Professional Documents

Culture Documents

Model of An Oil Tanker

Uploaded by

Ahmed SalemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model of An Oil Tanker

Uploaded by

Ahmed SalemCopyright:

Available Formats

Model Of An Oil Tanker

MODEL OF AN OIL TANKER

A PROJECT REPORT

Submitted by

DARSHAN SHAJI

DIBIN JOSEPH

JITHIN K.P

JITHIN R

MAHBOOB ALAM

MAHESH P DAMODARAN

In partial fulfillment for the award of the degree

of

BACHELOR OF TECHNOLOGY

In

MARINE ENGINEERING

K M SCHOOL OF MARINE ENGINEERING

COCHIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

COCHIN-682 022

JULY 2011

Model Of An Oil Tanker

CERTIFICATE

This is to certify that that this is a bonafide record of the project entitled MODEL

OF AN OIL TANKER submitted by DARSHAN SHAJI, DIBIN JOSEPH,

JITHIN K.P, JITHIN R, MAHBOOB ALAM, MAHESH P DAMODARAN to the

department of Kunjali Marakkar School of Marine Engineering towards the partial

fulfillment of the requirements for the VIII semester of the B.Tech Degree course in

Marine Engineering of Cochin University of Science and Technology.

Head of the Department

K M School of Marine Engineering

Cochin University of Science and Technology

Project guide

Asst. Prof. K. Vidhyadharan

Model Of An Oil Tanker

ACKNOWLEDGEMENT

First of all we bow our heads in all humbleness to the lord almighty who has given us the

strength to prepare this project well above the level of simplicity and into something

concrete.

We would also like to express our deep sense of gratitude to Director Prof K.A Simon for

providing us the necessary facilities.

We are very thankful to our project guide Asst. Prof. K. Vidhyadharan who was always

been there to show us the right track when the team needed the help and guided us

through the different stages of our project work. We are also very thankful to Prof.

(Dr.) P. V. Sasikumar gave us moral support and helped us in the matters regarding to

project report outline and its presentation.

We are equally thankful to our project coordinator Prof. N.G. Nair for his valuable help.

We would also like to thank the course coordinator Associate Prof. Roy.V.Paul for his

valuable suggestions

Last but not least, we would like to thank our parents and friends and all others who

helped us a lot in gathering different information, collecting data and guided us from time

to time in making the project despite of their busy schedule.

Model Of An Oil Tanker

ABSTRACT

The oil tanker model is a replica of a very large crude carrier (VLCC). The design of a ship

of vlcc deadweight range was done up to the stage of calculation of main dimension which

was then scaled down to obtain the models main dimensions. The scale used for the model

is 1:180. Two real ships of vlcc deadweight range were used to study the features of oil

tankers and to check the correctness of the calculated main dimensions.

The model exhibits key features including hull markings, cargo manifolds, ship

superstructure, survival crafts, mooring arrangement, protection for crew on deck, propeller

and rudder.

Model Of An Oil Tanker

TABLE OF CONTENTS

Page No

CERTIFICATE

ii

ACKNOLEDGEMENT

iii

ABSTRACT

iv

TABLE OF CONTENTS

LIST OF FIGURES

vii

LIST OF TABLES

CHAPTER 1 INTRODUCTION

1.1 OIL TANKERS

1.2 OIL TANKER CATEGORIES

1.3 DOUBLE HULL TANKERS

1.4 STANDARDS FOR THE DOUBLE HULL CONSTRUCTION

OF OIL TANKER

CHAPTER 2 MODEL FAMILIARISATION

7

9

2.1 MODEL DIMENSIONS

2.2 OTHER FEATURES

10

CHAPTER 3 DESIGN

3.1 MISSION ANALYSIS

19

3.2 PARENT SHIP DATA AND ANALYSIS

23

3.3 FIRST ESTIMATE OF THE MAIN DIMENSIONS AND

COEFFICIENTS

25

3.4 FIRST ITERATION

27

3.5 PRILIMINERY GENERAL ARRANGEMENT

28

CHAPTER 4 FBRICATION

32

Model Of An Oil Tanker

CHAPTER 5 DECK ARRANGEMENTS

49

5.1 MOORING ARRANGEMENTS AND LAYOUTS

49

5.2 SCUPPERS AND BULWARK

50

5.3 ANCHORS AND CABLES

50

5.4 WINDLASS

50

5.5 HOSE HANDLING CRANES

51

5.6 DAVITS

52

5.7 LIFEBOATS

52

5.8 FUNNEL

53

5.9 ENGINE CASING

54

5.10 FIRE MAIN

54

CHAPTER 6 SHIP CONSTRUCTION

55

6.1 BOTTOM STRUCTURE

55

6.2 SIDE FRAMING

55

6.3 DECK

57

6.4 BULKHEADS

57

6.5 SUPERSTRUCTURE

57

6.6 WEATHERTIGHT DOORS

58

6.7 FORE END STRUCTURE

58

6.8 RUDDERS

59

6.9 PROPELLERS

60

CHAPTER 7 TANKER SYSTEM

62

7.1 CARGO TANK VENTILATORS

62

7.2 INERT GAS SYSTEM

63

CHAPTER 8 CONCLUSION

66

Model Of An Oil Tanker

REFERENCES

67

Model Of An Oil Tanker

LIST OF FIGURES

Figure No

Title

Page No

1.1

Cargo tank boundary lines

1.2

Cargo tank boundary lines within the bilge for oil tankers

1.3

Cargo tank boundary lines for double bottom space

2.1

Model of Oil Tanker

10

2.2

General Arrangement

11

2.3

Fore End Structure

12

2.4

Ship Side

13

2.5

Weather Deck

14

2.6

Forecastle Deck

15

2.7

Amid Ship

16

2.8

Superstructure

17

2.9

Aft End Structure

18

3.1

Principal Ship Dimensions

21

3.2

Oil Tanker Marbat

30

3.3

Cap Victor

31

4.1

Wood was Selected as the Material

32

4.2

Dimensions were Marked on the Wood Before Cutting

33

4.3

The Wood is Cut Accordingly

33

4.4

Forward Portion is Shaped

34

4.5

Aft End is Shaped

34

4.6

Wooden planks of 4cm Thick are Marked on the Block

35

Model Of An Oil Tanker

4.7

Wooden Planks of 4cm Thick are Cut from the Block

35

4.8

The Planks are Arranged to the Shape of an Open Box

36

4.9

The Joints are made by Hammering in Adhesive Applied

Wooden Nails

37

4.10

Wooden Planks are Inserted at Equal Intervals

38

4.11

The Parallel Middle Body after Inserting Planks

38

4.12

Three Parts are Joined by Wooden Nails and Adhesives

39

4.13

The Parallel Middle Body is Closed

39

4.14

The Lower Edge of the Parallel Middle Body is Shaped

Using a Plane

40

4.15

Fully Assembled Hull

41

4.16

Coating of Filler and Adhesive is Applied

41

4.17

Inverted and Painted Crimson Red Using a Spray Gun

41

4.18

Painting of Crimson Red Completed

42

4.19

Masking Tape is Applied at Summer Load Line

42

4.20

Deep Blue is Applied on the Freeboard

43

4.21

Stages in Fabrication of Superstructure

44

4.22

Using Knitting Wire the Railings were Made

45

4.23

Anchor

45

4.24

Files used for Fabrication

46

4.25

Lifeboat and Life raft

46

4.26

Propeller Hub

47

Model Of An Oil Tanker

4.27

Overall View of Model from Stern

48

5.1

Windlass

51

5.2

Hose Handling Crane

51

5.3

Davit

52

5.4

Funnel

53

6.1

Longitudinally Framed Double Bottom Structure

55

6.2

Side Frame

56

6.3

Deck Plating

57

6.4

Weather tight Door

58

6.5

Fore End Construction

59

6.6

Rudder

60

7.1

High Velocity Vent

62

7.2

Simple High Velocity Vents

63

7.3

Inert Gas System

65

Model Of An Oil Tanker

LIST OF TABLES

Table No

Title

Page No

3.1

Parent Ship Analysis

23

3.2

Analysis of Ratios

24

3.3

Ratio of Main Dimensions

26

3.4

Result of Iteration

27

3.5.

Model Dimensions

28

Model Of An Oil Tanker

CHAPTER 1 - INTRODUCTION

1.1 OIL TANKERS

An oil tanker, also known as a petroleum tanker, is a merchant ship designed for the bulk

transport of oil. There are two basic types of oil tankers: the crude tanker and the product

tanker. Crude tankers move large quantities of unrefined crude oil from its point of

extraction to refineries. Product tankers, generally much smaller, are designed to

move petrochemicals from refineries to points near consuming markets.

Figure 1.1 Oil Tanker Ab Qaiq

Source: Internet

Oil tankers are often classified by their size as well as their occupation. The size

classes range from inland or coastal tankers of a few thousand metric tons

of deadweight (DWT)

to

the

mammoth ultra

large

crude

carriers (ULCCs)

of

550,000 DWT.

