Professional Documents

Culture Documents

F4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDF

Uploaded by

Dang Hieu NguyenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDF

Uploaded by

Dang Hieu NguyenCopyright:

Available Formats

1

19-Apr-15

YanWeiLi

Liu Liang

Cheng Yuguang

Wu Yong Jun

DH1/A3-C2/DE/M/2728

15-Mar-14

YanWeili

Xie Ruzhi

Cheng Yuguang

Wu Yongjun

DH1/A3-C2/DE/M/2617

26-Feb-14

YanWeili

Xie Ruzhi

Cheng Yuguang

Wu Yongjun

DH1/A3-C2/DE/M/2208

6-DEC-13

YanWeili

Xie Ruzhi

Cheng Yuguang

Wu Yongjun

FIRST ISSUE

RE

DATE

PREPARED BY

CHECKED BY

REVIEWED BY

APPROVED BY

DESCRIPTION

V.

OWNER

POWER GENERATION CORPORATION 1

THERMAL POWER PROJECT MANAGEMENT BOARD 3

CONSULTANT

POWER ENGINEERING

COMPANY 2

CONSULTING

JOINT

STOCK

CONTRACTOR

DONGFANG ELECTRIC CORPORATION LIMITED

SUBCONTRACTOR

GUANG DONG ELECTRIC POWER DESIGN INSTITUTE

HUNAN PROVINCIAL THERMAL POWER CONSTRUCTION

COMPANY

EVN

Ref.

DH1/TD640/045/001/00

No.:

DEC

Ref.

DH1-DE-A3-M-14-5121

No.:

PROJECT:

CONTRACT No.

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

DH1-30032010

Document

Status:

FOR APPROVAL

Document Title:

ITP for installation of equipment

and pipe in Compressed Air System

Document No.:

Rev.:

