Professional Documents

Culture Documents

Pump and Pipe Sizing

Uploaded by

CHANADASCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump and Pipe Sizing

Uploaded by

CHANADASCopyright:

Available Formats

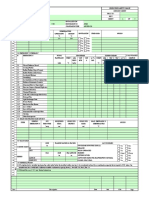

Determining Flowrates Through Pump an

http://excelcalculations.blogspot.com

For complete documentation click here

Parameters

Legend

Liquid density (kg m-3)

Liquid viscosity (Pa s)

1000

0.001

Gravity (m s-2)

Pipe diameter (m)

Pipe length (m)

Pipe roughness (m)

9.81

0.1

10

0.0001

Pipe cross-sectional area (m2)

Pump Curve Coefficients

Hpump =

Calculations

Guess value for liquid velocity

Reynolds number

Friction factor (Haaland)

Pump curve

System curve

Pump curve - System curve

Parameters specified by user

Intermediate calculations

Cells used in Goal Seek

0.007854

0.1

-0.001 Q

0.943791

94379.13

0.022083

0.100254

0.099993

0.000262

0 Q^2

Set to an initial guess value

With Goal Seek, vary this number

so that this number is zero

gh Pump and System Curves

ters specified by user

diate calculations

ed in Goal Seek

his number

Balancing a Pump Curve against a System Cu

Introduction

This article will demonstrate how you can balance a pump curve agai

First, we'll develop the equations that determine the liquid velocity i

The spreadsheet can be downloaded here, but read

Pump and Pipe System

Consider a centrifugal pump receiving liquid from a reservoir and for

First consider the pump. Its flowrate-head curve is can be described

Equation 1

But the volumetric flowrate is

Equation 2

where A is the cross-sectional area of the pipe and V is the liquid velo

Equation 3

This equation now describes the head produced by the pump as a fun

Now consider the pipe. Frictional head loss through the pipe can be d

Equation 4

We'll call Equation 4 the System Curve. f is the fric

Equation 5

where Re is the Reynolds Number.

Equation 6

The Haaland equation is only valid in turbulent flow, i.e. if the Reyno

For our pump and pipe system, the pump head is equal to the head lo

Equation 7

We can now use Excel to find the liquid velocity that satisfies Equatio

Excel Implementation

The Excel spreadsheet uses this cell coloring convention.

Step 1. First define the parameters and calculate the cross-sectional

Step 2. Now define the coefficients of the pump curve

Step 3. Set up the calculations required by Goal Seek

Step 4. Go to Data > What-If Analysis > Goal Seek. Make the changes

You should now have the correct value of the liquid velocity.

Ensure that the Reynolds number is greater than 2500 so that our assu

Visual Basic Macro to Automate G

If you're really keen, you can use Visual Basic to automate Goal Seek.

Private Sub Worksheet_Change(ByVal Target As Range)

Dim bSuccess As Boolean

On Error Resume Next

bSuccess = Range("C23").GoalSeek(0, Range("c18"))

On Error GoTo 0

If Not bSuccess Then

MsgBox "Goal Seek Failed"

End If

End Sub

Whenever any value in the worksheet is changed, the Worksheet_Cha

urve against a System Curve

w you can balance a pump curve against a system curve to calculate liquid velocity with Excel.

ns that determine the liquid velocity in a simple pump and pipe system. Then we'll discuss how these equations be solved using Excel's Goal Seek fea

e downloaded here, but read the rest of this article if you'd like to understand the theory.

System

eiving liquid from a reservoir and forcing liquid through a pipe to a reservoir.

wrate-head curve is can be described by a polynomial derived from empirical data, where a, b and c are best-fit coefficients, and Q is the volumetri

ea of the pipe and V is the liquid velocity through the pipe. Substituting Equation 2 into Equation 1 to eliminate Q gives

head produced by the pump as a function of the liquid velocity through the pipe.

al head loss through the pipe can be described by the Bernoulli equation and written as

e System Curve. f is the friction factor, given by the Haaland Equation.

lid in turbulent flow, i.e. if the Reynolds Number is over 2500.

the pump head is equal to the head loss in the pipe. Hence

e liquid velocity that satisfies Equation 7 (effectively determining the intersection between the pump curve and the system curve).

ntation

cell coloring convention.

ters and calculate the cross-sectional area of the pipe.

ents of the pump curve

required by Goal Seek

alysis > Goal Seek. Make the changes such that we find the liquid velocity that makes difference between pump curve and the system curve equal t

t value of the liquid velocity.

r is greater than 2500 so that our assumption of turbulent flow (and hence the use of the Haaland equation) is verified.

acro to Automate Goal Seek

e Visual Basic to automate Goal Seek.

