Professional Documents

Culture Documents

Commissioning and Gas In Procedure for New Gas Pipeline

Uploaded by

Ariz Joelee ArthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commissioning and Gas In Procedure for New Gas Pipeline

Uploaded by

Ariz Joelee ArthaCopyright:

Available Formats

PT.

HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

Commissioning and Gas In

Procedure

System Metering Gas Orifice

Gresik Station

MET-3001, 12 ANSI 600#

Pengembangan Meter Jawa Timur,

Pengadaan 8 & 3 Meter System

18/5/12

COMMISSIONING AND GAS IN

PROCEDURE

AJ

MF

IC

Revisio

n

Date

Description

By

Checked

By

Approved

by

COMMISSIONING AND GAS IN Procedure

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

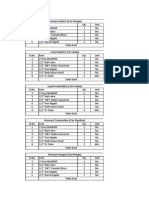

DAFTAR ISI

BAB

DESKRIPSI

TABLE OF CONTENT

HAL

SEC.

DESCRIPTION

PAGE

1.0

PENDAHULUAN

1.0

INTRODUCTION

2.0

PRE-COMMISSIONING

2.0

PRE-COMMISSIONING

2.1

2.2

UMUM

INSPEKSI

4

4

2.1

2.2

GENERAL

INSPECTION

4

7

3.0

COMMISSIONING

3.0

COMMISSIONING

3.1

3.2

3.3

3.4

UMUM

PUNCH LIST

COMMISSIONING

SISTEM PURGING

7

7

7

8

3.1

3.2

3.3

3.4

GENERAL

PUNCH LIST

COMMISSIONING

PURGING

7

7

7

8

4.0

GAS IN

11

4.0

GAS IN

11

LAMPIRAN

P&ID MET-6001

COMMISSIONING AND GAS IN Procedure

APPENDIX

P&ID MET-6001

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

1.0 PENDAULUAN

Tujuan pembuatan Prosedur

Commissioning dan Gas In ini adalah

untuk menentukan prosedur pelaksanaan

Commissioning dan Gas In jaringan pipa

salur dari PT Pertamina Gas.

1.0 INTRODUCTION

This document provides guideline for

Comissioning and Gas In procedure for

New Gas Pipeline PT Pertamina Gas.

2.0 PRE-COMMISSIONING

2.1. GENERAL

2.0 PRE-COMMISSIONING

2.1 UMUM

Preparation for Pre-Commissioning

Persiapan untuk pelaksanaan Preexecution consist of several important

commissioning terdiri dari beberapa

steps which must be follow :

tahap pelaksanaan yang harus dilakukan: 2.1.1 Check all pipeline installation

2.1.1 Memeriksa seluruh pemasangan pipa

completely with wrapping, cathodic

salur, lengkap dengan kondisi

protection and good backfill. Pipeline

wrapping, proteksi katodik dan

marker, test point for cathodic

penimbunan. Rambu-rambu pipa salur

protection position shall comply with

dan proteksi katodik test point, harus

engineering document.

sesuai dengan dokumen teknik.

2.1.2 Memeriksa sistem koneksi dalam

2.1.2 Check all system piping connection

perpipaan termasuk fitting, support

including fitting, pipe support and

pipa dan pondasi harus sesuai dengan

support foundation. And all shall comply

dokumen teknik.

with engineering document.

2.1.3 Memeriksa arah aliran yang ditunjukkan 2.1.3 Check gas direction flow, which should

dengan arah panah pada pipa bagian

be mark on offside of pipe.

luar.

2.1.4 Check all civil and structural work, and

2.1.4 Memeriksa seluruh pekerjaan civil dan

shall comply with engineering

struktur, dan harus sesuai dengan

document.

dokumen teknik.

2.1.5 Check all instrument equipment

2.1.5 Memeriksa letak alat instrumen dan

placement and its connection, and shall

sistem koneksinya harus sesuai dengan

comply with engineering document.

dokumen teknik.

2.1.6 Prepare Punch List

2.1.6 Membuat daftar peralatan dan hasil

2.1.7 Check all testing result for pipeline,

aktivitas perbaikan, punch list.

piping, instrument, civil/structure and

2.1.7 Memeriksa kembali hasil seluruh

cathodic. And the testing result should

pengujian untuk pipa salur, perpipaan,

be approved.

instrumen, civil/struktur dan katodik.

2.1.8 Check pipeline certificate from MIGAS.

Hasil uji sudah harus di setujui.

2.1.8 Memeriksa sertifikasi pipa salur yang 2.1.9 All equipment installed catalogue should

telah disetujui oleh MIGAS.

be ready.

2.1.9 Seluruh katalog peralatan yang

terpasang telah tersedia.

Tahapan-tahapan tersebut di atas harus

dipenuhi terlebih dahulu, sebelum menginjak

ke tahap berikutnya, Commissioning.

2.2 INSPEKSI

Inspeksi harus dilakukan Tim Inspeksi PreCommissioning untuk memastikan

keberadaan peralatan, fitting, perpipaan,

instrumen, civil/struktur, dan proteksi

katodik.

