Professional Documents

Culture Documents

Tutorial 2 OM - Chapter 7 & 7S - 16-09-2014

Uploaded by

cindy yulendaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial 2 OM - Chapter 7 & 7S - 16-09-2014

Uploaded by

cindy yulendaCopyright:

Available Formats

TUTORIAL 2 16-09-2014

OPERATIONS MANAGEMENT

CHAPTER 7 Process Design | CHAPTER 7S Capacity Planning

PROBLEM 1

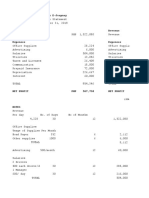

Creative Cabinets, Inc., needs to choose a production method for its new office shelf, the Maxistand. To

help accomplish this, the firm has gathered the following production cost data:

Process Type

Annualized Fixed Cost of

Variable Costs (per unit) ($)

Plant & Equipment ($)

Labor

Material

Energy

Mass Customization

1,260,000

30

18

12

Intermittent

1,000,000

24

26

20

Repetitive

1,625,000

28

15

12

Continuous

1,960,000

25

15

10

Creative Cabinets projects an annual demand of 24,000 units for the Maxistand. The Maxistand will

sell for $120 per unit.

a. Which process type will maximize the annual profit from production the Maxistand?

b. What is the value of this annual profit?

PROBLEM 2 (MID-TERM 2013)

As a prospective owner of a club known as the Red Rose, you are interested in determining the

volume of sales dollars necessary for the coming year to reach the break-even point. You have decided

to break down the sales for the club into four categories, the first category being beer. Your estimate

of the beer sales is that 50,000 drinks will be served. The selling price for each unit will average $2;

the cost is $1. The second major category is meals, which you expect to be 15,000 units, but with an

average price of $10 and a cost of $6. The third major category is desserts and wine, of which you also

expect to sell 10,000 units, but with an average price of $3 per unit sold and a cost of $2 per unit. The

final category is lunches and inexpensive sandwiches, which you expect to total 30,000 units at an

average price of$6.5 with a food cost of $3.5. Your fixed cost (rent, utilities, and so on) is $2,000 per

month plus $3,000 per month for entertainment.

a. What is your break-even point in dollars per month?

b. What is the expected number of meals each day if you are open 30 days a month?

RAF2909

Email kelas: operationsmgmt.raf@gmail.com

Password: operasiraf2014

PROBLEM 3 (UTS 2014)

Cepat Beres Shop is a specialized repair shop for trucks. This shop has a repairing capacity of 800

trucks per month. Because of maintenance for equipment and machinery should be scheduled every

month, the owner of PT Cepat Beres feels that his shop is only capable of repairing up to 600 trucks

per month. Last month, 2 employees left the shop for a few days, so that only 400 trucks were

completely repaired. What is the utilization and efficiency of the Cepat Beres Shop?

PROBLEM 4

A production process at Kenneth Day Manufacturing is shown in figure below. The drilling operation

occurs separately from, and simultaneously with, the sawing and sanding operations. A product needs

to go through only one of the three assembly operations (the operations are in parallel).

a. Which operation is the bottleneck?

b. What is the process time of the overall system?

c. What is the process cycle time of the overall system?

d. If the firm operates 8 hours per day, 20 days per month, what is the monthly capacity of the

manufacturing process?

e. Suppose that a second welding machine is added, and it has the same process time as the original

welding machine.

(i) What is the new process time of the system?

(ii) What is the new process cycle time?

RAF2909

Email kelas: operationsmgmt.raf@gmail.com

Password: operasiraf2014

You might also like

- OR Problems (All Topics) Linear Programming FormulationDocument24 pagesOR Problems (All Topics) Linear Programming FormulationHi HuNo ratings yet

- Breakeven Analysis Problems For Class Practice OM 2019Document20 pagesBreakeven Analysis Problems For Class Practice OM 2019Aman Kumar100% (1)

- AMBO-104 Accounting For Managers Assignment AssignmentDocument12 pagesAMBO-104 Accounting For Managers Assignment AssignmentEsha VermaniNo ratings yet

- Inventory Models Chapter Explains Economic Order Quantity and Reorder Point DecisionsDocument17 pagesInventory Models Chapter Explains Economic Order Quantity and Reorder Point DecisionshidayatsadikinNo ratings yet

- HW 1 MGT202Document4 pagesHW 1 MGT202Rajnish Pandey0% (1)

- SBE 2 Heuristic Aggregate PlanningDocument4 pagesSBE 2 Heuristic Aggregate Planning洪億珊No ratings yet

