Professional Documents

Culture Documents

012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDF

Uploaded by

Köksal PatanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDF

Uploaded by

Köksal PatanCopyright:

Available Formats

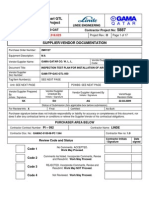

Pearl GTL

Project

LINDE ENGINEERING

Shell Project No: HP-3000-QAT

Project Document Number: T.4.250.953

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

Contractor Project No :

Project Rev.: O

Page 2 of 15

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

19.04.2008

Issued for Company Comments

AG

EE

ZG

ICC

29.03.2008

Issued for Review

AG

EE

ZG

IFR

28.03.2008

Issued for Internal Review

AG

EE

ZG

IIR

Date

Description

GAMA

Rev.

Project

Rev

No.

No.

Prepared Checked Approved

By

By

By

Status

ORIGINATOR

Document Title:

LINDE ENGINEERING AG

METHOD STATEMENT FOR WALL CLADDING, ROOF

CLADDING AND LIFELINE INSTALLATION

Document No.

Contractor

LOC470

Gama Qatar Co. W. L. L.

GAM

MTS

GEN

GTL

012

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.250.953

Vendor Code

Rev No.: O

GAM-MTS-MEC-GTL-012

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WALL CLADDING,

ROOF CLADDING AND LIFELINE INSTALLATION

19 April 2008, Rev. C

TABLE OF CONTENTS

1

INTRODUCTION ____________________________________________________________________ 5

1.1

GENERAL ____________________________________________________________________ 5

1.2

SCOPE ______________________________________________________________________ 5

REFERENCES _____________________________________________________________________ 5

DEFINITIONS ______________________________________________________________________ 5

RESPONSIBILITIES _________________________________________________________________ 5

RESOURCES ______________________________________________________________________ 6

EQUIPMENT & MANPOWER _______________________________________________________ 6

5.1

5.1.1

5.1.2

MATERIALS __________________________________________________________________ 6

5.2

6

METHOD OF EXECUTION _____________________________________________________________ 6

PRE-COMMENCEMENT WORKS____________________________________________________ 6

6.1

6.1.1

6.1.2

6.1.3

6.1.4

7

EQUIPMENT _______________________________________________________________ 6

MANPOWER _______________________________________________________________ 6

WORK PERMIT _____________________________________________________________

TRAFFIC MANAGEMENT PLAN _______________________________________________

EQUIPMENT AND PERSONNEL _______________________________________________

ACCESS ROADS ___________________________________________________________

6

6

6

7

INSTALLATION OF ROOF MATERIAL & LIFE LINE ERECTION___________________________________ 7

7.1

INSTALLATION OF ROOF MATERIAL ________________________________________________ 7

7.2

INSTALLATION OF SIDING MATERIAL _______________________________________________ 7

7.3

GENERAL CLEANUP OF THE WORK AREA ___________________________________________ 7

QUALITY ASSURANCE _______________________________________________________________ 7

HSSE ____________________________________________________________________________ 7

10

ATTACHMENTS ____________________________________________________________________ 8

10.1

TYPICAL LIFELINE ERECTION _____________________________________________________ 8

10.2

JOB SAFETY ANALYSIS _________________________________________________________ 8

T-4.250.953 Rev. O

Page 4 of 15

GAM-MTS-MEC-GTL-012

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WALL CLADDING,

ROOF CLADDING AND LIFELINE INSTALLATION

19 April 2008, Rev. C

1 INTRODUCTION

1.1 GENERAL

This document describes the methods proposed to be used for wall cladding, roof cladding &

Life installation works for the workshops, warehouses at TSF & ASU area that shall be carried

out as part of ASU Construction works of Qatar Shell GTL Plant (Pearl) in Ras Laffan

Industrial City (RLIC) of Qatar including similar works.

1.2 SCOPE

The cladding & Life erection works shall take place at TSF Area. The construction & erection

activities shall be carried out by GAMA QATAR.