Tankers have grown significantly in size since World War II. A typical T2 tanker of

the World War II era was 532 feet (162 m) long and had a capacity of 16,500 DWT. A

modern ultra-large crude carrier (ULCC) can be 1,300 feet (400 m) long and have a

capacity of 500,000 DWT. Several factors encouraged this growth. Hostilities in the Middle

East which interrupted traffic through the Suez Canal contributed, as did nationalization of

Middle East oil refineries.[28] Fierce competition among ship owners also played a part. But

apart from these considerations is a simple economic advantage: the larger an oil tanker is,

the more cheaply it can move crude oil, and the better it can help meet growing demands for

oil.

Model Of An Oil Tanker

In 1958, United States shipping magnate Daniel K. Ludwig broke the barrier of

100,000 long tons of heavy displacement. His Universe Apollo displaced 104,500 long tons,

a 23% increase from the previous record-holder, Universe Leader which also belonged to

Ludwig. The world's largest super tanker was built in 1979 at the Oppama shipyard

by Sumitomo Heavy Industries, Ltd. as the Sea wise Giant. This ship was built with a

capacity of 564,763 DWT, a length overall of 458.45 metres (1,504.1 ft) and a draft of

24.611 metres (80.74 ft). She had 46 tanks, 31,541 square metres (339,500 sq ft) of deck,

and at her full load draft, could not navigate the English Channel. Sea wise Giant was

renamed Happy Giant in 1989, Jahre Viking in 1991, and Knock Nevis in 1999 (when she

was converted into a permanently moored storage tanker). In 2009 she was sold for the last

time, renamed Mont, and scrapped. As of 2011, the world's two largest working super

tankers are the TI class super tankers TI Europe and TI Oceania. These ships were built in

2002 and 2003 as the Hellespont Alhambra and Hellespont Tara for the Greek Hellespont

Steamship

Corporation. Hellespont

sold

these

ships

to Overseas

Ship

holding

Group and Euronav in 2004. Each of the sister ships has a capacity of over 441,500 DWT, a

length overall of 380.0 metres (1,246.7 ft) and a cargo capacity of 3,166,353 barrels

(503,409,900 l). They were the first ULCCs to be double-hulled.[37] To differentiate them

from smaller ULCCs, these ships are sometimes given the V-Plus size designation.

With the exception of the pipeline, the tanker is the most cost-effective way to move

oil today. Worldwide, tankers carry some 2 billion barrels (3.21011 l) annually and the cost

of transportation by tanker amounts to only US$0.02 per gallon at the pump

1.2 OIL TANKER CATEGORIES

IMO distinguishes three categories of tankers that are:

Category 1 - oil tankers of 20,000 tonnes deadweight and above carrying crude

oil, fuel oil, heavy diesel oil or lubricating oil as cargo, and of 30,000 tonnes

deadweight and above carrying other oils, which do not comply with the

requirements for protectively located segregated ballast tanks (commonly known

as Pre-MARPOL tankers)

Category 2 - as category 1, but complying with protectively located segregated

ballast tank requirements (MARPOL tankers), and

Model Of An Oil Tanker

Category 3 - oil tankers of 5,000 tonnes deadweight and above but less than the

tonnage specified for Category 1 and 2 tankers

In 1954 Shell Oil developed the average freight rate assessment (AFRA) system

which classifies tankers of different sizes. To make it an independent instrument, Shell

consulted the London Tanker Brokers Panel (LTBP). At first, they divided the groups as

General Purpose for tankers under 25,000 tons deadweight(DWT); Medium Range for

ships between 25,000 and 45,000 DWT and Large Range for the then-enormous ships that

were larger than 45,000 DWT. The ships became larger during the 1970s, which prompted

rescaling.

The system was developed for tax reasons as the tax authorities wanted evidence that

the internal billing records were correct. Before the New York Mercantile Exchange started

trading crude oil futures in 1983, it was difficult to determine the exact price of oil, which

could change with every contract. Shell and BP, the first companies to use the system,

abandoned the AFRA system in 1983, later followed by the US oil companies. However,

the system is still used today. Besides that, there is the flexible market scale, which takes

typical routes and lots of 500,000 barrels. Merchant oil tankers carry a wide range of

hydrocarbon liquids ranging from crude oil to refined petroleum products. [3] Their size is

measured in deadweight metric tons (DWT). Crude carriers are among the largest, ranging

from 55,000 DWT panamax-sized vessels to ultra-large crude carriers (ULCCs) of over

440,000 DWT.

1.2.1 Suezmax

Suezmax is a naval architecture term for the largest ship measurements capable of transiting

the Suez Canal, and is almost exclusively used in reference to tankers. Since the canal has

no locks, the only serious limiting factors are draft (maximum depth below waterline), and

height due to the Suez Canal Bridge. The current channel depth of the canal allows for a

maximum of 20.1 m (66 ft) of draft, meaning a few fully laden super tankers are too deep to

fit through, and either have to unload part of their cargo to other ships ("transhipment") or to

a pipeline terminal before passing through, or alternatively avoid the Suez Canal and travel

around Cape Agulhas instead. The canal has been deepened in 2009 from 18 to 20 m (60 to

66 ft).The typical deadweight of a suezmax ship is about 240,000 tons and typically has a

beam (width) of 50 m (164.0 ft). Also of note is the maximum head room"air draft"

Model Of An Oil Tanker

limitation of 68 m (223.1 ft), resulting from the 70 m (230 ft) height above water of the

Suez Canal Bridge. Suez Canal Authority produces tables of width and acceptable draft,

which are subject to change. Currently the wetted surface cross sectional area of the ship is

limited by 945 m2, which means 20.1 m (66 ft) of draught for ships with the beam no wider

than 50.0 m (164.0 ft) or 12.2 m (40 ft) of draught for ships with maximum allowed beam

of 77.5 m (254 ft 3 in).

Figure 1.2 Oil Tanker Stena Vision

Source: Internet

1.2.2 Panamax

Panamax and New Panamax are popular terms for the size limits for ships travelling

through the Panama Canal. Formally, the limits and requirements are published by

the Panama Canal Authority (ACP) titled "Vessel Requirements". These requirements also

describe topics like exceptional dry seasonal limits, propulsion, communications and

detailed ships design. The allowable size is limited by the width and length of the

available lock chambers, by the depth of the water in the canal and by the height of

the Bridge of the Americas. Consequently, ships that do not fall within the Panamax-sizes

are called Post Panamax. The limits have influenced those constructing cargo ships, giving

clear parameters for ships destined to traverse the Panama Canal.

Model Of An Oil Tanker

Figure 1.3 Panama Canal Miraflores Locks

Source: Internet

1.2.3 Aframax

An Aframax ship is an oil tanker smaller than 120,000 metric tons deadweight (DWT) and

with a breadth above 32.31 m. The term is based on the Average Freight Rate

Assessment (AFRA) tanker rate system. Aframax class tankers are largely used in the

basins of the Black Sea, the North Sea, the Caribbean Sea, the China Sea and

the Mediterranean. Non-OPEC exporting countries may require the use of Aframax tankers

because the harbours and canals through which these countries export their oil are too small

to accommodate very-large crude carriers (VLCC) and ultra-large crude carriers (ULCCs).

Figure 1.4 The Aframax Tankers Gerd Knutsen

Model Of An Oil Tanker

Source: Internet

"Super tanker" is an informal term used to describe the largest tankers. Today it is

applied to very-large crude carriers (VLCC) and ULCCs with capacity over 250,000 DWT.

These ships can transport 2,000,000 barrels of oil/318 000 metric tons. By way of

comparison, the combined oil consumption of Spain and the United Kingdom in 2005 was

about 3.4 million barrels (540,000 m3) of oil a day. Because of their great size, super tankers

often can not enter port fully loaded. These ships can take on their cargo at off-shore

platforms and single-point moorings. On the other end of the journey, they often pump their

cargo off to smaller tankers at designated lightering points off-coast. A super tankers routes

are generally long, requiring it to stay at sea for extended periods, up to and beyond seventy

days at a time.

Smaller tankers, ranging from well under 10,000 DWT to 80,000 DWT panamax

vessels, generally carry refined petroleum products, and are known as product tankers. The

smallest tankers, with capacities under 10,000 DWT generally work near-coastal and inland

waterways.

1.3 DOUBLE HULL TANKERS

Double hulls' ability to prevent or reduce oil spills led to their being standardized for other

types of ships including oil tankers by the International Convention for the Prevention of

Pollution from Ships or MARPOL Convention.

Model Of An Oil Tanker

A double hull does not protect against major, high-energy collisions or groundings which

cause the majority of oil pollution, despite this being the reason that the double hull was

mandated by United States legislation.

After the Exxon Valdez oil spill disaster, when that ship grounded on Bligh

Reef outside the port of Valdez, Alaska, the US Government required all new oil tankers

built for use between US ports to be equipped with a full double hull. However, the damage

to the Exxon Valdez penetrated sections of the hull (the slops oil tanks) that were protected

by a partial double hull. The double hull required by the new regulations would not have

prevented extensive loss of oil from the Exxon Valdez, though it might have somewhat

limited the losses. Furthermore, a double-hulled tanker does not need longitudinal

bulkheads for longitudinal strength, as the inner hull already provides this. Eliminating

longitudinal bulkheads would result in much wider tanks, significantly increasing the free

surface effect. However, this problem is easily corrected with the addition of anti-slosh

baffles and partial bulkheads.

