Professional Documents

Culture Documents

Ejector Cooling

Uploaded by

Bourhan Mohammad TashtoushCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ejector Cooling

Uploaded by

Bourhan Mohammad TashtoushCopyright:

Available Formats

Pergamon

PII:

Solar Energy Vol. 64, Nos 46, pp. 223226, 1998

1998 Elsevier Science Ltd

S 0 0 3 8 0 9 2 X ( 9 8 ) 0 0 0 8 2 6 All rights reserved. Printed in Great Britain

0038-092X / 98 / $ - see front matter

A SOLAR EJECTOR COOLING SYSTEM USING REFRIGERANT R141b

B. J. HUANG, J. M. CHANG, V. A. PETRENKO and K. B. ZHUK

Department of Mechanical Engineering, National Taiwan University, Taipei 106, Taiwan

Received 8 October 1997; revised version accepted 14 July 1998

Communicated by BYARD WOOD

AbstractA high-performance solar ejector cooling system using R141b as the working fluid was developed.

We obtain experimentally a COP of 0.5 for a single-stage ejector cooling system at a generating temperature of

908C, condensing temperature of 288C, and an evaporating temperature 88C. For solar cooling application, an

optimum overall COP can be obtained around 0.22 at a generating temperature of 958C, evaporating

temperature of 88C and solar radiation at 700 W m 22 . 1998 Elsevier Science Ltd. All rights reserved.

Petrenko, 1992; Eames et al., 1995a; Lallemand

and Dorantes, 1995; Sun, 1996), while COP is

around 0.40.6 for a single-stage absorption

cooling system (Wilbur and Mancini, 1976; Bansal et al., 1997). In the present study, we develop a

solar ejector cooling system using R141b as the

working fluid which can obtain a better COP than

before.

1. INTRODUCTION

A solar cooling / refrigeration system which converts the solar thermal energy into cooling effect

has long been an interesting subject for scientists

and engineers (Chinnapa, 1961; Kakabaev and

Davletov, 1966; Anderson, 1975; Wilbur and

Mancini, 1976; Stchetinina et al., 1987; Korres et

al., 1989; Petrenko, 1992; Bansal et al., 1997). In

practical application, a solar collector is used to

absorb the solar thermal energy first. The heat is

then used to drive a heat-driven cooling machine

to produce a cooling effect.

The solar cooling system utilizing a LiBr

water or ammoniawater absorption cooling machine has been built frequently to demonstrate the

application of solar cooling technology. However,

the absorption cooling system utilizes a chemical

absorption process and is thus quite complicated

in design. Vacuum technology is also required for

a LiBrwater absorption system. High installation

cost retards their application in solar cooling

systems.

An ejector cooling system (ECS) can operate

with low boiling point refrigerants as the working

fluid and is known as one of the most promising

devices for solar cooling / refrigeration applications. ECS is a mechanical system utilizing the

Rankine cycle and the gas dynamic effect of

ejector (a thermal compression process). The

simplicity in design, high reliability and low

installation cost makes the ECS more attractive

than others. The only drawback of the ECS is its

low COP, usually lower than 0.3 for a single-stage

system (Jhadan et al., 1976; Huang et al., 1985;

2. DESIGN OF A SOLAR EJECTOR COOLING

SYSTEM

Author to whom correspondence should be addressed.

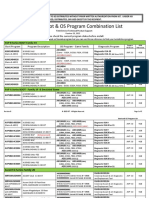

Fig. 1 is the schematic of a single-stage solar

ejector cooling system. The solar cooling system

Fig. 1. Schematic diagram of a solar ejector cooling system.

223

224

B. J. Huang et al.

consists of only four major components: solar

collector (generator), ejector, condenser / regenerator, evaporator. The solar collector acts as

the generator of the ECS in which the working

fluid is heated and evaporated. The mixing ejector

is used here with the separator to re-circulate the

liquid working fluid through the solar collector to

enhance the boiling heat transfer.

In the present study, R141b is selected as the

working fluid for the ejector cooling machine.

