Professional Documents

Culture Documents

Quality Audit Checklist On Fabricator

Uploaded by

arinmerlianaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Audit Checklist On Fabricator

Uploaded by

arinmerlianaCopyright:

Available Formats

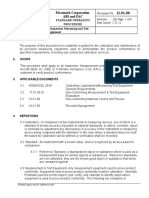

Process Assurance Checklist General

QMS-0000-PUR-FRM-CHV-000-00003-07

Quality Management System

Rev. 0

Company Name

Date of Audit

Web Address

Manufacturing Facility

Address

Telephone

Fax

Supplier Contacts (name

and e-mail address)

Chevron Assessors

(name and e-mail

address)

Project

Requested by

Commodity Evaluated

Supplier Qualification

Request #

Reference Documents

Associated check list #s

Associated I & T Plan #s

[Add references to other checklists here]

Additional documents

[Add other document references here, e.g.

Supplier Mandatory Quality Requirements QMS0000-QAC-SPC-CHV-000-00002-00 or QMS0000-QAC-SPC-CHV-000-00003-00]

Questionnaire Response

Reference #

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

1 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

1.0 SAFETY / SECURITY / ENVIRONMENT

1.1 Is there indication that the site has a safety-focused culture (safety

meetings, general signage, attention to housekeeping)

1.2 Is the site prepared for emergency situations?

Emergency phone numbers posted

Exits and mustering area clearly marked

Procedures communicated to employees

Safe walkways on floor

First aid & fire extinguishers readily available and serviced

When was the last emergency evacuation drill conducted?

1.3 Are workers adequately protected?

PPE available and used

Full face shields used when grinding

Hearing protection where applicable

1.4 Are workers protected from falls?

Fall protection used properly (harness / tie off)

Ladders used properly

Scaffolding subject to an inspection and tagging system

Pits and loading docks safe guarded or barricaded

Loads secured safely and material stacked safely

1.5 Is equipment adequately stored?

Chains and slings tagged with weight limits

Chains and slings subject to regular inspection and test and tagged

as such

Safety latches in place on all hooks

Welding leads and extension chords in good condition and stored /

laid out in such a fashion not to create a tripping hazard

Gas cylinders tied off correctly

Are flammable products stored safely and clearly marked?

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

2 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

1.6 Are tools and equipment well maintained?

Are guards available on all rotating equipment and in use?

Are hand tools adequately maintained?

1.7 Are vehicles maintained and properly used?

Are shop used vehicles rigged with adequate safety equipment?

Are drivers and operators certified to operate the vehicles?

1.8 Are overhead cranes maintained?

equipped with audible signals and strobe lights

Hooks subject to regular NDE examination (typically on an annual

basis)

1.9 Are lock out tag out procedures practiced?

1.10 Are overhead cranes properly used?

Equipped with audible signals and strobe lights

Hooks subject to regular NDE examination (typically on an annual

basis)

1.11 Test equipment maintained?

Isolated area available for hydrostatic and pneumatic testing

Qualified individuals available for conducting hydrostatic /and

pneumatic testing

1.12 Are visitors given a safety orientation prior to entering the shop?

1.13 Are the following documented and published:

near misses

lost time incidents

root cause analysis

corrective action to be taken?

1.14 Are housekeeping practices encouraged? Are the restrooms and

lunch rooms sanitary?

1.15 Is the lighting in the shop adequate?

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

3 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

1.16 Are hazardous materials disposed of properly? MSDS available?

1.17 Is plant access controlled both during and out of hours and are there

controls over vehicles entering the production area?