2 REFERENCES

T-4.129.853

T-4.129.867

T-4.129.865

T-4.129.868

T-4.219.611

T-4.234.080

T-4.234.084

T-4.234.542

T-4.219.622

:

:

:

:

:

:

:

:

:

Personal Protective Equipment

Hand Tools

Portable Power Tools

Work at Height - Scaffolding

HSSE Plan

General Scaffolding

Lifting (General)

Project Quality Plan

Working at Height

3 DEFINITIONS

Company

Contractor or LINDE

Sub Contractor

Contract

QCP

ITP

QA/QC

HSSE

JSA (RA)

FSI

:

:

:

:

:

:

:

:

:

:

QSGTL and/or its PMC

Linde Engineering AG

GAMA QATAR Co. W.L.L.

QSGTL Pearl Project C2 ASU Construction Works

Quality Control Procedure

Inspection and Test Plan

Quality Assurance / Quality Control

Health, Safety, Security and Environmental

Job Safety Analysis (Risk Assessment)

Flawless Start-up Initiative

4 RESPONSIBILITIES

Engineer / Supervisor shall;

Be responsible for safe execution and quality of the work.

Monitor the site activities and ensure the job is progressing according to the project

schedule and specifications.

Coordinate with QA/QC inspector for inspection of activities.

T-4.250.953 Rev. O

Page 5 of 15

GAM-MTS-MEC-GTL-012

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WALL CLADDING,

ROOF CLADDING AND LIFELINE INSTALLATION

19 April 2008, Rev. C

5 RESOURCES

5.1 EQUIPMENT & MANPOWER

A list of equipment and manpower is given below.

5.1.1 EQUIPMENT

Mobile cranes

Manlift

Hand tools

Rigging gear (Slings, shackles, etc.)

Surveying equipment and instruments

Safety Belt with double Lanyard

Trailer

5.1.2 MANPOWER

Site Manager

Foreman

Surveyor

Surveyor Helper

Helper

Rigger

HSSE Personnel

Banks men

5.2 MATERIALS

Fasteners

Sheeting & Flashings

Cladding materials

6 METHOD OF EXECUTION

6.1 PRE-COMMENCEMENT WORKS

6.1.1 WORK PERMIT

The erection operation of cladding & life line erection will starts with a request for

a permit to work.

6.1.2 TRAFFIC MANAGEMENT PLAN

Works shall not interrupt any kind of vehicle traffic on any access road leading to

any gates. In case of this kind of activity a revised traffic management plan shall

be provided.

6.1.3 EQUIPMENT AND PERSONNEL

All equipment shall be inspected and approved by the CONTRACTOR, and all

personnel shall be inducted and trained before they commence work on site.

T-4.250.953 Rev. O

Page 6 of 15

GAM-MTS-MEC-GTL-012

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WALL CLADDING,

ROOF CLADDING AND LIFELINE INSTALLATION

19 April 2008, Rev. C

6.1.4 ACCESS ROADS

The access roads may be diverted for some periods during the execution of the

works in order to ensure smooth execution of the works in the area. However,

no such diversion shall take place without prior written consent of the

CONTRACTOR or the COMPANY.

7 INSTALLATION OF ROOF MATERIAL & LIFE LINE ERECTION

The installation of roof material, installation of side materials, erecting of lifeline and

general cleanup.

7.1 INSTALLATION OF ROOF MATERIAL

Scaffold towers and life line erection will be maintained around workshops &

warehouses. Roof sheet will be lifted to the roof in a stack of 10 sheets at a time by

crane with proper sling tied around so as to stop from flying. After placing the sheet on

the purlins it will be tied with a rope. The sheet will be fixed by workers walking on the

roof tied to the lifeline. Only when the first sheet of roofing sheet is installed will a

second sheet will be fixed.

These sheets are of GI quality and thickness is min. 0.5mm.

Self tightening screws will be used with metallic and bitumen washer while fixing the

GI sheets. Hilti tool will be used to tighten the screws.

Special care must be shown in not attempting the roof material installation while high

wind is forecast.

