Professional Documents

Culture Documents

System Design and Experimental Results of Progressive Freeze Concentration System

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System Design and Experimental Results of Progressive Freeze Concentration System

Copyright:

Available Formats

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

System Design and Experimental Results of

Progressive Freeze Concentration System

Tipole Pralhad1, Patil Abhaysinha2, Ponathil Amal3, Oak Ninad4, Salvekar Pinak5

1

Assistant Professor, Department of Mechanical Engineering, Sinhgad Academy of Engineering, Kondhwa, Pune

2,3,4,5

Graduate Assistant, Department of Mechanical Engineering, Sinhgad Academy of Engineering, Kondhwa, Pune

ABSTRACT

The progressive freeze concentration process involves lowering the temperature of liquid food below freezing point of water in a

controlled manner in order to avoid reaching the eutectic temperature at which all the components of the liquid food solidifies

at once. If it reaches the eutectic point of the liquid food, separation is very difficult. The aim is to obtain a very pure ice, i.e.

only water, without retaining any of the solids in it. The purpose of removing this ice is to obtain a concentrated liquid product.

Concentration by freezing is the system that comes closest to the ideal objective of separating water from the liquid food

product without affecting the other components as its nutrition value, aroma and taste. This technique is very suitable for the

concentration of thermo sensitive liquid foods. Concentration of liquid food obtained in this method is higher as compare to

other methods. PFC is very flexible and is applicable to various liquid foods. This is applicable not only to food industry but

also various other industries like nuclear, chemical, ammunition and refrigeration systems etc.

Keywords: Eutectic Temperature, Concentrated liquid product, Thermo sensitive liquid foods, Nuclear, Chemical,

Ammunition and refrigeration systems.

1. Introduction

The progressive freeze concentration process is used to separate the water from liquid food. The progressive freeze

concentration process involves lowering the temperature of the liquid food below freezing point of water in a controlled

manner in order to avoid reaching the eutectic temperature. Eutectic temperature is the temperature at which all the

components of the liquid food solidify. If process reaches the eutectic point of the liquid food, separation is very

difficult. The aim is to obtain a very pure ice, without retaining any of the solids in it [1].

There are three methods available to remove water from the liquid food,

1. Heating

2. Reverse Osmosis

3. Freeze Concentration

Concentration by freezing is the system that comes closest to the ideal objective of separating water from the liquid food

product without affecting the other components as its nutrition value, aroma and taste. This technique also increases

food life. This technique is very suitable for the concentration of thermo sensitive liquid foods. [1, 3]

Freeze concentration is again divided into to two types:

A. Suspension Crystallization

B. Progressive freeze concentration

Progressive freeze crystallization (PFC) is a simpler method with single ice crystal. As the process does not involve any

heating most of the volatile organic components will stay in the concentrated solution and the water obtained from the

Progressive freeze concentration is pure water so this method can be applied for the wastewater treatment.

Concentration of liquid food obtained in this method is higher as compare to other methods. PFC is very flexible system

and is applicable to various liquid foods with wide ranged physical properties, even to emulsion and suspension. [2]

2. Objective

Food being stored may become spoiled in three ways:

1. Living organism.

2. Biochemical activity within the food itself (e.g. respiration, staling, browning and rancidity development).

3. Physical process (e.g. bursting and spillage of the contents of package or recrystallization phenomena in sugar

confectionery, fats and frozen products).

The three main factors of the storage environment which influence the storage life of a particular commodity are the

temperature, humidity and the composition of the store atmosphere. The most important factor of them is temperature.

It is well known that temperature controls the rate of all physiochemical reactions and as a consequence temperature

has a profound effect on the biological system.