F4281-GEDI-M-SS-ITP-1039-3

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

DH1-M-ITP-3-J/G-

ITP for installation of equipment and pipe in Compressed Air System

Date: 2015-04-18

Rev.: 1

Inspection/Test

NO

Welder qualification

Applicable

specification or rules

PARTICIPATION BY

Record format

check WPS/PQR

welder test in site

Compressed air tank,

buffer tank

Water-cooled air

compressor

Inspection

criteria

SUBCON

DEC

A3-C2

During and after

installation

Comply with

requirements

ASME B31

Frequency

Comply with

requirements

Comply with

Before installation

requirements

Before installation

DH1-M-ITP-3-J/G-0005-01-01

Design drawing

DH1-M-ITP-3-J/G-0005-01-02

dryer

2

Equipment installation

Installation of sewage

pump

Design drawing

DH1-M-ITP-3-J/G-0005-02

After installation

Comply with

requirements

Visual inspection of

equipment grouting

DL/T5047-95

DH1-M-ITP-3-J/G-0005-01-01

Before secondary

grouting

Comply with

requirements

DH1-M-ITP-3-J/G-0006-01

Before installation

Comply with

requirements

DH1-M-ITP-3-J/G-0006-02

After installation

Comply with

requirements

Pipe installation

Check according to

3.1 Inspection of take- material list

in materials

Appearance inspection

position check

Design drawing

DL5190.4-2004

DL5190.4-2004

DH1-M-ITP-3-J/G-0006-02

After installation

Pipe fit-up check

Design drawing

DH1-M-ITP-3-J/G-0006-05

After installation

Welding apperance check Design drawing

DH1-M-ITP-3-J/G-0006-06

After installation

NDT for pipe welded

junction

DL869-2004

DH1-M-ITP-3-J/G-0006-07

After installation

DL5190.4-2004

DH1-M-ITP-3-J/G-0006-03

After installation

position check

DL5190.4-2004

DH1-M-ITP-3-J/G-0006-04

After installation

size check

DL5190.4-2004

DH1-M-ITP-3-J/G-0006-04

After installation

Welding apperance check Design drawing

DH1-M-ITP-3-J/G-0006-06

After installation

Design drawing

DH1-M-ITP-3-J/G-0006-08

After installation

Comply with

requirements

Design drawing

DH1-M-ITP-3-J/G-0006-08

After installation

Comply with

requirements

3.2Pipe installation

3.3Pipe valve installation

3.4 Installation of

supports and hangers

Comply with

requirements

Comply with

requirements

Comply with

requirements

Comply with

requirements

Comply with

requirements

Comply with

requirements

Comply with

requirements

Comply with

requirements

size check

test range

NDT record of checking

pipe welded junction

system line inspection

4

Leak test and flushing of check remaining work

system

check test gage

watering leak test

pressurize to test pressure

check

test pressure falls to

working pressure check

4

Leak test and flushing of

flushing

system

compressed air blowing

Paint&anticorrosion for equipment and pipe

6

Legend

Hand over to

commission team

HHold

WPP

DH1-M-ITP-3-J/G-0006-09

punch list

DH1-M-ITP-3-J/G-0007-

Review all inspection

documents

WWitness

RRecord

PPerform

Before and after

anticorrosion

After installation

Comply with

requirements

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

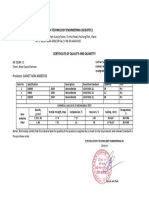

ID No.:DH1-M-ITP-3-J/G-0005--01-01(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air System

Finish Time:

Inspected work: Tank installation

Structure/Location: Air compressed house

Method of Inspection

Visual

No.

Laboratory Test

Working procedure

Measurement

Survey

Inspection item

Inspection criteria

Centerline deviation

10mm

Elevtion deviation

10mm

Spacing check of anchor bolt

10mm

Horizontal deviation

5mm

Centerline deviation

5mm

Elevation deviation

10mm

1

2

Foundation check

Equipment locating

Orientation of inlet and outlet

nozzle

Visual inspection of equipment

grouting

7

8

9

10

Others:

Assessment

DEC

PECC2

TPMB3

Comply with design requirements

clean, without debris

Equipment name

Visual check of

equipment

11

KKS number

Manufacturer

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full

Name

Note: = Accept, x = Reject.

Form:M-ITP-3-J/G-0005--01-01

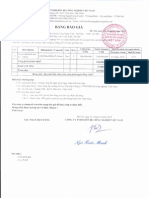

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0005--01-02(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air System

Finish Time:

Inspected work: Dryer and Water-cooled air compressor installation

Structure/Location: Air compressed house

Outlet Elevation

Method of Inspection

Visual

No.

Laboratory Test

Survey

Others:

Assessment

Inspection item

Inspection criteria

Centerline deviation

10mm

Elevtion deviation

10mm

Horizontal deviation

5mm

Centerline deviation

5mm

Elevation deviation

10mm

Orientation of inlet and outlet

nozzle

Comply with design requirements

Visual inspection of equipment

grouting

clean, without debris

1

2

Working procedure

Measurement

Foundation check

Equipment locating

8

9

DEC

PECC2

TPMB3

Equipment name

Visual check of

equipment

10

KKS number

Manufacturer

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full

Name

Note: = Accept, x = Reject.

Form:M-ITP-3-J/G-0005--01-02

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0005-02( )

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air System

Finish Time:

Inspected work: Installation of sewage pump

Structure/Location: Air compressed house

Centerline deviation

Steel beam upper surface

elevation

Reference line

Method of Inspection

Visual

Laboratory Test

Measurement

Survey

Assessment

Working

procedure

Iinspection item

Inspection criteria

Equipment

check

Visual inspection of shell

and component parts

No damage,crack,deformation,and layering

Elevation deviation

Centerline deviation

Installation of

equipment Steel beam levelness

deviation

Connection of equipment

and pipe

Others:

DEC

PECC2

TPMB3

10mm

5mm

2mm

No stress connection

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

M-ITP-3-J/G-0005-02

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0006-01-(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air System

Finish Time:

Inspected work: Material inspection

Based documentation for acceptance:

1. Request for inspection:

2. Approved drawings:

3. Inspection and Test Plan or related standards(if any)

4. Measurement and Test Result report:

5. Site Diary

6. Other relative documents (if any):

Method of Inspection

Visual

No.

Laboratory Test

Type of material

Pipe

Pipi fitting

Valve

Paint

Measurement

Specification

Material

Survey

Others:

Quantity

Visual

inspection

Assessment

ACC.

REJ.

