Professional Documents

Culture Documents

Api 682 Mechanical Seal Data Sheet For Centrifugal and Rotary Pumps

Uploaded by

Sakthikumar ChandrasekaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Api 682 Mechanical Seal Data Sheet For Centrifugal and Rotary Pumps

Uploaded by

Sakthikumar ChandrasekaranCopyright:

Available Formats

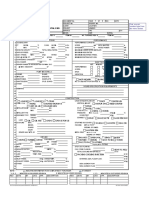

API 682 MECHANICAL SEAL DATA

SHEET FOR CENTRIFUGAL AND

ROTARY PUMPS

MANUFACTURER:

DETROIT HEAVY OIL UPGRADE PROJECT

MODEL NUMBER:

MICHIGAN REFINING DIVISION

SERIAL NUMBER:

A2IS

4P62

INQUIRY NUMBER:

A2IS-4-0601

P.O. NUMBER:

SHEET:

CLIENT:

PROJECT NAME:

PLANT:

SITE:

UNIT NUMBER:

4 - VACUUM UNIT

APPLICABLE TO:

SERVICE:

SLOP WAX PUMP

UNITS STANDARD FOR THIS DATA SHEET:

INFORMATION BELOW TO BE COMPLETED:

2HPX9A

One (1)

PROPOSAL

BY SEAL VENDOR

PURCHASE

AS BUILT

US CUSTOMARY UNITS

SEAL VENDOR OR PURCHASER

SEAL SPECIFICATION - (REFERENCE 4.1, FIGURES 1 TO 6)

8

9

CATEGORY

10

TYPE

11

(CODE - CW)

12

A'RNGMNT

13

1 (3.2)

SEAL CATEGORY 1 (4.1.1)

SEAL CATEGORY 2 (4.1.1)

SEAL CODE (ANNEX D)

TYPE A (3.72)

TYPE B (3.73)

ALTERNATIVE STATIONARY (TYPE A AND B)

TYPE C (3.74)

ALTERNATIVE ROTATING (TYPE C)

DEFAULT CONFIG

1 CW-FX

1 CW-FL

BUFFER

LIQUID

DIST. FLUSH

20

BARRIER

LIQUID

21

SLEEVE-SHAFT DRIVE

16

2 (3.3)

17

18

19

3 (3.4)

FX

SINGLE SPRING (TYPE A)

ALTERNATIVE BUSH

15

C2A2C325261

FLUSH PLANS (SEE ANNEX G)

ALTERNATIVE DESIGN

14

DIST. FLUSH

01

11

14

23

32

50

61

02

13

21

31

41

51

62

01

13

23

41

62

75

02

14

31

52

71

76

11

21

32

61

72

2 CW-CW

GAS

2 CW-CS

2 NC-CS

FX

3 CW-FB

3 CW-BB

FX

01

13

53A

54

3 CW-FF

TANGENTIAL LBO

02

14

53B

61

GAS

3 NC-BB

3 NC-FF

3 NC-FB

11

32

53C

62

TANGENTIAL LBO CONN'N

DIST. FLUSH

SET-SCREW INTO SHAFT

2

74

ALTERNATIVE (6.1.3.13) - SPECIFY:

MATERIALS (REFERENCE 6.1.6 AND ANNEX B)

22

23

SECONDARY SEALS

24

FKM

25

SPIRAL WOUND GASKET

SIC VS SIC

26

NBR

SS - SIC

27

OTHER:

OTHER:

SEAL FACES

FFKM

CARBON VS SIC

METAL BELLOWS

(Outboard)

SPRINGS

METAL PARTS

UNS N 10276 (TYPE B)

UNS N 10276

UNS S 31600 / S31635

(Inboard)

UNS N 07718 (TYPE C)

OR UNS N 06455

UNS N 10276

RB - SIC

UNS N 08020

UNS S 31600

UNS N 08020

OTHER:

OR S 31635

OTHER:

MECHANICAL SEAL DATA

28

FLOWSERVE

29

SEAL VENDOR:

30

DATA REQUIREMENTS FORM (ANNEX J)

31

SEAL / TYPE:

32

SEAL DRAWING NUMBER:

33

VENDOR'S SEAL CODE:

34

MODIFIED FACES FOR SEAL PERFORMANCE TEST

ALTERNATIVE SEAL FOR PUMP PERFORMANCE TEST

DYNAMIC SEALING PRESSURE RATING (3.19):

