Professional Documents

Culture Documents

Vent Gas

Uploaded by

JonesHutaurukCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vent Gas

Uploaded by

JonesHutaurukCopyright:

Available Formats

Bulletin 7-S

INTRODUCTION

Gas Scrubbers

The use of wet scrubbers for control of air pollution has

gained wide acceptance throughout the industry. The

ejector-venturi wet scrubber provides a number of

advantages over many of the conventional single-purpose

devices available. Particulate collectors such as cyclones

and electrostatic precipitators cannot efficiently absorb

gases or remove odors. Fabric filters, by design, cannot

cope with gas streams having a high moisture content and

are often affected by highly corrosive gases. Catalytic

incinerators can be quickly poisoned by certain organic

wastes.

On the other hand, ejector-venturi gas scrubbers are very

effective at removing noxious gases, particulates, odors,

fumes and dusts from gas streams.

Particulate

contaminants are removed through impaction by the high

velocity spray of scrubbing liquid. Gases and odors are

eliminated through absorption and/or chemical reaction

between the gases and scrubbing liquid. When properly

matched to the application, these scrubbers, by their

nature, are better able to cope with the high temperatures

and corrosive conditions often encountered.

Schutte & Koerting has over sixty years of experience in

the control of commercial and industrial air pollution using

wet scrubber technology.

The ejector-venturi gas

scrubbers described on the following pages have been

engineered to operate effectively in a variety of

applications. Using the same basic design, these standard

scrubbers can be sized to meet volume requirements from

a few CFM to thousands of CFM. This broad applicability

permits Schutte & Koerting to stock these scrubbers in a

wide range of sizes and materials. A stock ejector-venturi

scrubber can often be the most economical and efficient

solution to a pollution control problem.

Description

Fig. 7010 Ejector-Venturi Scrubber

Fig. 7040 Separators

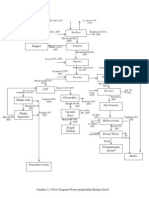

Fig. 7019 Vent Gas Scrubber System

Stock Systems

Fig. 7014 Scrubber-Separator System

Economical Stock Systems

Fig. 7009 Scrubbers Performance Charts

Fig. 7010 Carbon Steel and Stainless Steel

Fig. 7010 FRP and PVC

VERSATILE STOCK UNITS

To answer the need for an economical versatile and

efficient pollution control device, Schutte & Koerting offers

standard Fig. 7010 scrubbers in a variety of sizes and

materials. Stock 7010 scrubbers are available for

immediate shipment in sizes from 3" to 12" in materials

which include carbon steel, stainless steel, polyvinyl

chloride (PVC), Phenolic FRP (replaces previously

supplied HAVEG), fiberglass-reinforced plastic (FRP) and

cast iron. (A complete list of stock scrubbers is shown in

the dimensions tables.) A minimum of three spray nozzle

sizes are available with the stock scrubbers and can be

selected to properly match the motive liquid used and

capacity required.

Dimension

Tables

Fig. 7010 Larger Size Metal and FRP

Fig. 7010 Phenolic FRP

Fig. 7014 Carbon Steel

Fig. 7014 Stainless Steel and Alloys

Fig. 7014 FRP

Fig. 7014 PVC

Fig. 7009 PVC Vent Scrubber

Fig. 7009 Cast Iron and Stainless Steel Vent Scrubber

Fig. 7043 Liquid/Gas Separator

Fig. 7185 High Energy Venturi Scrubber System

Fig. 7055 Packed-Tower Gas Scrubber System

Fig. 7030 Venturi Chamber Scrubber System

How the Ejector Venturi Scrubber Works

Page

2

2

2

2

3

3

4

5

5

5

6

6

6

7

7

7

7

7

8-9

10-11

12-13

14

Schutte & Koerting 2510 Metropolitan Drive Trevose, PA 19053 USA tel: (215) 639-0900 fax: (215) 639-1597 www.s-k.com sales@s-k.com

Gas Scrubbers

FIG. 7010 EJECTOR-VENTURI SCRUBBER

The Fig. 7010 scrubber is the key component in the Schutte &

Koerting ejector-venturi system. These highly engineered

scrubbers operate on the ejector-venturi principle illustrated.