7.2 INSTALLATION OF SIDING MATERIAL

Siding material will be lifted into position with cranes or pulleys. Only when a siding

panel is securely fastened will a second siding be erected. Special care must be

shown in not attempting the siding material installation while high winds are forecast.

7.3 GENERAL CLEANUP OF THE WORK AREA

A general cleanup of the work area will be conducted to ensure that no unused

materials are left on the erection site. All materials retrieved will be sent to the

warehouse for proper storage.

8 QUALITY ASSURANCE

A Quality Assurance System shall be operated conforming to related standards.

9 HSSE

All works shall be in compliance with the State of Qatar laws and regulations, Ras Laffan Industrial

City and International standards, codes, LINDE ENGINEERING AG and QSGTL and/or its PMC

requirements and instructions.

In addition all employees and GAMA subcontractor employees on site will have gone through GAMA

Qatar Site Safety Induction, LINDE ENGINEERING AG Site Safety Induction and QSGTL Safety

induction for site safety, health, environmental and security prior to resuming work activities at site.

T-4.250.953 Rev. O

Page 7 of 15

GAM-MTS-MEC-GTL-012

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WALL CLADDING,

ROOF CLADDING AND LIFELINE INSTALLATION

19 April 2008, Rev. C

Other training courses will be attended as required by LINDE ENGINEERING AG or QSGTL and/or its

PMC as required.

Risk Assessment will have been prepared by the Risk Assessment Team (RAT) ranking the hazards

associated with project works and control measures to be taken to mitigate the hazards to an

acceptable level.

Each scope work or task will have a completed and approved Job Safety Analysis (JSA) identifying

the potential hazards and control measures that will be implemented to protect people and

environment.

The JSA (RA) will be used by Supervisor as the basis of conducting his daily TSTI meeting and his

weekly Tool Box Talk.

For additional safety requirements for a particular or specific task please refer to the JSA prepared for

that task.

All personnel will have PPE required for their specific tasks in addition to the minimum PPE (coveralls,

safety goggles, safety helmet, safety shoes, high-visibility vests, gloves) at site at all times as

required.

10 ATTACHMENTS

10.1

TYPICAL LIFELINE ERECTION

10.2

JOB SAFETY ANALYSIS

T-4.250.953 Rev. O

Page 8 of 15

JOB SAFETY ANALYSIS / RISK ASSESSMENT

Page No: 1 of 6

JSA For: T-4.250.953

Job being analyzed: METHOD STATEMENT FOR WALL CLADDING, ROOF CLADDING AND LIFELINE INSTALLATION

Department/Section doing JSA: HSSE & MECHANICAL WORKS

Normal Approvals:

Name

JSA by:

Mr. Atila Gun

JSA Members: Mr. Syd Osborne, Mr. Atila Gun

Job Performers: Mr. Atila Gun

Signature

19.04.08

Mr. Muslem TOPALOGLU

Job Supervisor:

Additional Approvals (Determined by Job Supervisor in correlation with Linde HSSE Manager).

Name

Date

Signature

Discipline Superintendent (Linde)

19.04.08

Date

General job requirements / Personal Protective

Equipment.

1. The following Personal Protective Equipment

shall be worn:

Approved coveralls, safety goggles, safety

helmet, safety steel toe shoes, safety harness

and leather gloves. Hearing protection must be

worn.

HSSE Representative (Linde)

2. Permit To Work.

OTHERS (List Below):

Approval required for hazardous work detailed in the Linde Work Permit Procedure.

Changing conditions and emergency procedures: Stop work. Switch off equipment. Supervisor directs personnel to nearest and safest muster point considering wind direction. Supervisor counts all employees.

Missing employees are reported to Linde HSSE Dept. When all clear is given, check with Linde HSSE before returning to work.

LINDE EMERGENCY TELEPHONE NO.

HSSE MANAGER:

Pearl HOT LINE :

583 40 72

474 88 88

Note: 1) If any of the tasks involves biological, physical or chemical hazards, then The LINDE Industrial Hygienist must also approve the work.

2) Use additional sheets as necessary.