300

PSIG

STATIC SEALING PRESSURE RATING (3.69):

300

PSIG

982935 (Rev. A)

MAXIMUM ALLOWABLE TEMPERATURE (3.40)

750

HXCX / HPCX

MINIMUM DESIGN METAL TEMPERATURE (6.1.6.11.1)

BXHH / BXHH - 2375 / 2375

36

ASME B 73.1 & 2

37

BOLT ON CHAMBER

SEAL CHAMBER FLUSH PORT REQUIRED

SEAL CHAMBER VENT REQUIRED

38

FLOATING THROAT BUSHING

FIXED THROAT BUSHING

CYLINDRICAL

TAPERED

ISO 13709

ISO 3069 - C

OTHER, SPECIFY:

SEAL CHAMBER HEATING REQUIRED

PUMP DATA

39

PUMP DESIGN

PUMP OPERATING PRESSURE

41

MANUFACTURER:

42

MODEL:

43

FRAME SIZE:

44

CASE MATERIAL:

FLOWSERVE

SUCTION PRESSURE RATED:

2HPX9A

-9

PSIG

DISCHARGE PRESSURE:

A8(Mod-316L SS)

61.1

PSIG

SEAL CHAMBER

SHAFT

12.85 PSIG

NORMAL PRESSURE:

HORIZONTAL

MSDP (3.42) MIN.:

PSIG

DIAMETER:

MSDP (3.42) MAX.:

PSIG

SHAFT SPEED:

MSSP (3.44)

PSIG

ROTATION

VERTICAL

1.95

IN

3,550

CW

RPM

CCW

FLUID DATA (QUENCH, BUFFER, AND BARRIER FLUID DATA)

45

46

PUMPED STREAM:

47

TYPE OR NAME:

48

DISSOLVED CONTAMINANT:

CL2 :

49

ATMOSPHERIC BOILING PT (LIQUID):

VACUUM SLOP WAX

CONCENTRATION:

H2S:

PPMW

PPMW

51

OTHER CORROSIVE/ERROSIVE:

52

PUMPING TEMPERATURE:

53

MIN.:

54

SPECIFIC GRAVITY AT TEMPERATURE INDICATED (LIQUID)

55

AT NORMAL TEMP:

56

VAPOR PRESSURE AT TEMPERATURE INDICATED (LIQUID)

AT NORMAL TEMP:

58

FLUSH FLUID (PLAN 32)

4.9 wt% Sulfur

OTHER:

FLUID SOLID AT AMBIENT

F

POUR POINT:

0.87

663

MAX.:

700

PSIA

REGULATION LEVEL:

PSIA

CON'N:

60

FLUID TEMPERATURE:

61

MIN.:

62

SPECIFIC GRAVITY AT TEMPERATURE INDICATED (LIQUID)

63

AT NORMAL TEMP:

64

VISCOCITY AT NORMAL TEMPERATURE (LIQUID):

PPMV

SPECIAL PUMP CLEANING PROCEDURES:

AT MAXIMUM TEMP.:

HVGO

ALTERNATIVE PROCESS FLUIDS AND CONCENTRATIONS:

VAPOR PRESSURE AT TEMPERATURE INDICATED (LIQUID)

0.85

AT NORMAL TEMP:

PSIA

NORMAL:

0.84

494

MAX.:

ISSUE STATUS

820

2.1

200

888

PSIG

0.81

FLOW RATE REQUIRED:

MAX.:

GPM

MIN.:

GPM

cP

SUPPLY PRESSURE:

MAX.:

PSIG

MIN.:

PSIG

REVISION LOG

DATE

PSIA

BOILING POINT AT SEAL CHAMBER PRESSURE:

AVAILABLE SUPPLY PRESSURE:

AT MAXIMUM TEMP:

65

579

0.9

AT MAXIMUM TEMP.:

ATMOSPHERIC BOILING POINT (LIQUID):

STREAM IS REGULATED FOR FUGITIVE OR OTHER EMITIONS

SEAL VENDOR REVIEW REQUIRED

TYPE OR NAME:

AT:

STREAM CAN PLATE OUT OR DECOMPOSE UNDER:

AT MAXIMUM TEMP.:

PUMPED STREAM SOLIDIFIES UNDER SHEAR

AGENTS THAT POLYMERIZE:

NORMAL:

cP

4 (185 at 85 F during startup)

FLAMMABLE

SOLIDIFIES AT:

57

PPMW

VISCOCITY AT NORMAL TEMP. (LIQUID):

HAZARDOUS

AT

SOLID CONTAMINANT:

85

WET

OTHER:

50

59

SEAL CHAMBER DATA

35

40

REV

No. Stages: 1

NUMBER REQUIRED:

BY PURCHASER

OF

FLOWSERVE

DETROIT, MICHIGAN

A2IS-4-0601

RFQ NUMBER:

Note: This data sheet has been modified from that in the annex of

API Standard 682, 3th Edition, September 2004.