R141b has a low boiling point (32.078C) and high

performance according to Lallemand and

Dorantes (1995).

We used a commercially-available doubleglazed selective-surface flat-plate solar collector

as the generator. The energy collection efficiency

of the collector is experimentally determined

according to the modified ANSI /ASHRAE 931986 Standard (Huang and Hsieh, 1990):

Ti 2 Ta

hsc 5 0.80 2 3.5 ]]

I

(1)

Fig. 2. Theoretical COP of a single-stage ejector cooling

system.

The analytical results are experimentally verified

and presented in Figs. 3 and 4.

The critical condensing temperature T c* is

defined as the vapor saturation temperature corresponding to the critical back pressure of the

ejector. For the back pressure of an ejector

where I is the incident solar radiation (W m 22 );

T i and T a are the collector inlet and the ambient

temperatures.

3. PERFORMANCE ANALYSIS OF AN

EJECTOR COOLING SYSTEM

The ejector cooling system utilizes an ejector

for vapor compression by use of the gas dynamic

effect. For the ejector performance analysis, we

developed an 1-D gas dynamic model which is

similar to that of Eames et al. (1995b) but

including the secondary flow choking phenomena

proposed by Munday and Bagster (1976), (1977);

Huang et al. (1985). The results are then used to

evaluate the performance of a single-stage ejector

cooling system.

The design specifications of the ejector are

listed in Table 1. Fig. 2 shows that the COP of a

single-stage ejector cooling system using R141b

as the working fluid can reach as high as 0.6 at

generation temperature 1008C, condensing temperature 308C, and evaporating temperature 88C.

Fig. 3. Measured and computed ejector entrainment ratio.

Table 1. Specifications of ejector

Primary flow nozzle:

Throat diameter, mm

Exit diameter, mm

Constant-area section:

Diameter, mm

Diffuser angle, deg:

Distance between nozzle and

constant-area section, mm:

2.64

4.50

cylindrical type

8.10

5

13

Fig. 4. Measured and computed COP of ejector cooling

system.

A solar ejector cooling system using refrigerant R141b

exceeding the critical back pressure, the choking

of the secondary or suction flow will disappear

and the ejector performance drops dramatically

(Huang et al., 1985).

It is shown from Fig. 4 that the ejector cooling

system designed in the present study has a very

high COP. For a generating temperature of 908C,

the COP reaches 0.5 at a condensing temperature

of 288C and evaporating temperature of 88C. This

experimental result exceeds the published test

data for freon ejector cooling systems.

The COP of the ECS can be improved further

by properly selecting the generating temperature

and using a better design of ejector. It can reach

nearly 0.6 at generating temperature 1008C, condensing temperature 308C, and evaporating temperature 88C from the prediction of Fig. 2.

4. SOLAR EJECTOR COOLING SYSTEM

PERFORMANCE

The performance of the solar ejector cooling

system can be analyzed by using the collector

characteristics in Eq. 1, the 1-D ejector analysis

(Fig. 2) and the testing results of the ejector

cooling system. The overall system COP of the

solar cooling system becomes:

COPo 5 COPECS 3 hsc

225

The solar ejector cooling system can also

become a refrigeration system if it was operated

at low evaporating temperature. Fig. 5 shows that

the solar refrigeration system has an optimum

overall COP around 0.12 at T i 51028C and T e 5

268C for solar radiation at 700 W m 22 . This

system can be used for an ice-storage air-conditioning system.

A solar refrigeration plant using the ejector

cooling system is shown to be feasible according

to the present study. A solar air-conditioning

system is proposed according to the present

results as follows:

Cooling capacity

Evaporating temperature

Condensing temperature

Generating temperature

COPECS

Solar collector eff. hsc

COPo

Solar collector area

10.5 kW (3RT)

88C

328C

958C

0.5

0.5

0.22

68 m 2

In practical design, a backup heater which is

driven by natural gas or oil is required at the exit

of the solar collector. A compact, low-cost gasfired instant domestic water heater may be used

with some simple temperature controller.

