Professional Documents

Culture Documents

Drill Hole Patterns with Loops and Subprograms

Uploaded by

Rohit SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Hole Patterns with Loops and Subprograms

Uploaded by

Rohit SinghCopyright:

Available Formats

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 234

CHAPTER

11

Do Loops and Subprograms

OBJECTIVES Upon completion of this chapter, you will be able to:

Describe a do loop.

Describe a subprogram.

Describe nested loops.

Write simple programs using loops, subroutines, and nested loops.

DO LOOPS

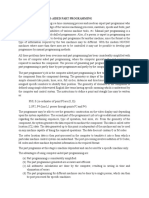

Figure 11-1 shows a part with a series of holes to be drilled, equally

spaced. If an operation is to be repeated over a number of equal steps, it

may be programmed in what is referred to as a do loop. In a do loop, the

MCU is instructed to repeat an operation (in this case, drill a hole five times)

rather than be programmed for five separate hole locations.

A do loop simply instructs the MCU to repeat a series of NC program

statements a specified number of times. The flowchart given in Figure 11-2

illustrates the basic construct of a do loop.

Usually, looping capability on a CNC controller is an optional item, therefore not all controllers have it. The looping feature is sometimes added to the

controller by the controllers manufacturer. In other cases, it is programmed

into the controller by the machine tool manufacturer. This means that the NC

codes used to initiate a do loop can vary widely from machine to machine,

even if they are all equipped with the same basic controller model.

Programming a Loop

Naturally, there is a G code to institute a do loop. As mentioned previously, there are no standard codes for do loops. The method described in

this section is only one of the schemes in use. The format for a do loop is:

234

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 235

DO LOOPS AND SUBPROGRAMS

235

TOOL CHANGE

FOR MACHINIST SHOP LANGUAGE: X-2 Y2

#2

#3

#4

(5 PLCS)

#5

#1

1/4 DRILL

1.000

4 EQ SPACES

@ 1.000 = 4.000

.500

#3

#4

#5

#2

#1

DO LOOP

MOVES ARE IN INCREMENTAL

FIGURE 11-1

Part drawing and cutter path for do loop example

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 236

236

CHAPTER 11

START

SET LOOP

COUNTER

TO 1

CNC

PROGRAM

BLOCKS

INCREMENT

COUNTER

BY 1

COUNTER

EXCEEDED

MAXIMUM

VALUE

YES

END

FIGURE 11-2

Process flow of a do loop

NO

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 237

DO LOOPS AND SUBPROGRAMS

N...

Nppp

N...

N...

Nqqq

237

G25 Pppp Qqqq Ll

X/Y/Z

X/Y/Z

X/Y/Z

X/Y/Z

Where:

G25Signals the start of a loop.

PSpecifies the beginning block number of the loop.

QSpecifies the ending block number of the loop.

LSpecifies the number of times to perform the loop.

The program in Figure 11-3, written to drill the part in Figure 11-1,

illustrates this type of do loop used on a FANUC-style CNC controller.

%

O1103

(* **********)

(* X0/Y0 IS LOWER LEFT CORNER)

(* TOOL 1 - NO. 3 C-DRILL)

(* **********)

N001 G00 G40 G80 G70 G90 G98

N101 T01 M06

N102 G00 X.5 Y1. S3500 M03

N103 G43 Z0. H01 M08

N104G81 G99 X.5 Y1. Z-.162 R0. F7.

(BEGIN LOOP)

N105 G25 P106 Q106 L5

N106 G91 X1.

N107 G80 M09

N108 G00 G91 G30 Z0. M05

N109 G30 X0. Y0. M19

N110 M01

(* **********)

(* TOOL 2 - 1/4 DRILL

(* **********)

N002 G00 G40 G80 G70 G90 G98

N201 T01 M06

N202 G00 X.5 Y1. S3500 M03

N203 G43 Z0. H01 M08

N204 G81 G99 X.5 Y1. Z-.375 R0. F7.

(BEGIN LOOP)

N205 G25 P206 Q20 6L5

N206 G91 X1.

N207 G80 M09

N208 G00 G91 G30 Z0. M05

N209 G30 X0. Y0. M19

N211 M30

%

FIGURE 11-3

Program to mill the part in Figure 11-1

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 238

238

CHAPTER 11

Program Explanation

O1103

Program number.

N001 through N103 is the tool change sequence

N001

Program safety line.

N101

T01 Places tool 1 in the tool change standby position.

M06 Initiates an automatic tool change.

N102

G00X.5Y1. Positions the spindle at the X/Y starting position of the

drill cycle at rapid traverse.

S3500M03 Sets the spindle speed to 3,500 rpm, and turns on the

spindle in a clockwise direction.

N103

G43 Turns on tool length compensation.

Z0. Positions the spindle .100 above the part at rapid.

H01 Instructs the MCU to use the value in register 1 for tool length

compensation.

M08 Turns on the coolant.

N104 through N108 are the tool motion statements

N104

G81 Turns on the canned drill cycle.

G99 Instructs the MCU to return the spindle to the reference plane at

the end of each cycle iteration.

X.5y1. Y/Y coordinates of the first hole.

Z-.162 The final feed depth for the Z axis.

R0. Sets Z0 as the reference plane (feed engagement point).

N105

G25 Initiates the do loop. The loop counter is initialized to 1.

