Professional Documents

Culture Documents

API570

Uploaded by

Rajesh ManoharanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API570

Uploaded by

Rajesh ManoharanCopyright:

Available Formats

API 570 Certification

Preparation

INTRODUCTION

ABOUT MSTS

This course gives a broad knowledge about In-Service

Piping Systems and prepares students for the API 570

exam. The course is an intensive one-week course with a

special emphasis on the use of the related codes and

calculations.

MSTS is a company specializing in providing the needed

practical training for petrochemical pressure equipment

inspectors and engineers.

This course content includes:

Using B31.3

Piping Calculations

Section IX Welding

API 570

B16.5 & other

Exam

Currently, MSTS provides eleven courses specifically

designed to help pressure equipment personnel improve

their technical knowledge and skills.

MSTS instructors are selected for their technical and

wake-ability skills. (Wake-ability the ability to

minimize snores during long, boring technical training.)

SPEAKERS BACKGROUND

API TRAINING

Mark Smith has worked in the petrochemical industry for 25

years and in the pressure equipment discipline for 16

years. He has been instructing inspection classes since

1992. Certifications obtained include: API 510/570/653.

MSTS most popular courses are the API certification

classes. MSTS offer classes prior to each API exam.

Currently about 150 students per year attend one of his API

courses. He is committed to helping each student achieve

success.

These classes and exams are not easy, so only

individuals who are serious about their pressure

equipment career should participate.

MSTS students generally have a 90% passing rate.

OBJECTIVES

WHO SHOULD JOIN

The course provides participants with the knowledge

necessary to:

This class is designed for pressure equipment inspectors

and engineers working in refineries, chemical & industrial

plants, gas plants, pipeline terminals, and oil fields.

Successfully pass the API 570 piping inspector

certification exam

Effectively use major codes: ASME B16.5 & B31.3;

ASME B&PV Sections V & IX

Perform all basic piping calculations needed for the

API exam (e.g. tmin, test pressure, MAWP, MDMT,

corrosion rates, remaining life, etc.)

Use APIs requirements during inspection, repairs,

and alterations of piping

Review welding procedures (WPS/PQR) and welder

performance qualifications (WPQ)

BRING TO CLASS

Students should bring to class: a calculator, a straight edge

(or triangle), pencils, highlighters, lots of questions, and a

CAN-DO attitude. Also, participants must bring the

appropriate codes required for the API exam.

Organized by:

HRD Approved Training Provider (AO470)

Ministry of Finance (Reg. No 357-02088676)

CLASS PARTICIPANTS

Students who wish to apply for the API Exam should have

at least 3 years of experience at a petro-, chemical- or

industrial facility and have at least 1 year of inspection

experience.

However, participants who do not meet this requirement

are also welcomed to attend this Training to further their

knowledge in the related areas.

NOTES

This is an intense course with daily homework and a final

exam (similar to the API 570 exam). A study guide is

issued to direct participants pre-class study. Download

pre-class Study Guide from www.msts-training.com

CLASS SIZE

Enrollment is limited to 24 students.

MSTS

Inspection Training Services

594752

Updated on 13 January 2010

API 570 Certification

Preparation

FEEDBACK FROM PAST PARTICIPANTS

My API training with MSTS made me confident to know now that I am

doing my job the right way. Mark not only explains the standards but also

shares his own experiences as he teaches the class. My training also

allowed me to meet and interact with my own peers and thus now have

my own network worldwide. I would only complete my API trainings and

reviews with MSTS.

Malou M. Baluyut

Senior Engineer

Shell Guam, Inc.

Have attended 2 API classes taught by Mark Smith. As

advertised, Mark is one instructor from MSTS that has a

very good technical and wake ability skills. He blends his

unique humor well in the class and is successful in keeping

everyone from snoring away in a week-long boring and yet

intensive session.