Volume 4, Issue 7, July 2015

Page 15

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

Figure 1: Temperature Vs Bacteria growth rate

The rate of growth of bacteria is reduced as the temperature falls. Lowering the temperature of a product will reduce its

rate of deterioration. The cooling of food is defined as a process which makes the temperature of food to decrease to a

temperature just above the freezing point of foods. Cooling can prolong the storage duration of the foods. It is easy to

understand that the cooling process involves the removal of thermal energy from a food product in an effort to reduce

the temperature to some level below that of ambience as well as to reduce the associated deterioration reaction

occurring in the product. [2]

3. Theory

The initial freezing temperature for a food product is always lower than the freezing temperature of water. This

depression of the freezing temperature for water is the result of soluble solutes in the product liquid phase. In addition,

the characteristic shape of the temperature-history curve during freezing is the result of continuous concentration of the

soluble solutes within the product. Since the concentration of solutes occurs as the freezing process continues, the

formation of ice crystals and the corresponding removal of latent heat occurs over a range of temperatures. During

typical food freezing, this gradual removal of latent heat will continue until the freezing process is completed and a

small fraction of unfrozen water remains in the product.

In other words, freezing commences when the temperature reaches just below 0C, when the liquid in food will become

solid, and a typical phase change takes place. It is well known that a large amount of energy exchange must accompany

a phase change of materials. Hence a large amount of latent heat of fusion in addition to sensible heat must be removed

in order to produce further cooling. The amount of heat extracted during a process of phase change is much greater

compared with a process of sensible heat change. It is more correctly defined as the removal of heat from a substance to

bring it to or keep it at a desirable low temperature, which is below the temperature of the surroundings. [4]

It is observed that heat and work are two mutually convertible forms of energy, and this is the basis of the First Law of

thermodynamics. It is also known as the principle of the conservation of energy. It is stated in the following way,

Energy can neither be created nor destroyed but it can be converted from one form to another, when one form of

energy disappears another form of energy appears while total energy of universe remains constant. [4]

Figure 2: Ideal freezing curve of solution

Initially the solution cools the same way the solvent did. At this freezing temperature, "A", however, the solvent starts

to crystallize out and the rate of cooling decreases sharply. This is because heat is added as the solvent crystallizes. As

more and more solvent freezes out, the liquid portion of the solution becomes more concentrated. The increasing

concentration lowers the equilibrium temperature between liquid and solid phases. Because there is only a fixed amount

Volume 4, Issue 7, July 2015

Page 16

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

of solute, as more and more ice is formed, the concentration increases at an exponential rate. Finally the ratio of solvent

in the liquid portion increases to the point where the solubility limit (eutectic point, "B"), is reached.

As more solvent is frozen out, the solute precipitates out at a corresponding rate, which keeps the temperature constant.

Finally, at "C", all the solvent becomes solid and the solid mass cools down to the bath temperature. But liquid foods

have the phenomenon of super cooling then this curve changes.

1. Nucleation

Freezing of water or a solution will not occur until nuclei are present to initiate crystallization. When the first ice

crystal forms, it starts nucleation and the solidification process. Two types of nucleation are possible [4, 5]

I. Homogeneous Nucleation: Water if exceedingly pure, is limited to nucleation of the homogeneous type. In very pure

water, the "nucleus" is water molecules orienting as crystals. A homogeneous nucleus forms by chance orientation of a

suitable number of molecules into a tiny ordered particle. Homogeneous nucleation is impossible at 0C and does not

become probable until the temperatures are reduced many degrees below 0oC, particularly if the sample is very small.

Homogeneous nucleation is of no concern with most practical situation.

II. Heterogeneous Nucleation: Heterogeneous or catalytic nucleation is the type that occurs in foods and living

specimens. Heterogeneous nucleation involves the formation of nuclei adjacent to suspended foreign particles, surface

film, or on the walls of containers. Although heterogeneous nucleation necessitates some super cooling, it is more

probable to occur than homogeneous nucleation at any given temperature and fixed sample. As the temperature is

lowered to some critical value characteristic of the sample, nucleation begins, and further decreases in temperature

result in an abrupt increase of rate

4. System Design

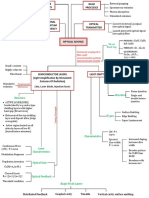

Figure 3:Schematic Representation of the system

I. Schematic Representation

1. Compressor

2. Condenser

3. Expansion Valve

4. Evaporator

5. Storage Tank 1

6. Storage Tank 2

The system works in the temperature -5OC (Evaporator Temperature) to 45OC (Condenser Temperature).