(ByVal Target As Range)

Seek(0, Range("c18"))

sheet is changed, the Worksheet_Change() event is initiated . The VB code then asks GoalSeek() to find the liquid velocity ("C18") that makes the di

be solved using Excel's Goal Seek feature. Finally, we'll show Visual Basic code that can be used to automate Goal Seek so that any parameter chang

t coefficients, and Q is the volumetric flowrate

d the system curve).

mp curve and the system curve equal to zero.

uid velocity ("C18") that makes the difference between the pump and system curve ("C23") equal to zero.

oal Seek so that any parameter change will automatically calculate the new liquid velocity.

You might also like

- Pump and Pipe SizingDocument2 pagesPump and Pipe SizingEnoch Twumasi100% (1)

- Separator Calculation For MedcoDocument25 pagesSeparator Calculation For MedcoTifano Khristiyanto100% (1)

- Worksheet in Test Nozzle - DesignDocument177 pagesWorksheet in Test Nozzle - DesignkeviletuoNo ratings yet

- Line Sizing Criteria As Per Different StandardsDocument4 pagesLine Sizing Criteria As Per Different Standardsadil alameenNo ratings yet

- Design of A Vapor-Liquid SeparatorDocument2 pagesDesign of A Vapor-Liquid SeparatorpowerveeNo ratings yet

- PSV data sheets for existing refinery steam boilerDocument1 pagePSV data sheets for existing refinery steam boilermaurya888No ratings yet

- NPSH Calculator Head LossDocument7 pagesNPSH Calculator Head LossMuhammad AtharNo ratings yet

- Horizontal Separator Adequacy CheckDocument4 pagesHorizontal Separator Adequacy CheckTech ManagerNo ratings yet

- Equivalent Length CalculationDocument1 pageEquivalent Length CalculationSaeid Rahimi MofradNo ratings yet

- Perforated Pipe Distributor Sizing CalcuDocument6 pagesPerforated Pipe Distributor Sizing CalcuInggit Prillasari100% (1)

- Vertical Knock Out Drum With Wire Mesh For NDocument1 pageVertical Knock Out Drum With Wire Mesh For NwdyouQNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Part 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsDocument1 pagePart 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsRafael ReyesNo ratings yet

- 01 - Transfer Pumps & Texsteam PDFDocument26 pages01 - Transfer Pumps & Texsteam PDFlidia ayuNo ratings yet

- Pump selection and head calculation exampleDocument37 pagesPump selection and head calculation exampleIhsan Wiratama100% (1)

- AutoPIPE QuickStart - Model Modification - WorkbookDocument63 pagesAutoPIPE QuickStart - Model Modification - WorkbookJames100% (1)

- Procees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetDocument17 pagesProcees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetMagesh leoNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Pump Sizing CalculationDocument28 pagesPump Sizing CalculationNguyễn DuyNo ratings yet

- Restriction Orifice Sizing CalculationDocument2 pagesRestriction Orifice Sizing CalculationSiLan Subramaniam100% (1)

- Pump Design - 2Document1 pagePump Design - 2kapsarcNo ratings yet

- Calculation of time needed to mix liquids with pitch blade impellersDocument10 pagesCalculation of time needed to mix liquids with pitch blade impellershadiNo ratings yet

- Line Sizing Design Basis - General Specification PDFDocument11 pagesLine Sizing Design Basis - General Specification PDFSaiKumarNo ratings yet

- Ogpe OGPE Oil Fields: Calculation SheetDocument4 pagesOgpe OGPE Oil Fields: Calculation SheetFaber TrujilloNo ratings yet

- Total Length Calcs For Pipes Valves and Fittings RevADocument11 pagesTotal Length Calcs For Pipes Valves and Fittings RevAjduran_65No ratings yet

