Professional Documents

Culture Documents

1950plus On-Line Total Organic Carbon (TOC) Analyzer: Features and Benefits

Uploaded by

MarcTimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1950plus On-Line Total Organic Carbon (TOC) Analyzer: Features and Benefits

Uploaded by

MarcTimCopyright:

Available Formats

DATA SHEET

Total Organic Carbon

1950plus On-line

Total Organic Carbon (TOC)

Analyzer

Features and Benefits

Reliable, Continuous TOC Reporting

Continuous on-line measurement of total organic carbon

(TOC) is necessary for government regulatory compliance

status and to actively control the TOC removal technology.

The Hach 1950plus On-line TOC Analyzer displays the

TOC concentration of the source and distribution water in

mg/L as well as the TOC removal percentage and the

pass/fail status.

Dual Stream Analysis of Source

and Distribution Water

DW

TOC removal can be optimized by continuously alternating

analysis between the two or paired sample points

representing the source and distribution water of the

treatment plant. The 1950plus TOC analyzer uses a fast-flow

sample loop to continuously provide a representative sample

alternating between the source and distribution water to the

port of entry.

Unattended Grab Sample Capability

The grab sample feature of the 1950plus TOC analyzer lets

samples be collected manually for manual analysis any time.

The analyzer will automatically go off-line, analyze the

sample, purge, and go back on-line. Grab sample analysis

can be performed unattended since the software will hold

the last analysis result with a time/date stamp.

The Hach 1950plus On-line TOC Analyzer uses intelligent

software to report pass/fail status for TOC removal

percentage. It complies with Standard Methods 5310 C and

EPA Method 415.1 for reporting purposes. It features a dual

stream sample system that can be used for source and

distribution water. Making grab sample analysis is easy for

immediate manual TOC measurements.

Durable Construction

The cell body of the 1950plus TOC analyzers NDIR

detection system is made of PVDF (KYNAR) that is

impervious to corrosion. The mirror and the window are

made of sapphire that is less susceptible to scratching

and provides a more accurate measurement.

Automatic Calibration, Validation, and Cleaning

The Hach 1950plus On-line TOC Analyzer can be set up for

automatic zero and span calibration, single-point validation

(system check), and analyzer cleaning. Each function can

be independently programmed for any time of day and

any day of the week. A system validation references the

calibration against a known standard assuring an accurate

measurement of the samples. Automatic cleaning simplifies

analyzer maintenance.

Detection Method

The 1950plus TOC analyzer uses a multi-staged UV

oxidation reactor and a chemically impervious nondispersive infrared (NDIR) CO2 detector system that is

in full compliance with Standard Methods 5310 C and

EPA method 415.1. Total inorganic carbon (TIC) in the

sample is converted to CO2 and removed. The remaining

TIC-free sample is routed through the multi-stage UV

reactor where the sample TOC is completely converted to

CO2. The gas/liquid mixture is transported to the gas liquid

separator (GLS) where the sample gas is separated and

diverted into the NDIR detector for direct and interferencefree CO2 measurement. The resulting CO2 concentration

measurement is directly proportional to the original TOC

concentration of the sample.

DW = drinking water WW = wastewater municipal PW = pure water / power

IW = industrial water E = environmental C = collections FB = food and beverage

Specifications*

Analysis Method

UV persulfate oxidations with acid sparging for TIC removal

followed by CO2 NDIR detector measurement

Range

Measurement: 0 to 5 up to 20,000 mg/L TOC

Process Control: 0 to 100% TOC removal

Accuracy

2% of full scale at 25C (77F)

Alarms

Five alarms selectable for sample concentration alarm,

analyzer system warning, or analyzer system shutdown alarm.

Each is equipped with an SPDT relay with contacts rated for

3A resistive load at 250 Vac

Serial Communication

One multi-function RS232 serial port

Power

115/230 Vac, 50/60 Hz (switch selectable), 500 VA maximum

Repeatability

2% of full scale nondiluted range

4% of full scale diluted range

Sample Inlet/Outlet Connection

1/4-inch OD tube, compression fitting

Minimum Detection Limit

0.015 mg/L for range 0 to 5 mg/L at 25C (77F)

Drain Connection

1 1/2-inch OD standard drain pipe

Response Time

T90 8 minutes; T20 3 minutes; range dependant

Carrier Gas

Clean, CO2 free air or nitrogen at 2.8 to 6.2 bar (40 to 90 psig)

Connection: 1/8-inch OD tube, compression fitting

Usage: Approximately 380 cc/min. at atmospheric pressure

Signal Drift

<2% with auto-clean and auto-calibration

Compliance/Certification

CE approved

Standard Methods 5310 C

EPA 415.1

Inlet Pressure

0.15 to 6 bar (2 to 87 psig)

Flow Rate

20 to 200 mL/minute

Enclosure

Cold rolled steel epoxy powder coated, IP56 (NEMA 4)

Optional stainless steel IP56 (NEMA 4X)

Sample Temperature

2 to 70C (36 to 158F)

Installation

Category II

Wall mount

Operating Temperature

5 to 40C (41 to 104F)

Recorder Outputs

Two 4-20 mA with an output span based on the selected

measurement range and the TOC removal percentage process

control range

Dimensions

721 x 981 x 220 mm (28.4 x 38.6 x 8.7 in.)