1.4 STANDARDS FOR THE DOUBLE HULL CONSTRUCTION OF OIL TANKER

MARPOL means the International Convention for the Prevention of Pollution by Ships,

1973, and the Protocols of 1978 and 1997 relating to the Convention, as amended from time

to time;

Oil tanker means a self-propelled vessel that is constructed or adapted primarily to

carry oil in bulk in its cargo spaces, and includes a combination carrier, an NLS tanker as

defined in Annex II of MARPOL or a gas carrier that is carrying a cargo or part cargo of oil

in bulk (note that in the Regulations an oil tanker includes both self-propelled and non-selfpropelled vessels);

Oil tanker delivered after 1 June 1982 has the same meaning as in regulation 1.28.4

of Annex I where it is defined to mean an oil tanker:

1. For which the building contract is placed after 1 June 1979; or

2. In the absence of a building contract, the keel of which is laid or which is at a similar

stager of construction after 1 January 1980; or

3. The delivery of which is after 1 June 1982; or

4. Which has undergone a major conversion:

Model Of An Oil Tanker

for which the contract is placed after 1 June 1979; or

in the absence of a contract, the construction work of which is begun after 1 January

1980; or

which is completed after 1 June 1982;

Oil tanker delivered before 6 July 1996 means an oil tanker which is not an oil

tanker delivered on or after 6 July 1996, as defined in regulation 1.28.5 of Annex I of

MARPOL;

Oil tanker delivered on or after 6 July 1996 refers to an oil tanker mentioned in

subsection 54(1) of the Regulations and has the same meaning as in regulation 1.28.6 of

Annex I of MARPOL were it is defined to mean an oil tanker:

1. For which the building contract is placed on or after 6 July 1993, or

2. In the absence of a building contract, the keel of which is laid or which is at a similar

stage

Of construction on or after 6 January 1994, or

3. The delivery of which is on or after 6 July 1996, or

4. Which has undergone a major conversion:

for which the contract is placed on or after 6 July 1993; or

in the absence of a contract, the construction work of which is begun on or after 6

January 1994; or

which is completed on or after 6 July 1996;

Model Of An Oil Tanker

CHAPTER 2 - MODEL FAMILIARISATION

2.1 MODEL DIMENSIONS

Length overall

183cm

Breadth

30cm

Depth

15.8cm

Draught

10.6cm

Freeboard

5.2cm

2.2 OTHER FEATURES

The ship has been given the name KMSME by our team. The oil tanker belongs to

Category 2 (MARPOL tanker) of IMOs oil tanker classification.

Deadweight

215000t (Very Large Crude Carrier)

Bulbous bow

provided

Machinery space location

Aft

Stern

Transom

Propulsion

Single screw

Propeller

4 blade skewed propeller

Rudder

Semi balanced

Model Of An Oil Tanker

Figure 2.1 Model of the Oil Tanker

Source: Team

Model Of An Oil Tanker

Figure 2.2 General Arrangements

Source: Team

1. Poop Deck

2. Engine Casing

3. Superstructure

4. Pipe Lines

5. Bunker Manifold

6. Weather Deck

7. Fore Castle

Model Of An Oil Tanker

Figure 2.3 Fore-End Structure

Source: Team

1. Name of the ship

2. Freeing Ports

3. Bulbous bow marking

4. Anchor

5. Chafing ring

6. Forward draught marking

7. Bulbous bow

Model Of An Oil Tanker

Figure 2.4 Hull Markings

Source: Team

1. Freeboard

2. Summer Load Line

3. Name of the Ship

4. Bunker Manifold Markings

5. Plimsoll Marking

6. Tug Marking

7. Bulbous Bow Marking

8. Forward Draught Marking

Model Of An Oil Tanker

Figure 2.5 Weather Deck

Source: Team

1. Side Railings

2. Gangway

3. Walkway

4. Cross Over

5. Catwalk

6. Bulwark Stay

Model Of An Oil Tanker

Figure 2.6 Forecastle Deck

Source: Team

1. Railing

2. Bulwark stay

3. Bulwark

4. Bollard

5. Anchor chain

6. Windlass

7. Forecastle space entry

8. Forward mast

Model Of An Oil Tanker

Figure 2.7 Amid ship

Source: Team

1. Walkway

2. Cargo hose handling crane

3. Drip tray

4. Bunker manifold

5. Catwalk

Model Of An Oil Tanker

Figure 2.8 Superstructure

Source: Team

1. Main mast

2. Monkey island

3. Bridge

4. Lifeboat

5. Gravity davit

6. Life raft

7. Weather tight door

8. Engine casing

9. Funnel

10. Mushroom shaped blower suction

Model Of An Oil Tanker

Figure 2.9 Aft End Structure

Source: Team

1. Aft end draught marking

2. Transom stern

3. Propeller blade

4. Rudder stock

5. Propeller hub

6. Rudder

Model Of An Oil Tanker

CHAPTER 3 - DESIGN

3.1 MISSION ANALYSIS

The main dimensions have a decisive effect on many of the ship characteristics. It affects

Stability

Hold capacity

Hydro dynamic qualities such as resistance, manoeuvring,sea keeping

Economic efficiency

Determining the main dimensions,proportions and form coeffient is one of the most

important phases of overall design.

Crude oil tankers are essentially slow speed ships carrying imperishable cargo. The

shipment of crude oil over the last two decades has increased tremendously. Hence the need

for eceonomic optimallity in design,capacity etc is necessiated.

The double skin tankers have a slightly reduced L/D ratio as compared to single skin

tankers. But both have similar B/T and L/T ratios.

Type of ship

Double skin crude oil tanker

Type of cargo

Crude oil

Speed

15 knots

Shape of hull

B.S.R.A

Shape of stern

Transom stern

Shape of stem

Bulbous bow is provided

Model Of An Oil Tanker

Model Of An Oil Tanker

Figure 3.1 Principal Ship Dimensions

Source: Ship Construction

After Perpendicular (AP): A perpendicular drawn to the waterline at the point where the

side of the rudder post meets the summer load line. Where no

rudder post is fitted it is taken as the centre line of the rudder

stock.

Forward Perpendicular (FP): A perpendicular drawn to the waterline at the point where the

fore side of the stem meets the summer load line.

Model Of An Oil Tanker

Length Between Perpendiculars (LBP): The length between the forward and aft

perpendiculars measured along the summer load line.

Amidships: A point midway between the after and forward perpendiculars.

Length Overall (LOA): Length of vessel taken over all extremities.

Base Line: A horizontal line drawn at the top of the keel plate. All vertical moulded

dimensions are measured relative to this line.

Moulded Beam: Measured at the midship section is the maximum moulded breadth of the

ship.

Moulded Draft: Measured from the base line to the summer load line at the midship section.

Moulded Depth: Measured from the base line to the heel of the upper deck beam at the

ships side amidships.

Extreme Beam: The maximum beam taken over all extremities.

Extreme Draft: Taken from the lowest point of keel to the summer load line. Draft marks

represent extreme drafts.

Extreme Depth: Depth of vessel at ships side from upper deck to lowest point of keel.

Half Breadth: Since a ships hull is symmetrical about the longitudinal centre line, often

only the half beam or half breadth at any section is given.

Freeboard: The vertical distance measured at the ships side between the summer load line

(or service draft) and the freeboard deck. The freeboard deck is

normally the uppermost complete deck exposed to weather and

sea which has permanent means of closing all openings, and

below which all openings in the ships side have watertight

closings.

Sheer: Curvature of decks in the longitudinal direction. Measured as the height of deck at

side at any point above the height of deck at side amidships.

Camber (or Round of Beam): Curvature of decks in the transverse direction. Measured as

the height of deck at centre above the height of deck at side.

Rise of Floor (or Dead rise): The rise of the bottom shell plating line above the base line.

This rise is measured at the line of moulded beam.

Half Siding of Keel: The horizontal flat portion of the bottom shell measured to port or

starboard of the ships longitudinal centre line. This is a useful

dimension to know when dry-docking.

Model Of An Oil Tanker

Tumblehome: The inward curvature of the side shell above the summer load line.

Flare: The outward curvature of the side shell above the waterline. It promotes dryness and

is therefore associated with the fore end of ship.

Stem Rake: Inclination of the stem line from the vertical.

Keel Rake: Inclination of the keel line from the horizontal. Trawlers and tugs often have

keels raked aft to give greater depth aft where the propeller

diameter is proportionately larger in this type of vessel. Small

crafts occasionally have forward rake of keel to bring propellers

above the line of keel.

Parallel Middle Body: The length over which the midship section remains constant in area

and shape.

Entrance: The immersed body of the vessel forward of the parallel middle body.