P106 Tells the MCU to begin the loop in block N106.

Q106 Tells the MCU that N106 is the end of the loop.

L5 Instructs the MCU to perform the loop 5 times.

N106

G91 Selects incremental positioning.

X1. Causes the spindle to move 1.000 inch along the X axis. Since

the drill cycle is still turned on, a hole will be drilled at this location.

N108

G80 Cancels the active drill cycle.

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 239

DO LOOPS AND SUBPROGRAMS

239

N108 through N109 are the tool cancel commands

N108

G00G91G30Z0. Sends the Z axis to tool change position.

M09 Turns off the coolant.

N109

G30X0.Y0. Sends the X and Y axes to tool change position.

M19 Orients the spindle for tool change gripper.

N110

M01 Optional stop code.

N002 through N203 is the tool change sequence

N002

Program safety line.

N201

T02 Places tool 2 in the tool change standby position.

M06 Initiates an automatic tool change.

N202

G00X.5Y1. Positions the spindle at the X/Y starting position of the

drill cycle at rapid traverse.

S3500M03 Sets the spindle speed to 3,500 rpm, and turns on the

spindle in a clockwise direction.

N203

G43 Turns on tool length compensation.

Z0. positions the spindle .100 above the part at rapid.

H02 Instructs the MCU to use the value in register 2 for tool length

compensation.

M08 Turns on the coolant.

N204 through N208 are the tool motion statements

N204

G81 Turns on the canned drill cycle.

G99 Instructs the MCU to return the spindle to the reference plane at

the end of each cycle iteration.

X.5y1. Y/Y coordinates of the first hole.

Z-.375 The final feed depth for the Z axis.

R0. Sets Z0 as the reference plane (feed engagement point).

N205

G25 Initiates the do loop.

P206 Tells the MCU to begin the loop in block N106.

Q206 Tells the MCU that N106 is the end of the loop.

L5 Instructs the MCU to perform the loop 5 times.

N206

G91 Selects incremental positioning.

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 240

240

CHAPTER 11

X1. Causes the spindle to move 1.000 inch along the X axis. Since

the drill cycle is still turned on, a hole will be drilled at this location, the do

loop instructions.

N207

G80 Cancels the active drill cycle.

M09 Turns off the coolant.

N208 through N209 are the tool cancel commands

N208

G00G91G30Z0. Sends the Z axis to tool change position.

M05 Turns off the spindle.

N209

G30X0.Y0. Sends the X and Y axes to tool change position.

M19 Orients the spindle for tool change gripper.

N210

M30 End of program code.

SUBPROGRAMS

A subprogram is a separate program called by another program. The

use of subprograms can significantly reduce the amount of programming

required on some parts. For example, on the part in Figure 11-4, note that

the holes occur in the same geometric and dimensional pattern in four different locations. A do loop could be programmed to drill the holes, but programming steps can be minimized by placing the pattern in a subprogram.

The drill can be sent to hole #1 and the subprogram called to drill the four

holes A, B, C, and D. Hole #2 can then be positioned and the subprogram

called again, and so on.

One way to use a subprogram is to place one or more do loops in the

subprogram. This is known as nesting. Subprograms can also be nested in

other subprograms, or nested within do loops. This gives the programmer a

great deal of flexibility and a powerful programming tool.

The flowchart in Figure 11-5 illustrates how a subprogram works. The

calling program is referred to as the main, or parent program. The subprogram is sometimes referred to as the subroutine or child program.

When the subprogram call statement is issued in the main NC program,

the MCU switches to the subprogram. The subprogram then executes. At the

end of the subprogram is a command that causes the MCU to switch back

to the main program. The MCU returns to the NC block in the main program

immediately following the command that called the subprogram in the first

place.

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 241

DO LOOPS AND SUBPROGRAMS

241

10.500

7.500

4.500

.500

1.500

1.500

3/8 TYP

.500

TOOL CHANGE: FOR MACHINIST SHOP LANGUAGE = X-2 Y2

ST

R

MO AIGH

TL

V

TO E

INE

OL FR

O

CH M

G.

A

PATTERN #1

CB

PATTERN #2

CB

PATTERN #3

D

#4

#3

CB

DA

DA

#2

DA

#1

PATTERN #4

MOVES TO HOLES #1, #2, #3, #4 IN ABSOLUTE

MOVES TO HOLES A, B, C, D IN SUBROUTINE ARE INCREMENTAL

FIGURE 11-4

Part drawing and tool path for subprogram example

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 242

242

CHAPTER 11

MAIN PROGRAM

01113

N . .X. . .Y. . .Z. .

N. . .X. . .Y. . . Z . .

N. . .X. . .Y. . . Z . .

N . . .M98P1000L1 .

N. . .X. . .Y. . . Z . .

N . . .M30

.

.

.

.

.

JUMP TO SUB

PROGRAM

SUBPROGRAM

01000

N. . .X. . .Y. . . Z . . .

N. . .X. . .Y. . . Z . . .

N. . .X. . .Y. . . Z . . .

N . . .M99

RETURN TO

MAIN PROGRAM

FIGURE 11-5

Subprogram call mechanics

CALLING A SUBPROGRAM

On FANUC and FANUC-style controllers, a subprogram is a program in

its own right. It has its own O number to identify it, and is sequence numbered independently of the parent program.