I like Marks training slides, they contain summaries of easy

to understand and digestible notes which is important for

the exam. Mark is very well verse with codes and

standards. Backed by his past working experience and

hands-on in the field, he is able to impart the requirement

knowledge to all the course participants. There are lots of

examples and stories relevant to the topics given which

allow knowledge level individual to understand easily.

My success in API examination attributed much to the

quality of his teaching and dedication in ensuring we are

prepared in the exam hall.

Lim Chon

Senior Inspector

Shell Refining Company

Port Dickson, Malaysia

I have sent my employees to other training classes and

have had little positive feed back from the employees. This

was reflected on their test scores. I then sent three other

employees and I myself attended a MSTS class and was

very pleased with the manner in which the subject matter

was presented. All of my employees left with a real understanding of the subject matter, and confidence that they

would pass their API exams!

Robert G. Maddox

Vice President of Operations

Materials Technology Group L.L.C

Organized by:

HRD Approved Training Provider (AO470)

Ministry of Finance (Reg. No 357-02088676)

I have attended numerous classes taught by Mark Smith

(MSTS). I have always found the classes to be very

interesting and extremely informative. Mark has a gift

when come to teaching that makes everyone feel comfortable with the material and he can teach at any level.

In many classes I have attended, he has had a wide

variety of skill levels and knowledge in his students and he

has the ability to make sure that everyone can follow along

and he keeps everyone participating in the class material.

He can sense when a student may be falling behind or not

fully understanding the material and makes it a point to

bring them back up to speed.

I would highly recommend to anyone interested in

succeeding in the inspection field to put their faith in Mark

Smith. I personally attribute much of my success in this

industry to Mark and his ability to teach!

James Moore

Senior Inspector

Motiva Enterprises

Convent, Louisiana

As I go along with MSTS, I found that it is really a worth

investment for your future career. The more you listen to

Mr Mark Smith, the more eager you want to be certified for

API Certification. He is really a good teacher with a very

wide knowledge and experience and for me, I can say

hes the No. 1 Lecturer so far. I really appreciate IDC for

its good service and support that has been given to me.

CM Yahya

Plant Inspector

Ethylene Malaysia Sdn Bhd

MSTS

Inspection Training Services

594752

Updated on 13 January 2010

API 570 Certification

Preparation

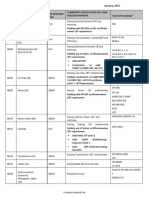

DAY 1

DAY 2

1) Welcome & Introduction

1) ASME B31.3 - Piping Code

Includes understanding:

Purpose & Scope of the Code

Organization of the Code

Piping Classes specified by the Code

Roles specified by the Code

Tips on how to find information in the Code

2) ASME B16.5 Flange Code

Learn how to determine:

Maximum Flange Pressure

Maximum Flange Temperature

Appropriate Flange Class

Maximum Hydrotest Pressure

Flange Dimensions

Maximum allowed Flaw Size on Flange Face

3) API 570 Sections 1-4, 6

Purpose of API 570

Scope of API 570

Responsibilities defined in API 570

Inspection Types & Intervals

Tips on how to memorize information in API Codes

Evening Session: ASME B16.5 & API 570 Homework

Practice all Calculations covered in Class.

2) ASME B31.3 Calculations & Charts

Learn how to determine:

Quality Factor E

Allowable Stress S

Minimum Thickness for a Pipe

Appropriate Pipe Schedule for new Pipe

Minimum Thickness for a Blank (Blind)

3) API 570 Section 7

Inspection Data Evaluation

Calculate MAWP of a Piping System

Evening Session: ASME B31.3 & API 570 Homework

Practice all Calculations covered in Class.

DAY 3

1) ASME B31.3 - Piping Code

Includes understanding:

Basic concepts of Piping Flexibility

Selection of Piping Materials

Fabrication Requirements

DAY 4

1) ASME B&PV Section IX - Welding Code

Understand the following key concepts.