Run: The immersed body of the vessel aft of the parallel middle body.

Tonnage: This is often referred to when the size of the vessel is discussed, and the gross

tonnage is quoted from Lloyds Register. Tonnage is a measure of

the enclosed internal volume of the vessel.

3.2 PARENT SHIP DATA AND ANALYSIS

The relevant data of double skin tankers in the dead weight range of 1,45,000t to 1,55,000t

were analysed and ratios calculated. They are expressed in the tabular form below.

Table 3.1 Parent Ship Analysis

NAME

Dwt

LBP

Vkm

L/B

B/T

T/D

L/D

Fn=v/(gxl)

African ruby

150173

260

45.0

24.3

16.0

15.5

5.78

2.81

.658

10.7

0.149

Atauilo Alves

152980

258

46.0

24.4

17.2

14.5

5.61

2.81

.705

10.5

0.140

British hunter

151459

264

47.8

23.6

17.0

15.5

5.73

2.62

.72

11.9

0.157

Cap georges

148500

264

45.0

22.8

16.1

15.5

5.52

2.71

.707

11.5

0.152

Model Of An Oil Tanker

Chilinh

150500

277

48.0

25.4

17.0

15.0

6.15

2.97

.669

10.9

0.148

Cosmic

150284

263

51.9

22.4

15.3

15.7

5.48

2.64

.676

11.7

0.140

Cossak Pioneer

151892

268

48.0

25.6

16.2

15.4

5.17

3.14

.633

10.7

0.141

Eliomar

150709

263

46.3

22.4

15.3

15.4

5.48

3.19

.683

11.7

0.142

Fair Way

149748

259

46.0

23.9

16.9

15.0

5.60

3.14

.683

10.8

0.143

Front Glory

149300

258

46.0

23.9

16.8

14.9

5.61

2.75

.705

10.7

0.153

Front Pride

149686

258

46.0

23.9

16.8

15.0

5.61

2.73

.704

10.7

0.143

GenmarArinston

151910

256

46.2

23.8

16.8

14.0

5.61

2.96

.704

10.7

0.144

Genmar Sky

151910

256

44.5

23.8

16.8

14.0

5.54

2.44

.671

10.7

0.143

Genmar Travler

149996

260

46.2

24.2

15.6

14.0

5.84

2.68

.686

10.7

0.144

Hudson

149999

264

48.0

23.1

15.9

14.0

5.50

2.81

.738

11.4

0.142

Table 3.2 Analysis of Ratios

RATIO

RANGE

AVERAGE

L/B

5.17-6.15

5.76

L/D

10.47-11.58

11.03

T/D

0.63-0.74

0.69

B/T

2.44-3.19

2.83

Model Of An Oil Tanker

3.3 FIRST ESTIMATE OF THE MAIN DIMENSIONS AND COEFFICIENTS

3.3.1 Symbols List and Their Units

Dwt

Dead weight (t)

Displacement(t)

LBP

Length between perpendiculars (m)

Velocity (kn)

Accelaration due to gravity (m/s2)

Moulded breadth of the ship (m)

Moulded deph of the ship (m)

Draft of the ship (m)

CB

Block coefficient of the ship

Fn

Froude number

3.3.2 Iterative Procedure for Determining Main Dimensions

1. Estimate the weight of the loaded ship

2. [using the typical value of cd=(Dwt/displacement)]

3. ChooseLBP (Using empirical formulae)

4. Determine B,T,D

3.3.2.1 Estimation of loaded displacement

Displacement is estimated using the deadwight to displacement ratio, cD.

CD

= 0.8to 0.86 for tankerss (from existing parent ship data)

CD is taken as 0.85 owing to more steel weight

250000/0.85

294100 t

3.3.2.2 Estimation of length

a) Schneekluth formula:

LBP

0.3 x V0.3 x C

Model Of An Oil Tanker

Where,

in tones, V in knots

C

3.2 if CB is with in the range of 0.48 to 0.85

Assume C

3.2

LBP

315m

b) Ashiks formula:

LBP

(5.35+0.4) x 1/3

382.3m

3.3.2.3 Range of length selected

From the length obtained by the above formula a range of length is selected.The rage is

from 315 to 382m

3.3.2.4 Estimation of block coefficient (CB)

CB

0.975-(0.9xFn)+0.02

Dankwart Formula

Fn

V/(gL)

schneekluth

CB corresponding to length found above is thus calculated.

3.3.2.5 Determination of B, T, D

B,T and D are calculated from the ratios (L/B, B/T, L/D) obtained from parent ships.

Table 3.3 Ratio of Main Dimensions

Ratio

Range

Average

L/B

5.17-6.15

5.76

L/D

10.47-11.58

11.03

T/D

0.63-0.74

0.69

B/T

2.44-3.19

2.83

Model Of An Oil Tanker

3.4 ITERATION

Selected length is L = 315m

Breadth

We have the mean value of L/B= 5.76

B=54m

Draught

We have the mean value of B/T=2.83

T =19.18m

Depth

We have the mean value of L/D=11.03

D= 28.5m

CB =0.75

Displacement

= L.B.T.CB x 1.025 x 1.006

= 253000 t

Table 3.4. Result of Iteration

LBP

315m

54m

28.5m

19.18m

CB

0.75

253000t

DWT

215050t

Model Of An Oil Tanker

Scale used for the model is 1:180

Table 3.5. Model Dimensions

Ship

Model

LOA

33Om

183cm

LBP

315m

175cm

54m

30cm

28.5m

15.8cm

19.2m

10.6cm

3.5 PRILIMINERY GENERAL ARRANGEMENT

The allocation and dimension of main spaces like length of cargo tanks, width of double

skin and height of double bottom etc of double hull tankers are determined by the regulation

13 F MARPOL 73/78 for the construction of new tankers. All new tankers of dead weight

above 5000 t are to have either a double hull or damage to the hull due to collision or

grounding.

The mid deck arrangement makes use of a horizontal subdivision (mid deck) of the

cargo spaces so that the oil pressure is reduced to level less than the hydrostatic pressure. As

a result of even if hull is damaged there oil out flow will be considerably reduced.

Double hull construction makes use of wing tanks and double bottom spaces through

the cargo region, so that even if the outer is damaged oil out flow will not occur. Double

hull construction is the modern trend.

Model Of An Oil Tanker

3.5.1 Ballast Tank or Spaces

According to regulations 13F AND 13G OF MARPOL 73/78 the entire cargo length should

be protected by ballast tanks or spaces other than cargo and fuel oil tanks.

a) Wing Tank or Spaces

Wing tank or spaces should extend the hull length of ship side, from the top of the

double bottom to the upper most deck, disregarding a rounded guwale where fitted.

They should be arranged such that the cargo tanks are located in board of section is

measured at right angles to the side shell as specified below.

W

OR

0.5+Dwt/20000 m

0.5+1500000/20000

8m

= 2m, whichever is the lesser

The minimum value of W is 1m.

b) Double Bottom Tanks or Spaces

At any cross section the depth of each double bottom tank or space is such that the

distance h between the bottom of the cargo tanks and moulded line of the bottom shell

plating measured at right angles to the bottom shell plating is not less than specified

below:

h=B/15= 3.13m

OR

h= 2m, whichever is lesser

The minimum value of h is 1.0m

3.5.2 Size and Arrangement of Cargo Tanks

The length of each cargo tank shall not exceed 10cm or nor of the following values,

whichever is the greatest

When two or more longitudinal bulkheads are provided inside the cargo tanks

i)

For wing cargo tanks

ii)

For centre cargo tanks

0.2LBP

Model Of An Oil Tanker

-if bi/B>1/5

0.2LBP

-if bi/B<1/5

0.2LBP

(0.5 bi/B + 0.1) LBP m, where no centreline bulkhead is provided

(0.25 bi/B + 0.15) LBP m, where a centreline bulkhead is provided

The following are the photos of two oil tankers which have been refered to check the

correctness of our main dimension calculation and also for information on deck

arrangement.

Figure 3.2 Oil Tanker Marbat

Source:Team

Length

: 333m

Breadth

: 60m

DWT

: 315000t

Speed ( Max/Avg )

: 19.6 / 19.6

Flag

: Malta

Model Of An Oil Tanker

Figure 3.3 Cap Victor

Source: Team

Length

: 274m

Breadth

: 48m

DWT

: 157700t

Speed ( Max/Avg )

: 16.5 / 15.1

Flag

: Greece

Model Of An Oil Tanker

CHAPTER 4 - FABRICATION

After completing the design selection and analysis the fabrication was done in steps.

The hull of the model is fabricated from wood. Due to the difference in technique of

fabrication the hull was made in three pieces and joined. The fore and aft portion of the ship

is shaped from solid block of wood using chisel and mallet. The parallel middle body of the

ship is made by joining planed wooden planks from all four sides. The joint is accomplished

by nailing. The parallel middle body is also provided internally with planks placed

transverse similar to the bulkheads of ship. The lower edge o the parallel middle body is

given a radius using plane along full length. The fore and aft portions have been joined with

the parallel middle body using nailed stiffening pieces from inside along with wood

adhesives. After completing the hull form the hull is finished by applying two coatings of

wood protector followed by a fine layer of filler and adhesive which completely eliminates

the joints. The surface is now rubbed gently with emery paper to give a good surface finish.

