Professional Documents

Culture Documents

Boiler Light-Up Program

Uploaded by

saisrikanths5168Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler Light-Up Program

Uploaded by

saisrikanths5168Copyright:

Available Formats

BOILER LIGHT-UP PROGRAMME.

Prior to Boiler light-up, charge PRDS from neighbouring unit & start HFO tank

heating,both LDOpumps .When HFO tank temperature reaches 50 deg.,start

both HFO pumps.

Start Air heater,ID&FD fans,adjust air flow to around 30% i.e.@ 750 to 800

T/Hr. Bring wind box to furnace DP 40 mmwclby adjusting SADC.

Take +300mm drum level & start one BCWpump, Drum level will drop, bring it to

+ 100mm & start second BCWpump

Now, maintain drum level to -200 mm before Light-up so as to avoid excess

draining of DM water during swelling & saving in heat energy.

00.00Hr:-Initiate furnace purge.After completion of ( 9 minutes) purging, Lightup the Boilerwith AB elevation(LDO-4 guns ) with LDO pressure 8

kg/cm2.Maintain firing rate such that drum metal tempearature rise is @ 1.5 to 2

deg./min. Start one CEP.&Start vacuum pulling activity at the same time.After

achieving vacuum of @640 mm of Hg, open Turbine side drains going to flash

tank and close CRH AND HRH ATMOSPHERIC drains. Try to achieve maximum

attainable vacuum before starting steam conditioning.

01.20Hr.-At drum pressure 2kg/cm2, close drum vents , S/H vents& R/H

vents. Keep start-up vents throttled.Take second Elevation guns ( CD elevation

) in service with HFO when hot air temp. at wind box ( i. e. Outlet temp. of

secondary air heaters ) is @ 80- 100 deg..

01.50Hr.At drum pressure 5kg/cm2,close S/H drains at 26 Mtr. Level (9

drains).Open Boiler outlet main valves bypass valvesMS-202 & 204 (Ensure MS

atmospheric drains should be crack open at Turbine side.) and start MS line

charging with bypass valves.After complete opening of bypass valves, open fully

MS-201 & MS-203, by inching operation gradually. After full charging of

MSline,checkAIR IS SUCKING through CRH atmospheric drain by slightly

opening it and close it again. Start steam conditioning by opening HP-LP

BYPASS valves .Start 2ndCEP.Closestart-up vents after establishing steam flow

through REHEATER. At 7kg/cm2 drum pressure, start 3RDBCW pump ( OR take

opportunity to start 3RDpump whenever excess swelling of drum level & same

can be used vice-versa while drum level sudden drop.)

02.20Hr:-Atdrum pressure 10 kg/cm2, give pegging steam to deaerator& start

MDBFP on recirculation.

02.20Hr:-Atdrum pressure 10 kg/cm2, startBoiler blow down by killing Boiler

fire. During blow down, maintain drum level& initiate furnace purge at the

earliest.

02.35Hr:-Light-up the boiler, after purging & completion of blow down, with AB

elevation. Ensure vacuum of 640 mm of Hg & opening of Turbine side drains

going to flash tank.

Keep MS atmospheric drain crack open. Start second CEP.

02.45Hr:-Open HP-LPbypass after ensuring warm-up valve operation & no

water is coming throughCRH atmospheric drain, start steam conditioning for

fulfilling the temperature.criterias for Turbine.Take second Elevation guns ( CD

elevation ) in service with HFO.Close start-up vents after opening of HP-LP

bypass and ensuring sufficient steam flow throughHP-LP bypass.