- 2013 Collin Technologies Case StudyDocument54 pages2013 Collin Technologies Case StudyHimanshu AgrawalNo ratings yet

- Spartan PlasticDocument2 pagesSpartan PlasticfareedahsanNo ratings yet

- Blue Nile Diamond CaseDocument7 pagesBlue Nile Diamond CaseNiharika MondalNo ratings yet

- Exam281 20131Document14 pagesExam281 20131AsiiSobhiNo ratings yet

- Home Assignment - RevisedDocument4 pagesHome Assignment - RevisedLê Quỳnh Anh100% (1)

- BE - Pre Foundation Phase - Sample PaperDocument3 pagesBE - Pre Foundation Phase - Sample PaperJaved MohammedNo ratings yet

- Berkshire Toy Case - Calculation Groupe 4 18 FevDocument9 pagesBerkshire Toy Case - Calculation Groupe 4 18 FevchandrakumaranNo ratings yet

- Bradford Manufacturing Group-6Document3 pagesBradford Manufacturing Group-6DizziNo ratings yet

- ACC2002 Managerial Accounting Textbook Solution-Ch8 EXERCISE 8-15Document10 pagesACC2002 Managerial Accounting Textbook Solution-Ch8 EXERCISE 8-15coffeedanceNo ratings yet

- 29 Purity Steel Compensation Plan AnalysisDocument7 pages29 Purity Steel Compensation Plan Analysisfajarina ambarasariNo ratings yet

- Anagene Case StudyDocument1 pageAnagene Case StudySam Man0% (3)

- BA 213 02D MidtermDocument5 pagesBA 213 02D MidtermBailey Eisenbarth100% (1)

- Bayonne Packaging PDFDocument13 pagesBayonne Packaging PDFMridula HariNo ratings yet

- Decision MakingDocument4 pagesDecision MakingRocket BhatNo ratings yet

- 6e Brewer CH03 B EOCDocument10 pages6e Brewer CH03 B EOCLiyanCenNo ratings yet

- 513-Daktronics v3Document7 pages513-Daktronics v3AhaNo ratings yet

- Braun Ma4 SM 09Document55 pagesBraun Ma4 SM 09nobleverma100% (1)

- Activity Based CostingDocument13 pagesActivity Based CostingSudeep D'SouzaNo ratings yet

- ACG2071 Managerial AccountingDocument12 pagesACG2071 Managerial AccountingKavita SinghNo ratings yet

- Kent's E-Jeepney Kent's E-Jeepney: TotalDocument20 pagesKent's E-Jeepney Kent's E-Jeepney: TotalKentNo ratings yet

- 02 QuestionsDocument3 pages02 QuestionsLt Gabriel100% (1)

- AIC Netbooks Optimizing Assembly Line EfficiencyDocument2 pagesAIC Netbooks Optimizing Assembly Line EfficiencyPedro José ZapataNo ratings yet

- Studi Kasus Hewlett Packard Company DeskDocument2 pagesStudi Kasus Hewlett Packard Company DeskTun Thu LinNo ratings yet

- Table 7.1 Quarterly Demand For Tahoe Salt: Year, QTR Period DemandDocument13 pagesTable 7.1 Quarterly Demand For Tahoe Salt: Year, QTR Period DemandФилипп СибирякNo ratings yet

- Operations Management QuizDocument1 pageOperations Management Quizjaykhan85No ratings yet

- Project Management Group-1 Individual Assignment-2: Case Analysis Pert MustangDocument9 pagesProject Management Group-1 Individual Assignment-2: Case Analysis Pert MustangANKIT GUPTANo ratings yet

- Gemini Electronics Template and Raw DataDocument9 pagesGemini Electronics Template and Raw Datapierre balentineNo ratings yet

- Managerial Accounting Chapter 5 Practice Exam SolutionsDocument4 pagesManagerial Accounting Chapter 5 Practice Exam Solutionsjklein2588No ratings yet

- Eureka ForbesDocument4 pagesEureka ForbesAniket PandeNo ratings yet

- OPIM 101 Extra Study Problems SolutionsDocument17 pagesOPIM 101 Extra Study Problems Solutionsjoe91bmw100% (1)

- OM1 Practice Exam2Document5 pagesOM1 Practice Exam2nonysinghNo ratings yet

- Home WorkDocument2 pagesHome WorkSudhanshu ShekharNo ratings yet

- Balakrishnan MGRL Solutions Ch14Document36 pagesBalakrishnan MGRL Solutions Ch14Aditya Krishna100% (1)