MARATHON OIL COMPANY

CONTRACT:

TAG ITEM NUMBER:

66

REV.

BY

CHECKED

APPROVED

67

Issued for Supplier Input

2/8/08

ON

TKS

BE

68

Issued for Purchase

2/22/08

ON

TKS

BE

69

Supplier comment for AS-BUILT

7/1/09

PK

JS

70

File Name:'file:///var/www/apps/conversion/tmp/scratch_1/257795735.xls'#$Sheet 1

API 682 MECHANICAL SEAL DATA

SHEET FOR CENTRIFUGAL AND

ROTARY PUMPS

MANUFACTURER:

DETROIT HEAVY OIL UPGRADE PROJECT

MODEL NUMBER:

MICHIGAN REFINING DIVISION

SERIAL NUMBER:

A2IS

4P62

SHEET:

PROJECT NAME:

PLANT:

SITE:

UNIT NUMBER:

4 - VACUUM UNIT

APPLICABLE TO:

SERVICE:

SLOP WAX PUMP

UNITS STANDARD FOR THIS DATA SHEET:

INFORMATION BELOW TO BE COMPLETED:

No. Stages: 1

0

One (1)

PROPOSAL

BY SEAL VENDOR

PURCHASE

SEAL VENDOR OR PURCHASER

QUENCH MEDIUM (PLAN 51, 62):

TYPE OR NAME:

BUFFER / BARRIER MEDIUM

SUPPLY TEMPERATURE:

MAX.:

MIN.:

FLOW RATE REQUIRED:

MAX.:

GPM/SCFH

MIN.:

GPM/SCFH

SPECIFIC GRAVITY AT TEMPERATURE INDICATED (LIQUID)

TYPE OR NAME:

AT NORMAL TEMP:

13

PURCHASER SELECTION

VAPOR PRESSURE AT TEMPERATURE INDICATED (LIQUID)

14

SEAL VENDOR REVIEW

15

FLOW RATE REQUIRED:

MAX.:

GPM/SCFH

MIN.:

GPM/SCFH

ATMOSPHERIC BOILING POINT (LIQUID):

16

SUPPLY PRESSURE:

MAX.:

PSI

MIN.:

PSI

VISCOCITY AT NORMAL TEMPERATURE (LIQUID):

17

FLUID OPERATING TEMPERATURE:

18

MIN.:

AT MAXIMUM TEMP.:

AT NORMAL TEMP:

PSIA

AT MAXIMUM TEMP.:

CONTROL VOLTAGE:

21

ELECTRICAL AREA:

22

DESIGN AMBIENT:

NORMAL:

MAX.:

MIN.:

-20

105

MAX.:

COOLING H2O PRESSURE:

PSIG

27

SPECIAL REQUIREMENTS FOR HAZARDOUS SERVICE

FLOWSERVE SEALS

EQUIPMENT SUPPORT SUPPLIER:

ISO 7

ASME B 1.20.1

FILLING SYSTEM SUPPLIER:

ASME CODE STAMP REQUIRED

28

EN 13445 OR OTHER CODE APPLICABLE:

8 GALLONS

29

SPECIAL CLEANING AND DECONTAMINATION REQUIREMENTS

RESERVOIR CAPACITY (8.5.4.3):

30

UTILITY MANIFOLD CONNECTIONS REQUIRED (8.4.4)

NLL TO GLAND PLATE HEIGHT (8.5.4.2):

31

TYPE AND SPECIFICATION OF HEAT TRACING (8.6.5.8)

RESERVOIR MAWP (3.41):

32

SET PRESSURE RANGE:

THERMAL RELIEF VALVES REQUIRED (9.8.3)

EQUIPMENT REFERENCE / CODE:

38

COOLING WATER LINES SUPPLIER:

TUBING

ISO 15549

BY BUYER

COOLING WATER FLOW RATE:

GPM

41

SIGHT FLOW INDICATORS (8.4.3)

OPEN

42

200

MIN:

PSIG

DAYS

REQUIRED COOLING WATER RATES & EQUIP. PRESSURE DROP:

RISING PRESSURE (ARR 2) SET AT:

PSIG

FALLING PRESSURE (ARR 3) SET AT:

PISG

TEST BASE H / Q CURVE FOR INTERNAL CIRCULATION DEVICE

EXTERNAL CIRCULATION PUMP (8.6.3.1)

PLAN 62, 65 SYSTEMS

CLOSED

CONNECTING LINE SUPPLIER:

43

PRIMARY EQUIPMENT

GPM

PRESS. DROP

PSI

44

SECONDARY EQUIP.

GPM

PRESS. DROP

PSI

TUBING

(PRESS. DROP SHALL BE SYSTEM NET WHEN PIPING FURN. BY PUMP VENDOR)

PLAN 72 AND 74 SYSTEMS

EQUIPMENT SUPPORT SUPPLIER:

BY BUYER

CONNECTING LINE SUPPLIER:

PIPING (8.5.2.2)

EQUIPMENT SUPPLIER:

PLAN 11, 13, 14, 21, 23, 31, 32, AND 41 SYSTEMS

TUBING

AT:

PSIG

HIGH LEVEL ALARM REQUIRED (8.5.4.2.i)

GALVANIZED PIPING (8.4.2)

40

48

30

PRESSURE SWITCH (8.5.4.2.h) TO ACTIVE ON:

AIR COOLED

37

39

PSIG

TEMPERATURE INDICATOR (PLANS 53B AND 53C)

HEAT EXCHANGER SUPPLIER:

WATER COOLED

620

MAX.:

SYSTEM HOLD-UP PERIOD (PLANS 53B AND 53C):

COOLING SYSTEM (PLAN 21, 22, 23, 41, 53B, 53C)

36

HIGH FLOW ALARMSWITCH (8.6.6.5)

PLAN 75 AND 76 SYSTEMS

PIPING (8.5.2.2)

49

RESTRICTION ORIFICE NIPPLE IN FLUSH LINE (8.5.2.4)

EQUIPMENT SUPPORT SUPPLIER:

50

CYCLONE SEPARATOR SUPPLIER:

HIGH LEVEL ALARM SWITCH (8.6.6.5)

51

PLAN 32 EQUIPMENT SUPPLIER:

52

PLAN 32 FLOW INDICATOR

54

PSIG

PLAN 52 AND 53 SYSTEMS CONTINUED

PIPE TAPER THREADS (8.1.9)

53

DESIGN:

ACCESSORIES (CLAUSES 8 AND 9)

26

47

NOR.:

ATEX (EC DIRECTIVE 94/9/EC)

GENERAL

JOINT USER / VENDOR LAYOUT OF EQUIPMENT (8.14)

46

BTU / H

COOLING H2O SUPPLY TEMPERATURE:

25

45

BTU / H-FT-F

COOLING HEATING REQUIRED (+ OR -):

CLASS 1, GROUPS C, D, DIVISION 2

23

35

cP

SITE AND UTILITIES

20

34

PSIA

SPECIFIC HEAT AT NORMAL TEMPERATURE:

19

33

AS BUILT

US CUSTOMARY UNITS

12

24

BY BUYER

TEST CONNECTION (8.6.5.4)

PLAN 32 TEMPERATURE INDICATOR

INSTRUMENTATION

PLAN 52 AND 53 SYSTEMS

USER SPECIFICATION REFERENCE FOR INSTRUMENTATION / CONROLS:

STANDARD (FIG G-27)

A3R111016-01 with Parker fittings

ALTERNATIVE (FIGURE G-28)

55

DIMENSIONAL VARIATIONS TO STANDARD (FIGURE G-27):

PRESSURE GAUGES (9.4)

OIL FILLED PRESSURE GAUGES (9.4.3)

56

DIMENSIONAL VARIATIONS TO ALTERNATIVE (FIGURE G-28):

PRESSURE SWITCHES (9.5.2):

TRANSMITER (9.5.2.3)

57

ALTERNATIVE FABRICATION STANDARD:

LEVEL SWITCHES (9.5.3)

TRANSMITER (9.5.3.2)