Weight

54 kg (120 lbs.)

*Specifications subject to change without notice.

Engineering Specifications

1. The TOC analyzer shall employ

UV/Persulfate oxidation utilizing a

multi-stage UV-Reactor coupled with

a NDIR CO2 detection system to

measure TOC in less than 8 minutes.

5. The enclosure of the analyzer shall

consist of a dual enclosure with

analytical/electrical separation that is

epoxy powder-coated cold rolled

steel.

2. The measurement method shall

comply with Standard Methods

5310 C and EPA Method 415.1

6. The enclosure shall be rated NEMA

4 / IP 56.

3. The standard dual stream

measurement system shall report

the TOC concentration(s) in mg/L

and the TOC removal percentage in

0-100%.

4. The EPA DBP rule compliant

software shall calculate the TOC

removal with Pass/Fail indication

based on retention time and

alkalinity entries. Such entries can

be up-dated via the front panel

keypad or serial communication.

7. The analyzer shall be equipped with

grab sample and validation utilities

for unknown sample or reference

standard measurement.

8. The analyzer shall be equipped with

user programmable auto calibration,

auto validation, and auto cleaning

capabilities.

9. The analyzer shall be equipped with

loss of sample flow and reactor feed

detection capabilities.

10. The analyzer shall be equipped with

a hinged pump assembly module.

11. The analyzer shall be equipped with

two 4-20mA parameter mapped

analog outputs.

12. The analyzer shall be userprogrammable, auto ranging over

four ranges.

13. The analyzer shall be equipped with

five volt free function mapped relay

outputs and one RS232 serial

communication output.

14. The analyzer shall comply with CE

safety codes and NAMUR industry

standard requirements.

15. The analyzer shall be the 1950plus

On-line Total Organic Carbon (TOC)

Analyzer manufactured by Hach

Company.

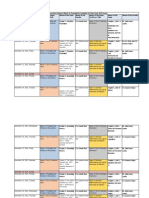

Dimensions

The Hach 1950plus On-line TOC Analyzer is designed to be wall-mounted with four 3/8-inch screws. Adequate clearance must be

left at the sides and bottom of the enclosure for plumbing and electrical connections. The sample inlet connection is 1/4-inch OD

tube compression fitting and the drain connection is 1 1/2-inch OD standard drain pipe. Electrical connections are inside the

instrument. A punch-out panel for ten conduit fittings is provided. Use oil-tight seals or sealing-type conduit fittings when wiring

power, alarms, and relay connections to maintain the IP56 enclosure rating.

Ordering Information

All 1950plus On-line TOC Analyzers include one month of reagents,

initial startup, and training.

Please select an analyzer and a preference package.

1950plus Analyzers

All 1950plus analyzers are constructed of cold rolled steel, are 115 V

and include 1 UV lamp and 2 sample streams.

EPA-4195-1010DS

0 to 5 mg/L

EPA-4195-1020DS

0 to 10 mg/L

EPA-4195-1030DS

0 to 25 mg/L

Preference Packages

4P95-1000-00

(no charge)

4P95-1001-00

Level Detection Kit

4P95-1010-00

additional UV Lamp

4P95-1011-00

Level Detection Kit. and additional UV Lamp

4P95-1100-00

View Window

4P95-1101-00

View Window and Level Detection Kit

4P95-1110-00

View Window and additional UV Lamp

4P95-1111-00

View Window, Level Detection Kit, and additional UV Lamp

Accessories

120161

Free-standing Rack Assembly

200201

Spare Parts Kit, 1 year

200202

Spare Parts Kit, 2 years

4300-0003

CO2 Air Purifier, with pneumatic timer for use with

compressed air

4300-0005

CO2 Air Purifier, with electronic timer for use with

compressed air, 115/230 volts

4300-0006

CO2 Air Purifier, with electronic timer and on-board

compressor, 110 volts

At Hach, its about learning

from our customers and

providing the right answers.

Its more than ensuring the

quality of waterits about

ensuring the quality of life.

When it comes to the things

that touch our lives...

Keep it pure.

Make it simple.

Be right.