5

6

7

8

9

10

11

12

13

14

15

16

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-J/G-0006-01

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0006-02-(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air System

Finish Time:

Inspected work: Pipe installation

Structure/Location: Air compressed house

Based documentation for acceptance:

1. Request for inspection:

2. Internal inspection report, attached:

3. Approved drawings:

4. Inspection and Test Plan or related standards(if any)

5. Measurement and Test Result report:

6. Site Diary

7. Other relative documents (if any):

Method of Inspection

Visual

Laboratory Test

Working procedure

Measurement

Survey

Inspection item

DEC

PECC2

2mm

Overhead:10m Trench:15mm

underfround:20mm

Coordinate deviation

Verticality deviation of stand pipe

2L/1000 and 15mm

Material of spacer for supports and hangers

Rubber,teflon or equivalent material as pipe

Type and size of

groove

Fit-up check

Assessment

Inspection criteria

Verticality deviation of flange

Pipe installation

Others:

Straightness of

butt-joint pipe

Visual

inspection of

welding

Comply with design requirements

Dn100mm

1mm

Dn100mm

2mm

No slag inclusion,porosity and crack

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-J/G-0006-02

HAI 1 THERMAL POWER PLANT PROJECT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0006-02-(

Date :

Start Time:

Finish Time:

Assessment

TPMB3

eed to carry out the next works.

Owner

TPMB3

Form: M-ITP-3-J/G-0006-02

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-JG-0006-03-(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air System

Finish Time:

Inspected work: Valve installation for pipe

Structure/Location: Air compressed house

Based documentation for acceptance:

1. Request for inspection:

2. Internal inspection report, attached

3. Approved drawings:

4. Inspection and Test Plan or related standards(if any)

5. Measurement and Test Result report:

6. Site Diary

7. Other relative documents (if any):

Drg.No.

Valve name

Valve type

KKS number

Installation

orientationas

per drawing

Bolt

tightening

Assessment

DEC

PECC2

TPMB3

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-JG-0006-03

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0006-04-(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title:Installation of equipment and pipe in Compressed Air

System

Finish Time:

Inspected work: Installation of supports and hangers for pipe

Structure/Location: Air compressed house

Based documentation for acceptance:

1. Request for inspection:

2. Internal inspection report, attached:

3. Approved drawings:

4. Inspection and Test Plan or related standards(if any)

5. Measurement and Test Result report:

6. Site Diary

7. Other relative documents (if any):

Method of Inspection

Visual

Laboratory Test

Measurement

Survey

Others:

Assessment

Working

procedure

Inspection item

Inspection criteria

DEC

Layout and process size

TPMB3

Comply with design requirements

Configuration Threaded suspender

of supports

and hangers Clampholder base plate

Not bent,burr-free thread,fit up with nut

Smooth,planeness,fit well

Root layout and process size

Comply with design requirements

Spacer of supports and hangers for

Installation of stainless steel pipe

supports and Span of supports and hangers

hangers

Welding inpsection

Comments from DEC:

PECC2

teflon spacer or same material as pipe

Comply with design requirements

Comply with stipulation of DL/T869

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-J/G-0006-04

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-JG-0006-05-(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air

Finish Time:

System

Inspected work: Pipe fit-up inspection report

Structure/Location: Air compressed house

Drawing No.

Line No./Part No.

Joint No.

Material

Pipe size(mm)

Diameter/Thickness

Root

Gap(mm)

Status

ACC

REJ

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion:

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-JG-0006-05

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0006-06-(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in

Compressed Air System

Finish Time:

Inspected work: Welding check for supports and hangers

Structure/Location: Air compressed house

Drawing No.

Joint No.

Welder ID

Material

Size

Thickness

NDT

RT

UT

Status

MT

PT

ACC

REJ

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion:

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-J/G-0006-06

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.: DH1-M-ITP-3-J/G-0006-07--(

RADIOGRAPHIC EXAMINATION REPORT

Page

Client Name:

of

Request No.:

Acceptance criteria:

Procedure No.:

Item:

Date of shooting:

Welding process:

Installation of equipment and pipe in Compressed Air

System

MATERIAL INFORMATION

Drawing No.:

Line No.:

Material:

EQUIPMENT

X-RAY

Test Voltage

Focal Spot Size

GAMMA RAY

KV

mA

mm x mm

Source Size

SFD

Serial No.:

mm

Film type

IQI

Film size

Location

:

Source side

Film side

Development

Manual

Automatic

SWSI

DWSI

Intensifying Screen Type

Front:

mm

: Lead

Rear:

Density Required

Sensitivity Required

TECHNIQUE

MATERIAL

FFD

Isotope / Activity

mm

Shooting

Technique

DWDI

Super imposed

Panoramic

EVALUATION

Joint No.

Film

Location

Welder ID.