- PUMP CALCULATION SHEETDocument4 pagesPUMP CALCULATION SHEETMuhammad BilalNo ratings yet

- Test Cyclone ExcelDocument16 pagesTest Cyclone Excelvivek mishraNo ratings yet

- 12 - NPS Pipe Thickness CalculatorDocument5 pages12 - NPS Pipe Thickness CalculatorSalman KhanNo ratings yet

- Hydraulic Calculation For Pipeline PumpsDocument12 pagesHydraulic Calculation For Pipeline PumpsDEEPAK PAL100% (1)

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetFahmi AtriadiNo ratings yet

- Centrifugal Pump CurvesDocument2 pagesCentrifugal Pump CurvesBesan LaduNo ratings yet

- Centrifugal Pump Calculation Summary Sheet: ConfidentialDocument3 pagesCentrifugal Pump Calculation Summary Sheet: ConfidentialPrafitri KurniawanNo ratings yet

- Calculation of PumpDocument19 pagesCalculation of Pumparifin rizal100% (1)

- Pump Sizing CalculationDocument18 pagesPump Sizing CalculationChaitanya BhattNo ratings yet

- DAT Centrifugal PumpDocument5 pagesDAT Centrifugal PumpEDUARDONo ratings yet

- Three Phase Separator Sizing (Double Weir 2)Document3 pagesThree Phase Separator Sizing (Double Weir 2)12377466790% (2)

- NPSH Calculator For Process EngineerDocument14 pagesNPSH Calculator For Process Engineerlutfi awnNo ratings yet

- Separator Sizing - PPTDocument21 pagesSeparator Sizing - PPTD K SNo ratings yet

- Pipe SizeDocument9 pagesPipe SizezniperxNo ratings yet

- Claus Process CalculationDocument105 pagesClaus Process CalculationDaniel SetyadiNo ratings yet

- Notice: I Have: Engineering CalculationDocument34 pagesNotice: I Have: Engineering CalculationAlexandre GelsiNo ratings yet

- Optimizing Gas/Liquid Separator PerformanceDocument14 pagesOptimizing Gas/Liquid Separator PerformanceWendellReeceFrankNo ratings yet

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- Autoclave ReactorDocument24 pagesAutoclave ReactorMeredith Villarete100% (1)

- How To Read Basic Pump CurvesDocument5 pagesHow To Read Basic Pump CurvesGauravNo ratings yet

- SpreadSheet Centrifugal PumpDocument2 pagesSpreadSheet Centrifugal PumpengenheiroalencarNo ratings yet

- Modeling Cyclone PerformanceDocument4 pagesModeling Cyclone PerformancesergioNo ratings yet

- Flare NetDocument2 pagesFlare NetPetrol SollyNo ratings yet

- Understanding NPSHDocument34 pagesUnderstanding NPSHeliyanto budiartoNo ratings yet

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 pagesNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNo ratings yet

- Pipe Flow ExpertDocument7 pagesPipe Flow ExpertDesnantaGandhaNo ratings yet

- PUMP A Spreadsheet Program For The Calculation of Piping Systems andDocument12 pagesPUMP A Spreadsheet Program For The Calculation of Piping Systems andmsaadullahNo ratings yet

- Prelab3 SolutionDocument8 pagesPrelab3 Solutionksajj100% (1)

- The Mathematics of Pumping Water: AECOM Design BuildDocument9 pagesThe Mathematics of Pumping Water: AECOM Design BuildAdel SharifiNo ratings yet

- Piping SystemsDocument5 pagesPiping SystemsDesislavNo ratings yet

- Lab Report 4Document7 pagesLab Report 4api-300265822100% (1)

- The Mathematics of Pumping Water: AECOM Design BuildDocument9 pagesThe Mathematics of Pumping Water: AECOM Design Buildmabrouk2013No ratings yet

- Pump Sizing CalculationDocument6 pagesPump Sizing CalculationIBIKUNLENo ratings yet

- Steady-State Analyses of Fluid Flow Characteristics For AFWS in PWR Using Simplified CFD MethodsDocument4 pagesSteady-State Analyses of Fluid Flow Characteristics For AFWS in PWR Using Simplified CFD MethodsViswanathan DamodaranNo ratings yet