3) Details on safety (PPE, Hazard etc) and environmental requirements can be found in LINDE and SHELL Safety and Environment Procedures.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.953

Q A T A R

ITEM

1

ACTIVITY

Roof Installation

HAZARDS / POTENTIAL

CONSEQUENCES

1.1 Dropped materials.

Initial Risk

RISK

P C

RANK

Residual Risk

1.1.1

1.1.2

C

HIGH

1.1.3

1.2

Wind Hazard.

1.2.1

1.2.2

1.2.3

C

LOW

1.2.4

1.2.5

1.3

Unprotected edges or

openings.

1.3.1

C

HIGH

1.3.2

1.4

Lifeline failure

1.4.1

2

MED

SCOPE : METHOD STATEMENT FOR WALL

CLADDING, ROOF CLADDING AND LIFELINE

INSTALLATION

1.4.2

MAIN

CONTROLS

Install barricades "exclusion zone"

with sign boards indicating roofing

works in progress to prevent

unauthorized entry.

All materials shall be safely

lowered from one level to the next

either by hand-to-hand or by lifting

equipments or by securely

attaching a rope and hauling.

Tools shall be tied by retaining

rope attached to the harness.

100% personal fall protection

system.

Monitor wind speed using

Anemometer.

Crane operations shall be stopped

at greater than 25 knots.

Lifting work must be stopped

during strong wind.

Ensure all roofing sheets to be

secured on the ground and on the

roof.

Full body harness and lanyards

shall be inspected & colour coded.

Harness and safety line to be

used when height more than 1.5

meters.

Ensure lifeline has a design

calculation/Engineering Design.

Ensure lifeline can withstand load

impact as per HSSE procedure.

ADDITIONAL

CONTROLS

1.1.1.1 Remove any unnecessary

materials.

1.1.1.2 Provision of watchman with

whistle & vest to control people

from barricaded area.

LOW

LOW

LOW

LOW

1.2.1.1 Personnel's should be aware of

the affect of weather conditions

on the operations.

1.2.1.2 Discuss in TSTI.

1.3.1.1 All personnel's working at

heights must complete "Work at

Height" training.

1.3.1.2 Discuss during TSTI and TBT.

1.4.1.1 Lifeline to be erected by

competent person, prior to use.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.953

Q A T A R

ITEM

2

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

Sliding installation. 2.1 Dropped materials.

2.2

2.4

HIGH

Wind Hazard.

2.3

Initial Risk

C RISK

Personnel injury from

poor body position

LOW

LOW

Fall of personnel, while

working at heights.

B

MED

MAIN

2.1.1 Install barricades "exclusion zone"

with sign boards indicating roofing

works in progress to prevent

unauthorized entry.

2.1.2 All materials shall be safely

lowered from one level to the next

either by hand-to-hand or by lifting

equipments or by securely

attaching a rope and hauling.

2.1.3 Tools shall be tied by retaining

rope attached to the harness.

2.2.1 100% personal fall protection

system.

2.2.2 Monitor wind speed using

Anemometer.

2.2.3 Crane operations shall be stopped

at greater than 25 knots.

2.2.4 Lifting work must be stopped

during strong wind.

2.2.5 Ensure all roofing sheets to be

secured on the ground and on the

roof.

2.3.1 Warm personnel's about pinch or

crush points.

2.3.2 Two tag lines shall be attached to

control the loads.

2.4.1 All employees shall wear

inspected full body harness fitted

with twin lanyards shall be fitted

with dual action self locking safety

hook for 100% Tie-off.

2.4.2 Ensure 100% fall protection.

SCOPE : METHOD STATEMENT FOR WALL

CLADDING, ROOF CLADDING AND LIFELINE

INSTALLATION

ADDITIONAL

Residual Risk

P C

R

2.1.1.1 Remove all unnecessary

materials.

2.1.1.2 Discuss in daily TSTI.

LOW

LOW

LOW

LOW

2.2.1.1 Personnel's should be aware of

the affect of weather conditions

on the operations.

2.2.1.2 Discuss in daily TSTI.

2.3.1.1 Discuss in daily TSTI.

2.4.1.1 Discuss working at heights at

daily TSTI.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.953

Q A T A R

ITEM

3

ACTIVITY

Using of Manlift.