The format for calling a subprogram is:

MAIN PROGRAM

O0001

N001 X/Y/Z

N002 .

N003 .

N004 M98P2000L1

N005 .

N006 .

N007 .

N008 M30

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 243

DO LOOPS AND SUBPROGRAMS

243

SUBPROGRAM

O2000

N001 X/Y/Z

N002 .

N003 .

N004 M99

Where

M98 Instructs the MCU to jump to a subprogram.

P2000 Tells the MCU that O2000 is the subprogram ID.

L1 Instructs the MCU to execute the subprogram one time.

The program in Figure 11-6 illustrates how a subprogram can be used

to drill the part in Figure 11-4.

Program Explanation

O1106

Program id number.

N001 through N103 is the tool change sequence

N001

Safety block.

N101

T01 Put tool 1 in tool change standby position.

M06 Initiate a tool change. Tool 1 will be placed in the spindle.

N102

G00G90X1.5Y1.5 Move to hole #1 at rapid, using absolute positioning.

S3500M03 Turns on the spindle clockwise at 3,500 rpm.

N103

G43 Turns on tool length compensation.

Z3. Positions the spindle to Z3.000

H01 Instructs the MCU to use the values in offset register 1 for tool

length compensation.

M08 Turns on the flood coolant.

N104 through N112 are the tool motion blocks

N104

G81 Turns on the canned drilling cycle.

G99 Specifies a retract to the reference plane at the end of each drill

cycle iteration.

X1.5Y1.5 X/Y coordinates of the first hole.

Z-.162 Final drilling depth.

R0. The reference plane. This is the Z coordinate where the MCU will

begin feeding the tool into the workpiece.

F10.5 Specifies a drilling feedrate of 10.5 inches per minute.

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 244

244

CHAPTER 11

%

O1106

(* **********)

(* X0/Y0 - LOWER LEFT CORNER)

(* Z0 - .100 ABOVE TOP OF PART)

(* **********)

(* TOOL 1 - NO. 3 C-DRILL)

(* **********)

N001 G17 G90 G40 G80 G98

N101 T01 M06

N102 G00 G90 X1.5 Y1.5 S3500 M03

N103 G43 G90 Z3. H01 M08

N104 G81 G99 X1.5 Y1.5 Z-.162 R0. F10.5

N105 P1000 M98 L1

N106 X4.5 Y1.5

N107 P1000 M98 L1

N108 X7.5 Y1.5

N109 P1000 M98 L1

N110 X10.5 Y1.5

N111 P1000 M98 L1

N112 G80 M09

N113 G00 G91 G28 Z0. M05

N114 G28 X0. Y0. M01

(* **********)

(* TOOL 1 - NO. 3 C-DRILL)

(* **********)

N002 G90 G40 G98 G80

N201 T02 M06

N202G00 X1.5 Y1.5 S3500 M03

N203 G43 G90 Z3. H01 M08

N204 G81 G99 X1.5 Y1.5 Z-.375 R0. F10.5

N205 P1000 M98 L1

N206 X4.5 Y1.5

N207 P1000 M98 L1

N208 X7.5 Y1.5

N209 P1000 M98 L1

N210 X10.5 Y1.5

N211 P1000 M98 L1

N212 G80 M09

N213 G00 G91 G28 Z0. M05

N214 G28 X0. Y0.

N215 M30

01000

(* **********)

(* START OF SUBPROGRAM 1000)

(* **********)

N001 G91 X-.5 Y.5

N002 Y-1.

N003 X1.

N004 Y1.

N004 G90

N006 M99

%

FIGURE 11-6

Program to machine the part in Figure 11-4

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 245

DO LOOPS AND SUBPROGRAMS

245

N105

This block is a jump to subprogram call.

P1000 Specifies program O1000 as the target of the subroutine jump.

M98 Instructs the MCU to jump to the target program (in this case,

O1000).

L1 Tells the MCU to execute the subprogram 1 time.

N106

X4.5Y1.5 Positions the spindle over hole #2.

N108

X7.5Y1.5 Positions the spindle over hole #3.

N109

P100M98L1 Jump to subprogram O1000 call.

N110

X10.5Y1.5 Positions the spindle over hole #4.

N111

P100M98L1 Jump to subprogram O1000 call.

N112

G80 Cancels the canned drilling cycle.

M09 Turns off the flood coolant.

N113 through N114 is the tool cancel sequence

N113

G00G91G28Z0. Sends the spindle to the Z axis home position in

rapid traverse mode.

M05 Turns off the spindle.

N114

G28X0.Y0. Sends the spindle to the X/Y home position.

M01 Optional program stop code. Provided for operator convenience.

N002 through N203 is the tool change sequence

N002

Safety block.

N201

T02 Put tool 2 in tool change standby position.

M06 Initiate a tool change. Tool 2 will be placed in the spindle.

N202

G00G90X1.5Y1.5 Move to hole #1 at rapid, using absolute positioning.

S3500M03 Turns on the spindle clockwise at 3,500 rpm.

N203

G43 Turns on tool length compensation.

Z3. Positions the spindle to Z3.000.

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 246

246

CHAPTER 11

H02 Instructs the MCU to use the values in offset register 2 for tool

length compensation.

M08 Turns on the flood coolant.

N204 through N212 are the tool motion blocks

N204

G81 Turns on the canned drilling cycle.

G99 Specifies a retract to the reference plane at the end of each drill

cycle iteration.