Now paint is applied over this finished surface.

Figure 4.1 Wood was Selected as the Material

Source: Team

Model Of An Oil Tanker

Figure 4.2 Dimensions were Marked on the Wood Before Cutting

Source: Team

Figure 4.3 The Wood is Cut Accordingly

Source: Team

Model Of An Oil Tanker

Figure 4.4 Forward Portion is Shaped

Source: Team

Figure 4.5 Aft End is Shaped

Source: Team

Model Of An Oil Tanker

Figure 4.6 Wooden planks of 4cm Thick are Marked on the Block

Source: Team

Figure 4.7 Wooden Planks of 4cm Thick are Cut from the Block

Source: Team

Model Of An Oil Tanker

Figure 4.8 The Planks are Arranged to the Shape of an Open Box

Source: Team

Model Of An Oil Tanker

Figure 4.9 The Joints are made by Hammering in Adhesive Applied Wooden Nails

Source: Team

Model Of An Oil Tanker

Figure 4.10 Wooden Planks are Inserted at Equal Intervals

Source: Team

Figure 4.11 The Parallel Middle Body after Inserting Planks

Source: Team

Model Of An Oil Tanker

Figure 4.12 Three Parts are Joined by Wooden Nails and Adhesives

Source: Team

Figure 4.13 The Parallel Middle Body is Closed

Source: Team

Model Of An Oil Tanker

Figure 4.14 The Lower Edge of the Parallel Middle Body is Shaped Using a Plane

Source: Team

Model Of An Oil Tanker

Figure 4.15 Fully Assembled Hull

Source: Team

Figure 4.16 Coating of Filler and Adhesive is Applied

Source: Team

Figure 4.17 Inverted and Painted Crimson Red Using a Spray Gun

Source: Team

Model Of An Oil Tanker

Figure 4.18 Painting of Crimson Red Completed

Source: Team

Figure 4.19 Masking Tape is Applied at Summer Load Line

Source: Team

Model Of An Oil Tanker

Figure 4.20 Deep Blue is Applied on the Freeboard

Source: Team

Model Of An Oil Tanker

The super structure of the model is made according to the drawings made. Copies of

the plan were made and required stencils cut out from it for each member required. These

are then used to get the profiles of all the required pieces marked on the fourex board and

duplex board. It is then cut precisely. Then corresponding fourex and duplex pieces are

joined. The pieces are then joined in order using adhesives to get the shape of

superstructure. Markings are then done on it for completion.

Figure 4.21 Stages in Fabrication of Superstructure

Source: Team

Model Of An Oil Tanker

The railing for the whole superstructure and deck has been made by cutting and

joining fibre threads.

Figure 4.22 Using Knitting Wire the Railings were Made

Source: Team

The ships anchors are shaped from insulating boards using files.

Figure 4.23 Anchor

Source: Team

Model Of An Oil Tanker

Figure 4.24 Files used for Fabrication

Source: Team

The lifeboats and life rafts have been shaped from insulating boards using files.

Figure 4.25 Lifeboat and Life raft

Source: Team

The pipelines on the deck have been made by joining fibre tubes and bents made by

heating.

Model Of An Oil Tanker

The propeller the ship has been made according to the plan. The profile of the skewed

propeller blades are carefully transferred on to the GI sheet and cut using metal strip. The

propeller hub is made from insulating board using files and the blades are attached to it at

required angle.

Figure 4.26 Propeller Hub

Source: Team

Model Of An Oil Tanker

Figure 4.27 Overall View of Model from Stern

Source: Team

Model Of An Oil Tanker

CHAPTER 5- DECK ARRANGEMENTS

5.1 MOORING ARRANGEMENTS AND LAYOUTS

The objective of a good shipboard mooring arrangement is to provide and arrange

equipment to accomplish the following:

a.

Provide for an efficient mooring pattern at conventional piers and Sea Islands

b.

Facilitate safe and quick mooring, unmooring and line- tending operations with

minimum demand on manpower.

c.

Facilitate safe and efficient handling of tugs.

d.

Permit safe and efficient conduct of other customary tanker operations such as hosehandling and mooring alongside of fuel barges.

e.

Allow safe and efficient specific anticipated operations such as ship-to-ship transfers

or canal transits.

f.

Provide for emergency situations such as excessive winds requiring doubling of

lines, emergency towing of disabled ships, or shipboard fires requiring the ship to be

towed off the berth quickly without shipboard assistance.

The primary concern in the shipboard mooring arrangement is suitability for mooring

at conventional piers and Sea Islands, since this is the requirement most commonly

encountered. The principles for an efficient and safe mooring operation at these terminals

are covered in Section 1. These principles apply to ships of all sizes and may be

summarized as follows:

a.

Mooring arrangements should be symmetrical.

b.

Breast lines should be as perpendicular as possible to the longitudinal centre line of

the ship.

c.

Spring lines should be as parallel as possible to the longitudinal centre line of the

ship.

d.

Mooring lines in the same service should have about the same length between the

vessel's winch and the jetty mooring points.

Model Of An Oil Tanker

In addition to the foregoing principles, the following general guidelines should be kept in

mind in laying out the mooring equipment:

a.

Keep mooring areas as clear as possible.

b.

Locate mooring operations as far forward and aft as possible.

5.2 SCUPPERS AND BULWARK

Scuppers are normally in close proximity to the super structure to ensure that there is

adequate drainage of any water to prevent corrosion where freeing ports are designed to

remove large volumes of water quickly that have been shipped due to weather. Scuppers

and freeing port in bulwarks not functioning satisfactorily could greatly reduce stability,

endangering the ship due to the large raising the centre of gravity and the large free surface

effect. Oil tankers have guard rails fitted instead of normal bulwarks as they have very low

freeboard and large open deck areas, thus require that a minimum of 30 percentage freeing

port area would have to be cut in bulwarks to ensure the rapid drainage of water off the

deck, also retention of water on deck would greatly increase the longitudinal bending

moment and possibly cause cracking. By fitting open rails green seas are not retained on

deck and there is no danger of cracks in the rails spreading into the hull.

A bulwark is an extension of the side shell plating above the upper deck and is a

safety barrier for personnel to preventing falling overboard.

5.3 ANCHORS AND CABLES

The forecastle deck houses the windlass or windlasses which raise and lower the anchor and

cable. Various items of mooring equipment, such as bollards, fairleads, etc., are also

arranged around the deck edge. The anchors are housed against the forward side shell,

sometimes in specially recessed pockets. The anchor cable passes through the shell via the

hawse pipe on to the forecastle deck. It travels over the cable stopper and on to the windlass

cable lifter drum. From the cable lifter it drops vertically down into the chain locker below.

5.4 WINDLASS

An anchor windlass is a machine that restrains and manipulates the anchor chain and/or

rope on a boat, allowing the anchor to be raised and lowered. A notched wheel engages the

links of the chain or the rope.

Model Of An Oil Tanker

F i gu r e 5 . 1 W i n d l a s s

Source: Team

5.5 HOSE HANDLING CRANES

During tanker loading and unloading operations large hoses have to be lift from the shore to

the ship deck to connect to the cargo manifolds. For this purpose tankers are provided with

hose handling cranes near to the cargo manifolds.

Figure 5.2 Hose Handling Crane

Source: Team

Model Of An Oil Tanker

5.6 DAVITS

Gravity davit is one the most common arrangement for lifeboat launching on merchant

ships.

Figure 5.3 Davit

Source: Team

5.7 LIFEBOATS

Open and partially enclosed lifeboats are no longer allowed on new constructions.

In addition all lifeboats must use buoyancy material, fire retardant resins and an engine

approved by IMO's SOLAS requirements and U.S. Lifeboats must also follow additional

USCG requirements. In tanker vessel fully enclosed life boats are used and it is mandatory

as per the regulations because of the dangers like fire, toxic vapours and in bulk carrier

vessels these dangers are very less. In tanker vessels when accidents happen there is a great

possibility of the cargo oil to spill in the sea and catches fire. In that situation with open

lifeboats no one can steer thru the water safely without getting roasted. So in tanker vessels

Fire retarded life boats with water sprinkler system are mandatory.

Model Of An Oil Tanker

5.8 FUNNEL

The funnel is a surround and support for the various uptakes which ensure the dispersion of

exhaust gases into the atmosphere and away from the ship. The shape of the funnel is

sometimes determined by the ship owners requirements but more often by smoke clearing

arrangements and the need for streamlining to reduce resistant. The owners housemark or

trademark is often carried on the outside of the funnel structure.

In the funnel ventilation louvers are fitted on the after end below the upper rainflat.

These louvers disperse the exhaust from the various ventilators led up the funnel. Fire flaps

are fitted in the air tight flat beneath these ventilators and are used to shut off the air outlet

from the engine room in the event of a fire. A hinged watertight door is fitted in the funnel

leading out on to the deck upon which the funnel stands. Holes or grilles are cut into the

forward face of the funnel towards the top, and the whistle is fitted on a small seat just aft of

the opening.