(2)

where COPECS is the COP of the ejector cooling

system presented in Fig. 2. We calculate the

collector efficiency using the collector inlet temperature at 108C higher than the generating temperature of the ejector cooling system, i.e. T i 5

T g 1108C. Assuming no heat loss in the pipe, Fig.

5 shows that the system will have an optimum

overall efficiency around 0.22 at T g 5958C and

T e 588C, for solar radiation at 700 W m 22 .

Fig. 5. Overall COP of a solar ejector cooling system.

5. DISCUSSIONS AND CONCLUSION

The design of the solar ejector cooling system

is very simple. By using the solar collector as the

generator of the ejector cooling system, it has

only four major components. The installation cost

thus can be lowered as compared to the absorption cooling system. However, the performance of

the ejector cooling system needs to be improved

further in order to compete with the absorption

system.

The performance of an ejector cooling system

is affected by the working fluid selected, the

ejector design and manufacturing, and the thermodynamic cycle design. In the present study, we

use R141b as the working fluid and experimentally obtain a very high COP (about 0.5) for a

single-stage ejector cooling system. If this was

used in solar cooling, the overall COP of the solar

ejector cooling system can reach as high as 0.22.

The solar cooling system can also be used for the

ice-storage air-conditioning system if it was operated at low evaporating temperature (268C).

The research on the ejector cooling system is

still underway at the National Taiwan University.

The final goal is to improve the COP of the

226

B. J. Huang et al.

ejector cooling system to about 0.7 so that it can

compete with the absorption cooling system. This

is possible based on the present and some other

recent studies (Eames et al., 1995a,b; Nahdi et al.,

1993). The ejector cooling system can also be

driven by various kinds of energy sources such as

solar, waste heat, bio-gas energy, natural gas, or

oil etc.

NOMENCLATURE

COPECS

COPo

I

Ta

T *c

Te

Tg

Ti

hsc

v

Coefficient of performance (COP) of the ejector

cooling system, dimensionless

Overall coefficient of performance (COP) of solar

ejector cooling system,

dimensionless

Solar radiation incident upon the collector slope,

W m 22

Ambient temperature, 8C

Vapor saturation temperature corresponding to the

critical back pressure of ejector, 8C

Evaporating temperature of ejector cooling system, 8C

Generating temperature of ejector cooling system,

8C

Collector inlet temperature, 8C

Solar collector efficiency, dimensionless

Ejector entrainment ratio (5primary flowrate / suction flowrate)

AcknowledgementsThe present study was supported by the

National Science Council, Taiwan, through Grant No. NSC862212-E002-088 and NSC86-2811-E002-004R and the Energy

Commission, the Ministry of Economic Affairs, Taiwan, ROC.

REFERENCES

Anderson H. (1975) Assessment of solar powered vapor jet

air-conditioning systems. Proc. 1975 ISES Congress, Los

Angeles, CA, USA, July 28August 1, 1975.

Bansal N. K., Blumenberg J., Kavasch H. J. and Roettinger T.

(1997) Performance testing and evaluation of solid absorption solar cooling unit. Solar Energy 61, 2, 127140.

Chinnapa J. C. V. (1961) Experimental study of the intermittent vapor absorption refrigeration cycle employing the

refrigerant-absorbent systems of ammonia water and ammonia lithium nitrate. Solar Energy 5, 118.

Eames I. W., Aphornratana S. and Sun D.-w. (1995) The

jet-pump cycle a low cost refrigerator option powered by

waste heat. Heat Recovery Systems and CHP 15, 8, 711

721.

Eames I. W., Aphornratana S. and Haider H. (1995) A

theoretical and experimental study of a small-scale stem jet

refrigerator. Int. J. Refrig. 18, 6, 378386.

Huang B. J. and Hsieh S. W. (1990) An automation of

collector testing and modification of ANSI /ASHRAE 931986 Standard ASME. J. Solar Energy Eng. 112, 257267.

