Professional Documents

Culture Documents

Lese Probe

Uploaded by

Santosh PavanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lese Probe

Uploaded by

Santosh PavanCopyright:

Available Formats

106

3 SAP ERP Operations

3.7 Logistics Execution

The Logistics Execution (LE) component controls and organizes both the movement

of material within the enterprise (warehouse management) and also transportation

between enterprises. Movement of material includes the outbound processing of

sending materials to customers, the corresponding inbound processing of receiving

materials from vendors, and organizing and monitoring the transportation of

material.

3.7.1 Architecture Overview

Purchase Order Processing

Production Order Processing

Sales Order Processing

Order Processing

R

Batch

Management

Advance

Shipping

Notification

Processing

Transfer

Order

Processing

Inbound

Delivery

Processing

Transfer

Orders

Billing

Outbound

Delivery

Processing

Proof of

Delivery

Processing

Picking Logic

Packing Logic

Warehouse

Management

Inbound

Shipment

Processing

Handling

Unit

Management

Inbound Shipment

Document

Inbound Shipping (SHP)

Transportation Management (TRA)

Freight Cost

processing

Outbound Delivery Document

Outbound Shipping (SHP)

Outbound Shipment

Document

Inbound Delivery Document

Extended

Warehouse

Management

(EWM)

Outbound

Shipment

Processing

Shipment Cost

Document

Logistics Execution (LE)

Invoice Receipt Processing

Goods Receipt Processing

Inventory Management

Inventory

Update

Inventory

Goods Issue Processing

Update

Inventory

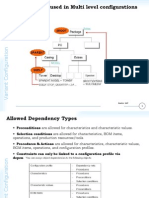

Figure 3-27: Architecture of Logistics Execution.

Transportation

Management

(TM)

3.7 Logistics Execution

107

From architecture perspective, LE is divided into the following areas (see figure 3-27):

Inbound delivery processing, which covers receiving goods from the vendor and

storing them in the company's warehouse

Warehouse management, which supports stock transfer, picking, and packing

Transportation management, which supports inbound and outbound shipment

processes

Outbound delivery processing, which includes picking the goods and transporting

them to the customer

Typically, logistics execution is initiated by purchase order processing in MM or sales

order processing in SD. The inventory itself is part of MM. Logistics execution

processes are closely integrated with inventory management, which maintains the

actual inventory

3.7.2 Integration Architecture

3.7.2.1

Integration with SAP ERP

LE is integrated with SD and MM using database integration. SD triggers LE to

perform the order fulfillment process for a sales order, in particular the delivery

processing. In this case an outbound delivery document is created referencing the

sales order.

When material is received by a company, LE creates an inbound delivery with

reference to the purchase order and triggers goods receipt processing in MM.

3.7.2.2

Integration with SAP Business Suite

LE can be integrated with SAP SCM to extend its functional scope. SAP EWM can be

connected to the warehouse management component of LE to provide additional

warehouse management functions in the areas of advanced shipment notification

(ASN), work assignment, and picking bin determination. Deliveries are created in LE

and transferred to SAP EWM using queued RFC.

The transportation management functionality of LE can be replaced by SAP

Transportation Management, which supports transportation request management,

transportation dispatching, and execution. In this case LE forwards all transportation

requests to SAP Transportation Management (SAP TM) using asynchronous message

transfer.

108

3 SAP ERP Operations

3.7.3 Inbound Delivery Processing

Inbound delivery processing only starts after the enterprise has purchased material

(raw material, goods) that the vendor has confirmed by sending a purchase order

confirmation. If the procured material needs to be transported to the enterprise,

inbound shipment processing is performed. It is part of transportation management

(see chapter 3.7.5)

To be prepared to receive the ordered material, inbound delivery processing is

initiated in one of the following ways:

An inbound delivery document is created manually with reference to the purchase

order.

The vendor sends an advance shipping notification to the enterprise via IDoc, (see

chapter 1.3.5) which triggers the creation of an inbound delivery document.

The vendor may send an updated version of the advance shipping notification, which

updates the inbound delivery document if this has not been processed yet.