---***---***---***---***---***---

UNIT # 6 SADC DAMPER EXTERNAL

POSITION

(AS PERPOWER CYLINDER)

DATE:-22/02/2013

CORNER-1

0%

100%

CORNER-2

0%

100%

CORNER-3

0%

100%

CORNER-4

0%

100%

AA

90

90

90

90

90

90

90

90

00

100

00

100

100

00

00

AB

00

100

10

100

100

JAM

50

100

00

00

00

100

00

100

00

00

00

00

BC

100

100

100

100

100

100

00

100

00

100

00

100

00

100

00

100

CD

10

100

00

100

00

100

00

100

00

100

00

100

00

00

100

DE

00

90

50

100

10

00

JAM

100

50

100

00

100

00

100

00

00

00

00

EF

00

100

00

100

00

90

00

100

00

100

00

100

00

00

00

00

FG

10

100

10

100

50

100

100

00

100

50

100

00

00

100

JAM

00

GH

00

100

50

100

00

100

100

00

100

00

100

00

100

100

JAM

00

HH

00

100

00

100

00

00

00

100

100

00

UNIT # 6 SADC DAMPER INTERNAL

POSITION

(100% CLOSED FROM PCR )

AA

CORNER-1

100% OPEN

DATE:-22/02/2013

CORNER-2

100% OPEN

A

AB

05% OPEN

B

BC

50% OPEN

100% OPEN

CORNER-3

100% OPEN

CORNER-4

100% OPEN

100% OPEN

05% OPEN

60% OPEN

10% OPEN

30% OPEN

60% OPEN

100% OPEN

10% OPEN

10% OPEN

10% OPEN

10% OPEN

C

CD

D

30% OPEN

DE

E

05% OPEN

EF

30% OPEN

05% OPEN

F

FG

10% OPEN

20% OPEN

50% OPEN

05% OPEN

GH

05% OPEN

50% OPEN

50% OPEN

100% OPEN

60% OPEN

30% OPEN

HH

05% OPEN

BOILER LIGHT-UP PROGRAMME.

Prior to Boiler light-up, charge PRDS from

neighbouring unit & start HFO tank heating,

both LDO pumps .When HFO tank temperature reaches 50

deg., start both HFO pumps.

Start Air heater, ID &FD fans, adjust air flow to

around 30% i.e. @ 750 to 800 T/Hr. Bring wind box to furnace

DP 40 mmwcl by adjusting SADC.

Take +300mm drum level & start one BCW pump,

Drum level will drop, bring it to + 100mm & start second BCW

pump

Now, maintain drum level to -200 mm before Lightup so as to avoid excess draining of DM water during swelling &

saving in heat energy.

00.00 Hr:-Initiate furnace purge. After completion of ( 9

minutes) purging, Light-up the

Boiler with AB

elevation (LDO-4 guns ) with LDO pressure 8 kg/cm2.Maintain

firing rate such that drum metal tempearature rise is @ 1.5 to 2

deg./min. Start one CEP. & Start vacuum pulling activity at

the same time.After achieving vacuum of @ 640 mm of Hg,

open Turbine side drains going to flash tank and close CRH AND

HRH ATMOSPHERIC drains. Try to achieve maximum attainable

vacuum before starting steam conditioning.

01.20Hr.At drum pressure 2kg/cm2, close drum

vents , S/H vents & R/H vents. Keep start-up vents

throttled. Take second Elevation guns ( CD elevation ) in

service with HFO when hot air temp. at wind box ( i. e. Outlet

temp. of secondary air heaters ) is @ 80- 100 deg..

01.50Hr.

At drum pressure 5 kg/cm2, close S/H drains

at 26 Mtr. Level (9 drains). Open Boiler outlet main valves

bypass valves MS-202 & 204 (Ensure MS atmospheric drains

should be crack open at Turbine side.) and start MS line

charging with bypass valves. After complete opening of bypass

valves, open fully MS-201 & MS-203, by inching operation

gradually. After full charging of MSline,checkAIR IS

SUCKINGthrouhCRH atmospheric drain by slightly opening it

and close it again. Start steam conditioning by opening HP-LP

BYPASS valves .Start 2ndCEP.Close start-up vents after

establishing steam flow through REHEATER. At 7 kg/cm2 drum

pressure, start 3RD BCW pump ( OR take opportunity to start

3RD pump whenever excess swelling of drum level & same can

be used vice-versa while drum level sudden drop.)

02.20Hr:At drum pressure 10 kg/cm2, give pegging

steam to deaerator& start MDBFP on recirculation.

02.20Hr:At drum pressure 10 kg/cm2, start Boiler

blow down by killing Boiler fire. During blow down, maintain

drum level& initiate furnace purge at the earliest.

