Professional Documents

Culture Documents

Tube Settler - Calculation

Uploaded by

Jai KumarOriginal Description:

Copyright

Available Formats

Share this document

Read this document in other languages

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tube Settler - Calculation

Uploaded by

Jai KumarCopyright:

Available Formats

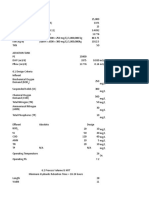

PROCESS DESIGN CALCULATIONS

FOR TUBE SETTLER IN WATER TREATMENT PLANT

5.0 (C) TUBE SETTLER

Raw water Flow

Recycle Flow

Design Flow

=

=

=

=

=

=

=

=

=

Shape of unit

Length/ Breadth of Tube Settler provided

=

=

100

5

100+5

105

4

105/4

26.250

26250.000

1093.750

Square

11.40

Tube Pack Data:

Shape

Cross sectional area

Hydraulic radius

Settling area : 60 Slope

Settling area : 55 Slope

Vertical Space between Tubes

Angle of inclination

=

=

=

=

=

=

=

Hexagonal - Chevron

120 x 44

mm x mm

0.015

m

11

m/m

13

m/m

0.044

m

55

Settling area of Tube Pack, corresponding to the inclination,

based on the effective volume of Tube Pack

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

1.00

m/m/h

0.70

1* 0.7

0.70

m/m/h

0.00000080

m/s

20.00

C

0.000001003

m/s

0.0000008/0.000001003

0.798

0.7*0.798

0.558

m/m/h

0.700

m/m/h

1.000

11.4*11.4

129.960

m

129.96*1

129.960

m

11.4*1 *(1/TAN55)

7.982

m

129.96-7.982

121.978

m

121.978*13

1585.709

m

Actual Settling rate on the horizontal projected area of Tube Pack

1093.75 / 1585.709

0.690

m/m/h

0.70

m/m/h

Hence O.K.

Number of units provided

So, Design flow per Tube Settler

Select, Settling rate on the horizontal projected area of Tube Pack

Apply the probability factor,as recommended by theTube Pack Vendor

Revised Settling rate on the horizontal projected area of Tube Pack

Kinematic viscosity of water at 30C

Design temperature of water

Kinematic viscosity of water at 20C

Correction Factor for Settling rate, w.r.t. Kinematic viscosity

Corrected Settling rate

Selected Settling rate on the horizontal projected area of Tube Pack

Selected vertical depth of Tube Pack

Plan area of the Tube Settler

Volume of Tube Pack provided

Loss of volume of Tube Pack, on account of inclination

Effective volume of Tube Pack

<

Mld

Mld

Mld

nos.

Mld

m/d

m/h

m

Check for the performance of the Tube Settler:

Sedimentation takes place in the length following the transition length and it will retain all particles

with a settling velocity less than Vs.

Vs

= V. k / { [sin + (Ls/d)cos ] }

Where,

Vs = Settling velocity, m/m/h

Ls = Settling length of Tube

d = depth of water in a Tube at right angle to the direction of flow, m

= angle of inclination of Tube Pack to the horizontal

k = a coefficient

= 1.33 for Hexagonal Tubes

Schiller formula to calculate transition length:

Lt = 0.0288 NR .D

Where,

Lt = Transition length

V = Average velocity of flow in the Tubes, m/h.m

= U / sin

U = Average upward velocity, m/h.m

= Surface loading rate of the Settling Tank

= Rate of flow / Tube entrance area

= Kinematic viscosity of water, m/s

NR = Reynolds Number

0.00000086

m/s

Ls = L - Lt

Where,

L = Length of Tube

Ls = Settling length of Tube

Plan area of the Tube Settler

=

11.4*11.4

=

129.96

m

The tube entrance area is reduced due to the thickness of the tube pack and also due to the supporting

structure provided.

The support width of minimum 60 mm is recommended at a centre-to-centre distance of 1000 mm, in a

square grid.

No. of supporting angles, lengthwise @ 1m c-c spacing

=

(11.4/1)+1

=

12.40

nos.

Say

=

13.00

nos.

No. of supporting angles, breadthwise @ 1m c-c spacing

=

(11.4/1)+1

=

12.40

nos.

Say

=

13.00

nos.