2.2.1Inspeksi Pipa Salur.

COMMISSIONING AND GAS IN Procedure

All steps above must be already done first

before continue to the next, Commissioning.

2.2 INPECTION/CHECK LIST

Check list must be perform by PreCommissioning Team to make sure that

equipment, pipeline, fitting, piping,

instrument, civil-structure and cathodic

protection are installed in a right place.

2.2.1 Pipeline Inspection/Check List.

1. Ensure NDT should already taken and

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

1. Memastikan NDT telah dilaksanakan

pada seluruh jalur pipa salur dengan

hasil baik dan disetujui.

2. Memastikan rambu-rambu pipa salur

telah terpasang dengan baik dan

benar, papan informasi pipa salur

juga terpasang.

3. Memastikan kedalaman pipa salur

ditanam dengan benar sesuai dengan

dokumen teknik.

the result are good and approved.

2. Ensure pipeline marker are installed

good and correctly, and pipeline sign

are already installed

3. Ensure pipeline buried are in correctly

depth,

and

shall

comply

with

engineering document.

4. Ensure the backfill is good and shall

comply with engineering document.

5. Ensure pipeline has been wrapping

using wrapping tape which is tested by

holiday test and must be approved.

6. Ensure catodic protection system has

been installed correctly. Transformer

Rectifier has been correctly installed,

and the length between

anode is

correct test point placement shall

comply with engineering document

7. Ensure installation of Insulation flange

is ready and correctly, shall comply

with engineering document

8. Ensure Pig Signal is ready installed and

correctly,

shall

comply

with

engineering document.

9. Ensure pipeline has been cleaning,

gauging

with good result and

approved before hydrostatic test start.

10. Ensure result of hydrostatic test have

been approved by MIGAS

4. Memastikan kondisi penimbunan

telah baik dan sesuai dengan

dokumen teknik.

5. Memastikan sepanjang pipa salur

telah di wrapping dan telah di uji

dengan holiday test, dan hasilnya

telah disetujui.

6. Memastikan sistem proteksi katodik

telah terpasang dengan benar.

Transformer Rectifier telah terpasang

dengan baik. Jarak anode sudah benar

letak test point telah sesuai dengan

dokumen teknik.

7. Memastikan pemasangan Insulation

Flange telah siap dan benar, sesuai

dengan dokumen teknik.

8. Memastikan pemasangan Pig Signal

telah siap dan benar, sesuai dokumen

teknik.

2.2.2

9. Memastikan bahwa dalam pipa salur

telah dibersihkan, gauging telah

dilakukan dan disetujui sebelum

hidrotest dilaksanakan.

10. Memastikan hasil hidrotest disetujui

MIGAS.

2.2.2

Inspeksi Pig Launcher dan Pig Receiver.

1. Memastikan bahwa semua data pig

launcher dan receiver sesuai dengan

dokumen teknik dan telah disetujui

MIGAS, meliputi :

- Ukuran

- Ketebalan

- Tekanan dan temperatur desain

- Volume desain

- Kondisi tekanan dan temperatur

operasi

- Tersedia closure

COMMISSIONING AND GAS IN Procedure

Pig Launcher and Receiver

Inspection/Check List.

1. Ensure data for Pig Launcher and

Receiver shall comply with

engineering document and has been

approved by MIGAS including:

- Size

- Thickness

- Design Pressure and Temperature

- Design Volume

Operating

Pressure

and

Temperature

- Nozzle Orientation and Elevation

- Closure

- Spectacle blind

- Coating

2. Ensure

instrumentation

for

Pig

Launcher and Receiver shall comply

with engineering document and have

been installed including:

- Pressure Safety Valve

- Pressure Gauge

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

Spectacle blind

Coating

2. Memastikan semua peralatan

instrumen yang terpasang pada pig

launcher dan receiver sudah sesuai

dengan dokumen teknik dan sudah

siap terpasang :

- Pressure Safety Valve

- Temperature Indicator

- Pig Signal

3. Memastikan denah peralatan sudah

sesuai dengan dokumen teknik.

4. Memastikan bahwa sertifikasi

Pressure Safety Valve sudah

dikeluarkan MIGAS.

5. Periksa apakah peralatan instrumen

sudah dikalibrasi dan sudah di-set

sesuai dengan kondisi operasi dan

sesuai dengan dokumen teknik.

6. Buka closure dan periksa dalamnya,

yakinkan sudah bersih dari kotoran

kemudian tutup kembali closure.

7. Periksa surat kelayakan operasi pig

launcher dan receiver sudah

dikeluarkan MIGAS. Termasuk laporan

NDT, Hidrotest dan Leak Test yang

telah disetujui.

8. Kondisi pondasi telah diperiksa sesuai

dengan dokumen teknik lengkap

dengan hasil tes pondasi.

9. Pastikan bahwa sambungan flange

dalam kondisi baik dan benar.