02.35Hr:-Light-up the boiler, after purging & completion of

blow down, with AB elevation. Ensure vacuum of 640 mm of

Hg & opening of Turbine side drains going to flash tank.

Keep MS atmospheric drain crack open. Start second

CEP.

02.45Hr:- Open HP-LP bypass after ensuring warm-up valve

operation & no water is coming through CRH atmospheric

drain, start steam conditioning for fulfilling the temperature.

criterias for Turbine. Take second Elevation guns ( CD

elevation ) in service with HFO. Close start-up vents after

opening of HP-LP bypass and ensuring sufficient steam flow

through HP-LP bypass.

---***---***---***---***---***---

You might also like

- 250 MW Boiler WorkingDocument12 pages250 MW Boiler WorkingAhemad100% (1)

- Requirements of Bed Material, Charcoal & Diesel. Bed MaterialDocument4 pagesRequirements of Bed Material, Charcoal & Diesel. Bed MaterialpurvgargNo ratings yet

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDocument7 pagesIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNo ratings yet

- BOE Intview Questions & Answers-2 PDFDocument19 pagesBOE Intview Questions & Answers-2 PDFRahul NigamNo ratings yet

- Top 50 Boiler Information Booster Question Answers - ASKPOWERPLANTDocument19 pagesTop 50 Boiler Information Booster Question Answers - ASKPOWERPLANTRaju MaityNo ratings yet

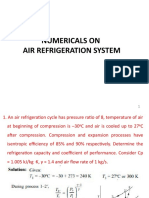

- Air Refrigeration Numericals NumericalsDocument32 pagesAir Refrigeration Numericals NumericalsRuturaj Umaranikar100% (1)

- Boiler Q ADocument26 pagesBoiler Q AGnanaSekar100% (1)

- SpreadSheet Centrifugal PumpDocument2 pagesSpreadSheet Centrifugal PumpengenheiroalencarNo ratings yet

- Boiler Lightup SOPDocument3 pagesBoiler Lightup SOPSudipta DasNo ratings yet

- Gen-Seal&cool-New - 500 MWDocument98 pagesGen-Seal&cool-New - 500 MWharisankar100% (2)

- 2.ibr Related TheoryDocument29 pages2.ibr Related TheoryRaag SNo ratings yet

- Indian Best Practices For Efficient O&M of Thermal Power PlantsDocument38 pagesIndian Best Practices For Efficient O&M of Thermal Power PlantsShankar JhaNo ratings yet

- SOP For Boiler Light Up ChecklistDocument9 pagesSOP For Boiler Light Up Checklistpradeep.selvarajan100% (1)

- The Great Indian National MovementDocument18 pagesThe Great Indian National MovementNishant Kumar100% (1)

- Coal Fired Boiler - PrincipalsDocument145 pagesCoal Fired Boiler - PrincipalsArfan AnwarNo ratings yet

- Boiler Protection AND InterlocksDocument54 pagesBoiler Protection AND InterlocksSarah Frazier100% (1)

- Centrifugal Compressor: Fluid Machinery and DisplacementDocument22 pagesCentrifugal Compressor: Fluid Machinery and DisplacementLuqman KhaqimNo ratings yet

- Furnace Safeguard Supervisory System: 8th March 2015 FsssDocument9 pagesFurnace Safeguard Supervisory System: 8th March 2015 FsssSiva KumarNo ratings yet

- Presentation For Supercritical TechnologyDocument113 pagesPresentation For Supercritical TechnologyVIVEK100% (1)

- APH Seal LeakagesDocument17 pagesAPH Seal LeakagesBhargav ChaudhariNo ratings yet

- Under Review/ This Is Not Final: Asif Shaikh Manager (Opn) Group-CDocument24 pagesUnder Review/ This Is Not Final: Asif Shaikh Manager (Opn) Group-CSAROJNo ratings yet

- BOE IntroductionDocument18 pagesBOE IntroductionAnsuman Sen SharmaNo ratings yet

- Boiler Protections, Emergencies and EfficiencyDocument40 pagesBoiler Protections, Emergencies and EfficiencyAnirudh MeshramNo ratings yet