58

FLOWSERVE SEALS

PRIMARY EQUIPMENT SUPPLIER:

59

60

SUPPLIER'S REFERENCE / CODE:

A3R111016-01

HYDROSTATIC

SUPPLIER'S REFERENCE / CODE:

62

TUBING

CAPACITANCE

ULTRASONIC

LEVEL INDICATORS (9.6)

BUYER

CONNECTING LINES SUPPLIER:

61

WELD PAD

EXTERNAL, REMOVABLE (9.6.2)

FLOW INSTRUMENTS (9.7)

TRANSMITER (9.7.3)

SCH 80 PIPING (8.5.44.9)

INSPECTION AND TESTING

63

64

PURCHASER PARTICIPATION IN INSPECTION AND TEST SPECIFY:

65

INSPECTOR'S CHECK LIST (10.1.17 AND ANNEX H)

66

PURCHASER APPROVAL REQUIRED FOR WELDED CONNECTION DESIGNS (6.1.6.10.5)

OPTIONAL QUALIFICATION TESTING REQUIRED (10.3.1.1.2)

67

HARNESS TEST (10.2.3.k) REQUIRED FOR:

MODIFIED FACES FOR PUMP TEST (10.3.5.1) SEE PAGE 1, LINE 34

68

100% INSPECTION OF ALL WELDS (6.1.6.10.5) USING:

LIQUID PENETRANT

RADIOGRAPHIC

MAG. PARTICLE

ULTRASONIC

ALTERNATIVE SEAL PUMP TEST (10.3.5.2) SEE PAGE 1, LINE 29

69

ISSUE STATUS

REVISION LOG

DATE

70

REV.

BY

CHECKED

APPROVED

71

Issued for Supplier Input

2/8/08

ON

TKS

BE

72

Issued for Purchase

2/22/08

ON

TKS

BE

73

Supplier comment for AS-BUILT

7/1/09

PK

JS

74

REV

FLUID DATA (QUENCH, BUFFER AND BARRIER, LIQUID AND GAS)

11

2HPX9A

NUMBER REQUIRED:

BY PURCHASER

OF

FLOWSERVE

10

A2IS-4-0601

P.O. NUMBER:

CLIENT:

A2IS-4-0601

RFQ NUMBER:

DETROIT, MICHIGAN

INQUIRY NUMBER:

Note: This data sheet has been modified from that in the annex of

API Standard 682, 3th Edition, September 2004.

MARATHON OIL COMPANY

CONTRACT:

TAG ITEM NUMBER:

You might also like

- Datasheet For Gate ValveDocument2 pagesDatasheet For Gate ValveAlvin Smith67% (3)

- 04 - Data Sheet - Mech Seals-Cipf Inj PumpDocument3 pages04 - Data Sheet - Mech Seals-Cipf Inj Pumpisaac2408No ratings yet

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetEason Ng100% (2)

- Api 676 UsDocument2 pagesApi 676 UsAbhai Gupta100% (1)

- API 682 4th Ed DatasheetDocument2 pagesAPI 682 4th Ed DatasheetHatem ShawkiNo ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- Calgary Presentation API 610 and 682Document90 pagesCalgary Presentation API 610 and 682dhanu_aqua100% (1)

- John Crane Seal Identification CodingDocument9 pagesJohn Crane Seal Identification CodingEloy Alejandro Justiniano Coimbra100% (1)

- Turbo Tutorial API 619 5thDocument33 pagesTurbo Tutorial API 619 5thmishraengg100% (2)

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- Spec List APIDocument16 pagesSpec List APIgdwvcdNo ratings yet

- API Vs Non-API PumpsDocument4 pagesAPI Vs Non-API Pumpssyedahmedmasood100% (3)

- Flowserve ANSI-Pumps PDFDocument68 pagesFlowserve ANSI-Pumps PDFArup MahantaNo ratings yet

- 674 Reciprocating Pump DatasheetsDocument6 pages674 Reciprocating Pump DatasheetsAKSHEYMEHTANo ratings yet

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- Rotary Pump Data SheetDocument2 pagesRotary Pump Data SheetRuzi Falahi KautsarNo ratings yet

- ASME B31.4 Wall Thickness CalculationDocument4 pagesASME B31.4 Wall Thickness CalculationSuthan100% (1)

- Pocket API 682 4th Edition Piping Plans - EN Burgmann PDFDocument131 pagesPocket API 682 4th Edition Piping Plans - EN Burgmann PDFPoncho RmzNo ratings yet