1.18 Environmental:

visible emissions, permits available for inspection, storm water

controls, leaks, drips, spills, containment, waste storage and

segregation

2.0 Engineering

2.1 Engineering Processes

Is there evidence of the following:

checking and approval of deliverables

inter / intra discipline checking

formal design review

controlled design change process

client review and incorporation of comments

criticality rating

3.0 Documentation Requirements

3.1 Document Submission

Compliance with SDRL (supplier document requirements list) for submittal

of deliverables and including incorporation of comments and expediting

approval documents in a timely manner (see Section 7.0 of the Supplier

Mandatory Quality Requirements)

3.2 Licenses and Certification

Review Licenses and certification the supplier has available and record the

scope and expiry dates

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

4 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

4.0 Purchasing

4.1 Specification

Verify system that assures that both engineering technical and quality

requirements are transmitted to procurement personnel and onwards in

POs to suppliers of materials, equipment and subcontracted services (both

COMPANY and statutory requirements ABS, USCG, NRTL)

4.2 Purchase Order Review

Are purchase orders reviewed and QC Checked by engineering / quality

personnel to ensure adequate definition of requirement.

4.3 Sub-supplier / subcontractor Qualification

Do the qualification procedures address the following:

criticality of material / service

information gathering e.g. questionnaire

need for a site visit

qualification of suppliers assessors (site visit and review of

information e.g. questionnaire)

use of third parties for qualification

reliability of past experience

qualification of sub suppliers

basis of recommendations and conclusions

4.4 Inspection

Verify inspection levels at sub-suppliers / sub-contractors and determine

criticality levels e.g. in process (resident / visiting inspector), receipt

inspection, audit, and third party inspectors

4.5 Sub-supplier Documentation Requirements

Verify sub supplier / sub-contractor documentation requirements and

determine how the supplier ensures accuracy, completion and adequacy

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

5 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

4.6 Sub-supplier Expediting

Verify supplier process to ensure timely delivery of material on order with

supporting quality records

4.7 Qualification of Supplier personnel

Verify qualification of personnel within each discipline including QA/QC and

Inspection personnel (i.e. those individuals conducting inspection of the

sub-suppliers / subcontractor product)?

5.0 Material Control

5.1 Procedure

Are the procedures sufficiently adequate to control:

receipt inspection

inventory

storage / protection

quarantine

segregation / protection from contamination

issue

traceability (to MTRs or material specs) with material origin and

material manufacturer, not stockist material certificates

compliance of MTRs to material specs (including PMI)

customer furnished material

5.2 Source of Supply of Material

Do recent purchase orders confirm the source of supply of major materials

as detailed in the suppliers response to the questionnaire?

5.3 Positive Material Identification (PMI)

Alloy materials: If the component in question requires PMI, does the

supplier have the facilities, equipment and qualified personnel to conduct

such testing?

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

6 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

6.0 Manufacturing Control

6.1 Control of Work in Progress

Verify Travellers, QC / Inspection & Test Plans (project approved), work

instructions etc

6.2 Control of Special Processes

Approved procedures covering the following, as applicable:

welding

casting

forging

heat treatment

NDT

plating

blast and coating

pressure testing

loop testing

6.3 In Process Inspection

Verify:

Qualified Inspectors for the acceptance and sign off of quality records

Approved Work instructions and ITPs for Inspectors

Language capabilities for international or local content

6.4 Customer Requirements

Verify CVX quality requirements and any amendments are conveyed to the

relevant personnel in Engineering, Procurement, and Fabrication and Test

areas.

Where applicable, verify COMPANY free issue documents and material

6.5 Traceability

Does the suppliers working practice cover traceability of the following:

material

consumables

trades

inspection

test

preservation

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

7 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

7.0 Inspection and Test

7.1 Stage Inspection

Are staged inspection points determined, monitored and recorded?

7.2 CVX Inspection and Test Plan

Can the supplier demonstrate an ability to conform to the applicable CVX

approved inspection and test plan (ITP)?

7.3 CVX Inspector

Does the supplier have adequate facilities to accommodate a CVX technical

and quality personnel?

7.4 Test Facilities

Are in-house facilities and resources for conducting required testing

adequate, in accordance with approved ITPs and CVX specification if not,

detail the extent of testing is subcontracted, noting if it is conducted on the

premises or remotely.

7.5 Independent Witnessing

Are all test results witnessed by qualified personnel independent of the work

including those tests conducted remotely?

7.6 Control of Non Conformance

Are the working practices adequate for controlling deficiencies identified

during manufacture (ref Section 9.0 of the Supplier Mandatory Quality

Requirements)?