X1.5Y1.5 X/Y coordinates of the first hole.

Z-.375 Final drilling depth.

R0. The reference plane. This is the Z coordinate where the MCU will

begin feeding the tool into the workpiece.

F10.5 Specifies a drilling feedrate of 10.5 inches per minute.

N205

P100M98L1 Jump to subprogram O1000 call.

N206

X4.5Y1.5 Positions the spindle over hole #2.

N208

X7.5Y1.5 Positions the spindle over hole #3.

N209

P100M98L1 Jump to subprogram O1000 call.

N210

X10.5Y1.5 Positions the spindle over hole #4.

N211

P100M98L1 Jump to subprogram O1000 call.

N212

G80 Cancels the canned drilling cycle.

M09 Turns off the flood coolant.

N213 through N214 is the tool cancel sequence

N213

G00G91G28Z0. Sends the spindle to the Z axis home position in

rapid traverse mode.

M05 Turns off the spindle.

N214

G28X0.Y0. Sends the spindle to the X/Y home position.

N214

M30 End of program memory reset code.

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 247

DO LOOPS AND SUBPROGRAMS

247

Subprogram Explanation

Notice that a subprogram has its own program ID number, in this case

O1000. The sequence blocks also are numbered independently from the

main program. The only difference between the subprogram and an independent program is the return to calling program command (M99) at the end

of the program.

O1000

Program ID number.

N001

G91 Selects incremental positioning mode. Incremental moves are

used throughout the subprogram.

X-.5Y.5 Moves the spindle to hole A. Since the drill cycle was turned

on in the main program, a hole will be drilled at this location.

N002

Y-1. Moves the spindle from hole A to hole B.

N003

X1. Moves the spindle from hole B to hole C.

N004

Y1. Moves the spindle from hole C to hole D.

N005

G90 Selects absolute positioning mode. Since the main program

uses absolute mode, operator confusion is minimized by placing the

machine back into absolute mode before returning from the subprogram.

N006

M99 Return to calling program code. The MCU will return to the main

program when this code is received. If this were an independent program

rather than a subprogram, an M30 would have been used here instead of

M99.

SUBROUTINES FOR CUTTER DIAMETER

COMPENSATION

As pointed out in chapter 10, subprograms are often used with cutter

diameter compensation. Figure 11-7 presents a program written for the part

shown in Figure 10-12. The program utilizes a subprogram to mill the part

periphery.

The first time the subprogram is called, CRO register D11 is used. If .520

is placed in the register, .010 stock per side of the part will be left for finishing. The second time the subprogram is called, register D11 is used. Placing

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 248

248

CHAPTER 11

%

O1107

(* **********)

(* X0/Y0 - LOWER LEFT CORNER)

(* Z0 - .100 ABOVE TOP OF PART)

(* THIS PROGRAM CALLS SUBPROGRAM 1007)

(* **********)

N001 G00 G40 G70 G90

(SAFETY LINE)

N101 T01 M06

(TOOL CHANGE)

N102 G00X7. Y.875

(MOVE CUTTER TO CRO RAMP-ON POSITION)

N103 G45 Z0. H01 M08

(PICK UP LENGTH OFFSET/COOLANT ON)

N104 G01 Z-.89

(POSITION CUTTER TO DEPTH)

N105 G17 G42 D11

(TURN ON THE CRO - USE REGISTER 11)

N106 P1007 M98 L1

(JUMP TO SUBROUTINE TO MILL PART)

N107 G00 X7. Y.875

(POSITION THE CUTTER FOR CRO RAMP-ON)

N108 G01 Z-.89

(POSITION CUTTER TO DEPTH)

N109 G17 G42

(TURN ON THE CRO - USE REGISTER 12)

N110 P1007 M98 L1

(JUMP TO SUBROUTINE TO MILL PART)

N111 G00 G91 G28 Z0. M09

(RAPID Z TO HOME/COOLANT OFF)

N112 G28 X0. Y0. M05

(RAPID X/Y TO HOME/SPINDLE OFF)

N113 M30

(END OF PROGRAM)

01007

(* **********)

(* SUBPROGRAM CALLED BY PROGRAM 1107)

(* **********)

N001 G01 X6.

(CRO ALREADY ON - RAMP-ON TO#1))

N002 Y4.

(FEED TO #2)

N003 X2.

(FEED TO #3)

N004 X0. Y2.

(FEED TO #4)

N005 Y0.

(FEED TO #5)

N006 X4.875

(FEED TO #6)

N007 G02 X6. Y1.125 I0. J1.125 (CUT ARC FROM #6 TO #1)

N008 G40 X7.

(CANCEL CRO AND RAMP-OFF)

N009 G00 Z0.

(RETRACT THE SPINDLE)

N010 M99

(RETURN TO CALLING PROGRAM)

%

FIGURE 11-7

Program to machine the part in Figure 11-8

a value of .500 in D12 results in a finish pass. Remark statements are included in the program listing that explain the program execution in detail.

The machining sequence used in this program is identical to that used

in Chapter 10. The difference is that the duplication of coordinate locations

is eliminated by using the subprogram.