=

65.000

mm

Width of supporting angle of standard size, provided

=

0.065

m

Plan area lost by the supporting angles of width 65 mm

=

(11.4*13*0.065)+(11.4*13*0.065

-(13*13*0.065*0.065)

=

0.768

m

=

3.00

% of plan area

Plan area lost by the thickness of the Tube Pack

=

3%*129.96

=

3.899

m

Total area of obstruction for flow through Tube Pack

=

0.768+3.899

=

4.667

m

Tube entrance area

=

129.96-4.667

=

125.293

m

Average upward velocity, U

=

1093.75/125.293

=

8.730

m/h

Average velocity of flow in the Tubes, V

=

U / sin

=

8.73 / sin 55

=

10.657

m/h

=

0.003

m/s

Hydraulic radius, R ( = CSA / Wetted perimeter)

Equivalent diameter, D ( = 4 R)

=

=

=

0.01500

4*0.015

0.060

Reynolds Number, NR

VR

m

m

=

=

0.003*0.015/0.00000086

51.632

Transition length of Tube

Settling length of Tube, Ls

Relative settling length of tube = Ls/d

Coefficient k for Hexagonal shaped Tubes

Vs

=

=

=

=

=

=

=

=

=

0.0288*NR*D

0.0288*51.632*0.06

0.089

m

L - Lt

1-0.089

0.911

0.911/0.044

20.700

1.33

V. k / { [sin + (Ls/d)cos ] }

=

=

>

10.657*1.33/((sin55+20.7*cos55))

1.117

m/m/h

0.690

Hence O.K.

=

=

=

=

=

11.40

1093.75

=

=

=

=

=

=

=

=

=

=

0.025

m/s

1093.75 / 3600 / 0.025

12.15

m

12.15 / 11.4

1.066

m

1.00

m

0.30

m

0.65 + 1 + 1.066 + 1 + 0.3

4.016

m

4.05

m

Hence O.K.

=

=

=

=

=

=

=

=

=

=

=

<

250

m/m/d

26250/250

105.000

m

105/(2*(11.4-(1/TAN 55)

4.907

6.000

nos.

6*2*((11.4)-(1/TAN55))

128.398 m

1093.75 / 128.398

8.52

m/m/h

204.44

m/m/d

250.00

m/m/d

Hence O.K.

30.000

Mld

30000.000

m/d

30000 / 128.398

233.65

m/m/d

Unit Size

Length / Breadth of Tube Settler provided

Flow per Tube Settler

Approx.liquid height above the top of the tube pack

Vertical Height of Plates

Horizontal velocity in the clarification shall be 0.02 to 0.03 m/s.

Horizontal Velocity in the clarification zone selected

C/S area of clarification zone required below Tube Pack

Height of the Clarification zone required

Depth of the sludge compression zone provided

Space provided for sludge scrapper

Side water depth of unit required

SWD provided

Provide V-Notch weir plates on the inner side of overflow launders.

Recommended weir loading for Tube Settler

Length of weir to be provided

No.of overflow launders to be provided

Say

Approx.length of weir provided in each Tube Settler

Discharge rate at design flow over the weir

Design Hydraulic flow per Tube Settler

Discharge rate at design Hydraulic flow over the weir

=

=

=

=

Size: 4 Nos. Tube Settlers, each of 11.4 m x 11.4 m x 4.05 m SWD

0.65

1.00

m

m/h

0.3038 m/s

m

m

You might also like

- ProTrack I ManualDocument203 pagesProTrack I ManualhishamuddinohariNo ratings yet

- 28-Guidelines For Drinking-Water Quality, Vol. 1, Recommendations (3rd Edition) - WHO-9241546387-Wo PDFDocument541 pages28-Guidelines For Drinking-Water Quality, Vol. 1, Recommendations (3rd Edition) - WHO-9241546387-Wo PDFJai KumarNo ratings yet

- SBR Design CalculationsDocument26 pagesSBR Design Calculationsn_zeinoun78% (9)

- Civil FormulaDocument80 pagesCivil FormulaBharat SharmaNo ratings yet

- Aeration Tank and Clarifier DesignDocument6 pagesAeration Tank and Clarifier DesignRajesh NareNo ratings yet