- Catalogo FiltriDocument221 pagesCatalogo Filtrisancsa_74No ratings yet

- Rotating Stall in Centrifugal CompressorDocument7 pagesRotating Stall in Centrifugal CompressorDennis Ygbuhay100% (1)

- Computational Fluid Dynamics Analysis of Electrostatic Precipitator OF 210Mw Thermal Power PlantDocument19 pagesComputational Fluid Dynamics Analysis of Electrostatic Precipitator OF 210Mw Thermal Power PlantSylvester marxNo ratings yet

- IR CFBC Cold Start Up ProcedureDocument15 pagesIR CFBC Cold Start Up ProcedureJose Angie CabreraNo ratings yet

- 500 MW Turbine CycleDocument8 pages500 MW Turbine CycleAhemadNo ratings yet

- Turbine Rolling-Tiroda PDFDocument11 pagesTurbine Rolling-Tiroda PDFs91No ratings yet

- NPTI Boiler QuestionsDocument2 pagesNPTI Boiler QuestionsJoydev GangulyNo ratings yet

- Stator Water System Monitoring For Large Turbo-Generator-A User'S PerspectiveDocument12 pagesStator Water System Monitoring For Large Turbo-Generator-A User'S PerspectiveUmesh HadiyaNo ratings yet

- Nursery Worksheet - N Term II.326102555Document8 pagesNursery Worksheet - N Term II.326102555saisrikanths5168No ratings yet

- SUPER CRITICAL BOILER (660 MW) at PROJECTDocument53 pagesSUPER CRITICAL BOILER (660 MW) at PROJECTWahedali SayyedNo ratings yet

- Cold Start Up - CSTPS PDFDocument19 pagesCold Start Up - CSTPS PDFAhemadNo ratings yet

- Boiler 210mwDocument15 pagesBoiler 210mwishakNo ratings yet

- Procedure of Deaerator Charging in Power Plant - ASKPOWERPLANTDocument16 pagesProcedure of Deaerator Charging in Power Plant - ASKPOWERPLANTOtuagaNo ratings yet

- Emergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingDocument4 pagesEmergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingPrakash ChoudharyNo ratings yet

- Emergency Procedure For Total Station Power FailureDocument4 pagesEmergency Procedure For Total Station Power FailureSelva Manian100% (1)

- 31-Station Acwp - SopDocument3 pages31-Station Acwp - SopSiddhant Satpathy100% (1)

- Price ListDocument11 pagesPrice ListPraveen SharmaNo ratings yet

- HP Bypass System and Reheater Protection LogicDocument11 pagesHP Bypass System and Reheater Protection LogicPrathamesh Gangal80% (5)

- Secondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Document3 pagesSecondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Bineet Kumar VarmaNo ratings yet

- Understanding Air Preheater Performance: Storm Technologies, IncDocument4 pagesUnderstanding Air Preheater Performance: Storm Technologies, IncMahesh MishraNo ratings yet

- Secondary Air Damper Control in BoilerDocument10 pagesSecondary Air Damper Control in BoilerSourav DasNo ratings yet

- Circulating Fluidized Bed Boiler Gyanendra Sharma NPTI DelhiDocument48 pagesCirculating Fluidized Bed Boiler Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Unit Start Up Sequence ActivitiesDocument6 pagesUnit Start Up Sequence ActivitiesranjanNo ratings yet

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Mill Reject SystemDocument22 pagesMill Reject SystemgangatharanNo ratings yet

- Stage 2 SchemeDocument84 pagesStage 2 Scheme008911No ratings yet

- Code: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionDocument5 pagesCode: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionPrakash ChoudharyNo ratings yet

- Ir-Cfbc Boiler Drive Start/Stop LogicDocument6 pagesIr-Cfbc Boiler Drive Start/Stop Logicsambhu100% (1)

- Thermal Power PlantDocument33 pagesThermal Power PlantManoj KumarNo ratings yet

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

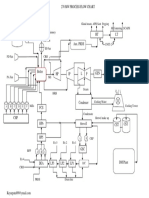

- C&I Part of SCDocument28 pagesC&I Part of SCLakshmi Narayan100% (1)