7.7 Suppliers Inspection and Test Plan

Can the supplier develop and adhere to their own quality control / inspection

and test plan (ref Section 3.0 of the Supplier Mandatory Quality

Requirements)

8.0 Inspection, Measuring and Test Equipment

8.1 Availability of Inspection and Test Equipment

Does the supplier regularly use all inspection, measuring and test

equipment required by the applicable inspection and test plan /

specification?

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

8 of 9

Process Assurance Checklist (General)

QUALITY MANAGEMENT SYSTEM

QMS-0000-PUR-FRM-CHV-000-00003-07

Rev 0

Requirements/Questions/Subject

Acceptance

YNN/A

Risk

H/M/L

Evidence/comments

8.2 Reference Datum

Does the supplier have a reference datum or instrument self check method

for determining the validity of calibration and accuracy checking?

8.3 FAT Measuring Equipment

Does the supplier have facilities for measuring weight, noise, vibration,

bearing temperature etc during FAT?

9.0 Storage, Preservation and Protection

9.1 Preservation

Preservation procedures approved

Handling and Storage procedures approved

Preparation for Shipping and Packaging procedures approved

10.0 Data Book Compilation

10.1 Supplier Experience

Can the supplier demonstrate a history of satisfactory data compilation

gathered progressively during manufacture (see Section 11.0 of the

Supplier Mandatory Quality Requirements)

11.0 Personnel

11.1 Turnover of Personnel

Turnover ratio

Availability of personnel locally

Average length of service with company

2008 Chevron Corporation. All rights reserved.

Paper copies of this document are uncontrolled. Please refer to the Chevron Quality Management System Intranet site for the current version.

9 of 9

You might also like

- Product Realization (Quality Control)Document16 pagesProduct Realization (Quality Control)Khaled AbdelbakiNo ratings yet

- QMS Audit ChecklistDocument8 pagesQMS Audit ChecklistAmb Patrick OghateNo ratings yet

- Q2-760-01-Control of Monitoring and Measuring DevicesDocument5 pagesQ2-760-01-Control of Monitoring and Measuring DevicesAlineNo ratings yet

- QC-GF-002 - Material Inspection ReportDocument2 pagesQC-GF-002 - Material Inspection ReportDarrel Espino Aranas100% (1)

- Planning Procedure Quality SystemDocument4 pagesPlanning Procedure Quality SystemMacelNo ratings yet

- BHGE-SOU-015 Supplier Quality Requirements ChecklistDocument11 pagesBHGE-SOU-015 Supplier Quality Requirements Checklistjamil voraNo ratings yet

- Document Change RequestDocument1 pageDocument Change RequestvyerramallaNo ratings yet

- Crossreference API Q1 9TH and ISO 9001 2015Document3 pagesCrossreference API Q1 9TH and ISO 9001 2015wachid50583% (6)

- Internal Audit ReportsDocument1 pageInternal Audit ReportsCQMS 5S DivisionNo ratings yet

- F4E-QA-102 Supplier Audit Implementation 296E7T v2 3Document18 pagesF4E-QA-102 Supplier Audit Implementation 296E7T v2 3Jai BhandariNo ratings yet

- IMS Awarness 03-IMSDocument14 pagesIMS Awarness 03-IMSRohit SoniNo ratings yet

- ISO QMS PresentationDocument29 pagesISO QMS PresentationFarid B. Mahali100% (1)

- Positive Material Identification ReportDocument1 pagePositive Material Identification ReportUmair AwanNo ratings yet

- QC Sample Manual GenericDocument34 pagesQC Sample Manual GenericIan Stewart PorterNo ratings yet

- 01 - Design & Development PlanDocument1 page01 - Design & Development Planasderbva100% (1)

- Quality Manual - ISO 9001 - 2015 & API Q1Document35 pagesQuality Manual - ISO 9001 - 2015 & API Q1Muhammad Irfan Arshad67% (3)

- Non Conformance ProcedureDocument3 pagesNon Conformance ProcedureBharamu Patil33% (3)

- NCR - SopDocument9 pagesNCR - SopanasNo ratings yet

- POSITIVE RECALL PROCEDUREDocument6 pagesPOSITIVE RECALL PROCEDURESiva RamNo ratings yet