- Closed Loop Control of PSFB ConverterDocument11 pagesClosed Loop Control of PSFB Converterhodeegits9526No ratings yet

- Fluor Piping Design Layout Training (Lesson 1 Pipe Stress)Document1 pageFluor Piping Design Layout Training (Lesson 1 Pipe Stress)Aroon KumarNo ratings yet

- Astm A106 1999Document13 pagesAstm A106 1999Rolando CastilloNo ratings yet

- Determination of Maximum Span Between Pipe Support Using Bending Stress TheoryDocument4 pagesDetermination of Maximum Span Between Pipe Support Using Bending Stress TheoryMannattil Krishna KumarNo ratings yet

- Heat ExchangerDocument9 pagesHeat ExchangerCHANADASNo ratings yet

- Peng-Robinson EOS For Z-FactorDocument29 pagesPeng-Robinson EOS For Z-FactorCHANADASNo ratings yet

- API RP 1102 Pipeline Crossing Calculations: Input DataDocument2 pagesAPI RP 1102 Pipeline Crossing Calculations: Input DataCHANADAS50% (4)

- AFT Calc1Document24 pagesAFT Calc1Job MateusNo ratings yet

- Sizing Column Distillation C-Factor MethodDocument20 pagesSizing Column Distillation C-Factor MethodCHANADASNo ratings yet

- Pump SizingDocument4 pagesPump SizingNikunj100% (5)

- Ponchon-Savarit distillation diagram for alpha-xylene separationDocument1 pagePonchon-Savarit distillation diagram for alpha-xylene separationCHANADAS100% (1)

- Thermophysical Properties and Glycol Contactor SizingDocument65 pagesThermophysical Properties and Glycol Contactor SizingCHANADASNo ratings yet

- Pump Design WorksheetDocument3 pagesPump Design Worksheetejzuppelli8036100% (8)

- Ivar J. Halvorsen and Sigurd SkogestadDocument19 pagesIvar J. Halvorsen and Sigurd SkogestadCHANADASNo ratings yet

- Simple Multi-Component DistillationDocument120 pagesSimple Multi-Component DistillationCHANADASNo ratings yet

- Workbook Dump User GuideDocument2 pagesWorkbook Dump User GuideVijay RajaindranNo ratings yet

- Section 22 - Sulfur RecoveryDocument145 pagesSection 22 - Sulfur RecoveryCHANADAS100% (1)

- 01 - Getting StartedDocument34 pages01 - Getting Startednaam2105_996631495No ratings yet

- Pipe Size OptimizationDocument3 pagesPipe Size OptimizationkamelkolsiNo ratings yet

- Dynamic Modeling of Natural Gas Pipe LinesDocument20 pagesDynamic Modeling of Natural Gas Pipe LinesWali AhsanNo ratings yet

- Pump CalcDocument121 pagesPump Calcravirawat15No ratings yet

- Section 10 - Air Cooled Heat ExchangersDocument70 pagesSection 10 - Air Cooled Heat ExchangersCHANADASNo ratings yet

- Learn Process Design Fundamentals & Equipment SizingDocument4 pagesLearn Process Design Fundamentals & Equipment SizingMojtabaPMNo ratings yet

- Section 18 - UtilitiesDocument5 pagesSection 18 - UtilitiesCHANADASNo ratings yet

- Section 17 - Fluid Flow and PipingDocument11 pagesSection 17 - Fluid Flow and PipingCHANADASNo ratings yet

- Section 25 - Equilibrium Ration (K) DataDocument39 pagesSection 25 - Equilibrium Ration (K) DataCHANADASNo ratings yet

- Section 23 - Physical PropertiesDocument14 pagesSection 23 - Physical PropertiesCHANADASNo ratings yet

- Hy Sys NormalDocument1 pageHy Sys NormalCHANADASNo ratings yet

- Aspen HYSYS Dynamics: Dynamic Modeling: Former Course Title/Number Who Should AttendDocument2 pagesAspen HYSYS Dynamics: Dynamic Modeling: Former Course Title/Number Who Should AttendCHANADASNo ratings yet