Figure 5.4 Funnel

Source: Team

Ladders and platforms are also provided inside the funnel for access purposes. Hugs

are fitted around the outside top shell plating to permit paining of the funnel.

Model Of An Oil Tanker

5.9 ENGINE CASING

The accommodation or upper deck spaces are separated from the engine room or machinery

spaces by the engine casing. Access doors are provided at suitable levels between the engine

casing and the accommodation. The volume enclosed by the casing is made as small as

possible but of sufficient dimensions to allow maintenance and machinery removal from the

engine room. The casing leads up to the upper decks, finishing below the funnel, fresh air is

drawn in through jalousies or jouvers in small fan room off the casing and passes down

trunking into the engine room. The hot air rises up the engine room into the casing and out

of the funnel at the top.

5.10 FIRE MAIN

All cargo ship in excess of 1000 gross tones must have at least two independently driven

fire pumps. Where these two pumps are located in one area an emergency fire pump must

be provided and located remote from the machinery space. The emergency fire pump must

be independently driven by a compression ignition engine or other approved means. Water

mains of sufficient diameter to provide an adequate water supply for the simultaneous

operation of two fire hoses must be connected to the fire pumps. An isolating valve is fitted

to the machinery space fire main.

Model Of An Oil Tanker

CHAPTER 6- SHIP CONSTRUCTION

6.1 BOTTOM STRUCTURE

At the centre line of the bottom structure is located the keel, which is often said to form the

backbone of the ship. This contributes substantially to the longitudinal strength and

effectively distributes local loading caused when docking the ship. The commonest form of

keel is that known as the flat plate keel, and this is fitted in the majority of ocean-going

and other vessels. If a double bottom is fitted the keel is almost inevitably of the flat plate

type. The double bottom of larger ships are usually longitudinally framed.

Figure 6.1 Longitudinally Framed Double Bottom Structure

Source: Ship Construction

6.2 SIDE FRAMING

The ships side framing consists of hold frames at every frame space and web frames at

equal intervals along with longitudinal stiffeners. The plates are welded over this side

framing.

Model Of An Oil Tanker

Figure 6.2 Side Frame

Source: Ship Construction

Model Of An Oil Tanker

6.3 DECK

Figure 6.3 Deck Plating

Source: Ship Construction

6.4 BULKHEADS

The principal bulkheads subdivide the ship hull into a number of large watertight

compartments.

6.5 SUPERSTRUCTURE

Superstructures might be defined as those erections above the freeboard deck which extend

to the ships side or almost to the side. Deckhouses are those erections on deck which are

well within the line of the ships side. Both structures are of importance in the assignment

of the load line as they provide protection for the openings through the freeboard deck. Of

particular importance in this respect are the end bulkheads of the superstructures,

particularly the bridge front which is to withstand the force of any seas shipped. The bridge

structure amidships or the poop aft are, in accordance with statutory regulations, provided as

protection for the machinery openings. It is possible however to dispense with these houses

or superstructures and increase considerably the scantlings of the exposed machinery

casing. Unless an excessive sheer is provided on the uppermost deck it is necessary to fit a

forecastle forward to give added protection in a seaway. Each structure is utilized to the full,

the after structure carrying virtually all the accommodation in modern ships. The crew may

Model Of An Oil Tanker

be located all aft in the poop structure or partly housed in any bridge structure with the

navigating spaces.

Of great structural importance is the strength of the vessel where superstructures and

deckhouses terminate and are non-continuous. At these discontinuities, large stresses may

arise and additional strengthening will be required locally as indicated in the following

notes on the construction.

6.6 WEATHERTIGHT DOORS

The integrity of houses on the freeboard and other decks which protect the openings in these

decks must be maintained. Access openings must be provided to the houses and

weathertight doors are fitted to these openings. These must comply with the requirements of

the Load Line Convention and are steel doors which may be secured and made watertight

from either side. Weathertightness is maintained by a rubber gasket at the frame of the door.

Figure 6.4 Weather tight Door

Source: Ship Construction

6.7 FORE END STRUCTURE

An overall view of the fore end structure, and the panting stiffening arrangements are of

particular importance. These have already been dealt with in detail earlier as they are

closely associated with the shell plating.

Model Of An Oil Tanker

On the forecastle deck the heavy windlass seating is securely fastened, and given

considerable support. The deck plating thickness is increased locally and smaller pillars

with heavier beams and local fore and aft intercostals, or a centre line pillar bulkhead, may

be fitted below the windlass.

Figure 6.5 Fore End Construction

Source: Ship Construction

6.7.1 Bulbous Bows

A greater degree of plate curvature is involved, unless a rather convenient cylindrical form

is adopted and fitted into the bow as a single unit. Floors are fitted at every frame space in

the bulb, and a centre line wash bulkhead is introduced when the bulb is large. Transverses

are fitted at about every fifth frame in long bulbs. Shell plating covering the bulb has an

increased thickness similar to that of a radiused plate stem below the waterline.

6.8 RUDDERS

Many of the rudders which are found on present-day ships are semi balanced, i.e. they have

a small proportion of their lateral area forward of the turning axis (less than 20 per cent).

Model Of An Oil Tanker

Pintles on which the rudder turns in the gudgeons have a taper on the radius, and a

bearing length which exceeds the diameter. Rudder stock may be of cast or forged steel, and

its meter is determined in accordance with the torque and any bending moment it is to

withstand. The weight of the rudder may be carried partly by the lower pintle and partly by

a rudder bearer within the hull.

Figure 6.6 Rudder

Source: Ship Construction

6.9 PROPELLERS

It is important that the propeller is adequately immersed at the service drafts and that there

are good clearances between its working diameter and the surrounding hull structure. The

bore of the propeller boss is tapered to fit the tail shaft and the propeller may be keyed onto

this shaft; a large locking nut is then fitted to secure the propeller on the shaft. For securing

Model Of An Oil Tanker

the propeller a patent nut with a built in hydraulic jack providing a frictional grip between

the propeller and tail shaft is available. A fairing cone is provided to cover the securing nut.

Model Of An Oil Tanker

CHAPTER 7- TANKER SYSTEM

7.1 CARGO TANK VENTILATORS

The cargo tank ventilators are to be entirely separate from air pipes from other

compartments of the tanker and positioned so that flammable vapour emissions cannot be

admitted to other spaces or areas containing any source of ignition.

7.1.1 High Velocity Vents

Tank vapours can be released and sent clear of the decks during loading through large high

velocity vents. This type has a moving orifice, held down by a counterweight to seal around

the bottom of a fixed cone. Pressure build up in the tank as filling proceeds causes the

moving orifice to lift. The small gap between orifice lip and the fixed cone gives high

velocity to the emitted vapour. It is directed upwards with an estimated velocity of 30m/s.

Air drawn in by the ejector effect dilutes the plume.

Figure 7.1 High Velocity Vent

Source: Marine Auxiliary Machinery

Model Of An Oil Tanker

7.1.2 Simple High Velocity Vent

A simpler design has two weighted flaps which are pushed open by pressure build up to

achieve a similar nozzle effect. The gauze flame traps and vents tend to collect a sticky

residue which should be cleaned off regularly to ensure unimpeded venting.

Figure 7.2 Simple High Velocity Vents

Source: Marine Auxiliary Machinery

7.1.3 Pressure Vaccum Valve

Moderate pressures of 0.24 bar acting on the large surface in liquid cargo tanks are

sufficient to cause damage and rupture. The pressure on each unit of area multiplied by the

total area gives a very large loading on the underside of the top of a tank or other surfaces.

Distortion can result or the metal plate may be ruptured.

7.2 INERT GAS SYSTEM

The inert gas system is to be so designed and operated as to render and maintain the

atmosphere of the cargo tanks non-flammable, other than when the tanks are gas free.

Model Of An Oil Tanker

Hydrocarbon gas normally encountered in oil tanks cannot burn in an atmosphere

containing less than 11 per cent of oxygen by volume, thus if the oxygen content in a cargo

tank is kept below, say, 8 per cent by volume fire or explosion in the vapour space should

not occur. Inert gas introduced into the tank will reduce the air (oxygen) content.

On an oil tanker, inert gas may be produced by one of two processes:

(1) Ships with main or auxiliary boilers normally use the flue gas which contains typically

only 2 to 4 per cent by volume of oxygen. This is scrubbed with sea water to cool it and to

remove sulphur dioxide and particulates, and it is then blown into the tanks through a fixed

pipe distribution system.

(2) On diesel engine ships the engine exhaust gas will contain too high an oxygen level for

use as an inert gas. An inert gas generating plant may then be used to produce gas by

burning diesel or light fuel oil. The gas is scrubbed and used in the same way as boiler flue

gas.

Non-return barriers in the form of a deck water seal, and non-return valve are

maintained between the machinery space and deck distribution system to ensure no

petroleum gas or liquid petroleum passes back through the system to the machinery space.

