FRONTIER 340E - Partslistvitprint22No ratings yet

- Perform Quantitative Risk AnalysisDocument12 pagesPerform Quantitative Risk AnalysissdfasdfasdfasfaNo ratings yet

- Lifetime Extension Steam TurbineDocument10 pagesLifetime Extension Steam Turbineramakantinamdar100% (1)

- Earned Value Management TutorialDocument7 pagesEarned Value Management TutorialracmalufNo ratings yet

- Cost and Manpower Loading in Primavera P6 - Video Uploaded - Project Management01Document20 pagesCost and Manpower Loading in Primavera P6 - Video Uploaded - Project Management01prabhuevsNo ratings yet

- EUCPMM1 - CE Methodology For Management Staff v0.91Document35 pagesEUCPMM1 - CE Methodology For Management Staff v0.91Ignacio De La SernaNo ratings yet

- Project Integration Management: Process Groups Discussed in PMBOK Guide. Solution 1Document21 pagesProject Integration Management: Process Groups Discussed in PMBOK Guide. Solution 1Boaz LiyonNo ratings yet

- ETABS Tutorial 1: EGN-5439 The Design of Tall BuildingsDocument46 pagesETABS Tutorial 1: EGN-5439 The Design of Tall BuildingsMuhammad Saqib Abrar100% (6)

- Lecture 3 - Project Cost EstimationDocument54 pagesLecture 3 - Project Cost Estimationjack jackNo ratings yet

- Reasons For Project ChangeDocument6 pagesReasons For Project ChangeHosea GatuaNo ratings yet

- Schedule Risk Analysis Simplified: by David T. Hulett, Ph. DDocument10 pagesSchedule Risk Analysis Simplified: by David T. Hulett, Ph. DFelipe Javier Arias CubillosNo ratings yet

- Planning Interview QuestionsDocument6 pagesPlanning Interview Questionsrahul.ril1660No ratings yet

- PWC Karnataka Aerospace Hub of India Report 091211Document32 pagesPWC Karnataka Aerospace Hub of India Report 091211sreeramk13No ratings yet

- Strengths of Primavera P6Document3 pagesStrengths of Primavera P6hashim malikNo ratings yet

- HarvestersDocument132 pagesHarvestersLeTraitimbenletkNo ratings yet

- Managing Financial Resources and DecisionsDocument17 pagesManaging Financial Resources and Decisionsmakenti890% (1)

- CPM and PertDocument34 pagesCPM and PertFata Hirzi Abi KaramiNo ratings yet

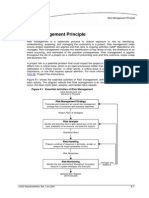

- Risk Management PrinciplesDocument6 pagesRisk Management PrinciplespekanselandarNo ratings yet

- Guidelines Probation Review Regulations Non-Academic StaffDocument8 pagesGuidelines Probation Review Regulations Non-Academic StaffdawudNo ratings yet

- Primavera TermsDocument13 pagesPrimavera Termsasma akramNo ratings yet

- 200 Organization: Project Control System ManualDocument11 pages200 Organization: Project Control System ManualRafael Fernandez SanchezNo ratings yet

- Key Definitions PDFDocument7 pagesKey Definitions PDFAhmed AbdelrahmanNo ratings yet

- Preparing A Project Timeline: A Seven Step ProcessDocument28 pagesPreparing A Project Timeline: A Seven Step ProcessMabtoor MabxNo ratings yet

- 2.11 Milestone Review - Phase 1Document7 pages2.11 Milestone Review - Phase 1nsadnanNo ratings yet

- What Is The Critical Path Method?Document9 pagesWhat Is The Critical Path Method?Thjnn ErrNo ratings yet

- The S Curves Made Easy With Oracle Primavera P6Document7 pagesThe S Curves Made Easy With Oracle Primavera P6sadiqaftab786No ratings yet

- Schedule Management PlanDocument3 pagesSchedule Management PlanGeeta RamsinghNo ratings yet

- Residual Life Assessment and Failure of The BoilerDocument21 pagesResidual Life Assessment and Failure of The BoilernagasureshNo ratings yet

- CHAPTER 4 - Project BudgetingDocument32 pagesCHAPTER 4 - Project BudgetingUmi Pascal100% (1)

- Domino A Series Classic Spares CatalogueDocument137 pagesDomino A Series Classic Spares CatalogueKoos Roets100% (2)

- Analyzing Business Case (Chapter-2)Document46 pagesAnalyzing Business Case (Chapter-2)Ayisha ManzoorNo ratings yet

- P6V82Webb Sample Slides - UnlockedDocument16 pagesP6V82Webb Sample Slides - UnlockedSuhas JadhalNo ratings yet

- PPMP20010 Project Status Report - TemplateDocument3 pagesPPMP20010 Project Status Report - TemplateAnkit DholariyaNo ratings yet

- Monitor Project Schedule Status & Manage ChangesDocument6 pagesMonitor Project Schedule Status & Manage ChangesAh GusNo ratings yet

- Topics Covered Topics Covered: Portfolio Planning ToolsDocument18 pagesTopics Covered Topics Covered: Portfolio Planning ToolsAMAYA.K.P 18BCO406No ratings yet