HAZARDS / POTENTIAL

CONSEQUENCES

3.1 Mechanical Breakdown.

3.2

LOW

Improper use of

equipment

B

3.3

Initial Risk

C RISK

LOW

Untrained personnel.

LOW

SCOPE : METHOD STATEMENT FOR WALL

CLADDING, ROOF CLADDING AND LIFELINE

INSTALLATION

MAIN

ADDITIONAL

3.1.1 Equipment shall be serviced

maintained and inspected as per

set maintenance and inspection

program.

3.1.2 Ensure E-Stop is in place through

the control system.

3.1.3 Perform equipment daily check

prior to use.

3.1.4 Supervisor shall ensure that work

will be properly supervised as per

work method statement.

3.1.5 Ensure an emergency stop should

be provided on the platform

control panel.

3.2.1 Manlift shall not be used as

cranes or jacks unless they have

specifically been designed for this

purpose by their manufacturers.

3.2.2 Leaning out of the platform will not

be allowed.

3.2.3 Colour code sticker to be available

on the equipment.

3.3.1 Ensure platforms must only be

used by authorized personnel who

have been trained in the operation

of the type of platform in use.

3.3.2 Initial training should cover

operating principles, machine

controls and environmental

conditions, which are likely to be

encountered.

3.1.1.1 Ensure equipment to be

provided with controls of the

dead man type, which only

allow movement of the machine

to take place whilst they are

actually being operated.

3.1.1.2 Dead man controls

automatically return to the

neutral position.

3.1.1.3 Appropriate trained & certified

persons only to use equipment.

3.2.1.1 Ensure equipment is inspected,

approved & colour coded as per

colour code chart.

3.2.1.2 Current inspection sticker must

be in place.

3.3.1.1 Ensure supervisor/foreman who

will be using the manlift should

be particularly aware of the

hazards which may be

encountered whilst using these

machines and of the

precautions which may be taken

to eliminate or minimize the

hazards.

Residual Risk

P C

R

LOW

LOW

LOW

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.953

Q A T A R

ITEM

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

3.4

LOW

Fall of personnel

3.5

Initial Risk

C RISK

MED

Overturning of Machine

MED

MAIN

3.3.3 Training and practice in this type

of work undertaken is essential.

3.3.4 Ensure that equipment operator is

certified by third party, valid

certificates.

3.4.1 Safety harness shall be provided

for the use of all personnel

working from mobile work

platforms so that in the event of

any advertent movement of the

platform they are working from,

they will not be thrown from it.

3.4.2 Boxes, hop-ups or ladders will not

be used to gain additional height

or reach from the platform of

manlift machine work platform.

3.5.1 Ensure no excessive force by the

operator on the platform by

introducing an element of side

load.

3.5.2 The outriggers or stabilizers, when

fitted, shall be fully extended and

in position, before the platform or

boom is raised.

3.5.3 The platform shall not be

overloaded exceeding the

regulated safe working load.

3.5.4 Ensure the machine will be located

to the most suitable position for

the job to be carried out before

any slewing takes place.

SCOPE : METHOD STATEMENT FOR WALL

CLADDING, ROOF CLADDING AND LIFELINE

INSTALLATION

ADDITIONAL

3.4.1.1 Discuss working at height

hazards in TSTI.

3.4.1.2 Supervisor shall ensure that

work will be properly supervised

at all times as per work method

statement.

3.5.1.1 When a manlift needs work in a

congested area, an approval for

the operation shall be obtained

from HSSE dept of Gama/Linde

authorized personnel's.

3.5.1.2 Considering the effects of the

acceleration and deceleration of

the manlift.

3.5.1.3 Discuss in TSTI.

Residual Risk

P C

R

LOW

LOW

LOW

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.953

Q A T A R

ITEM

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

B

3.6

Issuance of PTW

4.1

Initial Risk

C RISK

MED

Vehicle movement

Work Stoppage

MAIN

SCOPE : METHOD STATEMENT FOR WALL

CLADDING, ROOF CLADDING AND LIFELINE

INSTALLATION

ADDITIONAL

Slewing of the boom to the extent

that causes the machine to

overturn shall be avoided.