Purpose of the Code

Roles of the Welding Inspector

Organization of the Code

Welding Positions Test and Field

Testing Requirements and Acceptance Criteria

Welder Qualification Process and Restrictions

Tips on how to find information in the Code

2) ASME B31.3 Calculations & Charts

Learn how to determine:

Thermal Pipe Growth

Minimum Design Temperatures

Welding Preheat Requirements

PWHT Requirements

2) ASME B&PV Section IX Review and Evaluate a WPQ

(Welder Qualification). Understand

Essential Variables for welder qualification

Testing required for welder qualification

3) API 570 Section 8-9

Repairs, Alterations & Rerating

Underground Piping

Evening Session: ASME B31.3 & API 570 Homework

Practice all Calculations covered in Class. Also, complete

the Corrosion Rate/Remaining Life Self-Study Module

Evening Session: Section IX Homework. Evaluate two

WPQs.

DAY 5

3) API 570 Section 8 & 9

Repairs, Alterations & Rerating

Underground Piping

1) ASME B&PV Section IX - Welding Code

Understand the following key concepts

Weld Procedure Qualification Process and Restrictions

Evening Session: Section IX Homework. Evaluate one WPQ.

API 570 Homework. Also, complete the API 578 Self-Study

Module

2) WPS/PQR Review (Weld Procedure)

Evaluate a WPS with the associated PQR

Organized by:

HRD Approved Training Provider (AO470)

Ministry of Finance (Reg. No 357-02088676)

4) API 577 Welding Inspection & Metallurgy

MSTS

Inspection Training Services

594752

Updated on 13 January 2010

API 570 Certification

Preparation

DAY 6

DAY 7

1) ASME B&PV Section V NDE

Understand the following key concepts.

Purpose of the Code

Organization of the Code

RT Techniques

Purpose & Selection of IQIs

RT Film Density Requirements

Key terms discussed in the Code

Tips on how to find information in the Code

1) Course Review

2) API 570 Section 5

Inspection & Testing Practices

Registration on Day 1 at 8.00am

2) Practice Exam Exam is similar to the API 570 exam

DAILY SCHEDULE

8:30a.m. 5:30p.m. (Workshop)

7:00p.m. 9:00p.m. (Evening sessions)

3) API 571 - Damage Mechanisms in the Refinery Industry

Evening Session: ASME Section V & API 570 Homework.

Plus the Mega-Problem. This exercise includes most of the

calculations & tables covered in the class.

API APPLICATION INFO

The API Web-site at www.api.org/icp offers some

useful information (i.e. Exam Application Form, sample test question and required code books).

HOTEL ACCOMODATION INFORMATION

Statu

s

Hotel

Single

2 stars

SinggahSana Hotel

www.hspj.com.my

Tel:(603)-7956 2100

Fax:(603)-7954 2041

RM 125.00

Approximately

USD35

with breakfast

2 stars

Shah Village Hotel

www.shahsresorts.com

Tel:(603)-7956 9322

Fax:(603)-7955 7715

RM 138.00

Approximately

USD 40

with breakfast

4 stars

Armada PJ Hotel

www.armada.com.my

Tel :(603)-7954 6888

Fax:(603)-7956 8088

RM 253.00

Approximately

USD 77

With breakfast

4 stars

Crystal Crown Hotel

www.crystalcrown.com.my

Tel :(603)-7958 4422

Fax:(603)-7958 8408

RM 184.00

Approximately

USD 53

With breakfast

RM 207.00

Approximately

USD 60

With breakfast

About 15 mins walking distance. By taxi, about 8 mins.

5 stars

Hilton PJ Hotel

www.hilton.com

Tel :(603)-7955 9122

Fax:(603)-7955 3909

RM 350.75

Approximately

USD 100

with breakfast

RM 402.50

Approximately

USD 115

with breakfast

About 15 mins walking distance. By taxi, about 8 mins.

Double

Walking Distances from

Hotel to IDC / Amcorp Mall

About 15 mins walking distance

(just across the road).

RM 195.50

Approximately

USD 56

with breakfast

About 10 mins walking distance

(just across the road).

Has to go by train,

only 1 station away

*near Aeroline station in PJ

* Room rate is subject to change if the needs arise from the hotel.