- Water Demand Calculation and System DesignDocument27 pagesWater Demand Calculation and System DesignMario Sajulga Dela Cuadra100% (8)

- Process Calculations 1 MLD SBRDocument168 pagesProcess Calculations 1 MLD SBRAngelo EndozoNo ratings yet

- Vinayagar Agaval - Avvaiyar PDFDocument17 pagesVinayagar Agaval - Avvaiyar PDFkckejaman100% (1)

- Anoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Document4 pagesAnoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Vaish Kan100% (4)

- Dual Media FilterDocument4 pagesDual Media FilterPandiaraj MkNo ratings yet

- Clariflocculator CalculationsDocument4 pagesClariflocculator Calculationssanu80% (5)

- Calculation Example of Extended AerationDocument30 pagesCalculation Example of Extended AerationHRK65100% (1)

- Silo CalcDocument3 pagesSilo CalcJai KumarNo ratings yet

- Reverse Dial Indicator MethodDocument14 pagesReverse Dial Indicator MethodvinothenergyNo ratings yet

- Non-Linear Analysis Untar 040206Document21 pagesNon-Linear Analysis Untar 040206Gregorius Filipus100% (1)

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- Design of STP for HapurDocument5 pagesDesign of STP for HapurKalyca Nazhifa SalwaNo ratings yet

- Design of Slow Sand Filter FinalDocument11 pagesDesign of Slow Sand Filter FinalHemant SonawadekarNo ratings yet

- Water Treatment Plant DesignDocument36 pagesWater Treatment Plant Designnopime100% (2)

- STP Design CalculationsDocument31 pagesSTP Design CalculationsManish Garg75% (4)

- Design of a FlashmixerDocument1 pageDesign of a Flashmixersumitanurag100% (3)

- Primary ClarifierDocument26 pagesPrimary ClarifierDavid Charles Meissner100% (2)

- Water Dosing Calculation BookDocument12 pagesWater Dosing Calculation BookSugumar Panneer SelvamNo ratings yet

- Rapid Sand Filter Design Example PDFDocument2 pagesRapid Sand Filter Design Example PDFWONG TS95% (21)

- 4.introduction To The Design and Process Calculations (542089)Document35 pages4.introduction To The Design and Process Calculations (542089)ahmed salamNo ratings yet

- Battle Axe Pattern Revised Jan 2018Document4 pagesBattle Axe Pattern Revised Jan 2018Joelle GrondinNo ratings yet

- 7 - Inclined Plate Settler ClarificationDocument63 pages7 - Inclined Plate Settler ClarificationAlejandro Guerrero100% (5)

- Excel Spreadsheets for Secondary Clarifier DesignDocument3 pagesExcel Spreadsheets for Secondary Clarifier DesignNiong DavidNo ratings yet

- 20 KLD STP - Offer - MBBRDocument10 pages20 KLD STP - Offer - MBBRHarish Kumar MahavarNo ratings yet

- Rapid Sand Filter DesignDocument3 pagesRapid Sand Filter DesignCivilian Venkadesh100% (1)

- Screen and SBR v1.0Document3 pagesScreen and SBR v1.0Richard Magadia Jr0% (1)

- Tech City-STP 100 KLD Price Comparison (03092016)Document10 pagesTech City-STP 100 KLD Price Comparison (03092016)Preston VargheseNo ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (3)

- Design 2 MLDDocument9 pagesDesign 2 MLDANIL KUMAR H CNo ratings yet

- Lamella ClarifierDocument6 pagesLamella Clarifiermhossain_mozammel100% (1)

- Sequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsDocument37 pagesSequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsOn Gnios Ingeniería67% (6)

- MBBRDocument37 pagesMBBRLye Yp100% (2)

- Annex 30 Tool - Design - Waste Stabilization PondsDocument8 pagesAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- STP Design (With MBBR)Document9 pagesSTP Design (With MBBR)Sagar Patel.100% (1)

- STP 125 KLDDocument9 pagesSTP 125 KLDAbhay SisodiaNo ratings yet

- SBR DesignDocument2 pagesSBR DesignHRK65100% (6)

- SBR - 6 MLDDocument38 pagesSBR - 6 MLDsharan kommi100% (1)

- MBR DesignDocument52 pagesMBR Designpragatheesk100% (2)