- PIP PNSM0001 - Piping Line Class Design at or SystemDocument20 pagesPIP PNSM0001 - Piping Line Class Design at or SystemKusnadi100% (1)

- 610 10th Ed Datasheets (SI)Document11 pages610 10th Ed Datasheets (SI)sjois_hsNo ratings yet

- Restriction Orifice Sizing CalculationDocument2 pagesRestriction Orifice Sizing CalculationSiLan Subramaniam100% (1)

- Spec For Centrifugal Pumps - APIDocument12 pagesSpec For Centrifugal Pumps - APIjowar100% (1)

- Combustion Gas Turbine Specification SheetDocument10 pagesCombustion Gas Turbine Specification SheettutuionutNo ratings yet

- Hps 165958ecol AlsDocument195 pagesHps 165958ecol AlsKerry DillonNo ratings yet

- K02 Mechanical Seal Leak - RCA DocumentDocument8 pagesK02 Mechanical Seal Leak - RCA DocumentMidha NeerNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- API676 DatasheetDocument2 pagesAPI676 DatasheetLuvys Garcia MartinezNo ratings yet

- Native Data Sheet Asme b73.1Document4 pagesNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- Seat Leakage GuideDocument16 pagesSeat Leakage GuideLv RamanNo ratings yet

- Triplex Plunger PumpDocument163 pagesTriplex Plunger PumpBTconcord50% (2)

- List of API StandardsDocument3 pagesList of API StandardsMuthuKumar Arunachalam100% (7)

- Installation Manual: Manual 6687B Hydril I-P Series Pulsation DampenersDocument20 pagesInstallation Manual: Manual 6687B Hydril I-P Series Pulsation DampenersGerman VillalobosNo ratings yet

- SIHI Side Channel PumpsDocument7 pagesSIHI Side Channel PumpsChristian VargasNo ratings yet

- API 682 BasicsDocument8 pagesAPI 682 BasicsIslam FawzyNo ratings yet

- Flow Serve PDFDocument16 pagesFlow Serve PDFtaher100% (1)

- API Standards Guide Pressure Relief SystemsDocument1 pageAPI Standards Guide Pressure Relief SystemsKmt_AeNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- 3620 10th Lores 2Document8 pages3620 10th Lores 2Dinh Quang NhamNo ratings yet

- Orifice Plate Data SheetDocument2 pagesOrifice Plate Data SheethasnacuNo ratings yet

- API 682 GuidelinesDocument28 pagesAPI 682 GuidelinesSergio Solano100% (3)

- SEO-OPTIMIZED TITLEDocument3 pagesSEO-OPTIMIZED TITLEwado11No ratings yet

- API 676 DatasheetDocument2 pagesAPI 676 DatasheetTony_Black9950% (2)

- Asme B16.48-2010 PDFDocument56 pagesAsme B16.48-2010 PDFSleh Fki80% (5)

- API 692 Seal Gas Filters & SeparatorsDocument4 pagesAPI 692 Seal Gas Filters & SeparatorsTasawwur Tahir100% (1)

- API 610 PumpsDocument8 pagesAPI 610 PumpsSaurabh Singh67% (3)

- PT Trieka Aimex Reciprocating Pump Repair ReportDocument18 pagesPT Trieka Aimex Reciprocating Pump Repair ReportAdeImanudinNo ratings yet

- A-115 Cooks Mixer Certis USA SPX-Lightnin Mixer Manual For Model 16Q10 PDFDocument53 pagesA-115 Cooks Mixer Certis USA SPX-Lightnin Mixer Manual For Model 16Q10 PDFFJ L YawatakiNo ratings yet

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- Flange Dimensions and Pressure Ratings ChartDocument24 pagesFlange Dimensions and Pressure Ratings Chartgateauxboy100% (2)

- API 673 3rd Ed Data SheetsDocument27 pagesAPI 673 3rd Ed Data Sheetsjuan ninaNo ratings yet

- ISO Pump DataDocument9 pagesISO Pump DataJanakiraman MalligaNo ratings yet

- Rotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsDocument9 pagesRotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsghostamirNo ratings yet

- Centrifugal Pump Data Sheet for Yanbu Refinery ProjectDocument9 pagesCentrifugal Pump Data Sheet for Yanbu Refinery ProjectJanakiraman MalligaNo ratings yet