The inbound delivery document includes the following data:

Header:

o ID

o Status

o ID of corresponding purchase order

o Vendor

o Date of delivery

Item:

o Quantity and type of material to be received

The inbound delivery document is used to track the materials arrival, unloading,

unpacking, and placement into the warehouse. When the material is received at the

plant or warehouse, inbound delivery processing sends a proof of delivery (POD) as

IDoc to the provider. In addition, the inventory is updated by goods receipt

processing.

3.7.4 Outbound Delivery Processing

The outbound delivery processing within LE is mainly responsible for sales order

fulfillment. If the vendor organizes the transportation of the material to the customer,

outbound delivery processing initiates outbound shipment processing which is part of

transportation management (see chapter 3.7.5). Outbound delivery processing is

integrated with warehouse management if the materials are stored in the warehouse

(see chapter 3.7.6).

3.7 Logistics Execution

109

Sales order processing initiates outbound delivery processing as soon as the

requested material is available in the inventory (see figure 3-27). Then outbound

delivery processing creates an outbound delivery document with reference to the

sales order. It includes the following information:

Header:

o ID

o Status

o ID of corresponding sales order

o Customer

o Date of delivery

o Ship-to party

o Shipping point

o Route

Item:

o Quantity and type of material to be delivered

o Delivering plant or warehouse

o Loading point

Outbound delivery processing performs the following tasks:

Shipping point determination

Delivery scheduling

Route determination

Receipt of POD (proof of delivery)

If the material is not picked up directly by the customer but transported to the

customers ship-to location, outbound shipment processing is performed.

Once the goods are delivered, the goods issue processing updates the inventory by

reducing the quantity that was delivered. Subsequent financial documents are posted

so that billing can be performed.

3.7.4.1

Shipping Point Determination

The shipping point is the organizational unit of a company that is responsible for a

dedicated way of shipment (for example, the mail depot or a plant rail station). Within

LE the shipping point is responsible for delivery creation, updating, and monitoring

as well as goods issue processing. One delivery is processed by one shipping point

only.

110

3 SAP ERP Operations

Shipping Conditions

Delivery

Scheduling

Logic

Sold to Party / Order

Shipping

Determination

Logic

Loading

Group

Shipping Point

Material Master

Route

Determination

Logic

Plant

Sales Order

Shipping Point Determination

Figure 3-28: Shipping Point Determination.

Outbound delivery processing determines the shipping point for ordered material

based on the following three input values (see figure 3-28):

Shipping conditions (for example, that the material should be delivered as soon as

possible)

Plant that delivers the material (provided within the sales order document)

Loading group that defines the way of loading (for example, that the material must

always be loaded with a crane or a forklift)

For each possible combination of values, the corresponding shipping point is defined

in customizing tables. So outbound delivery processing looks up the corresponding

shipping point. The shipping point is a prerequisite for delivery scheduling and route

determination.

3.7.4.2

Delivery Scheduling

Delivery scheduling defines a timeline for all activities that have to be carried out

before the material can be delivered to the customer (for example, picking, packing,

and loading the material). To do so, delivery scheduling determines the material

availability deadline, at which point the material must be picked from the bin and

packed, as well as the loading deadline, at which point the material must be available

for loading.

3.7 Logistics Execution

3.7.4.3

111

Route Determination

A route describes a course of travel between the shipping point and an end point. A

transportation planner maintains routes, which are stored in customizing tables. At

run time the route determination logic checks if there is a route that connects the

shipping point to the ship-to location of the sales order. The following attributes

determine the route selection (see figure 3-29):

Departure Country +

Departure Zone

Shipping Point

Shipping Conditions

Sold to Party / Order

Transportation Group

Material Master

Route

Determination

Logic

Route

Transport

Scheduling

Logic

Destination Country +

Transportation Zone

Customer Master

Weight Group

Delivery

Route Determination

Figure 3-29: Route Determination.

Departure country and zone from where the materials are to be shipped (this

information comes from shipping point).

Shipping conditions, which defines how the materials are to be delivered (this

information comes from the sales order).

Transportation group (this information comes from material master).