Figure 4:p-h chart of R134a

Volume 4, Issue 7, July 2015

Page 17

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

From pressure-enthalpy chart,

h1 = hg1 = 395KJ/Kg

h3 = h4 = hf3 = 265KJ/Kg

Therefore from the entropy equation of superheated vapour,

Sg1 = Sg2 + Cpg * loge(Tsup2/T2)

(1)

1.73 = 1.2133 + 1.52*loge (Tsup2/318)

Tsup2 = 446K

And

h2 = hg2 + Cpg * loge(Tsup2-T2)

h2 = 263.8 + 1.52*(446-318)

h2 = 459.50KJ/Kg

(2)

And compressor work is,

W = h2 - h1

W = 459.5-395

W = 64.5KJ/Kg

(3)

Q = h2 - h3

Q = 459.5-265

Q = 194.5KJ/Kg

(4)

rE = h1 - h4

rE = 395-265

rE = 130KJ/Kg

(5)

Heat rejected in condenser, Q:

Net refrigeration effect, rE:

COP of system from P-h Chart

COP = rE / W

= 130/64.5

COP = 2.01

(6)

II. Evaporator Capacity

We select milk as our cooling load,

Tests quantity of milk = 10 lit.

Mass of milk = 10 e-3 m3

= 10 e-3 * 1030

= 10.3 Kg

Specific heat of milk = 3.99 kJ/kg

Temperature difference = 27-(-5)

= 32OC

= 305 K

Time = 120 minutes

= 7200 sec

Evaporator capacity = mm * Cpm * (Ti Tf) / Time

= 10.3 * 3.99 * 32/7200

= 0.183 KW

Assuming 20 % for unaccounted losses,

Evaporator capacity, RE = 1.2 * 0.183

RE = 0.219 KW

Calculation of mass flow rate of refrigerant, mR

RE = mR * (h1 h4)

0.219 = mR * (130)

mR = 1.684 e-3 Kg/s

Volume 4, Issue 7, July 2015

(7)

(8)

Page 18

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

Isentropic Compressor Power, P

P = mR*(h2 h1)

= 1.684e-3 *(64.5)

P = 108.618 Watts

(9)

Expected COP of the system = RE / P

(10)

= 219/108.618

COP = 2.01

Condenser Capacity, Qc = mR * ( h2 h3)

(11)

= 327.53 Watts

Assuming 20 % for unaccounted losses,

Qc = 342.16 Watts

III. Design of Compressor

It is standard part so we are directly going to select it as per our refrigerating load capacity.

IV. Design of Condenser

The function of condenser is to remove heat from the superheated high pressure refrigerant vapour and to condense the

vapour into a sub-cooled high pressure refrigerant liquid.

Condenser pressure = 11.6 bar

Assuming U = 1500 W/m2k

QC = U * A * T

342.16 = 1500 * A * (303-300)

A = 0.07603 m2

(12)

Assuming d = 0.01m, L = 0.25m

A=N**d*L

0.07603 = N * * 0.01 * 0.25

N = 9.68 = 10 turns

(13)

V. Design of Expansion device

An expansion device is a link between condenser and evaporator. As the high pressure sub cooled refrigerant liquid

from the condenser passes through the expansion device its pressure and temperature reduce and we get at its outlet low

pressure, low temperature refrigerant mostly in liquid stage.

The pressure drop across the expansion device is determined by the desired operating pressures of the system. Once this

is fixed, the size of expansion device has to be so adjusted that it will allow the required refrigerant mass flow

(determined by compressor capacity) at the required pressure drop.

Expansion devices are of many types and are selected as per the requirement. As our cooling load is fixed we use

capillary tube as expansion device.