- Tube Settler DesignDocument4 pagesTube Settler DesignKrishna Winx100% (1)

- Clarifier Sizing SpreadsheetDocument1 pageClarifier Sizing Spreadsheetarvin4dNo ratings yet

- Inclined Plate Clarifier (Parallel Plate Clarifier, Lamella Clarifier) Basic Theory of OperationDocument2 pagesInclined Plate Clarifier (Parallel Plate Clarifier, Lamella Clarifier) Basic Theory of OperationThanneeru Naga Raju100% (1)

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationAnonymous QiMB2lBCJLNo ratings yet

- Optimize DAF Performance StudyDocument4 pagesOptimize DAF Performance StudyNoureddine MerahNo ratings yet

- Design Spreadsheet Calculation For SBR Sequential Biological ReactorDocument12 pagesDesign Spreadsheet Calculation For SBR Sequential Biological ReactorHenry SPNo ratings yet

- Shanmuga KavasamDocument23 pagesShanmuga KavasamSubramaniam RamanNo ratings yet

- Planning and Design of Drip Irrigation SystemDocument35 pagesPlanning and Design of Drip Irrigation Systempink girlNo ratings yet

- Design of 100KLD STP Using MBBR TechnoloDocument9 pagesDesign of 100KLD STP Using MBBR TechnoloSTP VermifiltrationNo ratings yet

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocument7 pages20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- Cameron Compressor OperationDocument13 pagesCameron Compressor Operationfructora0% (1)

- Enviraj MBBR CalculatorDocument3 pagesEnviraj MBBR Calculatorankur100% (2)

- 45 KLD STP PROPOSAL VRANDAVAN GREENS PDFDocument9 pages45 KLD STP PROPOSAL VRANDAVAN GREENS PDFTech MongerNo ratings yet

- Design Criteria SBRDocument8 pagesDesign Criteria SBRranbeer41100% (1)

- Degasser Tower CalculationDocument1 pageDegasser Tower Calculationbalaji krishnan100% (1)

- Tube Settler - CalculationDocument3 pagesTube Settler - CalculationJai Kumar87% (15)

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- MBR-STP Design Features PDFDocument7 pagesMBR-STP Design Features PDFManjunath HrmNo ratings yet

- ETP Design CalculationDocument6 pagesETP Design Calculationmanuel.hernandez100% (1)

- DATABASE Kawasan Industri PolugadungDocument20 pagesDATABASE Kawasan Industri PolugadungRina Rachman100% (1)

- Design of WTP and STPDocument14 pagesDesign of WTP and STPVenu Ch100% (1)

- Methods For UASB Reactor DesignDocument5 pagesMethods For UASB Reactor Designecotechconsultants100% (1)

- MBBR PresentationDocument14 pagesMBBR Presentationtonymac96100% (3)

- SBR DesignDocument25 pagesSBR DesignConya Smathel100% (1)

- Design of Secondary ClarifierDocument7 pagesDesign of Secondary Clarifierusmansherdin100% (1)

- Design a vertical tube condenser and subcoolerDocument29 pagesDesign a vertical tube condenser and subcoolert_prithvi0% (1)

- Material StdsDocument1 pageMaterial StdsJai KumarNo ratings yet

- Water ExpansionDocument1 pageWater ExpansionJai KumarNo ratings yet

- Is 10500 SpecificationDocument10 pagesIs 10500 SpecificationbrahmishtanNo ratings yet

- Water Pollution Cess Act guides water cess levyDocument9 pagesWater Pollution Cess Act guides water cess levyJay Prakash TiwariNo ratings yet

- Guide To Ship SanitationDocument152 pagesGuide To Ship SanitationClarence PieterszNo ratings yet

- Water Act, 1974 Relevant Provisions IndiaDocument28 pagesWater Act, 1974 Relevant Provisions IndiaFaris MohamedNo ratings yet

- Availability CalculationDocument1 pageAvailability CalculationJai KumarNo ratings yet

- Water ChemistryDocument3 pagesWater ChemistryJai KumarNo ratings yet

- ChlorineDocument12 pagesChlorineJai KumarNo ratings yet

- சொற்பொருள்Document1 pageசொற்பொருள்Jai KumarNo ratings yet

- Potable Water Qty ComparisonDocument4 pagesPotable Water Qty ComparisonJai KumarNo ratings yet