- GPSA - Gas Processors Suppliers Association, Engineering 12th Ed (Excel)Document19 pagesGPSA - Gas Processors Suppliers Association, Engineering 12th Ed (Excel)CHANADASNo ratings yet

- Rules of Dynamic SimulationDocument1 pageRules of Dynamic SimulationImtihan KomahateeNo ratings yet

- Ferain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and CadmiumDocument12 pagesFerain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and Cadmiumarthur5927No ratings yet

- Declarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Document13 pagesDeclarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Jair Luiz S. FilhoNo ratings yet

- Arsh Final Project ReportDocument65 pagesArsh Final Project Report720 Manvir SinghNo ratings yet

- Pakage PAU (Fruits)Document70 pagesPakage PAU (Fruits)Gary Bhullar57% (7)

- Strategic Marketing FiguresDocument34 pagesStrategic Marketing FiguresphuongmonNo ratings yet

- Barker-Choucalas, Vida PDFDocument176 pagesBarker-Choucalas, Vida PDFAnn GarbinNo ratings yet

- Data Structures LightHall ClassDocument43 pagesData Structures LightHall ClassIwuchukwu ChiomaNo ratings yet

- Vortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimDocument7 pagesVortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimhiraNo ratings yet

- Iso 16399-2014-05Document52 pagesIso 16399-2014-05nadim100% (1)

- C++ Practical FileDocument15 pagesC++ Practical FilePreetish ChandraNo ratings yet

- Sles-55605 C071D4C1Document3 pagesSles-55605 C071D4C1rgyasuylmhwkhqckrzNo ratings yet

- Lecture-3 Sources of Bioelectric PotentialDocument13 pagesLecture-3 Sources of Bioelectric PotentialMurali krishnan.MNo ratings yet

- Blocked threads jstack analysisDocument69 pagesBlocked threads jstack analysisMike TNo ratings yet

- Phenolic Compounds in Rice May Reduce Health RisksDocument7 pagesPhenolic Compounds in Rice May Reduce Health RisksMuhammad Usman AkramNo ratings yet

- Living in a digital age unit review and digital toolsDocument1 pageLiving in a digital age unit review and digital toolsLulaNo ratings yet

- Reasons for Conducting Qualitative ResearchDocument12 pagesReasons for Conducting Qualitative ResearchMa. Rhona Faye MedesNo ratings yet

- SBLO Jepp Charts PDFDocument12 pagesSBLO Jepp Charts PDFElton CacefoNo ratings yet

- Present Perfect.Document1 pagePresent Perfect.Leidy DiazNo ratings yet

- PWC Annual ReportDocument46 pagesPWC Annual ReportAigulNo ratings yet

- Applied SciencesDocument25 pagesApplied SciencesMario BarbarossaNo ratings yet

- Rieka Fitri Sutrisno-CGK-SXBHSY-BTH-FLIGHT - ORIGINATINGDocument2 pagesRieka Fitri Sutrisno-CGK-SXBHSY-BTH-FLIGHT - ORIGINATINGfairuz fanaNo ratings yet

- 457 PDFDocument8 pages457 PDFAbbey Joy CollanoNo ratings yet

- Sheet Metal FormingDocument13 pagesSheet Metal FormingFranklin SilvaNo ratings yet

- Linear Circuit Analysis (ELEN-1100) : Lecture # 13: More On Mesh Current AnalysisDocument11 pagesLinear Circuit Analysis (ELEN-1100) : Lecture # 13: More On Mesh Current AnalysisPhD EENo ratings yet

- Kina23744ens 002-Seisracks1Document147 pagesKina23744ens 002-Seisracks1Adrian_Condrea_4281No ratings yet

- Admission Notice 2023-24Document2 pagesAdmission Notice 2023-24Galav PareekNo ratings yet

- Facebook Facing Off Againt TencentDocument6 pagesFacebook Facing Off Againt TencentWai Shan Lee0% (1)

- Mid Term Business Economy - Ayustina GiustiDocument9 pagesMid Term Business Economy - Ayustina GiustiAyustina Giusti100% (1)

- As 91435Document3 pagesAs 91435api-271057641No ratings yet

- Blink CodesDocument3 pagesBlink CodesNightin VargheseNo ratings yet