- Quality ObjectivesDocument1 pageQuality Objectivesgogulu100% (1)

- Contract checklist for Chennai customerDocument1 pageContract checklist for Chennai customerIsaiah100% (1)

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- PRESERVATION AND MATERIAL CONTROL AUDITDocument4 pagesPRESERVATION AND MATERIAL CONTROL AUDITAngel Angeleye100% (3)

- Site Quality ManualDocument376 pagesSite Quality ManualsNo ratings yet

- Production QA Process AuditDocument9 pagesProduction QA Process AuditDhananjay Patil100% (1)

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- Quality Control ManualDocument84 pagesQuality Control ManualMario100% (1)

- Flow Chart For New Enquiry HandlingDocument1 pageFlow Chart For New Enquiry HandlingVinod Sale100% (1)

- Material Receiving Inspection Procedure (MRIPDocument11 pagesMaterial Receiving Inspection Procedure (MRIPMaheshwar polepallyNo ratings yet

- Control Calibrated EquipmentDocument11 pagesControl Calibrated Equipmentmoytabura96100% (1)

- Control of Welding Rejection Rate and NDT Backlog in MEGA ProjectDocument10 pagesControl of Welding Rejection Rate and NDT Backlog in MEGA ProjectMubeenNo ratings yet

- API Audit Planning GuidanceDocument3 pagesAPI Audit Planning GuidanceTasha RamisettiNo ratings yet

- Automotive Quality Management System Identification and TraceabilityDocument6 pagesAutomotive Quality Management System Identification and Traceabilityom cncNo ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- ISO-BASED SUPPLIER AUDIT CHECKLIST REVIEWDocument20 pagesISO-BASED SUPPLIER AUDIT CHECKLIST REVIEWMartahanManurungNo ratings yet

- Supplier Evaluation and Approval - Disapproval PGP2001ADocument6 pagesSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasNo ratings yet

- Q1 9th Edition API Specification ExclusionDocument1 pageQ1 9th Edition API Specification Exclusionnaveen yadav0% (1)

- Quality Audit (QAP GTL 05) Rev.Document12 pagesQuality Audit (QAP GTL 05) Rev.GV Narayana ReddyNo ratings yet

- Quality Monthly Report - NOV 2015Document15 pagesQuality Monthly Report - NOV 2015KumaravelNo ratings yet

- Design Process TurtleDocument2 pagesDesign Process TurtleBAlaNo ratings yet

- 11.01.00 Calibration of Inspection Measuring and Test EquipmentDocument11 pages11.01.00 Calibration of Inspection Measuring and Test EquipmentSanjeev Reddy Kasula100% (1)

- Design Control Quality Assurance ProcedureDocument13 pagesDesign Control Quality Assurance ProcedurePrakash TiwariNo ratings yet

- Material Handling and Preservation ProcedureDocument2 pagesMaterial Handling and Preservation ProcedureIman ZNo ratings yet

- Supplier Audit ChecklistDocument11 pagesSupplier Audit ChecklistOlexei Smart100% (1)

- Final Inspection Release NoteDocument2 pagesFinal Inspection Release NoteMark ThrelfallNo ratings yet

- Inspection Procedure For ContractDocument24 pagesInspection Procedure For ContractVijaya PatilNo ratings yet

- Quality System ManualDocument46 pagesQuality System ManualJahel Looti100% (3)

- API Q1 Supplier Audit Check List - MRDocument8 pagesAPI Q1 Supplier Audit Check List - MRSandra SandersNo ratings yet

- Procedure For Design andDocument4 pagesProcedure For Design andSharif KhanNo ratings yet

- NCR Records FormDocument10 pagesNCR Records FormTariqMalik100% (1)

- API General Checklist Q1Manual 03-18-05Document4 pagesAPI General Checklist Q1Manual 03-18-05arrowhead3100% (4)

- Iatf-Qm-08 - Operation 8.5.1.1Document22 pagesIatf-Qm-08 - Operation 8.5.1.1SATISH HALGEKARNo ratings yet