LOW

3.6.1 Ensure all vehicle movement to be 3.6.1.1 Barricade and secure the

guided by competent banks men

working are with sign boards to

with high visibility vests.

prevent unauthorized entry.

3.6.2 Ensure that each piece of

equipment is fitted with an

automatic reverse alarm and

beacon or strobe light.

LOW

4.1.1 All Supervisors will be trained by

GAMA/Linde on PTW procedures.

Residual Risk

P C

R

LOW

LOW

LOW

You might also like

- 015-MS For Night Works PDFDocument16 pages015-MS For Night Works PDFKöksal Patan80% (5)

- 001-MS For Structural Steel Assembly and Erection PDFDocument28 pages001-MS For Structural Steel Assembly and Erection PDFKöksal Patan100% (1)

- 010-MS For Grouting PDFDocument33 pages010-MS For Grouting PDFKöksal PatanNo ratings yet

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pages016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pages017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 001-CIVIL MS For Surveying Works PDFDocument12 pages001-CIVIL MS For Surveying Works PDFKöksal Patan100% (1)

- Method Statement - SS Glass Handrail2Document18 pagesMethod Statement - SS Glass Handrail2dennis resano0% (1)

- 014-MS For General Scaffolding PDFDocument33 pages014-MS For General Scaffolding PDFKöksal Patan100% (2)

- Method Statement For Demolition & Modification Works at Existing Retaining Wall RW5Document47 pagesMethod Statement For Demolition & Modification Works at Existing Retaining Wall RW5Gary Lo75% (4)

- Method Statement For Concrete Works: The Custodian of Two Holy Mosques King Abdullah Ibn Abdul-Aziz Project KAP5-Group 4Document41 pagesMethod Statement For Concrete Works: The Custodian of Two Holy Mosques King Abdullah Ibn Abdul-Aziz Project KAP5-Group 4Domie Neil Bucag SalasNo ratings yet

- Method Statement For False Ceiling WorkDocument5 pagesMethod Statement For False Ceiling Worktrija_mrNo ratings yet

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- Jobs Safety Analysis (JSA)Document8 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Block Work MS (Sample)Document18 pagesBlock Work MS (Sample)jones100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument15 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshNo ratings yet

- Checklist For Dismantling & Preservation of Existing MEP Works-FinalDocument2 pagesChecklist For Dismantling & Preservation of Existing MEP Works-FinalMohammed Javid100% (1)

- 11 - MS For Painting WorkDocument9 pages11 - MS For Painting Workgulzaman100% (1)

- Method Statement For Formworks, Rebars, Cast-In-Situ ConcreteDocument28 pagesMethod Statement For Formworks, Rebars, Cast-In-Situ ConcreteAzhar Ali87% (15)

- Work Method Statement For Roof Sheeting WorksDocument8 pagesWork Method Statement For Roof Sheeting WorksRepl microsoft, Pune100% (1)

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- JSa For Operation of Jack HammeringDocument3 pagesJSa For Operation of Jack Hammeringyc safety0% (1)

- JSA For Working at HeightDocument2 pagesJSA For Working at HeightXUE JIANNo ratings yet

- Method Statement For ROOF SHEETDocument7 pagesMethod Statement For ROOF SHEETjones100% (1)

- Ms For Block WorkDocument8 pagesMs For Block Workprasath_subramanian100% (2)

- P07 F06 Method Statement For External Stone CladdingDocument9 pagesP07 F06 Method Statement For External Stone CladdingumaNo ratings yet

- 1 - Scaffolding WorkDocument16 pages1 - Scaffolding WorkPerwez21100% (14)

- Method Statement For Block PavingDocument7 pagesMethod Statement For Block Pavingjohng5697No ratings yet

- 001 JSA Site CompoundDocument15 pages001 JSA Site CompoundRui Ribeiro100% (1)