Organized by:

HRD Approved Training Provider (AO470)

Ministry of Finance (Reg. No 357-02088676)

MSTS

Inspection Training Services

594752

Updated on 13 January 2010

You might also like

- API 570 Certification Preparation: Course Length: Cost: InstructorDocument1 pageAPI 570 Certification Preparation: Course Length: Cost: InstructorFares ÆazizNo ratings yet

- Api 570 - 02 Asme B 31.3Document12 pagesApi 570 - 02 Asme B 31.3Mohammad RawoofNo ratings yet

- ASME 31.3 - 2016 VT, UtDocument2 pagesASME 31.3 - 2016 VT, UtsanketNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- ASME Question and AnswersDocument6 pagesASME Question and AnswersMohammed ShakilNo ratings yet

- API-570 SAMPLE Closed Book ExamDocument12 pagesAPI-570 SAMPLE Closed Book ExamuttamNo ratings yet

- IRTS Studying For The HARECDocument40 pagesIRTS Studying For The HARECserepezNo ratings yet

- API 653 PC 15may04 Exam 3 OpenDocument5 pagesAPI 653 PC 15may04 Exam 3 Openraobabar21No ratings yet

- Leak Testing For Closure Welds of Pressure Piping PDFDocument4 pagesLeak Testing For Closure Welds of Pressure Piping PDFezzataNo ratings yet

- ARAMCO QM Number ListDocument3 pagesARAMCO QM Number ListMohamed Yousuf Syed MohamedNo ratings yet

- API 510 Study GuideDocument3 pagesAPI 510 Study GuidedanikakaNo ratings yet

- Assessment 1 API 570Document5 pagesAssessment 1 API 570Mohamed ZainNo ratings yet

- Saudi Aramco Standards: WeldingDocument12 pagesSaudi Aramco Standards: WeldingGEORGE IVANNo ratings yet

- Asme Questions and Answers Part - IiiDocument6 pagesAsme Questions and Answers Part - IiiAshwani Dogra100% (3)

- API 570 DEC 2009 ClosedDocument17 pagesAPI 570 DEC 2009 ClosedMohammedBujairNo ratings yet

- API 1169 Training: Published byDocument4 pagesAPI 1169 Training: Published byMadjid OUCHENE50% (2)

- All You Need To Know About API 571 Corrosion and MaterialsDocument13 pagesAll You Need To Know About API 571 Corrosion and MaterialsMasood KhanNo ratings yet

- 1.API 570 & Asme DefinitionsDocument59 pages1.API 570 & Asme DefinitionsAMAL VISHNUNo ratings yet

- API 510 Data Sheet - AnswersDocument6 pagesAPI 510 Data Sheet - Answersjithinjose86No ratings yet

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Case Study - 7: Numerical in API 510 CodeDocument4 pagesCase Study - 7: Numerical in API 510 CodeVishal BailurNo ratings yet

- Final Exam Answer Ref GuideDocument8 pagesFinal Exam Answer Ref Guidefazeel mohammedNo ratings yet

- Api 510 Asme PCC2Document1 pageApi 510 Asme PCC2korichiNo ratings yet

- Closed Book Api 572-A (55-65) - 2Document11 pagesClosed Book Api 572-A (55-65) - 2slxanto100% (1)

- API-570 SAMPLE Open Book ExamDocument6 pagesAPI-570 SAMPLE Open Book ExamuttamNo ratings yet

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- API-570 Practical QuestionsDocument81 pagesAPI-570 Practical QuestionsSebastian Rajesh100% (4)

- 2-Questions API 650 Question N°02 2022Document3 pages2-Questions API 650 Question N°02 2022korichiNo ratings yet

- Api 510 Q&a-2Document32 pagesApi 510 Q&a-2Mohammed ShakilNo ratings yet

- API 570 Responsibilities 2019Document4 pagesAPI 570 Responsibilities 2019Sohn JmithNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- Classification of Shielding GasesDocument2 pagesClassification of Shielding GasesshivendrakumarNo ratings yet