Consider Capillary tube Dia. 2.3mm

mr = 0.00145Kg/s

Area = 4.1510-6 m2

G = m/A = 590.361Kg/m2s

X = (hk-hf1)/(hg1-hf1) = 0.0303

V = Vf1+X1(Vg1-Vf1) = 8.56510-4 m3/kg

Table No. 1: Tabulated Results

Ts

hf

hg

X

Vf10-3

Vg

o

KJ/Kg.K

KJ/Kg.K

m3/Kg

m3/Kg

C

V10-4

m3/Kg

45

260

425

0.8563

0.02304 8.565

25

255

420

0.030

0.8287

0.03095 0.1743

235

415

0.1388 0.80205

0.04355 0.6735

-5

210

405

0.2564 0.78245

0.0584

Volume 4, Issue 7, July 2015

1.55

Page 19

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

VI. Sample Calculation

pa = G* du = 1.59

pf = p-pa = 2.2149

= [(1-x1)* f ]+x1* g = 170.4910-6 N.S/m2

Re = G*D/ = 65536

f = 0.32/Re0.25 = 0.02

L = (pf * 2*D)/f*G*u = 2.196m

Table No. 2: Sample Calculation results

v10-4 u

p

pa

pf

(G*V)

m3/Kg

Bar

Bar

Bar

m/sec

Ts

Ps

0C

Bar

45

8.875

8.565

0.5053 0

2.196

25

6.656

0.1743

1.0238 2.2165

1.59

2.2149

0.5764

4,7365

0.6735

3.9738 1.9195

8.98

1.9105

0.2040

-5

3.498

1.55

9.1745 1.2385

15.85

1.2226

Total capillary length = L= 2.976 m.= 3m

VII. Design of Evaporator

Evaporator is the main component of refrigeration system in which actually refrigerant effect is produced. The function

of evaporator is to remove heat from the product or the area to be cooled and to maintain it at desired temperature.

While designing the evaporator we must consider the resistance acting during transfer of heat.

1. Inner convective thermal resistant, Ri.

2. Conductive thermal resistance due to copper wall, R1.

3. Outer convective thermal resistance, Ro.

Figure 5:Different Resistances during transfer of heat

R = Ri + R1+ Ro

(14)

As thickness of the tube is very small and coefficient of thermal conduction (K) is very high for copper, Therefore,

neglecting conductive thermal resistance due to copper wall.

(15)

As thickness of the tube is very small and coefficient of thermal conduction (K) is very high for copper, Therefore,

neglecting conductive thermal resistance due to copper wall.

That is

r2 = r1

Ao = Ai

Volume 4, Issue 7, July 2015

Page 20

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

Then equation becomes,

(16)

Evaporator Pressure: 2.5 bar

Evaporator capacity = 0.06TR = 219W.

Assume, hi = 360 W/m2k and

h0 = 60 W/m2k

Therefore, from equation (3)

U = 50W/m2k

QH = U * A * T

219 = 50 * A * (32)

A = 0.14 m2

Assuming D = 0.015m and L= 0.3m

A=N**D*L

0.14 = N * * 0.015 * 0.3

N = 9.9 = 10 turns

Figure 6:Actual Project Setup

5. Observations

Room temperature: 27 C

Food sample: Orange juice (0.5 litres)

Initial brix: 14.6

Density of juice: 1050 kg/m3

Compressor outlet temperature: 28 oC

Condenser temperature: 59 oC

Evaporator Temperature: -20 oC

6. Results & Discussions

Sr. No.

1

2

3

Table No. 3: For evaporator plate angle 20 degree

Time in minutes

Brix in

T

Concentrated Sample

0

14.6

10

14.7

20

14.8

Volume 4, Issue 7, July 2015

Ice Concentrate

14.6

14.5

14.3

Page 21

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

4

5

6

7

30

40

50

60

15

15.3

15.5

15.7

ISSN 2319 - 4847

14.1

13.9

13.6

13.5

Figure 7: Time Vs Brix

At 20 degree plate angle an orange juice of 0.5 litres quantity can be successfully concentrated from 14.6 to 15.7 Brix

in batch process.