- Method Statement - Plastering, Dated. Jan. 03. 2007Document5 pagesMethod Statement - Plastering, Dated. Jan. 03. 2007mohamed4879No ratings yet

- Method Statement For Trial Pit ExcavationDocument4 pagesMethod Statement For Trial Pit ExcavationCwazy MarooyNo ratings yet

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pages045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- JSA Erection of Steel StructureDocument9 pagesJSA Erection of Steel StructureLuqman Osman77% (13)

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDocument4 pagesPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNo ratings yet

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- 7 - Civil WorkDocument12 pages7 - Civil WorkPerwez21100% (1)

- Method Statement Civil WorksDocument12 pagesMethod Statement Civil WorksDaniel Offiong100% (1)

- Method Statement For Steel ErectionDocument15 pagesMethod Statement For Steel Erectionstrikersam95% (21)

- Method Statement For Excavation Compaction and BackfillingDocument8 pagesMethod Statement For Excavation Compaction and BackfillingIna RoseNo ratings yet

- Method Statement For Wall Insulation, CladdingDocument16 pagesMethod Statement For Wall Insulation, Claddingstrikersam100% (15)

- JSA For SealantDocument11 pagesJSA For SealantdipmipNo ratings yet

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works JsaNazir Hussain67% (12)

- JSA - Repair-Coating and Finition WorkDocument3 pagesJSA - Repair-Coating and Finition WorkAMIN100% (1)

- Excavation Safety ProcedureDocument8 pagesExcavation Safety ProcedureJamilNo ratings yet

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- Safe Work Method Statement (SWMS) For Painting ProjectsDocument12 pagesSafe Work Method Statement (SWMS) For Painting Projectsramy_arc74% (19)

- Method Statement For Reinforced Concrete PoursDocument6 pagesMethod Statement For Reinforced Concrete Poursselva1965No ratings yet

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- WMS Structural Steel Structual Steel ErectionDocument7 pagesWMS Structural Steel Structual Steel ErectionconcretemadNo ratings yet

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Method Statement For Conventional Formwork BlogDocument9 pagesMethod Statement For Conventional Formwork BlogMohasin KhanNo ratings yet

- 1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityDocument5 pages1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityAnwar AliNo ratings yet

- JHA - To Carry Out Reinstate of Interlock StonesDocument7 pagesJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- ARK JSA Manual Excavation A 3Document9 pagesARK JSA Manual Excavation A 3REMYANo ratings yet

- Tanks Confined Space JSADocument5 pagesTanks Confined Space JSAkosoko100% (1)

- Civil Work Method StatementDocument18 pagesCivil Work Method Statementغيثمحمود100% (1)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (4)

- Method Statement For Finishing Works PDFDocument6 pagesMethod Statement For Finishing Works PDFdndudc92% (12)

- 004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFDocument9 pages004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFKöksal Patan100% (1)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pages014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNo ratings yet

- 015-Method Statement For Painting Works (Building) PDFDocument21 pages015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pages014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNo ratings yet

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pages050-Itp For Installation of Air Intake Filter PDFKöksal PatanNo ratings yet

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pages013-MS Utilization of Hilti DX 76 PDFKöksal PatanNo ratings yet

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocument18 pages012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNo ratings yet

- 014-MS For General Scaffolding PDFDocument33 pages014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 013-MS For Mass Concrete Works PDFDocument26 pages013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pages040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNo ratings yet

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pages044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pages047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNo ratings yet

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pages011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pages010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNo ratings yet

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pages046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNo ratings yet

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pages045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 009-Method Statement - Main Erection Sequence For Acc PDFDocument68 pages009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pages043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 041 - ITP For Painting (Building) PDFDocument12 pages041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- 009-Civil-Ms Concrete Works PDFDocument27 pages009-Civil-Ms Concrete Works PDFKöksal PatanNo ratings yet

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- 006-MS For Purging of Stainless Steel PDFDocument18 pages006-MS For Purging of Stainless Steel PDFKöksal PatanNo ratings yet

- 038-Itp For Coldboxes PDFDocument25 pages038-Itp For Coldboxes PDFKöksal PatanNo ratings yet