- Bed Ash Cooler's in Ir-Cfbc Boilers PDFDocument12 pagesBed Ash Cooler's in Ir-Cfbc Boilers PDFpradeep1987coolNo ratings yet

- TTD PerformanceDocument5 pagesTTD PerformanceSriraja RajapNo ratings yet

- Best 60 Power Plant Information Booster Points - AskpowerplantDocument17 pagesBest 60 Power Plant Information Booster Points - AskpowerplantRaju MaityNo ratings yet

- AbgDocument28 pagesAbgHiltonNo ratings yet

- Tripping of Turbine On High Differential PressureDocument3 pagesTripping of Turbine On High Differential Pressureatulbhogare7No ratings yet

- Burner Tilt PDFDocument9 pagesBurner Tilt PDFEE POG-III CSTPSNo ratings yet

- Cold-Start Up of Coal Fired PowerplantsDocument6 pagesCold-Start Up of Coal Fired PowerplantsAbdulyunus AmirNo ratings yet

- HP-LP Bypass FDocument16 pagesHP-LP Bypass FSolaiNo ratings yet

- AFBC Boiler Cold Start-Up ProcedureDocument3 pagesAFBC Boiler Cold Start-Up ProcedurekiranNo ratings yet

- Boiler OperationDocument19 pagesBoiler OperationnogeshwarNo ratings yet

- What Is Scooptube in Boiler Feed Pump (BFPDocument1 pageWhat Is Scooptube in Boiler Feed Pump (BFPPravin KumarNo ratings yet

- Cold StartupDocument3 pagesCold StartupGajanan JagtapNo ratings yet

- Cold Start Up (1) .Document16 pagesCold Start Up (1) .Tamojit Tarit RoyNo ratings yet

- Cold Start Up 1Document16 pagesCold Start Up 1Hassan SamiNo ratings yet

- Boiler Lit-Up PDFDocument2 pagesBoiler Lit-Up PDFHoncho Abhi Sinha100% (1)

- Im 1488204871Document27 pagesIm 1488204871Anonymous OYXHZSksNo ratings yet

- Tender Subject:: Indian Port Rail Corporation Limited (Iprcl)Document1 pageTender Subject:: Indian Port Rail Corporation Limited (Iprcl)saisrikanths5168No ratings yet

- Upsc Question PapersDocument22 pagesUpsc Question Papersphanirao1No ratings yet

- TDC Qap PDFDocument69 pagesTDC Qap PDFagniva dattaNo ratings yet

- FM I Boundary Layer TheoryDocument13 pagesFM I Boundary Layer Theorysaisrikanths5168No ratings yet

- Enq en Val BSK 065 TotDocument32 pagesEnq en Val BSK 065 Totsaisrikanths5168No ratings yet

- DR TutkaneDocument66 pagesDR Tutkanesaisrikanths5168No ratings yet

- Condenser Graphical AnalysisDocument24 pagesCondenser Graphical Analysissaisrikanths5168No ratings yet

- IES CONV Mechanical Engineering 1987Document7 pagesIES CONV Mechanical Engineering 1987GURURAJ CNo ratings yet

- Thermal Power Plant Working - Indian Power SectorDocument1 pageThermal Power Plant Working - Indian Power Sectorsaisrikanths5168No ratings yet

- Maharashtra Boiler Board NotofDocument131 pagesMaharashtra Boiler Board NotofPrateekSharmaNo ratings yet

- AolDocument1 pageAolsaisrikanths5168No ratings yet

- Irctc EditableDocument4 pagesIrctc Editablesaisrikanths5168No ratings yet

- Engg Mock Cutoff DisplayDocument2,860 pagesEngg Mock Cutoff Displaysaisrikanths5168No ratings yet

- Fisheries2013 (Rupali Rohane)Document1 pageFisheries2013 (Rupali Rohane)saisrikanths5168No ratings yet

- IES CONV Mechanical Engineering 1985Document8 pagesIES CONV Mechanical Engineering 1985coolpawan10No ratings yet

