Professional Documents

Culture Documents

930 A&b MSDS 070109

Uploaded by

Dang Minh HuongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

930 A&b MSDS 070109

Uploaded by

Dang Minh HuongCopyright:

Available Formats

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part A Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

SECTION 1. PRODUCT IDENTIFICATION

PRODUCT NAME: JOHNSONITE 930 Part A

CHEMICAL FAMILY: Epoxy Resin, Part A

SECTION 2. HAZARDOUS INGREDIENTS AND EXPOSURE LIMITS

Chemical Name

% by

Weight

CAS Number

40-60

2-10

20-40

1-5

3-9

13 17-65-3

Proprietary

25085-99-8

85-68-7

68609-97-2

Calcium carbonate

Polyurethane prepolymer

Diglycidyl bisphenol A resin

Butyl benzene phthalate

Alkyl (C12-C14) glycidyl ether

EXPOSURE GUIDELINES

OSHA

ACGIH TLV TLV-TWA

OSHA PEL

10 mg/M3

10 mg/M3

10 mg/M3

Not established

Not established

Not available

Not established

Not established

Not established

Not established

Not established

5 mg/M3

5 mg/M3

Not established

Not established

SECTION 3. HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW: Causes eye irritation. Can cause respiratory irritation. Can cause central nervous

system depression. Can cause dermatitis.

POTENTIAL HEALTH EFFECTS:

EYE CONTACT: May cause severe irritation. May damage eyes.

SKIN CONTACT: Prolonged exposure may cause skin irritation May cause drying or flaking of skin. Skin

absorption of material may cause systemic toxicity.

INGESTION: Ingestion may cause severe injury to intestinal tract, liver, kidneys, stomach, throat, lungs, mouth and

mucous membranes. Harmful or fatal if swallowed. Do not ingest.

INHALATION: Overexposure may cause severe respiratory tract irritation. Prolonged overexposure may

cause central nervous system depression with narcotic effects (headaches, dizziness). Keep

exposure below OSHA exposure limits.

SECTION 4. FIRST AID MEASURES

EYES: Immediately flush eyes with plenty of water for at least 15 minutes. Get medical attention.

SKIN: Wash with soap and water. Get medical attention if irritation develops or persists. Immediately remove

contaminated clothing.

INGESTION: If swallowed, seek medical attention immediately.

INHALATION: Remove to fresh air. Restore breathing if necessary. Get medical attention. This material can

cause lung damage.

DO NOT LEAVE VICTIM UNATTENDED.

SECTION 5. FIRE-FIGHTING MEASURES

OSHA FLAMMABILITY CLASS:

FLASHPOINT:

LOWER EXPLOSIVE LIMIT:

UPPER EXPLOSIVE LIMIT:

Released January 2015

IIIB

>200F, >93C

Not applicable

Not applicable

Page 1 of 5

930-A MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part A Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

GENERAL HAZARD: May release flammable mixtures when temperatures are at or above the flash point. Toxic

gasses will form upon combustion. Closed containers may explode when exposed to extreme

heat. Vapors are heavier than air and may travel a considerable distance.

FIRE FIGHTING EQUIPMENT: Respiratory and eye protection required for firefighting personnel. Full protective

equipment and a self-contained breathing apparatus (SCBA) should be used in all indoor

fires and any large outdoor fires.

HAZARDOUS COMBUSTION PRODUCTS: Carbon monoxide, carbon dioxide, smoke and fumes, hydrocarbon

fragments.

SECTION 6. ACCIDENTAL RELEASE MEASURES

GENERAL INSTRUCTIONS: Keep all sources of ignition and hot metal surfaces away from spill. Isolate the danger

area and keep out unauthorized personnel. Stop spill if it can be done with minimal risk. Wear appropriate protective

equipment including respiratory protection as conditions warrant (see section 8). Prevent additional discharge of

material. Notify the appropriate authorities immediately. Contain spilled liquid with sand, earth or other noncombustible inert absorbent material. Prevent run-off from entering storm sewers, ditches or waterways. Transfer

absorbed waste material into properly identified drums. Treat waste material with same precautions as the adhesive.

Do not use solvent or flammable liquid to help clean up an accidental release.

Release to the environment may be reportable under environmental regulations.

SECTION 7. HANDLING AND STORAGE

HANDLING: Open container slowly to relieve any pressure. Do not enter confined spaces such as tanks without

following proper entry procedures as described in OSHA regulations at 29 CFR 1910.146. Do not

breathe vapors. The use of respiratory protection is recommended when airborne concentrations of

vapor exceed exposure guidelines. Wash thoroughly after handling. Do not wear contaminated clothing

or shoes. Wear appropriate protective gloves and clothing to prevent prolonged or repeated skin contact.