The Fig. 7010 is used in many applications to provide

efficiencies as high as 99% or more in a single stage system

(higher efficiencies can be obtained through use of multi-stage

configurations). Gas handling capacities of over 90,000 CFM

are possible with the larger size scrubbers (refer to Technical

Supplement 7S for capacity data).

Installation, operation and maintenance are greatly simplified

with these scrubbers. They can be mounted on an existing

discharge or storage tank or provided with a Schutte & Koerting

gas/liquid separator as shown.

To answer the need for an economical versatile and efficient

pollution control device, S&Koffers standard Fig. 7010

scrubbers in a variety of sizes and materials. Stock 7010

scrubbers are available for immediate shipment in sizes from 3

to 12 in materials which include carbon steel, stainless steel,

polyvinyl chloride (PVC), Phenolic FRP (replaces previously

supplied HAVEG), fiberglass-reinforced (FRP) and cast iron. (A

complete list of stock scrubbers is shown in the dimension

tables beginning on page 5.) A minimum of three spray nozzle

sizes are available with the stock scrubbers and can be

selected to properly match the motive liquid used and capacity

required.

FIG. 7040 SEPARATORS

The Fig. 7040 separator is designed for use with the 7010

scrubber to maximize gas/liquid separation after the mixture is

discharged from the scrubber. The Fig. 7040 reduces moisture

carryover from the scrubber to as low as 0.0002 gallons per 100

cubic foot which, in turn, contributes to overall scrubber

efficiency. The separator consists of an inlet at the top, a drain

at the bottom and a clean gas outlet at the side of the separator.

A separating element, which incorporates a unique baffling

arrangement, is located just below the inlet. Scrubbing liquid

from the separator can be drained to a storage tank or

recirculated through the system.

Bulletin 7S

FIG. 7019 VENT GAS SCRUBBER SYSTEM

The Fig. 7019 vent scrubber system is a compact, light-weight

and easy-to-install unit designed for economical and effective

control of pollution from low volume sources. Typical

applications include pollution from laboratory fume hoods,

schools and industrial shops, pilot or bench scale plant

equipment and smaller commercial and industrial uses.

These low-cost systems operate on the same ejector-venturi

principle as the larger scrubbers, creating their own draft via a

high velocity liquid spray, scrubbing fumes, gases, vapor or

dusts with efficiencies as high as 99% or more. Low water

consumption - a 3" unit will handle 30 CFM of air at 1" WC draft

using only 2.6 gpm of water - makes the scrubber economical

to operate, comparing favorably with a conventional laboratory

aspirator.

STOCK SYSTEMS

The Fig. 7019 vent scrubber system is comprised of a Fig. 7009

scrubber combined with a Fig. 7043 liquid-gas separator. Both

are available from stock. The Fig. 7009 scrubber is stocked in

cast iron, stainless steel and PVC in a variety of sizes. Fig.

7043 separators are available from stock in carbon steel,

stainless steel and polypropylene. The variety of sizes and

materials of construction enable you to specify a stock system

to meet your requirements and fit the corrosive properties of

your application.

Liquid

Cast Iron

Fig. 7009

Scrubber

Gas

Inlet

Clean Gas

Stock Fig. 7040 separators are available in sizes from 3 to 12

in fabricated steel, stainless steel, and FRP

for use with stock Fig. 7010 scrubbers of

the same size.