For current price information,

technical support, and ordering

assistance, contact the Hach

office or distributor serving

your area.

In the United States, contact:

HACH COMPANY World Headquarters

P.O. Box 389

Loveland, Colorado 80539-0389

U.S.A.

Telephone: 800-227-4224

Fax: 970-669-2932

E-mail: orders@hach.com

www.hach.com

U.S. exporters and customers in Canada,

Latin America, sub-Saharan Africa, Asia,

and Australia/New Zealand, contact:

HACH COMPANY World Headquarters

P.O. Box 389

Loveland, Colorado 80539-0389

U.S.A.

Telephone: 970-669-3050

Fax: 970-461-3939

E-mail: intl@hach.com

www.hach.com

In Europe, the Middle East, and

Mediterranean Africa, contact:

HACH LANGE GmbH

Willsttterstrae 11

D-40549 Dsseldorf

GERMANY

Tel: +49 (0) 211 5288-0

Fax: +49 (0) 211 5288-143

E-mail: info@hach-lange.de

www.hach-lange.com

Lit. No. 4372

XXX Printed in U.S.A.

Hach Company, 2005. All rights reserved.

In the interest of improving and updating its equipment, Hach Company reserves the right to alter specifications to equipment at any time.

You might also like

- Amp 17101 P 23Document3 pagesAmp 17101 P 23MarcTimNo ratings yet

- So Kero L Tech ReportDocument8 pagesSo Kero L Tech ReportMarcTimNo ratings yet

- Amine Levels in Steam-Humidified Air Remain Below Safety LimitsDocument5 pagesAmine Levels in Steam-Humidified Air Remain Below Safety LimitsMarcTimNo ratings yet

- ChemEngineering - Wet Cooling TowersDocument12 pagesChemEngineering - Wet Cooling TowersMarcTimNo ratings yet

- WTAnalyser (Filtration) Performance AnalysisDocument291 pagesWTAnalyser (Filtration) Performance AnalysisMarcTimNo ratings yet

- 2444 102611Document147 pages2444 102611anirbanbhowmick88No ratings yet

- SonyDocument124 pagesSonyMarcTimNo ratings yet

- Linking Verbs ExplainedDocument1 pageLinking Verbs ExplainedFelipe FCNo ratings yet

- Epri LargeDocument53 pagesEpri LargeMarcTimNo ratings yet

- SonyDocument124 pagesSonyMarcTimNo ratings yet

- Understanding Corrosion Inhibition of Mild Steel in Acid Medium by Some Furan Derivatives: A ComprehensiveDocument9 pagesUnderstanding Corrosion Inhibition of Mild Steel in Acid Medium by Some Furan Derivatives: A ComprehensiveMarcTimNo ratings yet

- 835397Document7 pages835397MarcTimNo ratings yet

- 2444 102611Document147 pages2444 102611anirbanbhowmick88No ratings yet

- CTDocument10 pagesCTMarcTimNo ratings yet

- Copper Deposition and MW LossDocument10 pagesCopper Deposition and MW LossVel MuruganNo ratings yet

- 250 Ways To Say It in Business English PDFDocument123 pages250 Ways To Say It in Business English PDFArtyom SentsovNo ratings yet

- Action Verbs For ResumesDocument2 pagesAction Verbs For Resumesapi-2627751040% (1)

- Business EnglishDocument145 pagesBusiness EnglishHo Ha67% (3)

- Describe: Characterize: Group: Organize: Systematize: System: Classify: Class: Category: Kind: Type: Methodology: Scheme: TaxonomyDocument7 pagesDescribe: Characterize: Group: Organize: Systematize: System: Classify: Class: Category: Kind: Type: Methodology: Scheme: TaxonomyMarcTimNo ratings yet

- CMI0311Document16 pagesCMI0311MarcTimNo ratings yet

- Watermath Corrosivity Estimator Limited2Document5 pagesWatermath Corrosivity Estimator Limited2MarcTimNo ratings yet

- WTAnalyser (Filtration) Performance AnalysisDocument291 pagesWTAnalyser (Filtration) Performance AnalysisMarcTimNo ratings yet

- Action Verbs For ResumesDocument2 pagesAction Verbs For Resumesapi-2627751040% (1)

- Chemical Technopark of Sverdlovsk region: on the base of Open Joint Stock Company «Uralсhimplast»Document21 pagesChemical Technopark of Sverdlovsk region: on the base of Open Joint Stock Company «Uralсhimplast»MarcTimNo ratings yet

- Chemical Technopark of Sverdlovsk region: on the base of Open Joint Stock Company «Uralсhimplast»Document21 pagesChemical Technopark of Sverdlovsk region: on the base of Open Joint Stock Company «Uralсhimplast»MarcTimNo ratings yet