OD/

Length

(mm)

Thk/

SCH

(mm)

(QUANTITY OF FILMS:

ABBREVIATION :

DEFECT (mm)

Film

Density

RESULT

Type

Length

Location

Remarks

00 )

ACC-ACCEPTABLE

REJ-REJECT

RS-RESHOOT

IP-INCOMPLETE PENETRANT

P-POROSITY

S-SLAG INCLUSION

LF-LACK OF FUSION

CV-CONCAVITY

C-CRACK

UC-UNDERCUT

TI-TUNGSTEN INCLUSION

BT-BURN THROUGH

FM-FILM MARK

CP-CLUSTER POROSITY

RW-REWELD

ER-EXCESSIVE ROOT

APAVE ASIA PACIFIC CO., LTD

DEC/EPC CONTRACTOR

EVNPECC2

EVNTPMB3

Evaluated by:

Name:

Name:

Review by:

Signature:

Signature:

Signature:

Signature:

Date:

Date:

Date:

Date:

Form:M-ITP-3-J/G-0006-07

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0006-08(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title:Installation of equipment and pipe in Compressed Air

System

Finish Time:

Inspected work: Leak test

Structure/Location: Air compressed house

Method of Inspection

Visual

Working

procedure

Laboratory Test

Inspection item

Measurement

Survey

Others:

Assessment

Inspection criteria

DEC

PECC2

TPMB3

Drawing No.

Check

before leak

test

Hydro test

System

flushing

Test boundary

Refer to attachement

NDT record of checking pipe

welded junction

Comply with ASME B31 requirements

System line check

Comply with design requirements

Remaining work check

Comply with design requirements

Pressure gauge check

Attach the qualified calibration report

Test pressure

150% of design pressure

water filling check

No leakage

Pressurized to test pressure

No leakage

Reduce to working pressure

No leakage

Water flushing

Outlet water and inlet water with same transparency

Compressed air purging

Comments from DEC:

Exhaust without smoke by visual inspection

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-J/G-0006-08

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

ID No.:DH1-M-ITP-3-J/G-0006-09(

INSPECTION REPORT

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed Air System

Finish Time:

Inspected work:Painting and anticorrosion for equipment and pipe

Structure/Location: Air compressed house

Method of Inspection

Visual

Laboratory Test

Check before

painting

Measurement

Survey

Primer Type

Lowest Derusting Grade

Asphalt primer

St3 or Sa2

Alkyd resin primer and epoxy aspalt primer

St3 or Sa2

Other type resin

Sa2

Zinc-rich primer of all kinds

Sa2.5

Installation location

Primer

Intermediate

Others:

Assessment

DEC

PECC2

TPMB3

Finish

Epoxy

Epoxy anti-corrosive

micaceous 1 paint 1 layer 40

layer 100 m

m

Epoxy

Painting of outdoor equipment,pipe,supports Epoxy xinc-rich 1 micaceous 1 Polyurethane finish

and hangers

layer 80m layer 100 1 layer 50m

m

Epoxy

Epoxy anti-corrosive

Epoxy xinc-rich 1 micaceous 1

Indoor platform & ladder,and lifting facilities

paint 1 layer 40

layer 50m layer 100

m

m

Epoxy

Epoxy xinc-rich 1

Outdoor platform & ladder,and lifting

micaceous 1 Polyurethane finish

layer 80m

facilities

layer 100 1 layer 50m

m

Modified epoxy anti-corrosive

Coal tar epoxy

Underground embedded pipe

anti-corrosive paint asphalt paint3 layers of glass

1 layer 200um cloth in 4 layers of paint 150

Epoxy asphalt

m

Epoxy asphalt

finish 1 layer

primer 1 layer 200

Trench pipe

100m

um

Comments from DEC:

Painting of indoor equipment,pipe,supports Epoxy zinc-rich 1

and hangers

layer 50m

Comments from PECC2:

Comments from TPMB3:

Conclusion: Accepted the above inspected work and agreed to carry out the next works.

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-J/G-0006-09

DUYEN HAI 1 THERMAL POWER PLANT PROJECT

OWNER

CONSULTANT

EPC CONTRACTOR

INSPECTION REPORT

ID No.:DH1-M-ITP-3-J/G-0007-(

Date :

Sub. Contractor: GEDI/HTPC

Start Time:

Work title: Installation of equipment and pipe in Compressed

Air System

Finish Time:

Inspected work: Punch list

Structure/Location: Air compressed house

Item No.

Description of defect

Originator

Responsible party

COMPLETION

DEC

PECC2

TPMB3

1

2

3

4

5

6

7

8

9

10

Comments from DEC:

Comments from PECC2:

Comments from TPMB3:

Conclusion:

Sub-Contractor

GEDI/HTPC

EPC Contractor

DEC

Consultant

PECC2

Owner

TPMB3

Position

Signature

Full Name

Note: = Accept, x = Reject.