- Time-saving Tricks in P6Document6 pagesTime-saving Tricks in P6anoopvvvNo ratings yet

- 21 Primavera Tips and ShortcutsDocument30 pages21 Primavera Tips and ShortcutsMarioNo ratings yet

- CH 10Document7 pagesCH 10Witness Wii MujoroNo ratings yet

- Project Integration Management LessonDocument55 pagesProject Integration Management LessonJohn AssadNo ratings yet

- Install Oracle Primavera PPM 6.2.1 StandaloneDocument9 pagesInstall Oracle Primavera PPM 6.2.1 StandalonesakkhanNo ratings yet

- Earned ScheduleDocument8 pagesEarned SchedulePMPNo ratings yet

- Planning, Scheduling and Resource Optimisation of Multiple Projects Using Oracle Primavera P6 PDFDocument6 pagesPlanning, Scheduling and Resource Optimisation of Multiple Projects Using Oracle Primavera P6 PDFesatjournalsNo ratings yet

- Primavera P6 EPPM-UPK User ProductivityDocument17 pagesPrimavera P6 EPPM-UPK User ProductivityPiere Christofer Salas HerreraNo ratings yet

- Why EVM Doesnt WorkDocument10 pagesWhy EVM Doesnt Workaqeel_al_triniNo ratings yet

- BigInterview Top 10 QuestionsDocument24 pagesBigInterview Top 10 QuestionsJogeshwar SinghNo ratings yet

- PMGT 701 Group Project Management PlanningDocument3 pagesPMGT 701 Group Project Management PlanningsalmanNo ratings yet

- IT Project Management Methodology CourseDocument5 pagesIT Project Management Methodology CoursehomsomNo ratings yet

- Matrix Bulletin PDFDocument8 pagesMatrix Bulletin PDFNayan MulkiNo ratings yet

- Rectangular Column DesignDocument2 pagesRectangular Column DesignNayan MulkiNo ratings yet

- Floor Slab System PDFDocument34 pagesFloor Slab System PDFNayan MulkiNo ratings yet

- BCM Anna University NotesDocument112 pagesBCM Anna University NotesaruchellamNo ratings yet

- BCM Anna University NotesDocument112 pagesBCM Anna University NotesaruchellamNo ratings yet

- Summary For Data: Data Is Not Normal (P 0.05)Document2 pagesSummary For Data: Data Is Not Normal (P 0.05)Nayan MulkiNo ratings yet

- Determining Construction ProgressDocument4 pagesDetermining Construction ProgressNayan MulkiNo ratings yet

- LIC renewal premium receipt for Rs. 5,000Document2 pagesLIC renewal premium receipt for Rs. 5,000Nayan MulkiNo ratings yet

- Rain Water Harvesting - Indian RailwaysDocument55 pagesRain Water Harvesting - Indian RailwaysGreater Charlotte Harbor Sierra ClubNo ratings yet

- Formula For MSPDocument1 pageFormula For MSPNayan MulkiNo ratings yet

- Duhva U2Document4 pagesDuhva U2Nayan MulkiNo ratings yet

- Machine Guarding LP PDFDocument4 pagesMachine Guarding LP PDFrexivyNo ratings yet

- Vastu Tips For CareerDocument2 pagesVastu Tips For CareerBeyond ThoughtsNo ratings yet

- SPECIFICATION WRITING MODULEDocument3 pagesSPECIFICATION WRITING MODULEHana YeppeodaNo ratings yet

- Actividad 5 TermodinamicaDocument4 pagesActividad 5 TermodinamicaAngel EncastinNo ratings yet

- LDRDocument4 pagesLDRRaymond ValdezNo ratings yet

- Banyule Standard DrawingsDocument103 pagesBanyule Standard DrawingsTarek AbulailNo ratings yet

- White Paper c11 737101Document13 pagesWhite Paper c11 737101Aleksandar PopovicNo ratings yet

- Lecture - Force MethodDocument73 pagesLecture - Force MethodF FNo ratings yet

- Bulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncDocument3 pagesBulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncHerlambang Miracle YudhianNo ratings yet

- Aegis Multifunction RelayDocument4 pagesAegis Multifunction RelaySuranjana DasNo ratings yet

- Microstrip AntennaDocument24 pagesMicrostrip AntennaUdit Sharma100% (1)

- E1 - Controlled Rectifiers PDF NotesDocument84 pagesE1 - Controlled Rectifiers PDF NotesSatyanarayana Gurram100% (1)

- Simatic Ipc547Document7 pagesSimatic Ipc547Wermeson SousaNo ratings yet

- Monarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListDocument1 pageMonarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListgangadevimgmNo ratings yet

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- What Is Transmission Channel ?Document12 pagesWhat Is Transmission Channel ?tusharNo ratings yet

- Fatigue Strength in Laser Welding of The Lap Joint: S.-K. Cho, Y.-S. Yang, K.-J. Son, J.-Y. KimDocument12 pagesFatigue Strength in Laser Welding of The Lap Joint: S.-K. Cho, Y.-S. Yang, K.-J. Son, J.-Y. KimbnidhalNo ratings yet

- HTML DOM TutorialDocument11 pagesHTML DOM Tutorialapi-3819971100% (1)

- N-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDDocument9 pagesN-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDAnonymous p1ig0zX6p0No ratings yet