- Alert 01 002Document2 pagesAlert 01 002SUKhanNo ratings yet

- Amse PiDocument5 pagesAmse PiNnamdi Celestine NnamdiNo ratings yet

- ASME P-Numbers PDFDocument1 pageASME P-Numbers PDFFahri Risfa ZulfiNo ratings yet

- Daily Points To Recall (Day 1) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 1) : Professional Training and ConsultationshakeelahmadjsrNo ratings yet

- ASME P-NumbersDocument9 pagesASME P-NumbersAamer MohammedNo ratings yet

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocument8 pagesAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNo ratings yet

- API 570 Course Model Test 9Document5 pagesAPI 570 Course Model Test 9Ismail Jamaluddin100% (1)

- 177538089-API-570-Final-Exam-Questions - REALIZARDocument26 pages177538089-API-570-Final-Exam-Questions - REALIZARALe Infinito100% (1)

- API 570 Exame Questions Dated 5 July 2018Document10 pagesAPI 570 Exame Questions Dated 5 July 2018Ahmed ShakirNo ratings yet

- Api 570Document63 pagesApi 570Ramzi BEN AHMED100% (1)

- Api 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationDocument2 pagesApi 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationNuwan RanaweeraNo ratings yet

- Api 653 QuestionsDocument28 pagesApi 653 Questionskorichi100% (1)

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocument4 pages(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (2)

- M.engineering - Piping SystemsDocument55 pagesM.engineering - Piping SystemsKordalhs KyriakosNo ratings yet

- Aramco Plumbing Interview QuestionsDocument6 pagesAramco Plumbing Interview QuestionsMohanad Suliman100% (1)

- Api 570 PDFDocument2 pagesApi 570 PDFK U Masood Ahmad100% (1)

- Asme B31.3 Open & Closed Book (165 Q&A) (For Api 570 & Si Examinations)Document28 pagesAsme B31.3 Open & Closed Book (165 Q&A) (For Api 570 & Si Examinations)nani356No ratings yet

- API571 - NEW APP - Effective 2011 - CompletedDocument12 pagesAPI571 - NEW APP - Effective 2011 - Completedtong2jeNo ratings yet

- API 570 DAY 1 BOOK (1 To 51) (PP)Document63 pagesAPI 570 DAY 1 BOOK (1 To 51) (PP)melvinNo ratings yet

- Nbic IsDocument2 pagesNbic IsDivakar PanigrahiNo ratings yet

- API 570 DemoDocument6 pagesAPI 570 Demojaire esparzaNo ratings yet

- API 653 NotesDocument3 pagesAPI 653 NotesPavan_yoyoNo ratings yet

- API 510 Data Sheets - QuizletDocument1 pageAPI 510 Data Sheets - Quizletads_1203No ratings yet

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocument23 pagesAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Certification Preparation: "In-Service Piping Systems"Document5 pagesCertification Preparation: "In-Service Piping Systems"Krishna Rao100% (1)

- Api 570 Daily Practice Exams PDFDocument181 pagesApi 570 Daily Practice Exams PDFRajesh Manoharan100% (1)

- API 510 Study QuestionsDocument49 pagesAPI 510 Study QuestionsDavid Drolet Tremblay100% (1)

- Additional Notes API570Document5 pagesAdditional Notes API570Rajesh ManoharanNo ratings yet

- API 570 Awareness Course PDFDocument63 pagesAPI 570 Awareness Course PDFRajesh Manoharan50% (4)

- API 570 Perpratory Course Notes 1-Printed PDFDocument151 pagesAPI 570 Perpratory Course Notes 1-Printed PDFRajesh Manoharan100% (1)

- Sitrans FX300Document80 pagesSitrans FX300Fredy Rojas BarraNo ratings yet

- Procedure of 5GDY108C Wheel Motor Traction Motor To Transmission Mounting and Setting of Sun Pinion EndfloatDocument19 pagesProcedure of 5GDY108C Wheel Motor Traction Motor To Transmission Mounting and Setting of Sun Pinion EndfloatPaul Huertas Apaza100% (1)