Form: M-ITP-3-J/G-0007

You might also like

- Class Test 4 & 5 Cams - Gears - Assignment Questions KomDocument10 pagesClass Test 4 & 5 Cams - Gears - Assignment Questions KomVenkateswar Reddy MallepallyNo ratings yet

- Human Reliability 07Document4 pagesHuman Reliability 07Fernando RomeroNo ratings yet

- Emerson Mentor MP Manual PDFDocument182 pagesEmerson Mentor MP Manual PDF6612poolNo ratings yet

- MSDS Ore Dressing AgentDocument6 pagesMSDS Ore Dressing AgentUrantuul dashNo ratings yet

- Supply Chain Optimization at Dalmia CementDocument14 pagesSupply Chain Optimization at Dalmia Cementmasoom razaNo ratings yet

- DEME Group Key Financial Figures For The FY 2020 Quick ReviewDocument27 pagesDEME Group Key Financial Figures For The FY 2020 Quick Reviewcitybizlist11No ratings yet

- Asme Se 446Document41 pagesAsme Se 446Christian Adiguna PurbaNo ratings yet

- Indian Standard: Carbon Steel Castings For General Engineering Purposes - SpecificationDocument8 pagesIndian Standard: Carbon Steel Castings For General Engineering Purposes - SpecificationchepurthiNo ratings yet

- RX-Multi Manual Explains Universal Receiver FeaturesDocument4 pagesRX-Multi Manual Explains Universal Receiver FeaturesricardoNo ratings yet

- D81 1 N - 1009 enDocument68 pagesD81 1 N - 1009 enbotondh77No ratings yet

- Commercial MD HD TruckFuelEfficiencyTechStudyDocument302 pagesCommercial MD HD TruckFuelEfficiencyTechStudyddi11No ratings yet

- VpCI-101 MSDS PDFDocument5 pagesVpCI-101 MSDS PDFJose Alberto Uribe Minier0% (1)

- 00 SRM D Design For Automotive - 2008 PDFDocument315 pages00 SRM D Design For Automotive - 2008 PDFEduardo BittencourtNo ratings yet

- Cat C15 Specifications PDFDocument30 pagesCat C15 Specifications PDFdiony182No ratings yet

- Simplex WT-Series ManualDocument9 pagesSimplex WT-Series ManualTitanplyNo ratings yet

- BU48A02B00 00E N - 007 (ProSafe ProjRef)Document12 pagesBU48A02B00 00E N - 007 (ProSafe ProjRef)Broken WindowNo ratings yet

- VCI User ManualDocument13 pagesVCI User ManualALEJANDRONo ratings yet

- TD107 Operation Manual PDFDocument42 pagesTD107 Operation Manual PDFshalabyahmedNo ratings yet

- WS Manual EC10 PDFDocument63 pagesWS Manual EC10 PDFSky100% (1)

- CY3 Multiproduct Pipeline Atmos LDS and Batch TrackingDocument19 pagesCY3 Multiproduct Pipeline Atmos LDS and Batch TrackingMario SitorusNo ratings yet

- Qmi Em5 ManualDocument88 pagesQmi Em5 ManualBenja87No ratings yet

- Pollution PortDocument49 pagesPollution PortCorto MalteseNo ratings yet

- Manual w200 WartsillaDocument452 pagesManual w200 Wartsillanikolasthermosolutions100% (1)

- Caterpillar XQ1000 Containerized Diesel Generator SetDocument10 pagesCaterpillar XQ1000 Containerized Diesel Generator SetMacAllister MachineryNo ratings yet

- DD100 5 PI Installation ManualDocument8 pagesDD100 5 PI Installation Manualprala_marian5780No ratings yet

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test Procedurelaleye_olumideNo ratings yet

- Cimc Vehicles Co.,Ltd: Cimc Fuel Tanker TrailerDocument3 pagesCimc Vehicles Co.,Ltd: Cimc Fuel Tanker TrailerOumarba KamandaNo ratings yet

- Key Maritime Logistics StakeholdersTITLEBill of Lading Functions in International TradeDocument7 pagesKey Maritime Logistics StakeholdersTITLEBill of Lading Functions in International Tradeparidhisahni0% (2)

- LT303-002 - Discovery Td5 - Incorrect Engine ECU Replacements - TOPIxDocument4 pagesLT303-002 - Discovery Td5 - Incorrect Engine ECU Replacements - TOPIxsam_cuty99No ratings yet