Sr. No.

1

2

3

4

5

6

7

Table No. 4: For evaporator plate angle 30 degree

Time in minutes

Brix in

T

Concentrated Sample

0

14.6

10

14.6

20

14.7

30

14.9

40

15

50

15

60

15.2

Ice Concentrate

14.6

14.5

14.4

14.2

14

13.8

13.7

Figure 8: Time Vs Brix

Volume 4, Issue 7, July 2015

Page 22

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

At 30 degree plate angle an orange juice of 0.5 litres quantity can be successfully concentrated from 14.6 to 15.2 Brix

in batch process.

Sr. No.

1

2

3

4

5

6

7

Table No. 5: For evaporator plate angle 60 degree

Time in minutes

Brix in

T

Concentrated Sample

0

14.6

10

14.6

20

14.7

30

14.7

40

14.8

50

14.9

60

15

Ice Concentrate

14.6

14.6

14.5

14.3

14.1

14

13.9

Figure 9: Time Vs Brix

At 60 degree plate angle an orange juice of 0.5 litres quantity can be successfully concentrated from 14.6 to 15 Brix in

batch process.

Calculations

7. Conclusion

By varying the evaporator plate angle an orange juice of 0.5 litres quantity was successfully concentrated with semi

industrial equipment, in batch process.

At 20 degree plate angle an orange juice can be concentrated from 14.6 to 15.7 brix in batch process.

At 30 degree plate angle an orange juice can be concentrated from 14.6 to 15.2 brix in batch process.

At 60 degree plate angle an orange juice can be concentrated from 14.6 to 15 brix in batch process.

It can be seen that as evaporator plate angle increases juice flow rate also increases and because of which juice

concentration rate decreases. So the evaporator plate angle is kept less than 45 degree for effective freeze concentration.

REFERENCES

[1] Petzold, G., & Aguilera, J. M. (2009). Ice morphology: Fundamentals and technological applications in foods.

Foods Biophysics, 4, 378396.

[2] Choi, Y., &Okos, M. R. (1986). Effects of temperature and composition on the thermalproperties of foods. Food

engineering and process applications (pp. 93101).London: Elsevier Applied Science Publishers

Volume 4, Issue 7, July 2015

Page 23

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 4, Issue 7, July 2015

ISSN 2319 - 4847

[3] Aider, M., & de Halleux, D. (2009). Cryoconcentration technology in the bio-food industry: Principles and

applications. LWT Food Science and Technology, 42,679685.

[4] Nonthanum, P., &Tansakul, A. (2008). Freeze concentration of lime juice. MaejoInternational Journal of Science

and Technology, 1, 2737.

[5] Freeze Concentration in the Fruit Juices Industry Food Science and Technology International August

2009 15: 303-315, first published on October 15, 2009.

Volume 4, Issue 7, July 2015

Page 24

You might also like

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 pagesSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 pagesA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Impact of Effective Communication To Enhance Management SkillsDocument6 pagesThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 pagesPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 pagesChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 pagesAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Detersolv CaDocument10 pagesDetersolv CaMainulHoqueNo ratings yet

- Redox ExerciseDocument4 pagesRedox ExerciseHau Hei, Matthew LinNo ratings yet

- Catalyticreformingprocess 17Document29 pagesCatalyticreformingprocess 17Sahil GuptaNo ratings yet

- Task No. 1 (Written Work) Direction: Problem Solving. Show Your Solution and Follow Proper Significant FiguresDocument2 pagesTask No. 1 (Written Work) Direction: Problem Solving. Show Your Solution and Follow Proper Significant FiguresMonica TanglaoNo ratings yet

- Chapter Three Amino Acids and Peptides: Mary K. Campbell Shawn O. FarrellDocument29 pagesChapter Three Amino Acids and Peptides: Mary K. Campbell Shawn O. FarrellSheila GarciaNo ratings yet