Avoid contact with eyes.

STORAGE: Keep containers tightly closed. Use and store this material in a cool, dry, well-ventilated area away

from heat, direct sunlight, hot metal surfaces, and all sources of ignition. Post area No Smoking or

Open Flames. Store only in approved containers. Protect containers against physical damage.

Indoor storage should meet OSHA standards and appropriate fire codes.

EMPTY CONTAINERS: May contain liquid and vapor residue and may be dangerous. Do not pressurize, cut, weld,

braze, solder, drill, grind, or expose such containers to heat, flame, sparks, or other sources of ignition.

They may explode and cause injury and death. Empty drums should be completely drained, properly

bunged, and promptly shipped to the supplier or a drum reconditioner. All containers should be

disposed of in accordance with governmental regulations.

Wash with soap and water before eating, drinking, smoking or using toilet facilities.

Consult NFPA and OSHA codes.

SECTION 8. EXPOSURE CONTROLS/PERSONAL PROTECTION

Released January 2015

Page 2 of 5

930-A MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part A Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

RESPIRATORY PROTECTION: A NIOSH/MSHA approved air purifying respirator with an organic vapor cartridge

may be used under conditions where airborne concentrations are expected to exceed exposure

guidelines. Protection provided by air purifying respirators is limited. Refer to respirator

manufacturers selection guide for appropriate respirator for conditions encountered. If in doubt, seek

the advice of an industrial hygienist or safety professional for appropriate air purifying respiratory

equipment.

Use positive pressure air supplied respirator if there is potential for an uncontrolled release,

exposure levels are not known, or in any other circumstances where air purifying respirators may

not provide adequate protection. When respiratory protection is used, a respiratory protection

program meeting OSHA regulations at 29 CFR 1910.134 must be followed.

SKIN PROTECTION: The use of gloves impermeable to the specific material handled is advised to prevent

prolonged or repeated skin contact. Where splashing is likely to occur, aprons impermeable to the

specific material may be worn. Refer to the glove and protective clothing manufacturers selection

guide for appropriate material.

EYE PROTECTION: Approved chemical splash goggles should be worn to safeguard against potential eye

contact, irritation or injury. Where splashing is likely to occur, hard hats and face shields may be

used to provide additional protection. Eye wash facilities should be available in the work area.

ENGINEERING CONTROLS: Provide sufficient mechanical ventilation to maintain exposure below TLV(s). The use of

local exhaust ventilation is recommended. Provide mechanical ventilation of confined spaces. If

current ventilation practices are not adequate to maintain airborne concentrations below the established

exposure guidelines, additional ventilation or exhaust systems may be required

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

APPEARANCE AND ODOR: Beige paste with low odor.

SPECIFIC GRAVITY:

Approx 1.3 (68F -20C)

pH:

Not applicable

BOILING POINT

>425oF, >218oC

FREEZING POINT:

<30oF, <-1oC

SOLUBILITY IN WATER:

Not Soluble

% SOLIDS (BY WEIGHT):

>99%

% VOLATILE (BY WEIGHT): <1%

VAPOR PRESSURE (MM of MERCURY): <1mm of Hg @ 68oF, 20oC

VAPOR DENSITY(air=1):

Heavier than air.

EVAPORATIONRATE (BUTYL ACETATE = 1): Slower than butyl acetate

EVAPORATION RATE (ETHYL ETHER = 1): Slower than ethyl ether

SECTION 10. STABILITY AND REACTIVITY

CHEMICAL STABILITY: Keep away from flames and spark producing equipment. Not dangerously unstable.

Avoid buildup of static electricity.

INCOMPATIBLE MATERIALS: Strong oxidizing agents, strong reducing agents, acids, bases, or unstable

chemicals, chloroform, nitric compounds, peroxides, sulfur dichloride, strong alkalis, amines,

anhydrides, mercaptans, materials that react with epoxies.

Released January 2015

Page 3 of 5

930-A MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part A Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

HAZARDOUS DECOMPOSITION PRODUCTS: Hazardous decomposition is unlikely to occur, but under fire

or extreme heat conditions, carbon monoxide, carbon dioxide, smoke and fumes, and hydrocarbon

fragments can be released.

HAZARDOUS POLYMERIZATION: Will not occur.

SECTION 11. TOXICOLOGICAL INFORMATION

MATERIAL:

Calcium carbonate

Polyurethane prepolymer

Diglycidyl bisphenol A resin

Butyl benzene phthalate

Alkyl (C12-C14) glycidyl ether

SKIN (Dermal LD50):

Not available

Not available

20,000 mg/kg (Rabbit)

>10,000 mg/kg (Rabbit)

>4,500 mg/kg (Rabbit)

CHRONIC:

None known.