The double hull and double bottom spaces of tankers required to have an inert gas

system are to have connections for the supply of inert gas.

Model Of An Oil Tanker

Figure 7.3 Inert Gas System

Source: Internet

7.2.1 Deck Seal

The fan discharge to the deck main via a seal which prevents back flow of gases. The seals

can be classified as wet or dry seals. Both types involves feeding inert gas through a flooded

trough. In dry seal type a venture gas outlet is used which effectively pulls the water away

from the end of the gas inlet at high flows allowing the inert gas to bypass the water trough.

The reason for developing this type of seal was because early wet-type seals frequently

caused water carry-over into the system. As with other components in the inert gas system

the internal surfaces of the deck seal must be corrosion protected usually by a rubber lining.

Model Of An Oil Tanker

CHAPTER 8 CONCLUSION

A suitable design was selected. The material used for the hull is wood and the material used

in the construction of the superstructure is hard board. All the equipments on the deck are

made of plastic mouldings. The minute details on the deck are in accordance with the design

of the vessel we had selected as the base.

As our project was supposed to be a still model we have not performed any test and trials on

the model. Thus we believe we have been able to construct the model in a satisfactory

manner and have provided the model with all the necessary details to the best of our

knowledge.

Model Of An Oil Tanker

REFERENCES

1. Dr. Cowley James, (2004) Fire Safety at Sea, IMarEST, London.

2. Eyres, D. J., (2007) Ship Construction, MPG Books Ltd, Great Britain.

3. McGeorge, H.D., (1995) Marine Auxiliary Machinery, MPG Books Ltd, Great

Britain.

4. Dr. Taylor, D. A., (1998) Merchant Ship Construction, IMarEST, United Kingdom

5. Consolidated Edition, (2005) Load Lines, IMO Publications, United Kingdom

You might also like

- Propulsion Trends in Tankers - HTMDocument22 pagesPropulsion Trends in Tankers - HTMlesmosNo ratings yet

- OTF CompleteDocument86 pagesOTF CompleteBrijendra Kumar Srivastava100% (1)

- From T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedFrom EverandFrom T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedNo ratings yet

- 20K DWT Bulk Carrier Tech SpecDocument97 pages20K DWT Bulk Carrier Tech Specİbrahim Aydın100% (4)

- General Arrangement Plan Lecture PDFDocument58 pagesGeneral Arrangement Plan Lecture PDFAktarojjaman Milton100% (1)

- Introduction to Ship Design and Naval Architecture BasicsDocument79 pagesIntroduction to Ship Design and Naval Architecture BasicsRENGANATHAN PNo ratings yet

- Ship Parts in DetailsDocument1 pageShip Parts in DetailsalvsburstNo ratings yet

- Ship Evacuation Analysis in Under 40Document20 pagesShip Evacuation Analysis in Under 40SvedenborgNo ratings yet

- Design III Cargo Handling CalculationDocument12 pagesDesign III Cargo Handling CalculationSean GyarinoNo ratings yet

- Lecture Notes of Naval Architecture I PDFDocument151 pagesLecture Notes of Naval Architecture I PDFPatrick Arances100% (2)

- Structural Strength of Ships LectureDocument181 pagesStructural Strength of Ships LectureJorge SilvaNo ratings yet

- Recent Advances in Damage Stability AssessmentDocument18 pagesRecent Advances in Damage Stability AssessmentgksahaNo ratings yet

- Rudder DesignDocument19 pagesRudder DesignRamkumar100% (1)

- Preliminary Design of 25,000-Ton General Cargo VesselDocument32 pagesPreliminary Design of 25,000-Ton General Cargo VesselRama KrishnaNo ratings yet

- SD 1.3.3 Bulk CarriersDocument36 pagesSD 1.3.3 Bulk CarriersMphil Averomar100% (1)

- Reversing Gears of A Marine Diesel EngineDocument4 pagesReversing Gears of A Marine Diesel Engineashry_tarekNo ratings yet

- Garme2012 - Resistance and PoweringDocument63 pagesGarme2012 - Resistance and PoweringSrikanth ShivramNo ratings yet

- Aft End Arrangement KalaiDocument19 pagesAft End Arrangement KalaiJeevanandhan PandiyanNo ratings yet

- ITTC Trials AnalysisDocument15 pagesITTC Trials Analysispapaki2100% (1)

- Sill Height of Watertight Door and HatchesDocument3 pagesSill Height of Watertight Door and HatchesOzata Tersanesi100% (1)

- Ship Type and Cargo DescriptionDocument12 pagesShip Type and Cargo DescriptionLiviu VladNo ratings yet

- Anchor Systems For Ships: Civil Engineering Electrical Engineering Marine Engineering Mechanical EngineeringDocument17 pagesAnchor Systems For Ships: Civil Engineering Electrical Engineering Marine Engineering Mechanical EngineeringrajishrrrNo ratings yet

- Stability StandardDocument78 pagesStability StandardJORGE ARTURO TORIBIO HUERTANo ratings yet

- Safeloading PDFDocument54 pagesSafeloading PDFFradjNo ratings yet

- Bottom ConstructionDocument8 pagesBottom ConstructionarmanimamsNo ratings yet

- Naval Arch Written QuestionsDocument47 pagesNaval Arch Written QuestionsOjasv50% (2)

- Ship Form Coefficient PDFDocument10 pagesShip Form Coefficient PDFSurendra Kumar SinghNo ratings yet

- Grontmij's Marine Department Designs Efficient 2300 TEU Container Feeder VesselDocument4 pagesGrontmij's Marine Department Designs Efficient 2300 TEU Container Feeder VesselJEORJENo ratings yet

- Ship Geometry PDFDocument81 pagesShip Geometry PDFignasius wisnu100% (1)

- Naval ArchitectureDocument11 pagesNaval ArchitecturePrabhat ChoudharyNo ratings yet

- Tanker SizeThere Are Different Tanker Sizes Used For The International Transportation of OilDocument4 pagesTanker SizeThere Are Different Tanker Sizes Used For The International Transportation of OilAnonymous UCveMQNo ratings yet

- Bulkheads FinalDocument15 pagesBulkheads Finalvikram5211No ratings yet

- 1 Piping Systems On ShipsDocument9 pages1 Piping Systems On ShipsBang NielNo ratings yet

- Anchor Chain Locker Volume CalculationDocument1 pageAnchor Chain Locker Volume Calculationbasant_konatNo ratings yet

- Propulsion Trend in Bulk CarrierDocument22 pagesPropulsion Trend in Bulk CarrierDương Văn ThanhNo ratings yet

- ITTC High Speed Marine Vehicles-Propulsion TestDocument6 pagesITTC High Speed Marine Vehicles-Propulsion TestGayatri LakkimsettiNo ratings yet

- Ship Hull DesignDocument66 pagesShip Hull DesignRiyan EsapermanaNo ratings yet

- Question:-Resistance QuestionsDocument3 pagesQuestion:-Resistance Questionsaimri_cochinNo ratings yet

- Initial Estimate of Ship Particulars FOR AFRAMAX CRUDE OIL TANKERDocument46 pagesInitial Estimate of Ship Particulars FOR AFRAMAX CRUDE OIL TANKERpramodkb_cusat100% (1)

- MULTIPURPOSE SHIP SPEcsDocument14 pagesMULTIPURPOSE SHIP SPEcsapi-26497192No ratings yet

- Basic Naval Architecture Chapter - 3 Classification Societies and Governmental OrganizationsDocument38 pagesBasic Naval Architecture Chapter - 3 Classification Societies and Governmental OrganizationsAtreyapurapu Krishna0% (1)

- Form CoefficientsDocument5 pagesForm CoefficientsjishnusajiNo ratings yet

- Shipbuilding Drawing-II SBT-8054 T P C 0 9 3Document2 pagesShipbuilding Drawing-II SBT-8054 T P C 0 9 3reaz uddin100% (1)

- SD-1.4.1-Container Carriers PDFDocument26 pagesSD-1.4.1-Container Carriers PDFTommyVercetti100% (1)

- Naval Auxiliary MachineryDocument278 pagesNaval Auxiliary MachinerymohzainalabidinNo ratings yet

- Intro To NADocument11 pagesIntro To NAAnshuman SharmaNo ratings yet

- Suezmax Oil Tanker Tankers 2021Document22 pagesSuezmax Oil Tanker Tankers 2021Виктор ВладимировичNo ratings yet

- Container Ship Displacement, LWT and DWT CalculationDocument28 pagesContainer Ship Displacement, LWT and DWT CalculationBudi PrayitnoNo ratings yet

- Preliminary Capacity PlanDocument10 pagesPreliminary Capacity PlantheyagarajanNo ratings yet

- Methods of Longitudinal Weight DistributionDocument24 pagesMethods of Longitudinal Weight DistributionWafaà WafaNo ratings yet

- Tut.1 Ship Design Terminology and General Arragment2Document50 pagesTut.1 Ship Design Terminology and General Arragment2elvisNo ratings yet