Huang B. J., Jiang C. B. and Hu F. L. (1985) Ejector

performance characteristics and design analysis of jet

refrigeration system. Trans ASME J. Eng. Power 107,

792802.

Jhadan S. Z., Petrenko V. A., Kitaev V. F. and Vasiliev J. Z.

(1976) Investigation of the ejector refrigeration machine

using R142b at the operating conditions. Kholodilnaya

Technicai I technologia, Kiev, Technica, 37.

Kakabaev A. and Davletov A. (1966) A freon ejector solar

cooler. Geliotekhnika 2, 5, 4248.

Korres C. J., Bardakas E. E. and Koumou-tsos N. G. (1989)

Performance analysis of a solar vapour thermal compression

chiller. Int. J. Energy Res. 13, 243252.

Lallemand R. and Dorantes A. (1995) Prediction of performance of a jet cooling system operating with pure

refrigerants or non-azeotropic mixtures. Int. J. Refrig. 18, 1,

2130.

Munday J. T. and Bagster D. F. (1976) The choking phenomena in ejector with particular reference to steam jet refrigeration. Thermal fluids Conference of Inst. of Eng. Australia,

Hobart, National Conference Publication, pp. 8488, 1976.

Munday J. T. and Bagster D. F. (1977) A new ejector theory

applied to steam jet refrigeration. Ind. Eng. Chem. Process

Des. Dev. 16, 4, 442449.

Nahdi E., Champoussin J. C., Hostache G. and Cheron J.

(1993) Optimal geometric parameters of a cooling ejector

compressor. Int. J. Refrig. 16, 1, 6772.

Petrenko V. A. (1992) A solar vapor ejector refrigerator testing

in air conditioning regime. World Renewable Energy Congress, Reading, UK, Sept. 1318, 1992.

Stchetinina N. A., Jhadan S. Z. and Petrenko V. A. (1987)

Comparison between the efficiency of different types of

heating for solar ejector freon refrigeration machine generator. Heliotechnica N4, 7174.

Sun D.-w. (1996) Variable geometry ejectors and their applications in ejector refrigeration systems. Energy 21, 10, 919

929.

Wilbur P. J. and Mancini T. R. (1976) A comparison of solar

absorption air conditioning systems. Solar Energy 18, 569.

You might also like

- Me-662 Convective Heat and Mass TransferDocument14 pagesMe-662 Convective Heat and Mass TransferBourhan Mohammad TashtoushNo ratings yet

- Analytical Slope AngleDocument18 pagesAnalytical Slope AngleBourhan Mohammad TashtoushNo ratings yet

- Full Text 01Document11 pagesFull Text 01Bourhan Mohammad TashtoushNo ratings yet

- Full Text 01Document11 pagesFull Text 01Bourhan Mohammad TashtoushNo ratings yet

- Full Text 01Document11 pagesFull Text 01Bourhan Mohammad TashtoushNo ratings yet

- Full Text 01Document11 pagesFull Text 01Bourhan Mohammad TashtoushNo ratings yet

- The Amazing Qur'AnDocument17 pagesThe Amazing Qur'Anhttp://www.toursofpeace.com/0% (1)

- Car VentilationDocument1 pageCar VentilationBourhan Mohammad TashtoushNo ratings yet

- An Approach To Analyse Energy and Exergy - Analysis of Thermal Power Plants A ReviewDocument10 pagesAn Approach To Analyse Energy and Exergy - Analysis of Thermal Power Plants A ReviewLieu Dinh PhungNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Block P2P Traffic with pfSense using Suricata IPSDocument6 pagesBlock P2P Traffic with pfSense using Suricata IPSEder Luiz Alves PintoNo ratings yet

- Real-Time Java and ATCDocument44 pagesReal-Time Java and ATCdnk_victon6248No ratings yet

- Pumping Station Modification PDFDocument15 pagesPumping Station Modification PDFcarlosnavalmaster100% (1)

- Ap22 FRQ World History ModernDocument13 pagesAp22 FRQ World History ModernDylan DanovNo ratings yet