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 249

DO LOOPS AND SUBPROGRAMS

249

NESTED LOOPS

Do loops may nest inside other do loop or subprograms. Similarly, subprograms may nest inside other subprograms. This concept will be demonstrated using the part illustrated in Figure 11-8 and the program in Figure

11-9. This program features two loops nested inside a subprogram. In Figure

11-8, the rows of holes have been labeled for easy reference. In writing a

CNC program, a reference sketch such as this is a valuable aid in developing a machining strategy and provides a way for the programmer to check

his or her work.

MTL: .50 THICK 1018 CRS

1.000

TYP

1.000

1/4 DRILL 24 PCS.

1.000

1.000

TYP

TOOL CHANGE

FOR MACHINIST SHOP

LANGUAGE, TOOL CHANGE =

X-5 Y2

LOOP 1 REPEATS

2

3

LOOP 2 REPEATS

A

1

LOOPS 1 AND 2

CONTAINED IN

SUBROUTINE

2ND LOOP MOVES

FROM B6 TO B1

IN 1.0-INCH

INCREMENTS

1ST LOOP

MOVES FROM

A1 TO A6 IN

1.0-INCH INCREMENTS

FIGURE 11-8

Part drawing and tool path for nested loop example

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 250

250

%

O1109

(* **********)

(* X0/Y0 - LOWER LEFT CORNER)

(* Z0 - .100 ABOVE TOP OF PART)

(* **********)

(* TOOL 1 NO. 3 C-DRILL)

(* **********)

N001 G00 G90 G80 G40 G98

N101 T01 M06

N102 G00 X1. Y1. S1700 M03

N103 Z-.163 H01 M08

N104 G81 G98 X1. Y1. Z-.162 R0. F5.1

N105 P1000 M98 L1

N106 Y1.

N107 P1000 M98 L1

N108 G00 G91 G28 Z0. M09

N109 G28 X0. Y0. M05

N110 M01

(* **********)

(* TOOL 2 1/4 DRILL)

(* **********)

N002 G00 G90 G80 G40 G98

N201 T01 M06

N202 G00 X1. Y1. S1700 M03

N203 Z-.163 H01 M08

N204 G81 G98 X1. Y1. Z-.162 R0. F5.1

N205 P1000 M98 L1

N206 Y1.

N207 P1000 M98 L1

N208 G00 G91 G28 Z0. M09

N209 G28 X0. Y0. M05

N210 M30

O1000

(* **********)

(* SUBPROGRAM 1000 CALLED BY)

(* PROGRAM NUMBER 1109)

(* **********)

N101 G25 P112 Q102 L5

N102 G91 X1.

N103 Y1.

N104 G25 P104 Q104 L5

N105 G91 X-1.

N106 G90

N107 M99

%

FIGURE 11-9

Program to machine the part in Figure 11-8

CHAPTER 11

(SAFETY LINE)

(TOOL CHANGE)

(POSITION AT A-1)

(TURN ON TOOL LENGTH OFFSET AND COOLANT)

(TURN ON DRILL CYCLE - DRILL A-1)

(JUMP TO SUBPROGRAM 1000)

(POSITION TO AND DRILL C-1)

(JUMP TO SUBPROGRAM 1000)

(RAPID Z HOME/COOLANT OFF)

(RAPID X/Y HOME/SPINDLE OFF)

(OPTIONAL STOP CODE)

(SAFETY LINE)

(TOOL CHANGE)

(POSITION AT A-1)

(TURN ON TOOL LENGTH OFFSET AND COOLANT)

(TURN ON DRILL CYCLE- DRILL A-1)

(JUMP TO SUBPROGRAM 1000)

(POSITION TO AND DRILL C-1)

(JUMP TO SUBPROGRAM 1000)

(RAPID Z HOME/COOLANT OFF)

(RAPID X/Y HOME/SPINDLE OFF)

(END OF PROGRAM - MEMORY RESET)

(BEGIN DO LOOP - REPEAT 5 TIMES)

(MOVE INCREMENTALLY 1.000 IN X)

(POSITION TO C-1)

(BEGIN A LOOP - REPEAT 5 TIMES)

(MOVE INCREMENTALLY -1.000 IN X)

(SWITCH TO ABSOLUTE POSITIONING)

(RETURN TO CALLING PROGRAM)

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 251

DO LOOPS AND SUBPROGRAMS

251

In the part program, one of the loops will drill the holes in row A, moving

from hole A1 to hole A6. Hole A1 will be drilled prior to instituting the do loop.

After positioning to drill hole B6, another loop will be used to drill holes B6

to B1, moving in the X direction. One loop could drill all the holes, but that

would require sending the spindle back to the first hole of each row prior to

using the do loop. By using two do loops, machine motion is more efficient,

drilling in both the positive and negative directions along the X axis. Nesting

the loops in a subprogram allows drilling rows C and D with the same do

loops.

SUMMARY

The important concepts presented in this chapter are:

A do loop instructs the MCU to repeat a series of instructions a specified

number of times.

The format for a do loop is:

G25 P... Q... L..

Where: G25 turns on the loop.

P is the beginning block number of the loop.

Q is the ending block number of the loop.

L is the number of times to repeat the loop.

A subprogram is a program called by another program in a parent-child

relationship.

The format for calling a subprogram is:

P.... M98 L..

Where: P is the program number of the subprogram.

M98 causes subprogram P to execute.

L specifies the number of times subprogram P executes.

Nested loops are placed inside other loops or inside subprograms.