- Boiler Film Forming Amines Hydrocarbon Engineering Sept2015Document5 pagesBoiler Film Forming Amines Hydrocarbon Engineering Sept2015MarcTimNo ratings yet

- CEAlertBrochure3 Latest Eg Main 017276Document6 pagesCEAlertBrochure3 Latest Eg Main 017276MarcTimNo ratings yet

- Mats Hanson 09 HG Index A CompleteDocument643 pagesMats Hanson 09 HG Index A CompleteMarcTimNo ratings yet

- 702.1. 090202 Code of Practice Edition 4 - LAST VERSIONDocument69 pages702.1. 090202 Code of Practice Edition 4 - LAST VERSIONMarcTimNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Eco 301 Final Exam ReviewDocument14 pagesEco 301 Final Exam ReviewCảnh DươngNo ratings yet

- Academic Language Use in Academic WritingDocument15 pagesAcademic Language Use in Academic WritingDir Kim FelicianoNo ratings yet

- Goldenberg and Reddy (2017)Document10 pagesGoldenberg and Reddy (2017)Mariana ToniniNo ratings yet

- New Wordpad DocumentDocument6 pagesNew Wordpad DocumentJonelle D'melloNo ratings yet

- Srimanta Shankardev: Early LifeDocument3 pagesSrimanta Shankardev: Early LifeAnusuya BaruahNo ratings yet

- Chair Locker Provides Storage and Space SavingsDocument32 pagesChair Locker Provides Storage and Space SavingsElza S. GapuzNo ratings yet

- Lesson Plan 160205 Jelly Snake PracticalDocument7 pagesLesson Plan 160205 Jelly Snake Practicalapi-309206763No ratings yet

- Jensen-English I SyllabusDocument6 pagesJensen-English I Syllabusapi-284900455No ratings yet

- Austin's Cover Letter Example - Cultivated CultureDocument1 pageAustin's Cover Letter Example - Cultivated CultureYash SNo ratings yet

- ICO Basic SyllabusDocument11 pagesICO Basic SyllabusRaúl Plasencia Salini100% (1)

- The Ultimate Manifesting Money Blueprint by Sonia RicottiDocument34 pagesThe Ultimate Manifesting Money Blueprint by Sonia RicottiViolet VioletNo ratings yet

- TG KPWKPDocument8 pagesTG KPWKPDanmar CamilotNo ratings yet

- My RepublicDocument4 pagesMy Republicazlan battaNo ratings yet

- ExportDocument18 pagesExportDolon MukherjeeNo ratings yet

- Year 2 - Push and Pull FPDDocument18 pagesYear 2 - Push and Pull FPDRebecca LNo ratings yet

- The Teacher and The LearnerDocument23 pagesThe Teacher and The LearnerUnique Alegarbes Labra-SajolNo ratings yet

- Demo TeachingDocument22 pagesDemo TeachingCrissy Alison NonNo ratings yet

- Specification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VDocument2 pagesSpecification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VJavierNo ratings yet

- Hireena Essay AnsDocument2 pagesHireena Essay AnsTasniiem ChandraaNo ratings yet

- PPPoE Packet Format - HCNADocument6 pagesPPPoE Packet Format - HCNARobert Sanchez OchochoqueNo ratings yet

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocument10 pagesChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINo ratings yet

- NVH PDFDocument3 pagesNVH PDFSubhendu BarisalNo ratings yet

- JASA SREVIS LAPTOP Dan KOMPUTERDocument2 pagesJASA SREVIS LAPTOP Dan KOMPUTERindimideaNo ratings yet

- Industrial/Organi Zational Psychology: Alday, Angeli Camille M. - 2P2Document51 pagesIndustrial/Organi Zational Psychology: Alday, Angeli Camille M. - 2P2SteffanyNo ratings yet

- Strategicmanagement Finalpaper 2ndtrisem 1819Document25 pagesStrategicmanagement Finalpaper 2ndtrisem 1819Alyanna Parafina Uy100% (1)

- Avance Collection Mixer Grinder SpecsDocument3 pagesAvance Collection Mixer Grinder SpecsfaNo ratings yet

- 1ST Periodical Test ReviewDocument16 pages1ST Periodical Test Reviewkaren rose maximoNo ratings yet

- Hall Design For SpeechDocument1 pageHall Design For SpeechSarovar SaroNo ratings yet

- Vikash Kumar: 1. Aunico India May 2018Document4 pagesVikash Kumar: 1. Aunico India May 2018Rama Krishna PandaNo ratings yet

- Learn R For Applied StatisticsDocument457 pagesLearn R For Applied StatisticsyasortyNo ratings yet