- TAC Norms FP ManualDocument113 pagesTAC Norms FP ManualJai KumarNo ratings yet

- Potable Water Qty ComparisonDocument4 pagesPotable Water Qty ComparisonJai KumarNo ratings yet

- Technical Cooling TowerDocument1 pageTechnical Cooling TowerJai KumarNo ratings yet

- Manual-De-Usuario Deshumidificador PDFDocument18 pagesManual-De-Usuario Deshumidificador PDFSoyManuNo ratings yet

- Modern spinning technology guideDocument6 pagesModern spinning technology guideParthrajPuranikNo ratings yet

- Screw Conveyor Specification for Industrial UseDocument5 pagesScrew Conveyor Specification for Industrial UseAbinashBeheraNo ratings yet

- Gravimetry Sample ProbDocument1 pageGravimetry Sample ProbRizza Mae RaferNo ratings yet

- Editable List of Procedure+Document5 pagesEditable List of Procedure+Koya ThangalNo ratings yet

- Optimization of Electroless Copper Coating Parameters On Graphite Particles Using Taguchi and Grey Relational AnalysisDocument6 pagesOptimization of Electroless Copper Coating Parameters On Graphite Particles Using Taguchi and Grey Relational AnalysisfacebookdeepuNo ratings yet

- Steel Tube Scale Exfoliation ResistanceDocument11 pagesSteel Tube Scale Exfoliation Resistancednageshm4n244No ratings yet

- DSU Manual PDFDocument204 pagesDSU Manual PDFCarlos Alberto RuedaNo ratings yet

- SC2057 PDFDocument3 pagesSC2057 PDFA MahmoodNo ratings yet

- John Carlo Dela Cruz - CHEM - Q3 - W4Document12 pagesJohn Carlo Dela Cruz - CHEM - Q3 - W4johncarlodc99No ratings yet

- Biodegradation Ofwasted Bioplastics in Natural andDocument37 pagesBiodegradation Ofwasted Bioplastics in Natural andMaria Inês Vasconcellos FurtadoNo ratings yet

- Copper Grades %: Value Per BlockDocument7 pagesCopper Grades %: Value Per BlockJhon Jayro Lavado FernándezNo ratings yet

- Davi-BARCODE-MCB-FOUR ROLLDocument12 pagesDavi-BARCODE-MCB-FOUR ROLLبازرگانی راهیان کار و دانشNo ratings yet

- Fabri-Valve 33 PTA / 33 PTD: Slurry ValvesDocument16 pagesFabri-Valve 33 PTA / 33 PTD: Slurry ValvesFelipe Ribeiro da CostaNo ratings yet

- EDGE Wire Diagram R3 (FR)Document2 pagesEDGE Wire Diagram R3 (FR)Peeyush AgarwalNo ratings yet

- International General Certificate Syllabus of Secondary Education Chemistry 0620 For Examination in June and November 2010Document37 pagesInternational General Certificate Syllabus of Secondary Education Chemistry 0620 For Examination in June and November 2010Farouk O LionNo ratings yet

- BM2312 004Document30 pagesBM2312 004julia.sacco.20No ratings yet

- Mohammed Et Al. (2022) - Graphene-CelluloseDocument8 pagesMohammed Et Al. (2022) - Graphene-CellulosealhassanNo ratings yet

- Pre101334 2204 PDFDocument227 pagesPre101334 2204 PDFEginaldo NetoNo ratings yet

- Stieber Clutch Bearings CatalogueDocument96 pagesStieber Clutch Bearings CatalogueCardoso MalacaoNo ratings yet

- Robotics and Vision SystemDocument64 pagesRobotics and Vision Systemasuras1234No ratings yet

- CBR PLUS Soil Stabilizer and Dust Control English CatalogueDocument4 pagesCBR PLUS Soil Stabilizer and Dust Control English CataloguecbrplusmexicoNo ratings yet

- Reinforcing Bar Couplers: For The Construction IndustryDocument32 pagesReinforcing Bar Couplers: For The Construction IndustryhutuguoNo ratings yet

- Forged Valve and Fittings For Sour ServiceDocument1 pageForged Valve and Fittings For Sour ServiceVijay AcharyaNo ratings yet