Motive Liquid

Inlet

Gas

Inlet

4-Piece

Style 2

Nozzle

Steel Separator with

stainless steel element

Fig. 7043 Carbon Steel

Liquid Gas Separator

Drain

Fig. 7019 Vent Scrubber System

Style 3

Molded Nozzle

Fabricated

Steel Scrubber

FRP Separator and

element

Schutte & Koerting 2510 Metropolitan Drive Trevose, PA 19053 USA tel: (215) 639-0900 fax: (215) 639-1597 www.s-k.com sales@s-k.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Typical Equipment Capacity Delivered Capital Cost Correlations.Document1 pageTypical Equipment Capacity Delivered Capital Cost Correlations.JonesHutaurukNo ratings yet

- Operating Cost Ethylbenzene 1Document1 pageOperating Cost Ethylbenzene 1JonesHutaurukNo ratings yet

- Operating Cost EthylbenzeneDocument2 pagesOperating Cost EthylbenzeneJonesHutaurukNo ratings yet

- ZSM-5 (Mfi)Document2 pagesZSM-5 (Mfi)JonesHutaurukNo ratings yet

- Ethilbenzen CostDocument2 pagesEthilbenzen CostJonesHutaurukNo ratings yet

- Research and Development For Ethylbenezene ProductionDocument1 pageResearch and Development For Ethylbenezene ProductionJonesHutaurukNo ratings yet

- ITS Undergraduate BibliographyDocument6 pagesITS Undergraduate BibliographyJonesHutaurukNo ratings yet

- Operating Cost EthylbenzeneDocument2 pagesOperating Cost EthylbenzeneJonesHutaurukNo ratings yet

- Introduction Gas ScrubbersDocument2 pagesIntroduction Gas ScrubbersJonesHutaurukNo ratings yet

- Product Profile of AromaticsDocument1 pageProduct Profile of AromaticsJonesHutaurukNo ratings yet

- ZSM-5 (Mfi)Document2 pagesZSM-5 (Mfi)JonesHutaurukNo ratings yet

- Product Profile of AromaticsDocument1 pageProduct Profile of AromaticsJonesHutaurukNo ratings yet

- Us 2495071 ADocument5 pagesUs 2495071 AJonesHutaurukNo ratings yet

- Research and Development For Ethylbenezene ProductionDocument1 pageResearch and Development For Ethylbenezene ProductionJonesHutaurukNo ratings yet

- John Calvin and The Reformation in GenevaDocument15 pagesJohn Calvin and The Reformation in GenevaJonesHutaurukNo ratings yet

- AppendixDocument139 pagesAppendixItonamyRitongaNo ratings yet

- Luther and Calvin: Ralph HancockDocument37 pagesLuther and Calvin: Ralph HancockhjjvrNo ratings yet

- AppendixDocument349 pagesAppendixLufya AdellaNo ratings yet

- Problem 2.17 DQ KernDocument1 pageProblem 2.17 DQ KernJonesHutaurukNo ratings yet

- Steady-state heat conduction through an axisymmetric shapeDocument2 pagesSteady-state heat conduction through an axisymmetric shapeJonesHutauruk100% (1)

- Comparative Study of Adsorptive Removal of Congo Red and Brilliant Green Dyes From Water Using Peanut ShellDocument5 pagesComparative Study of Adsorptive Removal of Congo Red and Brilliant Green Dyes From Water Using Peanut ShellJonesHutaurukNo ratings yet

- Solution Manual 1.45-1.46 KernDocument2 pagesSolution Manual 1.45-1.46 KernJonesHutaurukNo ratings yet

- 4 Description of Chemical ProcessesDocument45 pages4 Description of Chemical Processesishhh12No ratings yet

- Data TermodinamikaDocument1 pageData TermodinamikaJonesHutaurukNo ratings yet

- Daftar Pustaka: Universitas Sumatera UtaraDocument3 pagesDaftar Pustaka: Universitas Sumatera UtaraJonesHutaurukNo ratings yet

- Acetone CPDocument6 pagesAcetone CPJonesHutaurukNo ratings yet

- File Industri SemenDocument18 pagesFile Industri SemenJonesHutaurukNo ratings yet

- Reservoir Drive MechanismsDocument36 pagesReservoir Drive MechanismsUsman HasanNo ratings yet

- National Technical Regulation On Industrial WastewaterDocument5 pagesNational Technical Regulation On Industrial WastewaterpaultonkesNo ratings yet

- Guidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PDocument5 pagesGuidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PFSAAVEDRAFNo ratings yet

- Zeotropic Blend (20 % R-32, 40 % R-125, 40 % R-134a) : Main Applications OilsDocument5 pagesZeotropic Blend (20 % R-32, 40 % R-125, 40 % R-134a) : Main Applications OilsTomas ZapataNo ratings yet

- The Atmosphere: (Composition, General Characteristics and Stability)Document15 pagesThe Atmosphere: (Composition, General Characteristics and Stability)Aldin0% (1)

- Construction of A Deep Tube Well - A Case StudyDocument33 pagesConstruction of A Deep Tube Well - A Case Studyanirbanpwd76No ratings yet

- Designing an Acetone-Water Distillation ColumnDocument23 pagesDesigning an Acetone-Water Distillation ColumnamandaNo ratings yet

- ADC3022L 6500 Series Cylinder RegulatorsDocument2 pagesADC3022L 6500 Series Cylinder RegulatorsWaldo ArellanoNo ratings yet

- Statika Fluida: Lecturer: Hadi Kardhana, ST., MT., PHDDocument42 pagesStatika Fluida: Lecturer: Hadi Kardhana, ST., MT., PHDRaja Plaurint SimanullangNo ratings yet

- Company ProfileDocument4 pagesCompany ProfileLOGIN ANIMONo ratings yet

- DocumentDocument21 pagesDocumentSuper 7No ratings yet

- Fluid MechanicsDocument2 pagesFluid MechanicsLokendra Singh JhalaNo ratings yet

- condensationDocument7 pagescondensationkai ゑNo ratings yet

- Pressure Pressure - Manometry Manometry: Man Tech 4Tf3 Man Tech 4Tf3Document22 pagesPressure Pressure - Manometry Manometry: Man Tech 4Tf3 Man Tech 4Tf3aushad3mNo ratings yet

- Alfa Laval FWG 26-C80Document34 pagesAlfa Laval FWG 26-C80VagifNo ratings yet

- HydroDocument33 pagesHydroMiresa HordofaNo ratings yet

- ME2134 Fluid Mechanics I Tutorial 1 SEO-Optimized TitleDocument4 pagesME2134 Fluid Mechanics I Tutorial 1 SEO-Optimized TitleCl SkyeNo ratings yet

- Presented By: Sid ShahidDocument21 pagesPresented By: Sid ShahidMohamoud AbdulahiNo ratings yet

- Assignment-1 Noc18 Me46 86Document2 pagesAssignment-1 Noc18 Me46 86Namita GondNo ratings yet

- Bca 28279 Cbfe 7 C 94Document7 pagesBca 28279 Cbfe 7 C 94Theophile IZERENo ratings yet

- VG64 ManualDocument8 pagesVG64 ManualJonathan StewartNo ratings yet

- DistillationDocument8 pagesDistillationRaz MahariNo ratings yet

- Wash Water Injection in Hydroprocessing UnitsDocument13 pagesWash Water Injection in Hydroprocessing Unitscüneyt şanNo ratings yet

- Assignment - IDocument4 pagesAssignment - IchritNo ratings yet

- Valvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FDocument2 pagesValvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FGrecia Paola Garza RodriguezNo ratings yet

- MCWD Water Safety Forum 2018Document31 pagesMCWD Water Safety Forum 2018Shirlee Alicor L MacheteNo ratings yet

- NPSH Calculation - A Step-by-Step GuideDocument7 pagesNPSH Calculation - A Step-by-Step GuideSrihariGopalakrishnanNo ratings yet

- Agitator Power Requirementand Mixing Intensity CalculationDocument26 pagesAgitator Power Requirementand Mixing Intensity Calculationkkaranag100% (1)

- 1 - Gas Thermometer and Absolute ZeroDocument6 pages1 - Gas Thermometer and Absolute ZeroPeggie ZengNo ratings yet

- Knowledge Sharing Water HammerDocument16 pagesKnowledge Sharing Water HammerNaveen NagisettiNo ratings yet