2.2.3 Inspeksi Perpipaan.

1. Memastikan seluruh sistem perpipaan

berdasarkan engineering document.

2. Periksa sambungan antara pipa

dengan flange atau pipa dengan pipa

atau pipa dengan elbow, atau flange

dengan flange. Memastikan bahwa

prosedur pengelasan telah sesuai

dengan dokumen teknik.

3. Memastikan perpipaan telah di

flushing.

4. Memastikan bahwa valve dapat

membuka dan menutup dengan baik

dan mudah dimana peletakan valve

telah sesuai dokumen teknik.

5. Memastikan elevasi dan letak dari

sistem perpipaan harus sesuai

dokumen teknik.

6. Memastikan bahwa support pipa dan

accessories yang lain, telah terpasang

sesuai dokumen teknik.

COMMISSIONING AND GAS IN Procedure

- Pig Signal

3.Ensure lay-out of equipment shall

comply with engineering document

4.Ensure certification of Pressure Safety

Valve has been released from MIGAS.

5.Ensure installation of instrument has

been calibrated and set appropriate

with operation condition shall comply

with engineering document.

6.Open closure in shell and check,

ensure closure is clean form debris,

and close.

7.Check certification of operating Pig

Launcher and Receiver has been

release from MIGAS. Including NDT,

Hydrostatic Test and Leak Test report

should be approved.

8. Ensure to check foundation of Pig

Launcher and Receiver shall comply

with engineering document and has

been tested for concrete foundation.

9. Ensure connection using flange in

good condition and correctly.

Piping Inspection/Check List

1. Ensure piping system shall comply

with engineering document.

2. Check connection between pipe with

flange or pipe with pipe or pipe with

elbow or flange with flange. Ensure

welding procedure shall comply with

engineering document

3. Ensure piping has been flushing.

4. Ensure valve can be opened and

closed correctly and easily, and the

placement shall comply with

engineering document.

5. Ensure elevation and lay-out of piping

system shall comply with engineering

document.

6. Ensure pipe support and other

accessories have been installed and

shall comply with engineering

document.

7. Ensure anchor bolts have been good

installed.

8. Ensure service platform have been

installed correctly.

9. Ensure piping system have been

hydrostatic test and the report have

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

7. Pastikan bahwa anchor bolt telah

been approved by MIGAS

terpasang dengan baik.

8. Memastikan servis platform telah

terpasang dengan benar.

2.2.4 Instrument Inspection/Check List

9. Memastikan bahwa sistem perpipaan

1. Ensure all instruments have been

telah di Hidrotest dan hasilnya telah

calibrated and shall comply with

disetujui oleh MIGAS.

engineering document.

2. Ensure all instruments have been

2.2.4 Inspeksi Instrumen

installed.

1. Memastikan seluruh peralatan

3. Ensure pressure safety valves have

instrumen telah dikalibrasi sesuai

been approved by MIGAS.

dengan dokumen teknik.

4. Check condition of panel instrument

2. Memastikan seluruh peralatan

based on engineering document

instrumen telah siap terpasang.

5. Check the tubing connection should

3. Memastikan Pressure Safety Valve

be correctly and good condition and

telah disetujui oleh MIGAS.

shall comply with engineering

4. Periksa kondisi panel instrumen

document.

apakah sudah sesuai dengan

6. Ensure all instruments have been

dokumen teknik.

functional test with good result based

5. Periksa sambungan tubing sudah

on engineering document.

benar dan baik dan sesuai dengan

7. Ensure actuator for control valve have

dokumen teknik.

been installed and function test.

6. Memastikan seluruh peralatan

8. Ensure Catalog of all instrument are

instrumen telah dilakukan function

complete.

test dan berhasil baik sesuai dokumen

teknik.

7. Memastikan actuator control valve

2.2.5 Civil and Structure Inspection/Check List

telah terpasang dan telah di function

1. Check condition of all equipment and

tes.

piping foundation and with good

8. Memastikan katalog dari tiap

result.

peralatan instrumen telah lengkap.

2. Ensure elevation of foundation shall

comply with engineering document

2.2.5 Civil dan Structure

3. Ensure fence and fence foundation

1. Periksa seluruh kondisi pondasi

shall comply with engineering

equipment maupun perpipaan dan

document.

dengan hasil test baik.

4. Ensure painting based on approval

2. Memastikan seluruh elevasi pondasi

specification.

harus sesuai dengan dokumen teknik.

3. Memastikan kondisi pondasi pagar

3.0 COMMISSIONING

yang baru dan pagar sesuai dokumen

Commissioning can start after preteknik.

commissioning completely finished.

yang ditentukan.

3.0 COMMISSIONING

Commissioning dapat dilaksanakan

setelah pre-commissioning selesai

dilaksanakan.

3.1 UMUM

Team Leader Commissioning bertanggung

jawab terhadap koordinasi dan arahan

langkah-langkah yang akan dilakukan

selama Commissioning.

Purging akan dilakukan saat

commissioning.