- Ferry Car Ramp Operating Mechanism Re Design Engineering EssayDocument13 pagesFerry Car Ramp Operating Mechanism Re Design Engineering EssayHND Assignment HelpNo ratings yet

- Basic ship design and hull form characteristicsDocument75 pagesBasic ship design and hull form characteristicsRENGANATHAN P100% (1)

- Ship S PartsDocument33 pagesShip S PartsRuan Jamir100% (3)

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsFrom EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsRating: 4.5 out of 5 stars4.5/5 (3)

- Gas Turbine Working PrincipalsDocument27 pagesGas Turbine Working PrincipalsAhmed SalemNo ratings yet

- Guidelines For The Prevention of Human Error Aboard Ships PDFDocument42 pagesGuidelines For The Prevention of Human Error Aboard Ships PDFAhmed SalemNo ratings yet

- Conversation On Merchant Ship PDFDocument115 pagesConversation On Merchant Ship PDFAhmed Salem100% (1)

- Maritime Resource ManagementDocument13 pagesMaritime Resource ManagementAhmed SalemNo ratings yet

- Forty Years of FerriesDocument9 pagesForty Years of FerriesAhmed SalemNo ratings yet

- Guidelines For The Prevention of Human Error Aboard Ships PDFDocument42 pagesGuidelines For The Prevention of Human Error Aboard Ships PDFAhmed SalemNo ratings yet

- Conversation On Merchant Ship PDFDocument115 pagesConversation On Merchant Ship PDFAhmed Salem100% (1)

- Preglednica A III 2Document10 pagesPreglednica A III 2Ahmed SalemNo ratings yet

- Arctic Passion News 2 2018 Testing-EEDI-bow-FormsDocument2 pagesArctic Passion News 2 2018 Testing-EEDI-bow-FormsAhmed SalemNo ratings yet

- Energy Efficiency Design IndexDocument13 pagesEnergy Efficiency Design IndexVidoz DiedozzNo ratings yet

- ABS Rules-Safety of Passenger ShipsDocument128 pagesABS Rules-Safety of Passenger ShipsAhmed SalemNo ratings yet

- MRMDocument13 pagesMRMkum512No ratings yet

- Roll-On Roll-Off Ships Cargo Handling SystemsDocument6 pagesRoll-On Roll-Off Ships Cargo Handling SystemsAhmed SalemNo ratings yet

- Ship Construction PDFDocument118 pagesShip Construction PDFAhmed SalemNo ratings yet

- Reed's Vol 05 Ship Construction For Marine StudentsDocument96 pagesReed's Vol 05 Ship Construction For Marine StudentsAhmed SalemNo ratings yet

- Analysis and Design of Ship StructureDocument76 pagesAnalysis and Design of Ship Structureapi-26548846100% (3)

- Faster, Better, Safer, HSCDocument94 pagesFaster, Better, Safer, HSCAhmed SalemNo ratings yet

- Oows 0305Document2 pagesOows 0305Ahmed SalemNo ratings yet

- Question of Rudder and PropellerDocument1 pageQuestion of Rudder and PropellerAhmed SalemNo ratings yet

- General Cargo Ship Structure, Equipment & ArrangementDocument10 pagesGeneral Cargo Ship Structure, Equipment & ArrangementAhmed SalemNo ratings yet

- CargoDocument16 pagesCargoAhmed SalemNo ratings yet

- CargoDocument16 pagesCargoAhmed SalemNo ratings yet

- Container ShipsDocument11 pagesContainer ShipsAhmed SalemNo ratings yet

- BS1 Tjedan06 Types of Ships - 2Document23 pagesBS1 Tjedan06 Types of Ships - 2Ahmed SalemNo ratings yet

- 8 Energy Saving by Lighting 5500 TEU Container VesselDocument5 pages8 Energy Saving by Lighting 5500 TEU Container VesselAhmed SalemNo ratings yet

- Gravic Remark Office OMR Offer V - 1Document13 pagesGravic Remark Office OMR Offer V - 1Ahmed SalemNo ratings yet

- 001 78newDocument66 pages001 78newAhmed SalemNo ratings yet

- Casualty Analysis of Large TankersDocument11 pagesCasualty Analysis of Large TankersAhmed SalemNo ratings yet

- Ole Skeltved 3 Marts 08Document30 pagesOle Skeltved 3 Marts 08Ahmed SalemNo ratings yet

- Safety Plan and General ArrangementDocument2 pagesSafety Plan and General ArrangementAhmed SalemNo ratings yet

- HMD's Prestige in ShipbuildingDocument15 pagesHMD's Prestige in Shipbuildingkawaumi2005No ratings yet

- Machinery Selection and Warship Design LecturesDocument31 pagesMachinery Selection and Warship Design Lecturesknowme73No ratings yet

- Charter PartyDocument3 pagesCharter PartyJa KovNo ratings yet

- Daikai: Engineering ProfileDocument20 pagesDaikai: Engineering Profilewellington freitasNo ratings yet

- Subject: Transportation (Finals Tips) Professor: Atty. Ampil By: Butch Ramiro and Pierre Martin Reyes C2013Document6 pagesSubject: Transportation (Finals Tips) Professor: Atty. Ampil By: Butch Ramiro and Pierre Martin Reyes C2013Mae SampangNo ratings yet

- Captura de Ecrã 2023-05-29 À(s) 12.30.19Document1 pageCaptura de Ecrã 2023-05-29 À(s) 12.30.19Lorena TeodoroNo ratings yet

- Safety Drill Evaluvation Report: CommentsDocument2 pagesSafety Drill Evaluvation Report: CommentsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Duties and Responsibilities of PersonnelDocument9 pagesDuties and Responsibilities of PersonnelKyla ResuelloNo ratings yet

- Titanic PowerpointDocument30 pagesTitanic Powerpointthethingsyoucanread100% (1)

- 12GL1866 20301061012115123 Oct26122210Document1 page12GL1866 20301061012115123 Oct26122210lucifer121319No ratings yet

- Basic Purse Seine Crew Course Learners GuideDocument64 pagesBasic Purse Seine Crew Course Learners Guidefarhan100% (1)

- Arriving at A Port.Document40 pagesArriving at A Port.Carlos BermudezNo ratings yet

- Everything You Need to Know About Cruise Ship Styles and FacilitiesDocument18 pagesEverything You Need to Know About Cruise Ship Styles and FacilitiesRonajane BaelNo ratings yet

- No. 103 Guidance For The Compilation of The IOPP Supplement No. 103Document2 pagesNo. 103 Guidance For The Compilation of The IOPP Supplement No. 103aakhyar_2No ratings yet

- Section 16 Superstructures and DeckhousesDocument4 pagesSection 16 Superstructures and DeckhousesJ T Mendonça SantosNo ratings yet

- Federal Barge Lines CollectionDocument6 pagesFederal Barge Lines CollectionPaul BradeaNo ratings yet

- Diamond 53 Brochure PDFDocument3 pagesDiamond 53 Brochure PDFJaryNo ratings yet

- Worldwide Shipbuilding Productivity Status and TrendsDocument50 pagesWorldwide Shipbuilding Productivity Status and TrendsozgenmfNo ratings yet

- SOLAS CHAPTERS I-III REGULATIONS FOR SHIP SAFETYDocument24 pagesSOLAS CHAPTERS I-III REGULATIONS FOR SHIP SAFETYRisky RamadhanNo ratings yet

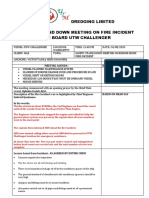

- Dredging Limited Safety Stand Down Meeting On Fire Incident On Board Utw ChallengerDocument2 pagesDredging Limited Safety Stand Down Meeting On Fire Incident On Board Utw ChallengerVICTORNo ratings yet

- OMMS15ExamTask Adrian NovelDocument5 pagesOMMS15ExamTask Adrian NovelAdrian NofxNo ratings yet

- Pilotage Bulletin May 2016Document6 pagesPilotage Bulletin May 2016Alexandre Gonçalves da RochaNo ratings yet

- Union Carbide VS Manila Railroad CompanyDocument8 pagesUnion Carbide VS Manila Railroad CompanyLhai Tabajonda-MallillinNo ratings yet

- Buttons of The Shipping Cos Ferries EtcDocument17 pagesButtons of The Shipping Cos Ferries Etccorinne mills100% (2)

- BilgingDocument104 pagesBilginggeminiansailor100% (2)

- BL en Excel en Blanco Desarrollado en Clases Oct. 31Document4 pagesBL en Excel en Blanco Desarrollado en Clases Oct. 31luanacardona35No ratings yet

- Cospas SarsatDocument5 pagesCospas SarsatPatricia CottonNo ratings yet

- Ship TerminologyDocument32 pagesShip TerminologyRagunath KarthickNo ratings yet

- Asm Orals Question Set Till March19Document195 pagesAsm Orals Question Set Till March19vikram sahu100% (1)

- Kinds of Merchant and Navy VesselsDocument7 pagesKinds of Merchant and Navy Vesselsmaria murilloNo ratings yet