- API 610 11th Ed DatasheetDocument13 pagesAPI 610 11th Ed DatasheetHatem ShawkiNo ratings yet

- PROJECT UNITS DATA SHEETDocument7 pagesPROJECT UNITS DATA SHEETHatem ShawkiNo ratings yet

- DS-21-J-0026 - 2 TPCDR Approved PDFDocument40 pagesDS-21-J-0026 - 2 TPCDR Approved PDFsumant.c.singh1694No ratings yet

- Datasheet PompaDocument8 pagesDatasheet PompaagusnnnNo ratings yet

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- 143 Yer Pe MJ3 0004Document9 pages143 Yer Pe MJ3 0004Janakiraman MalligaNo ratings yet

- IELTS Advantage - Reading SkillsDocument139 pagesIELTS Advantage - Reading SkillsYashel Bartolome100% (9)

- Academic Writing Task 2 PDFDocument42 pagesAcademic Writing Task 2 PDFTôi Yêu Tiếng AnhNo ratings yet

- R For BeginnersDocument76 pagesR For BeginnersChiucheng LiuNo ratings yet

- Static Equipment EngineerDocument5 pagesStatic Equipment EngineerSakthikumar ChandrasekaranNo ratings yet

- CAT 2015 - Salient FeaturesDocument2 pagesCAT 2015 - Salient FeaturesSakthikumar ChandrasekaranNo ratings yet

- Handbook of Mechanical Engineering TermsDocument366 pagesHandbook of Mechanical Engineering Termsjakejohns95% (44)

- BOB Check List For Education Loan PDFDocument1 pageBOB Check List For Education Loan PDFSakthikumar ChandrasekaranNo ratings yet

- MATLAB Introduction25 116Document114 pagesMATLAB Introduction25 116Kadiyam VijayNo ratings yet

- Six Sigma PracticeDocument4 pagesSix Sigma PracticeSakthikumar ChandrasekaranNo ratings yet

- Power BI BasicDocument2,387 pagesPower BI BasicSakthikumar Chandrasekaran100% (1)

- Degree Enrollment Report 2013Document65 pagesDegree Enrollment Report 2013Sakthikumar ChandrasekaranNo ratings yet

- Static Equipment EngineerDocument5 pagesStatic Equipment EngineerSakthikumar ChandrasekaranNo ratings yet

- Pressure Vessel Specification PDFDocument14 pagesPressure Vessel Specification PDFSakthikumar ChandrasekaranNo ratings yet

- Common Admission Test (CAT) 2015Document1 pageCommon Admission Test (CAT) 2015Sakthikumar ChandrasekaranNo ratings yet

- MATLAB Introduction25 116Document114 pagesMATLAB Introduction25 116Kadiyam VijayNo ratings yet

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument7 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013No ratings yet

- CAT 2015 - What The Changes Mean For StudentsDocument2 pagesCAT 2015 - What The Changes Mean For StudentsSakthikumar ChandrasekaranNo ratings yet

- Kanthar Sashti KavasamDocument26 pagesKanthar Sashti KavasamSOWMYANo ratings yet

- BS5950 Load CasesDocument46 pagesBS5950 Load CasesthespecifierNo ratings yet

- AaaDocument3 pagesAaaSakthikumar ChandrasekaranNo ratings yet

- Piping PDFDocument46 pagesPiping PDFGORO43100% (1)

- Occidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ADocument45 pagesOccidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ASakthikumar ChandrasekaranNo ratings yet

- Sample Pressure Vessel DatasheetDocument2 pagesSample Pressure Vessel Datasheetvofaith67% (3)

- Tank Fabrication SpecsDocument21 pagesTank Fabrication Specsjlcheefei9258100% (1)

- Pressure Vessel & Process Equipment Design & EngineeringDocument9 pagesPressure Vessel & Process Equipment Design & EngineeringSakthikumar Chandrasekaran0% (1)

- Shell and Tube Heat Exchanger DesignDocument41 pagesShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Api 682 Mechanical Seal Data Sheet For Centrifugal and Rotary PumpsDocument2 pagesApi 682 Mechanical Seal Data Sheet For Centrifugal and Rotary PumpsSakthikumar Chandrasekaran100% (3)

- DTL Series Heat Exchanger Sizing GuideDocument6 pagesDTL Series Heat Exchanger Sizing GuideSakthikumar ChandrasekaranNo ratings yet