- Assignment MRPDocument5 pagesAssignment MRPKhánh Linh NguyễnNo ratings yet

- Problem: Inventory Management (Chapter 12) Problem-01Document23 pagesProblem: Inventory Management (Chapter 12) Problem-01tariNo ratings yet

- Using Solver to maximize profitDocument3 pagesUsing Solver to maximize profitMinh ThanhNo ratings yet

- ABC Costing With Setup and Production ActivitiesDocument3 pagesABC Costing With Setup and Production ActivitiesArun JosephNo ratings yet

- Cafe Monte BiancoDocument21 pagesCafe Monte BiancoWilliam Torrez OrozcoNo ratings yet

- 1y0 403Document65 pages1y0 403velianlamaNo ratings yet

- Management Sheet 1 (Decision Making Assignment)Document6 pagesManagement Sheet 1 (Decision Making Assignment)Dalia EhabNo ratings yet

- The Finance Director of Stenigot Is Concerned About The LaxDocument1 pageThe Finance Director of Stenigot Is Concerned About The LaxAmit PandeyNo ratings yet

- Cost Per Kg. Supreme Crisps Tropical Chocolate Rolls Sublime Rolls Quantit y Cost Quantit y Cost Quantit y CostDocument4 pagesCost Per Kg. Supreme Crisps Tropical Chocolate Rolls Sublime Rolls Quantit y Cost Quantit y Cost Quantit y Costaccounting0923No ratings yet

- Egger's Roast Coffee Daniel Egger, Duke University Business Metrics For Data-Driven CompaniesDocument2 pagesEgger's Roast Coffee Daniel Egger, Duke University Business Metrics For Data-Driven CompaniesraluchiiNo ratings yet

- Macpherson - Sindikat 3 Emba64-2Document17 pagesMacpherson - Sindikat 3 Emba64-2Arief AradhiyaNo ratings yet

- Guide Questions - Inventory & Aggregate PlanningDocument3 pagesGuide Questions - Inventory & Aggregate PlanningErica SalasNo ratings yet

- Operations Management Assignment Don't Bother Me I Can't CopeDocument3 pagesOperations Management Assignment Don't Bother Me I Can't CopeSharan SaarsarNo ratings yet

- MA Session 5 PDFDocument35 pagesMA Session 5 PDFArkaprabha GhoshNo ratings yet

- MABE Reference Doc 1Document7 pagesMABE Reference Doc 1roBinNo ratings yet

- Hankuk Electronics Started Production On A Sophisticated New Smartphone Running The Android Operating System in January 2017Document3 pagesHankuk Electronics Started Production On A Sophisticated New Smartphone Running The Android Operating System in January 2017Elliot RichardNo ratings yet

- Finance Management-Week 10Document4 pagesFinance Management-Week 10arwa_mukadam03No ratings yet

- Capacity PlanningDocument17 pagesCapacity PlanningfuriousTaherNo ratings yet

- Midterm Exam 522Document5 pagesMidterm Exam 522Ghulam AliNo ratings yet

- Sample Final Exam Accounting (Aug 2012 ISB 2.1 and 2.2)Document5 pagesSample Final Exam Accounting (Aug 2012 ISB 2.1 and 2.2)Michael DavisNo ratings yet

- Productivity CompressDocument10 pagesProductivity CompresstayerNo ratings yet

- Audit Problems at New Century FinancialDocument4 pagesAudit Problems at New Century Financialcindy yulenda100% (1)

- Topic 1.6 Section 23 Revenue: The Ifrs For SmesDocument42 pagesTopic 1.6 Section 23 Revenue: The Ifrs For SmesDuc BuiNo ratings yet

- IS/LM Notes - Putting the Economy TogetherDocument8 pagesIS/LM Notes - Putting the Economy Togethercindy yulendaNo ratings yet

- Tutorial 2 LSCM - Chapter 3-16-09-2014Document2 pagesTutorial 2 LSCM - Chapter 3-16-09-2014cindy yulendaNo ratings yet

- Jones10e Ab - Az.chpt04Document16 pagesJones10e Ab - Az.chpt04cindy yulendaNo ratings yet

- Mentoring Program Resource LibraryDocument32 pagesMentoring Program Resource LibraryMilbia MorenoNo ratings yet

- Tutorial 2 LSCM - Chapter 3-16-09-2014Document2 pagesTutorial 2 LSCM - Chapter 3-16-09-2014cindy yulendaNo ratings yet