The codes for subprograms and do loops vary from controller to controller. To program a particular machine, it will be necessary to consult the

programming manual for the machine in question.

VOCABULARY INTRODUCED IN THIS CHAPTER

Do loop

Main program

Nested loop

Subprogram

Subroutine

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 252

252

CHAPTER 11

REVIEW

QUESTIONS

1.

2.

3.

4.

What is a do loop? A subprogram? A nested loop?

What is the format for a do loop?

What is the format for a subprogram call?

Write a do loop to drill the hole patterns in Figure 11-10.

1/4 TYP

1.000

6 EQ. SPACES @

.625 = 3.750

.437

MATERIAL: 1/8 THICK 2024 T-3 ALUMINUM

TOOL CHANGE

FOR MACHINIST

SHOP LANGUAGE

TOOL CHANGE = X-4 Y2

X0/Y0 = LOWER

LEFT CORNER

TOOLS: #3 C DRILL

1/4 DRILL

FIGURE 11-10

Part drawing for review question #4

Seames Chap 11 QRK

3/2/01

10:07 AM

Page 253

DO LOOPS AND SUBPROGRAMS

253

5. Write a program utilizing a subprogram to mill the slots in Figure 11-11.

MTL 2075 ALUM. ALLOY .25 THICK

.500

2.000

2.250

.250 TYP

1.250

3.000

.500

TYP

TOOL CHANGE

FOR MACHINIST

SHOP LANGUAGE

TOOL CHANGE = X4 Y2

#1

.750

#2

TOOLS 1/4 DIA END MILL

INSTRUCTIONS: MILL SLOTS

#1, #2, #3, #4 IN THAT

ORDER

FIGURE 11-11

Part drawing for review question #5

#3

#4

You might also like

- Makino Basic ProgrammingDocument104 pagesMakino Basic ProgrammingAPSARAUSA100% (8)

- CNC Programming WRKB Lathe Sample LockedDocument51 pagesCNC Programming WRKB Lathe Sample Lockedkree_bigdaddyNo ratings yet

- F L8 TA 202 NC Part ProgrammingDocument26 pagesF L8 TA 202 NC Part ProgrammingShiva Krishna BhagavatulaNo ratings yet

- Cad AssignmentDocument6 pagesCad AssignmentorigafelixNo ratings yet

- PLC S7 - 300 Applications: Electric Power / ControlsDocument24 pagesPLC S7 - 300 Applications: Electric Power / ControlsChu Văn ThànhNo ratings yet

- CNC Turning (Bridgeport)Document63 pagesCNC Turning (Bridgeport)Siti Idah TawhidNo ratings yet

- SubprogramDocument5 pagesSubprogrammohamed rabieiNo ratings yet

- CNC MillingDocument70 pagesCNC Millingiresa_nurat100% (2)

- NC Part ProgrammingDocument36 pagesNC Part Programmingabyzen0% (1)

- Training Programme On CNC LatheDocument33 pagesTraining Programme On CNC Lathesharafudheen_sNo ratings yet

- Description For M Codes3Document19 pagesDescription For M Codes3balabooksNo ratings yet

- Appendix A - G and M Codes: This Part Program Is Used With The Ballbar TestDocument40 pagesAppendix A - G and M Codes: This Part Program Is Used With The Ballbar TestIvan Hren100% (1)

- Turning: Chapter ObjectivesDocument78 pagesTurning: Chapter ObjectivesDany EscobarNo ratings yet

- Module 4Document59 pagesModule 4Musadiq Ahmed100% (1)

- Fem PDFDocument302 pagesFem PDFeddy_p_ajiNo ratings yet

- NEX Series Maintenance ManualDocument123 pagesNEX Series Maintenance ManualGelu Bonea100% (5)

- CHAPTER 8manual Part ProgrammingDocument111 pagesCHAPTER 8manual Part ProgrammingHrishikesh deshpandeNo ratings yet

- 5 - G-CodeDocument55 pages5 - G-CodefamilyumaNo ratings yet

- 990TDBDocument106 pages990TDBRodrigo Torneiro MecânicoNo ratings yet

- Intro to G-Code ProgrammingDocument55 pagesIntro to G-Code ProgrammingJusuf Kunic100% (1)

- CNCDocument31 pagesCNCPravin DeshmaneNo ratings yet

- EN - Complete Sinumerik Operate Milling - v26Document690 pagesEN - Complete Sinumerik Operate Milling - v26Hieu Nguyen100% (1)

- CNC Programming Guide for Mechanical EngineersDocument21 pagesCNC Programming Guide for Mechanical EngineersVarshaNo ratings yet

- Vertical Machining Centre (VMC)Document3 pagesVertical Machining Centre (VMC)anil chejaraNo ratings yet

- NC ProgrammingDocument29 pagesNC ProgrammingManju Parkavi0% (1)

- G-Code InstructionsDocument55 pagesG-Code InstructionsSantiago LopezNo ratings yet

- CNC For CADCAM and Technology StudentsDocument95 pagesCNC For CADCAM and Technology Studentscaptain_jack_zzz609No ratings yet

- Seminar Report: CNC Machines and ProgrammingDocument25 pagesSeminar Report: CNC Machines and ProgramminggurshantholaniNo ratings yet

- Post Mastercam 4 AxisDocument62 pagesPost Mastercam 4 AxisGiacongcokhi CokhihotroNo ratings yet