- Fog Detector Atex - DATADocument2 pagesFog Detector Atex - DATArocket-vtNo ratings yet

- Maintenance Log SheetDocument6 pagesMaintenance Log Sheetvivek adNo ratings yet

- Honda CITY 2009 FUSEDocument2 pagesHonda CITY 2009 FUSEIntercare EgyptNo ratings yet

- Stahl PDFDocument20 pagesStahl PDFLuis LopezNo ratings yet

- Iveco Eurocargo Ml180e28 Rigid 4x2Document1 pageIveco Eurocargo Ml180e28 Rigid 4x2marianchiNo ratings yet

- I-Panda Specification of MPPT Solar Charge ControllerDocument6 pagesI-Panda Specification of MPPT Solar Charge ControllernextgenpowerNo ratings yet

- W.O. 35644 - Commissioning Check ListDocument3 pagesW.O. 35644 - Commissioning Check Listphankhoa83-1No ratings yet

- Tutorial 1 - Basic Engineering Science: Instrumentation and ControlDocument6 pagesTutorial 1 - Basic Engineering Science: Instrumentation and ControlMohd A IshakNo ratings yet

- Fuel CatalystDocument13 pagesFuel CatalystMashooq Jain100% (1)

- PMT Raw Material Cutting Request FormDocument1 pagePMT Raw Material Cutting Request FormAMIT SHAHNo ratings yet

- Price List Orbitec Sales Rent English 1mbDocument19 pagesPrice List Orbitec Sales Rent English 1mbMarcos AndréNo ratings yet

- OKI ML3320-21 Maintenance ManualDocument155 pagesOKI ML3320-21 Maintenance ManualAnthony DaskalierosNo ratings yet

- Monitoring Lead-Acid Batteries in Coal Mines with Thermal ImagingDocument17 pagesMonitoring Lead-Acid Batteries in Coal Mines with Thermal ImagingBenNo ratings yet

- Manual Pro Test 1500 InglesDocument19 pagesManual Pro Test 1500 InglesAnonymous SSp6xSPQNo ratings yet

- 02 Alignment TrainingDocument59 pages02 Alignment TrainingPhương TrầnNo ratings yet

- Description: Tags: 03session7Document63 pagesDescription: Tags: 03session7anon-157775No ratings yet

- 001Document2 pages001Nacer Mezghiche50% (4)

- AVL 733SrDocument131 pagesAVL 733SradNo ratings yet

- CBS CatalogueDocument140 pagesCBS CataloguefreeeflyerNo ratings yet

- Kenco KlceDocument6 pagesKenco KlcenelsonNo ratings yet

- Calibrating BFP Turbine Expansion SensorsDocument9 pagesCalibrating BFP Turbine Expansion Sensorsnaresh977977No ratings yet

- Digital Multimeter User ManualDocument83 pagesDigital Multimeter User ManualJoseEliasNo ratings yet

- HVL Electrical Installation (Document File 1)Document431 pagesHVL Electrical Installation (Document File 1)RaymondNo ratings yet

- Cummins Position Profiles - Mechanical EngineerDocument28 pagesCummins Position Profiles - Mechanical EngineerLakkakula SubbuNo ratings yet

- Air CompressorDocument4 pagesAir CompressorHENRYNo ratings yet

- AHD 414 Start-Stop-Diesel Control UnitDocument9 pagesAHD 414 Start-Stop-Diesel Control UnitAL KUSCUNo ratings yet

- GM - Series PumpDocument64 pagesGM - Series PumpTô Thiên ĐăngNo ratings yet

- DH3-31HFC-T-ITP-0010 ITP For Commissioning of Coal Pulverizing System REV.0Document69 pagesDH3-31HFC-T-ITP-0010 ITP For Commissioning of Coal Pulverizing System REV.0hungNo ratings yet

- Method Statement Risk Assessment Form: DSP - Tecom K22-006Document14 pagesMethod Statement Risk Assessment Form: DSP - Tecom K22-006Sharvin NageebNo ratings yet

- Hydrotest Method Statement 12th Mar 2012-1Document21 pagesHydrotest Method Statement 12th Mar 2012-1sethu1091100% (21)

- GB 150.1 Part 1 PDFDocument49 pagesGB 150.1 Part 1 PDF123habib123fikriNo ratings yet