- By Niranjan S. L.N College of Engineering, Raichur.Document29 pagesBy Niranjan S. L.N College of Engineering, Raichur.alistuguiNo ratings yet

- On-Line Monitoring of Bacterial and Pathogen Load Through Adenosine TriphosphateDocument8 pagesOn-Line Monitoring of Bacterial and Pathogen Load Through Adenosine TriphosphateKhoiril NNo ratings yet

- MSCCH 506Document176 pagesMSCCH 50620tamilselvi-ugcheNo ratings yet

- Unit III Engine Exhaust Emission ControlDocument49 pagesUnit III Engine Exhaust Emission ControlMani Karthi100% (1)

- Aijstpme (2012) 5 (4) 7-20Document14 pagesAijstpme (2012) 5 (4) 7-20maziar60No ratings yet

- Api Melafix Safety Data Sheet PDFDocument10 pagesApi Melafix Safety Data Sheet PDFumaNo ratings yet

- Zinc Nickel Electroplating Guide ZyliteDocument9 pagesZinc Nickel Electroplating Guide ZyliteBryan DixNo ratings yet

- Question Phy 101Document19 pagesQuestion Phy 101Mohammed kashimNo ratings yet

- CPE 1ST YR CHEM ENGDocument3 pagesCPE 1ST YR CHEM ENGKhairie MahadiNo ratings yet

- Optimization of Biodiesel Production From Castor Oil by Taguchi DesignDocument12 pagesOptimization of Biodiesel Production From Castor Oil by Taguchi Designjuan estebanNo ratings yet

- Rishab IntroDocument4 pagesRishab IntroDeborsha DekaNo ratings yet

- A Project of Mechanics of MaterialsDocument13 pagesA Project of Mechanics of MaterialsShahZaib AnwarNo ratings yet

- Thermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)Document3 pagesThermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)rajaraghuramvarmaNo ratings yet

- Diffusivity Formula Chart (Infographic)Document3 pagesDiffusivity Formula Chart (Infographic)Safayet AzizNo ratings yet

- Triple Science Chemistry Chemical Analysis Revision QuestionsDocument32 pagesTriple Science Chemistry Chemical Analysis Revision QuestionsShakira MaribaoNo ratings yet

- Protocols Cleaning Disinfection SterilizationDocument23 pagesProtocols Cleaning Disinfection SterilizationGeneSegoviaNo ratings yet

- HW Proteins EnzymesDocument2 pagesHW Proteins Enzymesapi-524061079No ratings yet

- Suitable dimensions, performance requirements, and processes for optical transmittersDocument1 pageSuitable dimensions, performance requirements, and processes for optical transmittersshruti soniNo ratings yet

- Lecture 1 - AggregateDocument9 pagesLecture 1 - AggregateDuronto Pothik100% (1)

- Pre-Cal - Exponential Equations and Functions, and Logarithms WorksheetDocument5 pagesPre-Cal - Exponential Equations and Functions, and Logarithms WorksheetFons Roxas-ChuaNo ratings yet

- Kate Coleen D. Galera BS in Chemistry II May 4, 2017 Experiment 11 Acyl Compounds: Soaps and DetergentsDocument5 pagesKate Coleen D. Galera BS in Chemistry II May 4, 2017 Experiment 11 Acyl Compounds: Soaps and DetergentsKateNo ratings yet

- Philippine Red Cross Molecular Laboratory: Covid-19 RT-PCR Test Report & CertificationDocument1 pagePhilippine Red Cross Molecular Laboratory: Covid-19 RT-PCR Test Report & CertificationFrancis SevillenoNo ratings yet

- 00 Gas Conversion ChartsDocument6 pages00 Gas Conversion Chartskarun agrawalNo ratings yet

- Cosme Lab3 Mens Toiletries Group 1Document54 pagesCosme Lab3 Mens Toiletries Group 1just loveNo ratings yet

- Duplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document11 pagesDuplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Mathew CherianNo ratings yet