Sebelum purging dimulai, sebaiknya

COMMISSIONING AND GAS IN Procedure

3.1 GENERAL

Commissioning Team Leader is in charge

on coordinate and conduct on

Commissioning during activity going on.

Purging will be perform during

commissioning.

Before purging is started, punch list

review should be discussed.

3.2 PUNCH LIST

Pre-Commissioning team will produce

Check List.

Check List report is present of equipment

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

dilakukan pembahasan punch list.

3.2 PUNCH LIST

Tim pre-commissioning akan

mengeluarkan laporan Check List.

Di dalam check list terdapat pernyatan

yang menyatakan diterima atau diterima

dengan persyaratan atau tidak sama

sekali terima oleh tim pre-commissioning.

Berdasarkan Check List akan dihasilkan

Punch List. Punch List ini akan

mengeluarkan rekomendasi peralatan

atau hasil pekerjaan mana saja yang

perlu diperbaiki atau dipasang ulang atau

diganti.

3.3 COMMISSIONING

Tim commissioning akan melakukan

pekerjaan berdasarkan Punch List.

Pemeriksaan yang akan dilakukan adalah

sebagai berikut :

1. Memeriksa hasil pekerjaan yang telah

diperbaiki.

2. Memeriksa peralatan yang telah

diperbaiki.

3. Memeriksa kembali pekerjaan ulang

yang telah dilakukan.

4. Memeriksa kembali peralatan yan

telah diganti.

5. Membahas/mendiskusikan ulang

terhadap peralatan/pekerjaan yang

tidak dapat di perbaiki/diganti.

6. Melakukan function test dan running

test peralatan tanpa menunggu

purging dan gas in.

7. Melakukan purging ke seluruh system.

installation approval or construction

approval declaration (approved / not

approved / approved with comment) by

Pre-commissioning team.

From check list will perform Punch List.

The Punch List will present which one

equipment or piping installation must be

repaired/reinstall or even replaced

recommendation.

3.3 COMMISSIONING

Commissioning team will start active base

on Punch List.

The inspection steps should be done is as

follows:

1. Check if all repaired job which is done.

2. Check if all equipment repaired which

is done.

3. Re-check all of repaired job.

4. Check all equipment replacement.

5. Check if there are repaired or

replacement job which is cannot done

and discuss it.

6. Perform function test and running test

if possible without waiting on purging

and gas in.

7. Purging for all system and connection.

Commissioning Team will perform Mechanical

Completion. Which is present of all activity

approval and equipment installation approval

declaration (approved / approved with

comment). With possibility approved with

note.

Hasil Tim Commissioning adalah

Mechanical Completion. Yaitu pernyataan

bahwa seluruh hasil pemeriksaan

terhadap pekerjaan/ peralatan dapat

diterima penuh dan kemungkinan adanya

catatan yang perlu diperhatikan.

.

4.0 GAS IN

PIPA SALUR PT Pertamina Gas

1. Pastikan valve 12-600# (Line pipa

Inlet Metering) BUKA perlahan-lahan

sampai

tekanan

operasi

yang

diinginkan.

COMMISSIONING AND GAS IN Procedure

4.0 GAS IN

PIPELINE PT Pertamina Gas

1. Ensure valve 12-600# (Line Pipe Inlet)

is OPEN until operating pressure

desired.

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

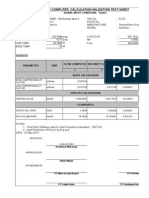

STATION METER

STATION METER

1. Pastikan 12-600# S-1 upstream

TERTUTUP.

2. Pastikan 12-600# S-8 TUTUP.

3. Pastikan 12-600# M-101 TERTUTUP.

4. Pastikan 12-600# M-101 TERTUTUP.

5. Pastikan 12-600# Line M-100

TERTUTUP.

6. BUKA perlahan-lahan valve 12-600#

Line Outlet, sampai tekanan yang

diinginkan

1. Ensure valve 12-600# S-1 upstream

is CLOSE.

2. Ensure valve 12-600# S-8 is CLOSE

3. Ensure valve 12-600# M-101 is

CLOSE.

4. Ensure valve 12-600# M-101 is

CLOSE.

5. Ensure valve 12-600# Line M-100 is

CLOSE.

6. Open slowly valve 12-600# Line

Outlet for Gas In, until operating

pressure.

Dengan dibukanya valve 12-600# , maka

proses Gas In telah selesai dan Station

siap operasi.

Catatan :

Pengaturan arah aliran gas disesuaikan

dengan kebutuhan operasional PT.

PERTAMINA GAS

COMMISSIONING AND GAS IN Procedure

After valve 12-600# was opened, Gas In

process was finished and the station is

ready for operation.