Destination country and transportation zone, which indicates where the materials

are to be delivered (this information comes from customer master).

Weight group (relevant for delivery), which indicates how much of materials can

be delivered. The weight group is determined on the basis of the total weight of the

delivery.

112

3 SAP ERP Operations

Based on the above input values, the route is determined during the creation of a

delivery. Route determination is a prerequisite for transportation scheduling, which

defines the timelines for preparing and carrying out the transportation.

Transportation scheduling determines the following two deadlines:

The transportation scheduling deadline is the date on which transportation of the

goods must be organized.

The goods issue deadline is the date on which the goods must leave the company

in order to arrive at the customer location without any delays.

To do so, it calculates, for example, the transit time of a foreign forwarding agent and

the transportation lead time for arranging a truck.

3.7.4.4

Proof of Delivery Processing

Customers can send a proof of delivery (POD) document to LE to confirm that they

received the ordered material. The POD is required in business processes in which an

invoice is issued only after the customer has confirmed the receipt of the delivery.

The POD includes the following attributes:

POD date

POD time

Actual quantity that arrived

Reason for possible differences in quantities, if any. This is especially important for

deliveries in which the delivery quantity varies because of the nature of the goods

or for which the exact delivery quantity is unknown from the start.

The POD document reflects the actual delivery status thereby facilitating an accurate

billing process and eliminating unnecessary credit memos. The ship-to party transfers

the POD to SAP ERP Operations via IDoc. The message is received by POD

processing. Now billing is initiated based on the POD quantity.

In case the customer also uses SAP ERP, inbound delivery processing sends the

POD via EDI technology. Inbound delivery processing calls output determination,

which determines the system address to which the POD has to be sent. Then inbound

delivery processing creates an IDoc, which is transmitted to the vendors SAP ERP

application. For more details on output determination, see section 3.4.3.3

3.7.5 Transportation Management

Transportation management embraces inbound shipment processing as well as

outbound shipment processing. It is triggered by the respective delivery processing.

Transportation management includes the following functions:

3.7 Logistics Execution

113

Transportation planning and shipment completion

Service agent selection

Shipment costs calculation

Shipment costs settlement

Billing of customer freight

Follow-up and supervision of shipments

Management of shipment costs

Inbound as well as outbound shipment processing creates a shipment document that

first of all defines which deliveries is part of one shipment. In addition, the following

information is maintained in the shipment document:

Service agent or logistics provider that is responsible for the transport

Mode of transport, such as rail, truck, or plane

Shipment type

Estimated freight cost

During shipment processing, the shipment document is used to keep track of the

shipment status. In addition, the system does a leg determination, which provides

information about how the material reaches the destination from the source by

calculating subsequent legs and transfer points (mode of transport: air, land, water)

from the point of departure to destination. The determination is based on the simple

rules maintained in the customizing and does not involve optimization algorithms

and also has no geographical intelligence.

One aspect of the transportation management is to handle the freight costs or the

shipment costs that were involved when the material was delivered. The handling of

freights is an integral part of the LE transportation functions and always happens in

SAP ERP even though an external transportation management system is used. In this

case the freight requests are initiated by the external system to do the freight cost

settlement in SAP ERP. The costs incurred during the freights are booked separately,

and separate financial documents are generated for this purpose to settle the freights.

The freights can be handled by the manufacturer or a third-party logistics provider.

3.7.5.1

Shipment Costs Processing

The following explains how the shipment costs are calculated in SAP ERP Operations

with respect to the inbound and outbound point of view.

Shipment Costs: Inbound Shipment Processing

As mentioned, the inbound delivery processing creates a delivery document based on

the purchase order. If transportation is required, an inbound shipment document is

114

3 SAP ERP Operations

subsequently created with reference to the delivery. The shipment document specifies

who transports the material to the customer and when.

Purchase Order (PO)

Processing

Purchase

Order

Invoice

Verification

Logic

Invoice for Materials

+ Invoice for

Delivery Costs

Inbound Delivery

Processing

Delivery

Post Goods Receipt

Inbound Shipment

Processing

Shipment

Goods Receipt

Processing

Financials

Shipment Cost

Processing

Shipment

Cost Document

Transfer Delivery

Costs

Pricing Logic

Transportation + Delivery Cost

Goods Receipts

Logistics Execution (LE) Inbound

Figure 3-30: Inbound Shipment Cost Processing.