- Fundamentals of Heat Exchanger Theory and DesignDocument3 pagesFundamentals of Heat Exchanger Theory and DesignSakthikumar ChandrasekaranNo ratings yet

- Seal Flushing PlansDocument11 pagesSeal Flushing PlansSakthikumar ChandrasekaranNo ratings yet

- STAAD Structural Analysis Software DocumentDocument84 pagesSTAAD Structural Analysis Software DocumentSabu Abdul NoorNo ratings yet

- Matriks Compressor 2023Document27 pagesMatriks Compressor 2023Puji RustantoNo ratings yet

- AT-8600 Series Switch: Hardware ReferenceDocument30 pagesAT-8600 Series Switch: Hardware ReferenceSubbuNo ratings yet

- PGCB ReportDocument36 pagesPGCB ReportNayemul Hasan NayemNo ratings yet

- Arinc Industry Activities Cabin Systems Overview: Version 2018-01Document42 pagesArinc Industry Activities Cabin Systems Overview: Version 2018-01je_carD23No ratings yet

- Sda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Document1 pageSda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Himani PatelNo ratings yet

- Philips 26 PFL 3405 Chassis Tpn1.1e-La SM PDFDocument63 pagesPhilips 26 PFL 3405 Chassis Tpn1.1e-La SM PDFViorel GabrielNo ratings yet

- Дизельные электростанции PramacDocument124 pagesДизельные электростанции PramacBrizmotorsNo ratings yet

- 9303 Part 1 Vol 1 PDFDocument99 pages9303 Part 1 Vol 1 PDFrexthrottleNo ratings yet

- ParkerOriga PDFDocument338 pagesParkerOriga PDFilyesNo ratings yet

- INDUCTORDocument18 pagesINDUCTORBhavaniPrasadNo ratings yet

- Kurnool - 30 NM - RWY 2000Document1 pageKurnool - 30 NM - RWY 2000aeeNo ratings yet

- Instructions Isb YlpDocument3 pagesInstructions Isb YlpVikas BhoomaNo ratings yet

- CV for Mechanical Inspector and Welding InspectorDocument28 pagesCV for Mechanical Inspector and Welding InspectorAJMAL KAREEMNo ratings yet

- Sni+03 6868 2002Document3 pagesSni+03 6868 2002abanghasanNo ratings yet

- ZQYM Diesel Cummins Series Injector 2023.07Document13 pagesZQYM Diesel Cummins Series Injector 2023.07harbh9355No ratings yet

- Request Documents or InfoDocument6 pagesRequest Documents or InfoRashika RampalNo ratings yet

- IEEEtran HOWTO PDFDocument28 pagesIEEEtran HOWTO PDFMario CruzNo ratings yet

- Microstation GuideDocument158 pagesMicrostation GuideMishra KirtiwardhanNo ratings yet

- DA 65we EnglishDocument2 pagesDA 65we EnglishAlvin NguyenNo ratings yet

- High-Temp, Non-Stick Ceramic Cookware CoatingDocument3 pagesHigh-Temp, Non-Stick Ceramic Cookware CoatingTomescu MarianNo ratings yet

- Staggered Truss System - Wikipedia, The Free EncyclopediaDocument3 pagesStaggered Truss System - Wikipedia, The Free EncyclopediashawnideaNo ratings yet

- Answer Key Workbook Academic Plan DynEd Pro Certification B1 1Document22 pagesAnswer Key Workbook Academic Plan DynEd Pro Certification B1 1Dendel Ciprado EbioNo ratings yet

- Understanding Calculation ScriptsDocument17 pagesUnderstanding Calculation ScriptsKrishna TilakNo ratings yet

- Elite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21Document40 pagesElite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21aayush raghav (RA1811003020302)No ratings yet

- Hytherm 500, 600Document2 pagesHytherm 500, 600Oliver OliverNo ratings yet

- Free and Open Source SoftwareDocument31 pagesFree and Open Source Softwaremoin321No ratings yet

- iPLON India SolutionsDocument4 pagesiPLON India Solutionssudhirm16No ratings yet

- Sl1000 MLT User Guide v1 Key TelephoneDocument24 pagesSl1000 MLT User Guide v1 Key TelephoneRavi Sudharsan0% (1)

- Procedure For Management ReviewDocument3 pagesProcedure For Management ReviewMAYMODERN STEELNo ratings yet