- 01 Cadfil - NC - Controller - RequirementsDocument3 pages01 Cadfil - NC - Controller - RequirementsHuber AlvaradoNo ratings yet

- Manual FanucDocument104 pagesManual FanucTauasi TauasisNo ratings yet

- Fanuc Ot CNC Program Manual Gcodetraining 588Document104 pagesFanuc Ot CNC Program Manual Gcodetraining 588hiepkhachbk2010824350% (2)

- Experiment P3 CNC Machining: ObjectiveDocument13 pagesExperiment P3 CNC Machining: ObjectivePhạm Ngọc HòaNo ratings yet

- Programming MillDocument81 pagesProgramming MillEddy ZalieNo ratings yet

- Series 8000 Mill OperationDocument429 pagesSeries 8000 Mill OperationNumai EuNo ratings yet

- Semester Project "Computer Numerical Controlled Machine": Ee332 Control Systems Lab - CNC MachineDocument19 pagesSemester Project "Computer Numerical Controlled Machine": Ee332 Control Systems Lab - CNC MachinezakiNo ratings yet

- CAM Lab MtechDocument33 pagesCAM Lab MtechrkNo ratings yet

- 5 - G-CodeDocument55 pages5 - G-CodeTan TeongShengNo ratings yet

- CNC MachiningDocument14 pagesCNC MachiningAl Fredo100% (13)

- Introduction To NC and CNC Machines CNC Controls and RS274 ProgrammingDocument32 pagesIntroduction To NC and CNC Machines CNC Controls and RS274 ProgrammingNuno Miguel Silva100% (1)

- Computer-Aided Part ProgrammingDocument10 pagesComputer-Aided Part ProgrammingPradip PatelNo ratings yet

- Tejas DCM Lab 8Document6 pagesTejas DCM Lab 8Piyansh ThukralNo ratings yet

- CNC Lab ManualDocument25 pagesCNC Lab Manualiamav31No ratings yet

- Readme PDFDocument18 pagesReadme PDFMohammad GolastanehNo ratings yet

- Okuma Lathe ManualDocument23 pagesOkuma Lathe ManualWong Lee QinNo ratings yet

- Lab Manual CNC LatheDocument10 pagesLab Manual CNC LatheSai Naga Sri Harsha100% (1)

- Custom MacroDocument31 pagesCustom Macroshiva d100% (1)

- CNC ProgrammingDocument27 pagesCNC ProgrammingAbhijit BiswasNo ratings yet

- CNC Programming Handbook Smid 195 - 293Document99 pagesCNC Programming Handbook Smid 195 - 293Răzvan Iordache100% (1)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Introduction to Electronic Analogue Computers: International Series of Monographs in Electronics and InstrumentationFrom EverandIntroduction to Electronic Analogue Computers: International Series of Monographs in Electronics and InstrumentationNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Practical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11From EverandPractical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11No ratings yet

- Density of Paper and PaperboardDocument2 pagesDensity of Paper and PaperboardRohit SinghNo ratings yet

- Grades of PaperDocument25 pagesGrades of PaperRohit SinghNo ratings yet

- True Position: Special NoteDocument2 pagesTrue Position: Special NoteRohit SinghNo ratings yet

- Quantitative AptitudeDocument2 pagesQuantitative AptitudeSivakumar MNo ratings yet

- Syllabus For Production and Industrial EngineeringDocument3 pagesSyllabus For Production and Industrial EngineeringviveknarayanNo ratings yet

- Datums in GD&T: Symbol: DefinitionDocument2 pagesDatums in GD&T: Symbol: DefinitionRohit SinghNo ratings yet

- 2 Engineering MaterialsDocument14 pages2 Engineering MaterialsPRASAD326100% (1)

- Shri Nitish KumarDocument2 pagesShri Nitish KumarRohit SinghNo ratings yet

- Blank CalculationDocument4 pagesBlank CalculationSatish Zle100% (5)

- Sample Aadhaar Enrolment IDDocument1 pageSample Aadhaar Enrolment IDRohit SinghNo ratings yet

- Plastic Injection Molding - Knowledge Base - Shrinkage% of Material in MouldsDocument2 pagesPlastic Injection Molding - Knowledge Base - Shrinkage% of Material in MouldsRohit SinghNo ratings yet

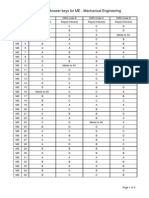

- Answer Key Gate 2012Document2 pagesAnswer Key Gate 2012Tejas ParmarNo ratings yet

- Foreword III Preface V: 1. Real Numbers 1Document4 pagesForeword III Preface V: 1. Real Numbers 1Saravanan AnnamalaiNo ratings yet

- GATE Mechanical Exam Question Pattern ExplainedDocument1 pageGATE Mechanical Exam Question Pattern ExplainedWilfredVincentNo ratings yet

- MECHANICALDocument2 pagesMECHANICALShubhamDabralNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Mechanical EngineeringDocument2 pagesMechanical EngineeringmannamalairajaNo ratings yet

- Academic Calendar: University Schools & Affiliated Institutions (For The Academic Session 2014-2015Document3 pagesAcademic Calendar: University Schools & Affiliated Institutions (For The Academic Session 2014-2015Lovenish SachdevaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Appendix 1Document21 pagesAppendix 1Saravanan AnnamalaiNo ratings yet