- Asme3d1 nd-1000Document8 pagesAsme3d1 nd-1000Dang Hieu NguyenNo ratings yet

- Q345EDocument2 pagesQ345Eiergun80No ratings yet

- MAN6110 - EN Pressure Sand FilterDocument2 pagesMAN6110 - EN Pressure Sand FilterDang Hieu NguyenNo ratings yet

- 125KQW138 60 37 2.datasheetDocument1 page125KQW138 60 37 2.datasheetDang Hieu NguyenNo ratings yet

- 125KQW138!60!37 2.outside DrawingDocument1 page125KQW138!60!37 2.outside DrawingDang Hieu NguyenNo ratings yet

- To: Subject: Valve Electric actuators-TETDocument1 pageTo: Subject: Valve Electric actuators-TETDang Hieu NguyenNo ratings yet

- Appendix A.2 Water TWorks Capacity ChecksDocument8 pagesAppendix A.2 Water TWorks Capacity ChecksTuấn VũNo ratings yet

- CycleDocument2 pagesCycleDang Hieu NguyenNo ratings yet

- Compressed Air Distribution (Systems)Document33 pagesCompressed Air Distribution (Systems)Nacho.pNo ratings yet

- Orifice plate dimensioning for air flowDocument21 pagesOrifice plate dimensioning for air flowDang Hieu NguyenNo ratings yet

- Viet Solution Technology Engineering JSC (Sotec) : Products: Gasket Non-AsbestosDocument1 pageViet Solution Technology Engineering JSC (Sotec) : Products: Gasket Non-AsbestosDang Hieu NguyenNo ratings yet

- Sizing The Air ReceiverDocument3 pagesSizing The Air Receivernandhamech25No ratings yet

- MAN6110 - EN Pressure Sand FilterDocument2 pagesMAN6110 - EN Pressure Sand FilterDang Hieu NguyenNo ratings yet

- IDT Instalacion Manual3016 - USMetricDocument24 pagesIDT Instalacion Manual3016 - USMetricCarlos GarciaNo ratings yet

- Metal Backing Flange GuidelinesDocument19 pagesMetal Backing Flange GuidelinesDang Hieu NguyenNo ratings yet

- Air Compressor Pipe Thickness CalculationDocument2 pagesAir Compressor Pipe Thickness CalculationDang Hieu NguyenNo ratings yet

- Bon Be 10m3 TB1Document1 pageBon Be 10m3 TB1Dang Hieu NguyenNo ratings yet

- HDKT Thue Thiet Bi HongnamDocument4 pagesHDKT Thue Thiet Bi HongnamDang Hieu NguyenNo ratings yet

- Arrangement Chutes SupportsDocument1 pageArrangement Chutes SupportsDang Hieu NguyenNo ratings yet

- Process Piping Design & Engineering Per ASME B 31.3Document16 pagesProcess Piping Design & Engineering Per ASME B 31.3naveenbaskaran1989No ratings yet

- DWG TrueView DWG Convert Conversion ReportDocument1 pageDWG TrueView DWG Convert Conversion ReportCosmin CinciNo ratings yet

- Astm A53 DN PDFDocument2 pagesAstm A53 DN PDFDang Hieu NguyenNo ratings yet

- T10206-YD00-P1HA - 320011 - 0 - Boiler Pressure Part Arrangement (Side Elevation View)Document1 pageT10206-YD00-P1HA - 320011 - 0 - Boiler Pressure Part Arrangement (Side Elevation View)Dang Hieu NguyenNo ratings yet

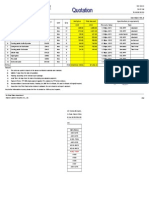

- Description Unit Q.ty Unit Price Specification (Or Equivalent) USD USD Pressure, Temp Type Dimensions / Capacity Total AmountDocument2 pagesDescription Unit Q.ty Unit Price Specification (Or Equivalent) USD USD Pressure, Temp Type Dimensions / Capacity Total AmountDang Hieu NguyenNo ratings yet

- Appendix 3 List of Submittal DocumentsDocument26 pagesAppendix 3 List of Submittal DocumentsDang Hieu NguyenNo ratings yet

- Ho-So-Bon Be - TankDocument29 pagesHo-So-Bon Be - TankDang Hieu NguyenNo ratings yet

- The Love Song of J.alfred Prufrock - AnalysisDocument6 pagesThe Love Song of J.alfred Prufrock - AnalysismsrobotoNo ratings yet

- Wesley Street 17, SouthportDocument2 pagesWesley Street 17, SouthportJames BradshawNo ratings yet