Note :

Gas flow direction is depend on

PT.PERTAMINA GAS operational need

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

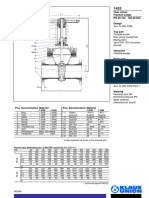

DRAWING

ATTACHMENT

COMMISSIONING AND GAS IN Procedure

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

LIST OF DRAWING

1. P&ID

2. General Arrangement Drawing

3. Procces Flow Diagram

COMMISSIONING AND GAS IN Procedure

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

P&ID

COMMISSIONING AND GAS IN Procedure

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

General Arrangement Drawing

COMMISSIONING AND GAS IN Procedure

PT. HANDIYAN HOTTAP INSTRUMEN

PT SURYA CIPTA TEKNIK

Process Flow Diagram

COMMISSIONING AND GAS IN Procedure

You might also like

- Gas in Procedure PrasadDocument14 pagesGas in Procedure PrasadAminarco -No ratings yet

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- Prosedur CommissioningDocument21 pagesProsedur Commissioningaswin100% (1)

- For Gas MeteringDocument24 pagesFor Gas Meteringsugeng wahyudiNo ratings yet

- Contoh Proposal Risk Register and Process Safety Studies - PERTAMINA RU VI Balongan - RevDocument23 pagesContoh Proposal Risk Register and Process Safety Studies - PERTAMINA RU VI Balongan - RevAnonymous cKdbnUHNo ratings yet

- Marine Gangway Lifting Plan For IFAT in KPME Jombang-13 Feb 21Document19 pagesMarine Gangway Lifting Plan For IFAT in KPME Jombang-13 Feb 21KMPE Div PPICNo ratings yet

- Gas Metering SpecificationDocument50 pagesGas Metering Specificationsugeng wahyudi100% (1)

- SGP Stress Analysis ReportDocument14 pagesSGP Stress Analysis ReportDenstar Ricardo Silalahi100% (2)

- 1308-306-Ins-Dts-001 - Datasheet Custody Metering System Rev.1Document12 pages1308-306-Ins-Dts-001 - Datasheet Custody Metering System Rev.1AyahKenzieNo ratings yet

- Method Statement of Instrumentation CalibrationDocument20 pagesMethod Statement of Instrumentation CalibrationArdi C. PrayogiNo ratings yet

- Data Sheet Daniel Model 788 Digital Control Valve en 43714Document16 pagesData Sheet Daniel Model 788 Digital Control Valve en 43714dreyko77No ratings yet

- Data Sheet Meter Turbin G.65Document1 pageData Sheet Meter Turbin G.65HerruSetiawanNo ratings yet

- SNO R DB 100 005 - Start Up and Operating Manual Rev B1Document61 pagesSNO R DB 100 005 - Start Up and Operating Manual Rev B1Muhamad Fadli Arsyada100% (2)

- Oil Gas Flow Metering SystemDocument252 pagesOil Gas Flow Metering Systemsaid250009250No ratings yet

- Pressure Gauge and Differential Gauge Datasheet for Gas Pipeline ProjectDocument20 pagesPressure Gauge and Differential Gauge Datasheet for Gas Pipeline Projectsugeng wahyudiNo ratings yet

- Installation ITP for Instrumentation SystemDocument8 pagesInstallation ITP for Instrumentation SystemSreerag NageriNo ratings yet

- ITP Elektrical InstrumentDocument17 pagesITP Elektrical InstrumentsswahyudiNo ratings yet

- 1007 DISQ 0 P SS 48080 Sales Gas Metering Package SpecificationDocument43 pages1007 DISQ 0 P SS 48080 Sales Gas Metering Package SpecificationAnonymous XbmoAFtI100% (1)

- Draft Report RLA Pipeline PDFDocument47 pagesDraft Report RLA Pipeline PDFTengku Nizarul AslamiNo ratings yet

- F-NC-174 (Elephant) Field Development Project - GOSP: Inspection and Test Plan (Itp)Document5 pagesF-NC-174 (Elephant) Field Development Project - GOSP: Inspection and Test Plan (Itp)bhct1987100% (1)

- Kik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualDocument27 pagesKik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualKhalid AliNo ratings yet

- NPE CD 000 CPL SPC 0003 Piping Construction Specification - Rev.2Document36 pagesNPE CD 000 CPL SPC 0003 Piping Construction Specification - Rev.2faddzul hidayat Putra100% (1)

- ID-N-RW-JJ1-DSR-ST-87-3001 2 - DS-Shutdown Valve (SDV) PDFDocument21 pagesID-N-RW-JJ1-DSR-ST-87-3001 2 - DS-Shutdown Valve (SDV) PDFHarry SubiantoroNo ratings yet

- Gas Pipeline & Instrumentation SystemDocument66 pagesGas Pipeline & Instrumentation Systemanon_484647789No ratings yet

- PT ANSI MEGA Factory Acceptance TestDocument56 pagesPT ANSI MEGA Factory Acceptance Testana erika Menendez SalvatierraNo ratings yet

- PGN Commissioning ProcedureDocument7 pagesPGN Commissioning ProcedureAndreas Schlager100% (4)

- LPG Panjang Project Information LPG Presentation Share1Document35 pagesLPG Panjang Project Information LPG Presentation Share1swatched100% (1)