If the transportation cost is not included in the sales prices, inbound shipment

processing creates a shipment cost document. The shipment cost document stores the

price of the transport, which can be entered manually or using price determination

based on the customized pricing conditions. The second case is used if the enterprise

has a contract with the transportation provider.

Afterwards the goods receipt processing is triggered, which calls the shipment

costs interface to transfer the cost, as shown in figure 3-30. Thereby the shipment cost

is transferred to goods receipt processing logic, which passes it on to SAP ERP

Financials. The successful receipt of material is also documented in the purchase

order, and the delivery costs are also updated in the purchase order.

The whole process ends with the invoice verification, in which two separate

invoices are posted with reference to the purchase order: one invoice for the supplier

and another for paying the delivery costs to the transportation agent. The payment is

then initiated by SAP ERP Financials.

3.7 Logistics Execution

115

Sales

Orders

Sales Order Processing

R

Outbound Delivery

Processing

Delivery

Order Processing + Order Fullfillment

R

Billing Logic

Outbound Shipment

Processing

Shipment

Shipment Cost

Processing (Estimated Cost)

Shipment Cost

Document

Financials

Pricing Logic

Account Assignment Logic

Customizing

Transportation + Freight Costs

R

Billing

Document

Transfer

Cost Data

Purchase Order

Processing

Purchase Order

Service Entry

Sheet Processing

Service Entry Sheet

Invoice Verification

Logic (Actuals)

Invoice

MM

Logistics Execution (LE) Outbound

Figure 3-31: Outbound Shipment Cost Processing.

Shipment Costs: Outbound Shipment Processing

Outbound shipment processing creates a shipment document to manage the

transportation of the material from the shipping point to the ship-to location. One

shipment document can plan the transportation of one or more deliveries.

Shipment cost processing contains the functions for calculating and settling shipment

costs that arise from material transportation. To do so, outbound shipment processing

triggers the creation of a shipment cost document with reference to the original

shipment document (see figure 3-31). The separate shipment cost document helps

companies to effectively plan transportation with transparent cost.

Shipment cost processing calls the pricing engine to calculate the estimated

shipment cost. The calculation of shipment costs is carried out using the condition

116

3 SAP ERP Operations

technique in pricing (see chapter 3.4.3.1). In addition, shipment cost processing

triggers the account assignment logic, where the appropriate accounting object for the

shipment cost is determined (for example, cost center).

If a third-party logistics provider is involved in the shipment, the shipment cost

processing triggers the creation of a purchase order in MM to procure the

corresponding services. The shipment cost as well as the account is passed to the

purchase order. Now the process continues in MM: Once the materials are delivered, a

service entry sheet is created with reference to the purchase order. As soon as the

invoice from the third-party logistics provider is received and verified, SAP ERP

Financials is triggered, which initiates payment of the invoice and billing of the

shipment cost to the customer.

3.7.6 Warehouse Management

SAP ERP Operations keeps track of the material stock in the inventory provided by

MM. Every movement of goods into or out of the company is reflected there.

Warehouse management (WM) supports controlling the movement and storage of

material inside the company, more precisely within the companys warehouse. The

typical operations in a warehouse include receiving, put away, picking, packing, and

transfer of material.

LE provides only lean warehouse management. But SAP ERP Operations can be

integrated with the extended warehouse management functionality provided by SAP

SCM.

3.7.6.1

Technical Representation of the Warehouse

Within Logistics Execution a warehouse is represented in the following way:

Warehouse number

Each warehouse has an identifier, which allows for the management of multiple

warehouses in parallel.

Storage type

A warehouse can provide multiple storage areas, which are defined by the storage

type. Examples are high rack storage, bulk storage, or fixed storage.

Picking area (aka storage section)

Each storage type has a picking area, where the material is picked.