- 6.pv Elite Training Manual PDFDocument9 pages6.pv Elite Training Manual PDFjeevansingh20266No ratings yet

- Erection Material List JGS320Document2 pagesErection Material List JGS320Rashid Mahmood JaatNo ratings yet

- SKF Supergrip BoltDocument18 pagesSKF Supergrip Boltformech100% (1)

- 6) Tender Specification DOLIYADocument262 pages6) Tender Specification DOLIYADwsc BharuchNo ratings yet

- 60QT003209, Rev 2Document11 pages60QT003209, Rev 2fenny fauziNo ratings yet

- Fisher Vee-Ball (V150, V200 & V300) (NPS 1 Through 12)Document52 pagesFisher Vee-Ball (V150, V200 & V300) (NPS 1 Through 12)Arianeth BalcazarNo ratings yet

- Yz125 2005Document58 pagesYz125 2005Ignacio Sanchez100% (1)

- Gestra - Technical-Information-2016 enDocument194 pagesGestra - Technical-Information-2016 enAlexanderNo ratings yet

- BERMAD IR Engineering 900 MDocument19 pagesBERMAD IR Engineering 900 MRita CaselliNo ratings yet

- Astm F1200 1988 PDFDocument4 pagesAstm F1200 1988 PDFmatteo_1234No ratings yet

- Heavy Duty, Radially Split, Two-Stage Pumps: API 610 / ISO 13709Document10 pagesHeavy Duty, Radially Split, Two-Stage Pumps: API 610 / ISO 13709bandmmillwardNo ratings yet

- 7MF0300 Highlighted PDFDocument81 pages7MF0300 Highlighted PDFmajmor-1No ratings yet

- Series 3250 Globe Control Valve Type 3251 Pneumatic Control Valves Type 3251/3271 and Type 3251/3277Document14 pagesSeries 3250 Globe Control Valve Type 3251 Pneumatic Control Valves Type 3251/3271 and Type 3251/3277Mohamed RaafatNo ratings yet

- GATE VALVES - UL Product IqDocument5 pagesGATE VALVES - UL Product IqEliud RodriguezNo ratings yet

- Test U1 ASMEFormDocument1 pageTest U1 ASMEFormB DASNo ratings yet

- WP320L WP460LDocument59 pagesWP320L WP460Ljohn smithNo ratings yet

- Pipe HandbookDocument26 pagesPipe HandbookBeatriz Berçot100% (1)

- Is 7332 1 1991 PDFDocument15 pagesIs 7332 1 1991 PDFslamienkaNo ratings yet

- Kice - Dust Duct ManualDocument2 pagesKice - Dust Duct ManualtylerstearnsNo ratings yet

- Deficiencies Summary: Hand Hole (N8)Document1 pageDeficiencies Summary: Hand Hole (N8)vietsdsNo ratings yet

- 2tc TiafDocument40 pages2tc TiafNuno PiresNo ratings yet

- TBV Cryogenic Ball Valves PDFDocument20 pagesTBV Cryogenic Ball Valves PDFANILNo ratings yet

- 2SP3 1t2sp470e1Document54 pages2SP3 1t2sp470e1Bahar SkNo ratings yet

- Eco DLX PDFDocument110 pagesEco DLX PDFestefania julioNo ratings yet

- Pressure Vessel Itp PDFDocument4 pagesPressure Vessel Itp PDFkorbelNo ratings yet

- RP 158 PDFDocument40 pagesRP 158 PDFDeependra SinghNo ratings yet

- Attieh Brochure (Small FS)Document20 pagesAttieh Brochure (Small FS)Ismail Sabri50% (2)

- Felker Piping Products: Stainless Steel Pipe, Tube & FittingsDocument58 pagesFelker Piping Products: Stainless Steel Pipe, Tube & FittingsRahul PillaiNo ratings yet