- 008-CIVIL-MS Backfilling Works PDFDocument16 pages008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- CV - Muhammad A.Wahab - Rig Safety and Training AdvisorDocument6 pagesCV - Muhammad A.Wahab - Rig Safety and Training Advisorelazaly100% (1)

- Accident and Their EffectsDocument44 pagesAccident and Their EffectsZainorin Ali67% (3)

- Hazards and Risk Management PDFDocument93 pagesHazards and Risk Management PDFPaul TorresNo ratings yet

- Company Profile-Clean Edge Hygiene Solutions LimitedDocument19 pagesCompany Profile-Clean Edge Hygiene Solutions LimitedCLEAN EDGE HYGIENE SOLUTIONSNo ratings yet

- Assisted Living Rules New AZDocument40 pagesAssisted Living Rules New AZKuiper Tenney100% (1)

- Searchable Text2Document547 pagesSearchable Text2ChrisNo ratings yet

- BaruDocument19 pagesBaruAnjaliRajuNo ratings yet

- Niosh Case MSDDocument590 pagesNiosh Case MSDAntonio NeiNo ratings yet

- Bulldog Diving Safety ManualDocument67 pagesBulldog Diving Safety Manualafreddy1958No ratings yet

- Ethics Workplace SafetyDocument12 pagesEthics Workplace SafetyKenny Martin100% (3)

- Method Statement For Erection of Tank t147 UpdatedDocument22 pagesMethod Statement For Erection of Tank t147 UpdatedAshutosh29% (7)

- MS - Sub-Base and Base Course Preparation RA-239 17 Mar 2016Document8 pagesMS - Sub-Base and Base Course Preparation RA-239 17 Mar 2016Joel AlcantaraNo ratings yet

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- CATU 2012-13 CatalogueDocument160 pagesCATU 2012-13 Cataloguekunaltirpankar100% (1)

- Contractor Safety RequirementsDocument24 pagesContractor Safety RequirementseastNo ratings yet

- PM Handbook (Full PDFDocument88 pagesPM Handbook (Full PDFGary LoNo ratings yet

- Serving It Safe WorkbookDocument145 pagesServing It Safe Workbookannarome100% (2)

- UVQF, ATP BeauticianDocument64 pagesUVQF, ATP BeauticianMoses OryemaNo ratings yet

- ImistDocument33 pagesImistprakashNo ratings yet

- Safety Systems For CO2 PlantsDocument16 pagesSafety Systems For CO2 PlantsJimmie PerezNo ratings yet

- Hse AbbrevationsDocument4 pagesHse AbbrevationsBrian FunteNo ratings yet

- Responsibilities of A Construction Safety OfficerDocument2 pagesResponsibilities of A Construction Safety Officersteward reyes100% (1)

- Part B 5 Suicide RatesDocument4 pagesPart B 5 Suicide Ratesfernanda1rondelli100% (1)

- Act Nov 08Document96 pagesAct Nov 08Bqdcc6No ratings yet

- Dust Explosions in The Pulp and Paper IndustryDocument17 pagesDust Explosions in The Pulp and Paper Industryaugur886No ratings yet

- Comprehensive CSHP Application FormDocument3 pagesComprehensive CSHP Application FormJUCONS ConstructionNo ratings yet

- 002-MS Nitrogen Filling, Cyrogenic Vaporizer PDFDocument18 pages002-MS Nitrogen Filling, Cyrogenic Vaporizer PDFKöksal PatanNo ratings yet

- MSD Prevention Toolbox PartC English in Depth Risk Assessment FinalDocument49 pagesMSD Prevention Toolbox PartC English in Depth Risk Assessment FinalLuiz Rubens Souza CantelliNo ratings yet

- Cash in Transit GuideDocument10 pagesCash in Transit GuideFrancisco Saraiva100% (1)

- Gse Ms Ag 002 Rev 1 - Method Statement For Above Ground PipingDocument17 pagesGse Ms Ag 002 Rev 1 - Method Statement For Above Ground PipingsugumarNo ratings yet