- Msog-M1402-P-Rp-006 Rev 1Document44 pagesMsog-M1402-P-Rp-006 Rev 1Mohd Nazir NorlanNo ratings yet

- TIMAS-PR-PI-001 - Hot Tapping ProcedureDocument11 pagesTIMAS-PR-PI-001 - Hot Tapping ProcedureMechanical Static WRKNo ratings yet

- 26071-100-VSC-MAH0-40023 - Method Statement For Installation Fire Fighting System (Equipment Safety and Fire Suppression System) - 001Document27 pages26071-100-VSC-MAH0-40023 - Method Statement For Installation Fire Fighting System (Equipment Safety and Fire Suppression System) - 001ogyrisky100% (1)

- Procedure of CrossingDocument68 pagesProcedure of Crossingrizalbaso100% (4)

- MOS For InstrumentationDocument6 pagesMOS For Instrumentationrenjithv_4100% (1)

- To HQ 02 027 00 PhilosophyforFlowMeteringSystems OnshoreDocument12 pagesTo HQ 02 027 00 PhilosophyforFlowMeteringSystems OnshoreagaricusNo ratings yet

- Procedure - Tie-In To Existing FacilitiesDocument8 pagesProcedure - Tie-In To Existing FacilitiesjabpunNo ratings yet

- Automatic Tank GaugingDocument4 pagesAutomatic Tank Gaugingvishnunair27No ratings yet

- Freshmen Electrical Engineering Training CourseDocument20 pagesFreshmen Electrical Engineering Training CourseFadlur RahmanNo ratings yet

- PC-J-95 Instrument Loop Check (Analogue Inputs)Document1 pagePC-J-95 Instrument Loop Check (Analogue Inputs)Memyhu MahmudahNo ratings yet

- List of CPI Specification & StandardDocument6 pagesList of CPI Specification & StandardErick SavrinaldoNo ratings yet

- 4 - Custody Transfer SystemlDocument24 pages4 - Custody Transfer SystemlBassem Balghouthi100% (1)

- 4.SOP Emergency Shut DownDocument5 pages4.SOP Emergency Shut DownDodik NugrohoNo ratings yet

- LTJ Ins 002 - (Ifb)Document11 pagesLTJ Ins 002 - (Ifb)sswahyudiNo ratings yet

- EDG Commissioning - Activity ReportDocument3 pagesEDG Commissioning - Activity ReportmohamedNo ratings yet

- MJPN PGAS 3514 GA PR 012 - Construction and As Build Survey Procedure - E - RevADocument19 pagesMJPN PGAS 3514 GA PR 012 - Construction and As Build Survey Procedure - E - RevABayu Setiawan100% (1)

- LNG Pipeline SystemDocument46 pagesLNG Pipeline SystemfanhadNo ratings yet

- Instrument Loop CheckDocument3 pagesInstrument Loop Checknayum100% (1)

- Instruments Hookup BOQDocument2 pagesInstruments Hookup BOQSijo JoyNo ratings yet

- Instrument Installation RequirementsDocument98 pagesInstrument Installation Requirementszelda1022100% (3)

- Inspection and Test Plan: On-Shore Pipeline CertificationDocument2 pagesInspection and Test Plan: On-Shore Pipeline CertificationKayra Riri Chirul100% (1)

- Instrument Loop Testing ProcedureDocument9 pagesInstrument Loop Testing ProcedureSusanto Pausinugroho100% (1)

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFDocument612 pagesGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahNo ratings yet

- Install Insulation SOPDocument5 pagesInstall Insulation SOPnida ahmad musyafa ptasrNo ratings yet

- HSE Plan Contractor Pertamina Retrofit PIN (Assesment & Trouble Shooting PC CEMSDocument21 pagesHSE Plan Contractor Pertamina Retrofit PIN (Assesment & Trouble Shooting PC CEMSNanangAji100% (3)

- Method Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWDocument8 pagesMethod Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWsugeng wahyudiNo ratings yet

- Cathodic Protection System Inspection and Test PlanDocument10 pagesCathodic Protection System Inspection and Test PlanNoor A QasimNo ratings yet

- RFQ For Pressure TransmitterDocument21 pagesRFQ For Pressure Transmittersugeng wahyudiNo ratings yet

- HPCL safety procedure pre-commissioningDocument14 pagesHPCL safety procedure pre-commissioningVineet AgrawalNo ratings yet

- Itp PipingDocument12 pagesItp PipingCak Nhass100% (1)

- Pre-Commissioning and CommissioningDocument9 pagesPre-Commissioning and CommissioningSaurabh Sharma100% (6)

- Prosedur Kerja Tie-In Pipa 10 Dan Demolish Pipa 8Document7 pagesProsedur Kerja Tie-In Pipa 10 Dan Demolish Pipa 8Rio Cristovan MantiriNo ratings yet

- METHOD STATEMENT FOR HYDRO-TESTING OF CONDENSATE DRAIN PIPINGDocument7 pagesMETHOD STATEMENT FOR HYDRO-TESTING OF CONDENSATE DRAIN PIPINGAnish KumarNo ratings yet