- 01 Supplier Pre-Qualification AssessmentDocument18 pages01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- Complete Maco Quality Manual Vol. 1Document172 pagesComplete Maco Quality Manual Vol. 1Syed Imran100% (3)

- Vendor Audit Checklist PDFDocument3 pagesVendor Audit Checklist PDFMaria Magdalena Palacios HernandezNo ratings yet

- 9706-770-PRO-1003 Rev E1 Material Receiving Inspection ProcedureDocument9 pages9706-770-PRO-1003 Rev E1 Material Receiving Inspection ProcedureAjiNo ratings yet

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- Msds Harness HerbicideDocument6 pagesMsds Harness HerbicidearinmerlianaNo ratings yet

- ArgonDocument4 pagesArgonarinmerlianaNo ratings yet

- NIOSH Guide: Hydrogen chloride HazardsDocument2 pagesNIOSH Guide: Hydrogen chloride HazardsarinmerlianaNo ratings yet

- 16 Tenses in EnglishDocument4 pages16 Tenses in EnglishBunt Onlineshop100% (2)

- Tube To Tube SheetDocument9 pagesTube To Tube Sheetcmpatel_00100% (2)

- Lembur Maret 2016 PDFDocument1 pageLembur Maret 2016 PDFarinmerlianaNo ratings yet

- Tube To Tube SheetDocument9 pagesTube To Tube Sheetcmpatel_00100% (2)

- MSDS Thinner CatDocument2 pagesMSDS Thinner CatFendiNo ratings yet

- Safety Data Sheet for Argon GasDocument4 pagesSafety Data Sheet for Argon GasarinmerlianaNo ratings yet

- Expanded and WeldedDocument9 pagesExpanded and WeldedarinmerlianaNo ratings yet

- Fan BeltDocument4 pagesFan Beltforevertay2000No ratings yet

- NDE 2011 Proceedings Discusses Quality Control of Tube Joints in Fast Breeder ReactorsDocument5 pagesNDE 2011 Proceedings Discusses Quality Control of Tube Joints in Fast Breeder ReactorsvaibraineaterNo ratings yet

- ASME certification stepsDocument2 pagesASME certification stepsmail_younes6592No ratings yet

- Welding DefectDocument1 pageWelding DefectarinmerlianaNo ratings yet

- PmiDocument6 pagesPmiSai FujiwaraNo ratings yet

- Casing Design Manual - BG (2001)Document51 pagesCasing Design Manual - BG (2001)PetroleumEngineering100% (21)

- 13WTO 117 01 FDS Rev - AB 1Document3 pages13WTO 117 01 FDS Rev - AB 1arinmerlianaNo ratings yet

- SteelDocument5 pagesSteelarinmerlianaNo ratings yet

- HSE PlanDocument13 pagesHSE Planarinmerliana0% (1)

- Serial Number IDMDocument1 pageSerial Number IDMarinmerlianaNo ratings yet

- Serial Number IDMDocument1 pageSerial Number IDMarinmerlianaNo ratings yet

- Etching Specialty AlloysDocument6 pagesEtching Specialty AlloysNitin100% (1)

- SHS WeldingDocument42 pagesSHS Weldingsleepyhead1984100% (2)

- SHS WeldingDocument42 pagesSHS Weldingsleepyhead1984100% (2)

- Certificate TemplateDocument3 pagesCertificate TemplatearinmerlianaNo ratings yet

- Kalender AkademikDocument3 pagesKalender AkademikBing GoNo ratings yet

- Metal Joining - 02 - Heat Flow in WeldingDocument31 pagesMetal Joining - 02 - Heat Flow in Weldingdjsun_No ratings yet

- Metalurgi Manufaktur Solidification Processing Kelompok:: Tugas 1Document1 pageMetalurgi Manufaktur Solidification Processing Kelompok:: Tugas 1arinmerlianaNo ratings yet

- CH 3030 Applications of Mass Transfer: 4 August 2020Document17 pagesCH 3030 Applications of Mass Transfer: 4 August 2020Ram Lakhan MeenaNo ratings yet