Storage bin

You might also like

- Snacks Main Course Sweets & DesertsDocument1 pageSnacks Main Course Sweets & DesertsSantosh PavanNo ratings yet

- Snacks Main Course Sweets & DesertsDocument1 pageSnacks Main Course Sweets & DesertsSantosh PavanNo ratings yet

- Canada Express Entry ...Document5 pagesCanada Express Entry ...Santosh PavanNo ratings yet

- Variant Configuration in ERP SAPDocument52 pagesVariant Configuration in ERP SAPbalashowryraju100% (72)

- Creating Factory Holiday Calendar PDFDocument10 pagesCreating Factory Holiday Calendar PDFSantosh PavanNo ratings yet

- Canada Express Entry ...Document5 pagesCanada Express Entry ...Santosh PavanNo ratings yet

- QuestionDocument3 pagesQuestionFaisal ShahzadNo ratings yet

- Variant Config 1Document26 pagesVariant Config 1Goutam GhoshNo ratings yet

- Variant ConfigurationDocument62 pagesVariant ConfigurationAhmed Talaat100% (9)

- Variant Config 2Document25 pagesVariant Config 2Tan_nu100% (5)

- Variant Configuration 3Document19 pagesVariant Configuration 3Tan_nu100% (1)

- Inspection of Incoming MaterialDocument41 pagesInspection of Incoming MaterialK Veera Kishore KumarNo ratings yet

- GelfandSaul TrigonometryDocument1 pageGelfandSaul TrigonometrySantosh Pavan0% (1)

- Guideline For QM Certificate For Delivery WikiDocument14 pagesGuideline For QM Certificate For Delivery WikiMohammad ArifNo ratings yet

- SAP MRP Strategy Made Easy PDFDocument172 pagesSAP MRP Strategy Made Easy PDFraky0369100% (4)

- Sap MM TutorialDocument39 pagesSap MM Tutorialiqbal1439988No ratings yet

- In Process Inspection in Production Sampling PDFDocument6 pagesIn Process Inspection in Production Sampling PDFSantosh PavanNo ratings yet

- ZURRAAKDocument1 pageZURRAAKSantosh PavanNo ratings yet

- Basic CalculusDocument292 pagesBasic Calculuslouis_kwan_10% (1)

- Trig NotesDocument183 pagesTrig NotesJason SonidoNo ratings yet

- Bump ChikDocument1 pageBump ChikSantosh PavanNo ratings yet

- Trig NotesDocument1 pageTrig NotesSantosh PavanNo ratings yet

- VDGRDocument1 pageVDGRSantosh PavanNo ratings yet

- SAP MM Training - Purchase Requisition CreationDocument41 pagesSAP MM Training - Purchase Requisition CreationMandar BahadarpurkarNo ratings yet

- BUMP CHIK - Hip Hop DanceDocument1 pageBUMP CHIK - Hip Hop DanceSantosh PavanNo ratings yet

- SAP 4.6 Basic Skills Self-Study (MIT) PDFDocument152 pagesSAP 4.6 Basic Skills Self-Study (MIT) PDFEliezer Alvarez LaresNo ratings yet

- Basic CalculusDocument1 pageBasic CalculusSantosh PavanNo ratings yet

- Sap PP TutorialDocument21 pagesSap PP TutorialSantosh Pavan67% (3)

- Citation 318013425Document1 pageCitation 318013425Santosh PavanNo ratings yet

- HR Verb 1Document3 pagesHR Verb 1Santosh PavanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Oracle Service Procurement Advisory & ConsultingDocument22 pagesOracle Service Procurement Advisory & ConsultingPrakashNo ratings yet

- Introduction to Retailing: Customer Needs and Buyer BehaviorDocument6 pagesIntroduction to Retailing: Customer Needs and Buyer BehaviorHazel Lynn ChungNo ratings yet

- Important FrameworksDocument12 pagesImportant FrameworksPrabhat MehtaNo ratings yet

- Jishan Mahmud - Midterm Spring 2020 PDFDocument5 pagesJishan Mahmud - Midterm Spring 2020 PDFJishan Mahmud-1220No ratings yet