- Jones10e Ab - Az.chpt02Document22 pagesJones10e Ab - Az.chpt02cindy yulendaNo ratings yet

- CHPT 03Document16 pagesCHPT 03raheelmalik32No ratings yet

- Understanding InvestmentDocument9 pagesUnderstanding InvestmentUzma AliNo ratings yet

- Land-Use PlanningDocument15 pagesLand-Use PlanningCiara MaryNo ratings yet

- Amity Online Exam OdlDocument14 pagesAmity Online Exam OdlAbdullah Holif0% (1)

- Gabriel Nobre de Souza - Groningen Mini-MetropolisDocument9 pagesGabriel Nobre de Souza - Groningen Mini-MetropolisGabrielNobredeSouzaNo ratings yet

- Lorain Schools CEO Finalist Lloyd MartinDocument14 pagesLorain Schools CEO Finalist Lloyd MartinThe Morning JournalNo ratings yet

- Westford University College readies flagship campus with new programsDocument20 pagesWestford University College readies flagship campus with new programsSaju JanardhananNo ratings yet

- Ra 11223 PDFDocument34 pagesRa 11223 PDFNica SalazarNo ratings yet

- 1 CAT O&M Manual G3500 Engine 0Document126 pages1 CAT O&M Manual G3500 Engine 0Hassan100% (1)

- Hong Kong A-Level Chemistry Book 3ADocument69 pagesHong Kong A-Level Chemistry Book 3AMARENG BERNABENo ratings yet

- Generate Ideas with TechniquesDocument19 pagesGenerate Ideas with TechniquesketulNo ratings yet

- Metal Oxides Semiconductor CeramicsDocument14 pagesMetal Oxides Semiconductor Ceramicsumarasad1100% (1)

- Roxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaDocument2 pagesRoxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaJennilyn omnosNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary EducationAdaaan AfzalNo ratings yet

- DionWIred Black FridayDocument13 pagesDionWIred Black FridayAmon SimelaneNo ratings yet

- Exploratory Data Analysis: M. SrinathDocument19 pagesExploratory Data Analysis: M. SrinathromaNo ratings yet

- Motor Electrico Bojin J4103 - B User ManualDocument6 pagesMotor Electrico Bojin J4103 - B User ManualJordan BonnettNo ratings yet

- OB HandoutsDocument16 pagesOB HandoutsericNo ratings yet

- Anticipate Problems Before They Emerge: White PaperDocument7 pagesAnticipate Problems Before They Emerge: White PaperYotsapol KantaratNo ratings yet

- Ukraine and Russia E IRDocument287 pagesUkraine and Russia E IRtatgirNo ratings yet

- Berger Paints (India) Limited 21 QuarterUpdateDocument7 pagesBerger Paints (India) Limited 21 QuarterUpdatevikasaggarwal01No ratings yet

- Double Burden of Malnutrition 2017Document31 pagesDouble Burden of Malnutrition 2017Gîrneţ AlinaNo ratings yet

- User Manual - Numrolgy SoftwareDocument14 pagesUser Manual - Numrolgy SoftwareComputershastriNoproblem0% (1)

- Effectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting OperationDocument10 pagesEffectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting Operationchandan kumar100% (1)

- Otis Brochure Gen2life 191001-BELGIUM SmallDocument20 pagesOtis Brochure Gen2life 191001-BELGIUM SmallveersainikNo ratings yet

- Brochure HorticultureDocument46 pagesBrochure HorticulturezulfiqaralimalikNo ratings yet

- RFID Receiver Antenna Project For 13.56 MHZ BandDocument5 pagesRFID Receiver Antenna Project For 13.56 MHZ BandJay KhandharNo ratings yet

- Painter CardDocument1 pagePainter CardPraveen RANANo ratings yet

- Accounting Students' Attitude Towads AccountingDocument29 pagesAccounting Students' Attitude Towads AccountingSham Salonga Pascual50% (2)

- Argenti, P. Corporate Communication. Cap. 8-9Document28 pagesArgenti, P. Corporate Communication. Cap. 8-9juan100% (1)

- EDUC 5 - QuestionairesDocument7 pagesEDUC 5 - QuestionairesWilliam RanaraNo ratings yet

- LP IV Lab Zdvzmanual Sem II fbsccAY 2019-20z 20-ConvxvzzertedDocument96 pagesLP IV Lab Zdvzmanual Sem II fbsccAY 2019-20z 20-ConvxvzzertedVikas GuptaNo ratings yet