- Plastic Waste Powerpoint TemplateDocument39 pagesPlastic Waste Powerpoint TemplateVinh Lê KhảiNo ratings yet

- NYU Stern Evaluation NewsletterDocument25 pagesNYU Stern Evaluation NewsletterCanadianValueNo ratings yet

- Nippon Metal Primer Red Oxide TDSDocument2 pagesNippon Metal Primer Red Oxide TDSPraveen KumarNo ratings yet

- The Importance of Personal Protective Equipment in Pesticide App 2018Document4 pagesThe Importance of Personal Protective Equipment in Pesticide App 2018Anees MalikNo ratings yet

- Thesis Statement About Plastic BagsDocument7 pagesThesis Statement About Plastic Bagslyjtpnxff100% (2)

- Chapter 7 - Trade and Investment EnvironmentDocument7 pagesChapter 7 - Trade and Investment EnvironmentMa. Cristel Rovi RibucanNo ratings yet

- Cost Analysis Format-Exhaust DyeingDocument1 pageCost Analysis Format-Exhaust DyeingRezaul Karim TutulNo ratings yet

- Project Proposal: Retail Environment Design To Create Brand ExperienceDocument3 pagesProject Proposal: Retail Environment Design To Create Brand ExperienceMithin R KumarNo ratings yet

- Tdi Hazid TemplateDocument11 pagesTdi Hazid TemplateAnonymous rwojPlYNo ratings yet

- Introduction To Management: Planning & Goal SettingDocument31 pagesIntroduction To Management: Planning & Goal SettingMaisarah NorzihanNo ratings yet

- Unit 8 Risk in The WorkplaceDocument11 pagesUnit 8 Risk in The WorkplaceAnonymous WalvB8No ratings yet

- 15 04 06 SCDocument30 pages15 04 06 SCSugarNo ratings yet

- Banking Software System Monitoring ToolDocument4 pagesBanking Software System Monitoring ToolSavun D. CheamNo ratings yet

- Climate Smart Agriculture Manual FINAL 2 2 Sent in Sierra Leones PDFDocument201 pagesClimate Smart Agriculture Manual FINAL 2 2 Sent in Sierra Leones PDFKarthikNo ratings yet

- Norlys 2016Document124 pagesNorlys 2016elektrospecNo ratings yet

- POLS219 Lecture Notes 7Document7 pagesPOLS219 Lecture Notes 7Muhammad Zainal AbidinNo ratings yet

- Speaking Telephone RoleplaysDocument2 pagesSpeaking Telephone RoleplaysremimiguelNo ratings yet

- JESTEC TemplateDocument11 pagesJESTEC TemplateMuhammad FakhruddinNo ratings yet

- Igt - Boot Os List Rev B 10-28-2015Document5 pagesIgt - Boot Os List Rev B 10-28-2015Hector VillarrealNo ratings yet

- Creating A Simple PHP Forum TutorialDocument14 pagesCreating A Simple PHP Forum TutorialLaz CaliphsNo ratings yet

- EzraCohen TVMasterclass 2.0Document10 pagesEzraCohen TVMasterclass 2.0Pete PetittiNo ratings yet

- Refractomax 521 Refractive Index Detector: FeaturesDocument2 pagesRefractomax 521 Refractive Index Detector: FeaturestamiaNo ratings yet

- Tutorial: Energy Profiles ManagerDocument6 pagesTutorial: Energy Profiles ManagerDavid Yungan GonzalezNo ratings yet

- Open Recruitment Member Kejar Mimpi Periode 2023 (Responses)Document22 pagesOpen Recruitment Member Kejar Mimpi Periode 2023 (Responses)Sophia Dewi AzzahraNo ratings yet

- Ade.... Data Analysis MethodsDocument2 pagesAde.... Data Analysis MethodszhengNo ratings yet

- Graphics Coursework GcseDocument7 pagesGraphics Coursework Gcseafiwhlkrm100% (2)