- Tax Administration SimplifiedDocument74 pagesTax Administration SimplifieddeogratiasNo ratings yet

- Advances in Accounting Education: Teaching and Curriculum InnovationsDocument15 pagesAdvances in Accounting Education: Teaching and Curriculum InnovationsFachrul RoziNo ratings yet

- MG6851-Principles of Management Question BankDocument5 pagesMG6851-Principles of Management Question BankThirumal AzhaganNo ratings yet

- Urbanization, Agriculture and Rural DevelopmentDocument11 pagesUrbanization, Agriculture and Rural Developmenthimelhimel34No ratings yet

- Latihan Application LetterDocument5 pagesLatihan Application LetterjhequeNo ratings yet

- Performance Task 1Document3 pagesPerformance Task 1Diana CortezNo ratings yet

- PT Petrosea Tbk Company ProfileDocument14 pagesPT Petrosea Tbk Company Profilekakashi hatakeNo ratings yet

- Global Supplier Manual GSM-06 Revision 6Document28 pagesGlobal Supplier Manual GSM-06 Revision 6yyqzrs6fs6No ratings yet

- Business Strategy Analysis for Traphaco CompanyDocument11 pagesBusiness Strategy Analysis for Traphaco Companybakhtawar soniaNo ratings yet

- Amazon's Market-Oriented MissionDocument4 pagesAmazon's Market-Oriented MissionPerez WaiswaNo ratings yet

- PD Enec 308 - May 2012Document2 pagesPD Enec 308 - May 2012Abraham Seco ArmestoNo ratings yet

- Journalpublication PJMTR Vol - Xiino.1 January June2022 Version1662!1!22 RetailDocument23 pagesJournalpublication PJMTR Vol - Xiino.1 January June2022 Version1662!1!22 RetailJohn Xavier QuilanticNo ratings yet

- Syndicate 1 - Microsoft Competing On TalentDocument9 pagesSyndicate 1 - Microsoft Competing On TalentardianabyNo ratings yet

- (Barbara B. Moran, Robert D. Stueart) Library and PDFDocument524 pages(Barbara B. Moran, Robert D. Stueart) Library and PDFMartha IlaganNo ratings yet

- Nature and Scope of Cost Accounting - Dynamic Tutorials and ServicesDocument9 pagesNature and Scope of Cost Accounting - Dynamic Tutorials and Servicesprakashzodpe20130% (1)

- Indian Institute of Management Ahmedabad: Organizational Dynamics: Class-Participation AssignmentDocument5 pagesIndian Institute of Management Ahmedabad: Organizational Dynamics: Class-Participation AssignmentMNo ratings yet

- Sample Research Paper About HotelsDocument6 pagesSample Research Paper About Hotelsefdwvgt4100% (1)

- RHD Management ManualDocument93 pagesRHD Management ManualSadia Hossain DristiNo ratings yet

- Ebook EUMDR Auditing (LEF-V0a)Document260 pagesEbook EUMDR Auditing (LEF-V0a)workNo ratings yet

- Strategy and Operations Expert Arpita Rathore Seeking New OpportunityDocument5 pagesStrategy and Operations Expert Arpita Rathore Seeking New OpportunityArpita Kusum Singh RathoreNo ratings yet

- MBA View Book 08 09Document48 pagesMBA View Book 08 09Mahfuzur RahmanNo ratings yet

- A Presentation On: "Audit and AssuranceDocument10 pagesA Presentation On: "Audit and AssuranceSaiful Alam MirazNo ratings yet

- Program Corporate Social Responsibiliti CSR PTPN VDocument25 pagesProgram Corporate Social Responsibiliti CSR PTPN VauliaNo ratings yet

- From Good to Great: An Introduction to Servant LeadershipDocument33 pagesFrom Good to Great: An Introduction to Servant LeadershipPapa KingNo ratings yet

- PMP 9th Ed Extra Exercises Network DiagramsDocument8 pagesPMP 9th Ed Extra Exercises Network DiagramsivanNo ratings yet

- ACC 100 - Course Outline Student VersionDocument3 pagesACC 100 - Course Outline Student VersionJhoylie BesinNo ratings yet