- IES-CONV-Mechanical Engineering-1986 PDFDocument6 pagesIES-CONV-Mechanical Engineering-1986 PDFGanesh GPNo ratings yet

- BARC 2010, MAY 30: 100 QUESTIONS 2 Hrs. +3,-1 NO CALCDocument14 pagesBARC 2010, MAY 30: 100 QUESTIONS 2 Hrs. +3,-1 NO CALCsaisrikanths5168No ratings yet

- Mechnical Engineering Sample PapersDocument7 pagesMechnical Engineering Sample Paperssaisrikanths5168No ratings yet

- High Pressure BoilersDocument16 pagesHigh Pressure BoilersDhruv Sharma100% (4)

- Construction Schedule For SMP 1. (Package) : Project Name: VLSU (Package-G)Document6 pagesConstruction Schedule For SMP 1. (Package) : Project Name: VLSU (Package-G)hoang nguyenNo ratings yet

- Taller ABC MarioDocument36 pagesTaller ABC MarioAlejo OspinaNo ratings yet

- Ebara Corporation - Standard Pumps - Corporate ProfileDocument29 pagesEbara Corporation - Standard Pumps - Corporate ProfilePrince ChaudharyNo ratings yet

- TB50SE13Document11 pagesTB50SE13Novianto RachmadNo ratings yet

- Cheet Sheet For Becker Rotary Vane PartsDocument12 pagesCheet Sheet For Becker Rotary Vane PartsMistysPartsNo ratings yet

- Tutorial 2-Questions (Air-Craft ARC) : Simple Gas Refrigeration CycleDocument3 pagesTutorial 2-Questions (Air-Craft ARC) : Simple Gas Refrigeration CycleRajaNo ratings yet

- BlowerDocument7 pagesBlowerghanshyam29998987100% (2)

- Module 7 Exercises Problem No. 1Document3 pagesModule 7 Exercises Problem No. 1Ariel GamboaNo ratings yet

- Rotary Pump ExperimentDocument3 pagesRotary Pump ExperimentArooj MukarramNo ratings yet

- Willy Vleminckx TraneDocument72 pagesWilly Vleminckx TraneAnonymous ffje1rpaNo ratings yet

- Exercises Problem 2 Pumps - PascualDocument4 pagesExercises Problem 2 Pumps - PascualJef PascualNo ratings yet

- Ref. IN For PROCUREMENTDocument68 pagesRef. IN For PROCUREMENThungleteNo ratings yet

- R600 enDocument10 pagesR600 enGinoGuanNo ratings yet

- TE-2 Unit - 4 &5 NotesDocument110 pagesTE-2 Unit - 4 &5 NotesKrishna VamsiNo ratings yet

- Openwell Submersible Pump SetsDocument17 pagesOpenwell Submersible Pump SetsLalsinh LalsinhNo ratings yet

- 6 - Bombas - Curva - 2018Document51 pages6 - Bombas - Curva - 2018Jack Chancahuaña MamaniNo ratings yet

- Flow Proses Plant#2 CFK #3 1 X 50 MWDocument2 pagesFlow Proses Plant#2 CFK #3 1 X 50 MWNur Ali SaidNo ratings yet

- Price List: Crompton Greaves Consumer Electricals LimitedDocument25 pagesPrice List: Crompton Greaves Consumer Electricals LimitedNishanth GaneshNo ratings yet

- 2015-Final HACCP Bag.4 Diagram AliR Revisi 0Document8 pages2015-Final HACCP Bag.4 Diagram AliR Revisi 0Bo'i ArNo ratings yet

- Power Plant Process Flow Chart PDFDocument1 pagePower Plant Process Flow Chart PDFFikriHidayatullahNo ratings yet

- FALLSEM2018-19 - MEE2026 - ETH - MB219 - VL2018191003620 - Reference Material I - Lecture 13 Axial Fans and CompressorsDocument17 pagesFALLSEM2018-19 - MEE2026 - ETH - MB219 - VL2018191003620 - Reference Material I - Lecture 13 Axial Fans and CompressorsJanga Sri Rushitha 16BEM0029No ratings yet

- 04 CompressorsDocument12 pages04 CompressorsApostolos AvraamidesNo ratings yet