- Sources of EnergyDocument7 pagesSources of EnergyRohit SinghNo ratings yet

- TargetDocument3 pagesTargetRohit SinghNo ratings yet

- Magnetic Effects of Electric CurrentDocument13 pagesMagnetic Effects of Electric CurrentRohit SinghNo ratings yet

- 40-character General Awareness Quiz TitleDocument3 pages40-character General Awareness Quiz TitleRohit SinghNo ratings yet

- GK 2Document16 pagesGK 2sruthyaNo ratings yet

- Current RoverDocument1 pageCurrent RoverRohit SinghNo ratings yet

- General Awareness (Banking Industry) Model Question Paper With Answer KeyDocument17 pagesGeneral Awareness (Banking Industry) Model Question Paper With Answer KeyAnonymous 8SNpyXNo ratings yet

- Complete Pearcing Sheet 1Document1 pageComplete Pearcing Sheet 1Rohit SinghNo ratings yet

- CATIAcommand 8Document1 pageCATIAcommand 8Rohit SinghNo ratings yet

- Tutorial (Chapter 3)Document5 pagesTutorial (Chapter 3)MATHAVAN A L KRISHNANNo ratings yet

- Resturant Management System: Submitted By: Dishita ChughDocument11 pagesResturant Management System: Submitted By: Dishita ChughDishita ChughNo ratings yet

- Python Syllabus 1Document8 pagesPython Syllabus 1Pradeep GNo ratings yet

- Question Bank ASQLDocument2 pagesQuestion Bank ASQLMeenakshi Vaylure PaulNo ratings yet

- Install Sun - Oracle Java JDK - JRE 7u17 On Fedora 18 - 17, CentOS - RHEL 6.3 - 5Document19 pagesInstall Sun - Oracle Java JDK - JRE 7u17 On Fedora 18 - 17, CentOS - RHEL 6.3 - 5Kẹo MútNo ratings yet

- Free English TextbooksDocument110 pagesFree English TextbooksyassienNo ratings yet

- Question Bank Swing SolutionDocument4 pagesQuestion Bank Swing SolutionSalilNitinRajeNo ratings yet

- Data Structures and Algorithms - 2018Document3 pagesData Structures and Algorithms - 2018Franklin TamayoNo ratings yet

- Rest API CheatsheetDocument4 pagesRest API CheatsheetnitishNo ratings yet

- Jenkins and Its SetupDocument45 pagesJenkins and Its SetupAbid AliNo ratings yet

- A Gentle Introduction To PythonDocument29 pagesA Gentle Introduction To PythonKishor Paul100% (2)

- Cambridge International AS & A Level: Computer Science 9618/32Document12 pagesCambridge International AS & A Level: Computer Science 9618/32Mbewe MbeweNo ratings yet

- C How To Program - Chapter4Document45 pagesC How To Program - Chapter4Oscar LarutaNo ratings yet

- c99 PHPDocument71 pagesc99 PHPegyhackerNo ratings yet

- Algorithm and Programming Language MCQ'SDocument25 pagesAlgorithm and Programming Language MCQ'SGuruKPO100% (3)

- JOIN OUR TELEGRAM COMMUNITY - FUNDAMENTALS OF DATA STRUCTURESDocument196 pagesJOIN OUR TELEGRAM COMMUNITY - FUNDAMENTALS OF DATA STRUCTURESAakanksha BarakadeNo ratings yet

- Customising EdgeCAMDocument5 pagesCustomising EdgeCAMDulis DulisNo ratings yet

- AI Pratical File (Indervir Singh)Document24 pagesAI Pratical File (Indervir Singh)shashi kumar seth 428No ratings yet

- Tutorial: Turning Your Python Ogre Game Scripts Into A Windows .ExeDocument2 pagesTutorial: Turning Your Python Ogre Game Scripts Into A Windows .ExerobertNo ratings yet

- Social, Professional and Ethics Issues in ITDocument9 pagesSocial, Professional and Ethics Issues in ITKalebNo ratings yet

- Excel Spreadsheets From RPG With POIDocument20 pagesExcel Spreadsheets From RPG With POIJoshua HintonNo ratings yet

- MIT 6.006 Introduction to Algorithms Quiz 1Document16 pagesMIT 6.006 Introduction to Algorithms Quiz 1Khatia IvanovaNo ratings yet

- Assignment 2Document2 pagesAssignment 2Zain aliNo ratings yet

- Moving from BackgroundRB to Resque Improves Reliability and ScalabilityDocument30 pagesMoving from BackgroundRB to Resque Improves Reliability and ScalabilityJames CoxNo ratings yet

- Brick BreakerDocument18 pagesBrick BreakerAnkush JangidNo ratings yet

- Virtual Memory ManagementDocument6 pagesVirtual Memory ManagementAmudha ShanmugamNo ratings yet

- Leetcode DSA Sheet by FrazDocument21 pagesLeetcode DSA Sheet by FrazCatalyst GamingNo ratings yet

- Configure PO Release Strategy < 10KDocument2 pagesConfigure PO Release Strategy < 10KSoumen DuttaNo ratings yet

- Dbms Manual 2022Document58 pagesDbms Manual 2022SaladAss GamingNo ratings yet

- The Data Analytics Handbook2 PDFDocument43 pagesThe Data Analytics Handbook2 PDFwaldemarroberti100% (2)