- SDFGHJKLDocument1 pageSDFGHJKLAriz Joelee ArthaNo ratings yet

- HGFDDocument1 pageHGFDAriz Joelee ArthaNo ratings yet

- Echivalenta INCH METRIC For Bolt Stud Dimensions For Ansi FlangesDocument1 pageEchivalenta INCH METRIC For Bolt Stud Dimensions For Ansi FlangesVasilica Barbarasa100% (1)

- FLOW COMPUTER VALIDATIONDocument11 pagesFLOW COMPUTER VALIDATIONAriz Joelee ArthaNo ratings yet

- RP 42.1Document16 pagesRP 42.1Ariz Joelee ArthaNo ratings yet

- Table Am Tool 05Document16 pagesTable Am Tool 05Ariz Joelee ArthaNo ratings yet

- KIM DATA SHEET GAS ANALYZERS REV 0 From PTGDocument6 pagesKIM DATA SHEET GAS ANALYZERS REV 0 From PTGAriz Joelee ArthaNo ratings yet

- ControlWave Micro - Hybrid RTUPLC - CE Certification For ControlWave Process Automation Controller.Document1 pageControlWave Micro - Hybrid RTUPLC - CE Certification For ControlWave Process Automation Controller.Ariz Joelee ArthaNo ratings yet

- ControlWave Micro - Hybrid RTUPLC - CE Certification For ControlWave Process Automation Controller.Document1 pageControlWave Micro - Hybrid RTUPLC - CE Certification For ControlWave Process Automation Controller.Ariz Joelee ArthaNo ratings yet

- ControlWave Micro - Hybrid RTUPLC - ATEX Certification For ControlWave Micro.Document11 pagesControlWave Micro - Hybrid RTUPLC - ATEX Certification For ControlWave Micro.Ariz Joelee ArthaNo ratings yet

- Datasheet Ei Bimetal ThermometerDocument2 pagesDatasheet Ei Bimetal ThermometerlyorhitmaNo ratings yet

- PFD Ngoro-1Document1 pagePFD Ngoro-1Ariz Joelee ArthaNo ratings yet

- Corporate Network LicenseDocument1 pageCorporate Network LicenseAriz Joelee ArthaNo ratings yet

- RP 311Document38 pagesRP 311kirandevi1981No ratings yet

- RP 55.1Document94 pagesRP 55.1Ariz Joelee ArthaNo ratings yet

- Ptg-kcs-30 Inst Dwg-1001 Skid General Arrangement Drawing Gas Meter From PTGDocument4 pagesPtg-kcs-30 Inst Dwg-1001 Skid General Arrangement Drawing Gas Meter From PTGAriz Joelee ArthaNo ratings yet

- RP 37.2Document36 pagesRP 37.2Ariz Joelee ArthaNo ratings yet

- RP 60.4Document30 pagesRP 60.4Ariz Joelee ArthaNo ratings yet

- Inspection Report Summary GC DanalyzerDocument5 pagesInspection Report Summary GC DanalyzerAriz Joelee ArthaNo ratings yet

- Terminology, Dimensions, and Safety Practices For Indicating Variable Area Meters (Rotameters)Document14 pagesTerminology, Dimensions, and Safety Practices For Indicating Variable Area Meters (Rotameters)kirandevi1981No ratings yet

- Corporate Network LicenseDocument1 pageCorporate Network LicenseAriz Joelee ArthaNo ratings yet

- Installation of RotametersDocument14 pagesInstallation of Rotameterspandan27No ratings yet

- Invoice To DJA 068Document1 pageInvoice To DJA 068Ariz Joelee ArthaNo ratings yet

- Ptg-Kcs 40 - Inst Dts-2002 Data Sheet Gas Analyzers Rev 0 From PTGDocument6 pagesPtg-Kcs 40 - Inst Dts-2002 Data Sheet Gas Analyzers Rev 0 From PTGAriz Joelee ArthaNo ratings yet

- Ngc8206 Data SheetDocument8 pagesNgc8206 Data SheetAriz Joelee ArthaNo ratings yet

- Ptg-kcs-30 Inst Dwg-1011 P&id Skid Gas Metering (Only) Rev 0 (1 Sheet) From PTGDocument1 pagePtg-kcs-30 Inst Dwg-1011 P&id Skid Gas Metering (Only) Rev 0 (1 Sheet) From PTGAriz Joelee ArthaNo ratings yet

- MMC Manual MMC Flexi-Dip D-2401Document53 pagesMMC Manual MMC Flexi-Dip D-2401BigBaby Julian100% (1)

- Ptg-kcs-40 Inst Dwg-2001 Skid General Arrangement Drawing Gas Meter Rev 0 (4 Sheet)Document4 pagesPtg-kcs-40 Inst Dwg-2001 Skid General Arrangement Drawing Gas Meter Rev 0 (4 Sheet)Ariz Joelee ArthaNo ratings yet