- The Boscombe Valley Mystery: Sir Arthur Conan DoyleDocument8 pagesThe Boscombe Valley Mystery: Sir Arthur Conan DoyleJulian David Carrion SanchezNo ratings yet

- Prayer and WorshipDocument3 pagesPrayer and WorshipaleachonNo ratings yet

- Aldini Accordion Warmups 1 Thru 8Document8 pagesAldini Accordion Warmups 1 Thru 8VytautasNo ratings yet

- Mighty Empires RulebookDocument4 pagesMighty Empires RulebookScottie Swanson100% (1)

- The Speckled BandDocument16 pagesThe Speckled BandAnonymous mTcVcYoqNo ratings yet

- A Detailed Lesson Plan in English 1Document5 pagesA Detailed Lesson Plan in English 1Abdulhamim Tanggote MindalanoNo ratings yet

- Syllabus Contemporary Southern Cone Fiction DiazlunaDocument6 pagesSyllabus Contemporary Southern Cone Fiction Diazlunaapi-300076680No ratings yet

- Little Office of The Blessed Virgin Mary-Tue-Morning PrayerDocument8 pagesLittle Office of The Blessed Virgin Mary-Tue-Morning PrayerarchivisimusNo ratings yet

- Chapter - 3: "Black Man's Confrontation With The White Devil"Document35 pagesChapter - 3: "Black Man's Confrontation With The White Devil"Chris LatchmanNo ratings yet

- Succeed at Cambridge Advanced Test 2 Use of EnglishDocument2 pagesSucceed at Cambridge Advanced Test 2 Use of EnglishFiorellaNo ratings yet

- 2011 The Great Day Is Coming - Alan E. HighersDocument1 page2011 The Great Day Is Coming - Alan E. HighersAnatoly DyatlovNo ratings yet

- LESSON MANUSCRIPT ANALYSISDocument12 pagesLESSON MANUSCRIPT ANALYSISjeysonmacaraigNo ratings yet

- Sugarveil Cheat Tutorial: WIN Tickets!Document55 pagesSugarveil Cheat Tutorial: WIN Tickets!susanNo ratings yet

- Blades in The Dark - Quickstart v4Document52 pagesBlades in The Dark - Quickstart v4triad3204No ratings yet

- Bach Expression and MeaningDocument447 pagesBach Expression and MeaningNarcis LlongueresNo ratings yet

- Reckless - Love, Sheet Music, 7 PagesDocument7 pagesReckless - Love, Sheet Music, 7 PagesMora PierreNo ratings yet

- Media LanguageDocument7 pagesMedia Languagejohn christopher50% (2)

- Corteva Lumisena Guidelines LRDocument33 pagesCorteva Lumisena Guidelines LRDaniel BatemanNo ratings yet

- The Complete Guide to Ikat TextilesDocument19 pagesThe Complete Guide to Ikat Textilesvishal trivedi25% (4)

- Martin McKenna (Artist)Document7 pagesMartin McKenna (Artist)Федор0% (1)

- 6C Queenstown - Worksheet, Answers, Script PDFDocument3 pages6C Queenstown - Worksheet, Answers, Script PDFCsilla Szabó0% (1)

- Language Focus 7 1: Unit 1 Test: Standard - Answer KeyDocument2 pagesLanguage Focus 7 1: Unit 1 Test: Standard - Answer KeyJanet FernandezNo ratings yet

- White and Black Poster Paint Paint Brush Oslo Paper Sliced Bananas Peanut Butter Rice Crispies ToothpickDocument9 pagesWhite and Black Poster Paint Paint Brush Oslo Paper Sliced Bananas Peanut Butter Rice Crispies ToothpickPauleen RheiNo ratings yet

- Grammar PracticeDocument4 pagesGrammar PracticespamdetectorjclNo ratings yet

- A Weeklong Poetry Mini-Unit For Grades 2-6 That Includes Resources Classroom Posters/models, and Student PrintablesDocument6 pagesA Weeklong Poetry Mini-Unit For Grades 2-6 That Includes Resources Classroom Posters/models, and Student Printablespete2835No ratings yet

- Ncert Solutions For Class 9 English Beehive Chapter 7Document6 pagesNcert Solutions For Class 9 English Beehive Chapter 7rakhi.chatterjeeNo ratings yet

- Indian-Women Critical AnalysisDocument2 pagesIndian-Women Critical AnalysisAbhishek M N50% (8)

- THE NARRATIVE TECHNIQUESDocument15 pagesTHE NARRATIVE TECHNIQUESsaad_sheikh_1No ratings yet