- A User Guide Advanced Diagnostic Tools ADT View Software ENDocument43 pagesA User Guide Advanced Diagnostic Tools ADT View Software ENAlex ZXNo ratings yet

- Basic Calculus: Quarter 3 - Module 3Document12 pagesBasic Calculus: Quarter 3 - Module 3Norman LoNo ratings yet

- Resume Updated Format 2013Document6 pagesResume Updated Format 2013afiwfrvtf100% (2)

- IA 3 - ViscosityDocument9 pagesIA 3 - ViscosityManav Shah100% (1)

- KNS 1073 Assignment 1 Muhammad KhairinDocument6 pagesKNS 1073 Assignment 1 Muhammad KhairinMuhammad khairinNo ratings yet

- Stanley Umd 0117E 10896.pdf JsessionidDocument212 pagesStanley Umd 0117E 10896.pdf JsessionidAlessandro GuidiNo ratings yet

- SITE VISIT REPORT FOR BE CIVIL STUDENTSDocument4 pagesSITE VISIT REPORT FOR BE CIVIL STUDENTSPiyush Bhandari100% (2)

- If TRLDocument38 pagesIf TRLbdNo ratings yet

- Seminar Presentation On GeneticsDocument60 pagesSeminar Presentation On GeneticsHardeep KaurNo ratings yet

- Pricelist Forte ObatDocument4 pagesPricelist Forte ObatKlinik CortexNo ratings yet

- Comic StripDocument10 pagesComic StripRamNo ratings yet

- Assessment Item 2 - Research Proposal Presentation: RequirementsDocument2 pagesAssessment Item 2 - Research Proposal Presentation: Requirementsxuni34No ratings yet

- Commercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsDocument44 pagesCommercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsChrise5502No ratings yet

- Student Assignment Analyzes Statistics ProblemsDocument2 pagesStudent Assignment Analyzes Statistics ProblemsKuberanNo ratings yet

- IFRS Reporting Standards PakistanDocument7 pagesIFRS Reporting Standards Pakistanamna hafeezNo ratings yet

- Project Report On Population ExplosionDocument11 pagesProject Report On Population ExplosionFarnaz Bharwani60% (5)

- Castle Leasing Corporation Which Uses Ifrs Signs A Lease Agreement PDFDocument1 pageCastle Leasing Corporation Which Uses Ifrs Signs A Lease Agreement PDFFreelance WorkerNo ratings yet

- Revising and Editing Translated TextDocument47 pagesRevising and Editing Translated TextBinh Pham ThanhNo ratings yet

- MPL Annual Report 2022 2023Document125 pagesMPL Annual Report 2022 2023viveksinghthakur340No ratings yet

- Sports Management Masters Thesis TopicsDocument7 pagesSports Management Masters Thesis Topicsaflnwcaabxpscu100% (2)

- Workday Studio - Complex Integration Tool OverviewDocument3 pagesWorkday Studio - Complex Integration Tool OverviewHarithaNo ratings yet

- Focus Plastics Case StudyDocument8 pagesFocus Plastics Case StudyraiaNo ratings yet

- Astm C31-C31M-23Document7 pagesAstm C31-C31M-23mustafa97a141No ratings yet

- 18 Cae MawrDocument5 pages18 Cae MawrMarios TheodoulouNo ratings yet

- Course Schedule 2020 - NIOSHCertDocument3 pagesCourse Schedule 2020 - NIOSHCertJamsari SulaimanNo ratings yet

- RM Question and AnswerDocument19 pagesRM Question and AnswerPadmavathiNo ratings yet

- OBR Assignment 2 Team D 1Document5 pagesOBR Assignment 2 Team D 1kazi noor ahmedNo ratings yet

- Ethernet Cable Colour - Code Standards & Methods of CrimpingDocument15 pagesEthernet Cable Colour - Code Standards & Methods of CrimpingSajjad Najum ShakirNo ratings yet

- Morbidity and Mortality Weekly Report, Vol. 62 / No. 18Document32 pagesMorbidity and Mortality Weekly Report, Vol. 62 / No. 18Southern California Public RadioNo ratings yet