- Ptg-kcs-30 Inst Dwg-1002 System Architecture Gas Meter Rev 0 (1 Sheet) From PTGDocument1 pagePtg-kcs-30 Inst Dwg-1002 System Architecture Gas Meter Rev 0 (1 Sheet) From PTGAriz Joelee ArthaNo ratings yet

- Ptg-kcs-40 Inst Dwg-2002 System Architecture Gas Meter Rev 0 (1 Sheet)Document1 pagePtg-kcs-40 Inst Dwg-2002 System Architecture Gas Meter Rev 0 (1 Sheet)Ariz Joelee ArthaNo ratings yet

- Power Shuttle, Valve Assembly Without Pto PDFDocument3 pagesPower Shuttle, Valve Assembly Without Pto PDFRetropartes AcevedoNo ratings yet

- Well Completion Equipment OverviewDocument91 pagesWell Completion Equipment OverviewRanim Hisham100% (1)

- Centrifugal Fan, Blowers and CompressorsDocument41 pagesCentrifugal Fan, Blowers and CompressorsAjejejeNo ratings yet

- Compressor Anti-Surge ValveDocument2 pagesCompressor Anti-Surge ValveMoralba SeijasNo ratings yet

- 07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFDocument8 pages07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFfotickNo ratings yet

- Piping Arrangement Around PumpDocument7 pagesPiping Arrangement Around Pumpanung_scribdNo ratings yet

- 4058 CZ SG 0000000006 IS0 Pressure Vessels Standard DrawingsDocument89 pages4058 CZ SG 0000000006 IS0 Pressure Vessels Standard DrawingsAhmed AbidNo ratings yet

- H GP SpecificationsDocument5 pagesH GP Specificationszss84No ratings yet

- GDJP Q BabkkDocument6 pagesGDJP Q BabkkganeshkumarbemechNo ratings yet

- Piping Material Specification 2010014 00 l0 Gs 001Document215 pagesPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- Bungartz enDocument10 pagesBungartz enmaheshthemtb_8197478No ratings yet

- Fire Water Hydraulic CalculationsDocument23 pagesFire Water Hydraulic Calculationsmano.ahanjNo ratings yet

- Gate Valves: Flexible Wedge PN 40-160 DN 50-600Document2 pagesGate Valves: Flexible Wedge PN 40-160 DN 50-600Radoo NephilaNo ratings yet

- Surface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFDocument14 pagesSurface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFKaleem UllahNo ratings yet

- Steam Traps - Impulse Type Working PrincipleDocument3 pagesSteam Traps - Impulse Type Working PrincipleTimmyJuriNo ratings yet

- Tormene: L 5-10 X DNDocument1 pageTormene: L 5-10 X DNRoyer LeonNo ratings yet

- Equipment Design Problems (EDR-1) (Fluids-Handling Equipment)Document13 pagesEquipment Design Problems (EDR-1) (Fluids-Handling Equipment)Franz Patrick CamaroNo ratings yet

- Chapter 3 Part 1Document26 pagesChapter 3 Part 1Yohannes EndaleNo ratings yet

- Unit 4 Combustion Chamber PresentationDocument25 pagesUnit 4 Combustion Chamber PresentationADVAITH P SHETTYNo ratings yet

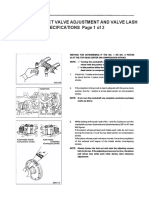

- Hino H07C H07CT Valve Adjustment and Valve Lash Clearance SpecificationsDocument2 pagesHino H07C H07CT Valve Adjustment and Valve Lash Clearance Specificationsferran_alfonso0% (1)

- TECNI AR Parker Store Brasil HY11 3362 Press Control PPCC UKDocument30 pagesTECNI AR Parker Store Brasil HY11 3362 Press Control PPCC UKItamar SchuhNo ratings yet

- Hydraulics NotesDocument16 pagesHydraulics NotesMadhusudhan ReddyNo ratings yet

- GT 5-8 Alarm Trip ListDocument3 pagesGT 5-8 Alarm Trip Listmuddasirmasood100% (1)

- Kec FLUID MACHINERYDocument3 pagesKec FLUID MACHINERYanadinath sharmaNo ratings yet

- ASTM standards and specifications for polyethylene plastic pipesDocument2 pagesASTM standards and specifications for polyethylene plastic pipesAnonymous wze4zUNo ratings yet

- Rac MCQ'SDocument15 pagesRac MCQ'SGanesh100% (2)

- Well Intervention Operation FlyerDocument21 pagesWell Intervention Operation Flyerfakhrurrozi arbianNo ratings yet

- Turbulent Boundary Layer: Global ParametersDocument49 pagesTurbulent Boundary Layer: Global Parametersshehbazi2001No ratings yet

- 6011 Dominionfittings CatalogueDocument154 pages6011 Dominionfittings CatalogueVijay ThimmappaNo ratings yet

- Core Flooding Manual-1Document6 pagesCore Flooding Manual-1Boniphace JohnNo ratings yet