INGESTION (Oral LD50):

6,450 mg/kg Oral/Rat

>5,000 mg/kg Oral/Rat

>5,000 mg/kg Oral/Rat

20,000 mg/kg Oral/Rat

19,200 mg/kg Oral/Rat

CHRONIC / CARCINOGENICITY (CANCER CAUSING):

IARC:

Not suspected as a human carcinogen.

OSHA:

Not suspected as a human carcinogen

NTP

Not suspected as a human carcinogen

OTHER:

This product contains the following chemicals known to the state of California

(Proposition 65) to cause cancer or reproductive toxicity: None known.

None known

OTHER:

SECTION 12. ECOLOGICAL INFORMATION

No data available.

SECTION 13. DISPOSAL CONSIDERATIONS

Incinerate at an EPA approved facility or dispose of in accordance with all federal, state/provincial and local regulations.

JOHNSONITE 930A is a hazardous waste if discarded (CFR., Vol 40, part 261, pgs. 51-114).

See Section 2, Page 1 of this MSDS for hazardous ingredients.

PROPER WASTE DISPOSAL IS THE RESPONSIBILITY OF THE OWNER OF THE WASTE!

Call Johnsonite Inc. if additional information is necessary.

SECTION 14. TRANSPORT INFORMATION

D.O.T./T/D/G/: Not Regulated

All packaged material must be labeled in accordance with DOT and OSHA standards.

SECTION 15. REGULATORY INFORMATION

OSHA: Not hazardous.

Released January 2015

Page 4 of 5

930-A MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part A Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

SECTION 313: This product contains the following substances subject to the reporting requirements of Section

313 of TITLE III of Superfund Amendments and Reauthorization Act of 1986 and CFR Part 372: None known.

CALIFORNIA VOC (Volatile Organic Compound) COMPLIANCE

SCAQMD Rule 1168

VOC Compliant

SCAQMD Rule 443.1: Grams of VOC per Liter of Material < 12 gram/liter

WHMIS INFORMATION:

Class D, Division 2, Subdivision B - Toxic, Eye and skin irritant

SECTION 16. OTHER INFORMATION

HMIS RATINGS:

Health = 2

Flammability = 1 Reactivity = 0

Personal Protective Equipment = B

Hazard rating scale: 0=Minimal

1=Slight

2=Moderate

TSCA: = Components of this product are listed on the TSCAA inventory.

3=Serious

4=Severe

Johnsonite believes the statements, technical information and recommendations contained herein are reliable. They

are given without warranty or guarantee of any kind, expressed or implied.

DATE ISSUED: January 3, 2015

Released January 2015

CONTACT: Don Styka

Page 5 of 5

930-A MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part B Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

SECTION 1. PRODUCT IDENTIFICATION

PRODUCT NAME: JOHNSONITE 930 Part B

CHEMICAL FAMILY: Polyamine / Polyamide

SECTION 2. HAZARDOUS INGREDIENTS AND EXPOSURE LIMITS

Chemical Name

Benzyl alcohol

Polyamide resin

Polyamine

Nonylphenol

4.4-Methylene biscyclohexanamine

Calcium carbonate

% by

Weight

CAS

Number

EXPOSURE GUIDELINES

OSHA

ACGIH TLV

TLV-TWA

OSHA PEL

<6

5-10

10-20

<14

<3

40-60

100-51-6

68410-23-1

Proprietary

25154-52-3

1761-71-3

13 17-65-3

Not established

Not established

Not established

Not established

Not established

10 mg/m3

Not established

Not established

Not established

Not established

Not established

10 mg/m3

Not established

Not established

Not established

Not established

Not established

10 mg/m3

SECTION 3. HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW: Causes eye burns or irritation. Can cause respiratory irritation. Can cause central

nervous system depression. Can cause dermatitis.

POTENTIAL HEALTH EFFECTS:

EYE CONTACT: May cause severe irritation. May damage or burn eyes.

SKIN CONTACT: Prolonged exposure may cause skin irritation or burns May cause drying or flaking of skin.

Skin absorption of material may cause systemic toxicity.

INGESTION: Ingestion may cause severe injury to intestinal tract, liver, kidneys, stomach, throat, lungs, mouth and

mucous membranes. Harmful or fatal if swallowed. Do not ingest.

INGESTION: Ingestion may cause severe injury to intestinal tract, liver, kidneys, stomach, throat, lungs, mouth and

mucous membranes. Harmful or fatal if swallowed. Do not ingest.

INHALATION: Overexposure may cause severe respiratory tract irritation. Prolonged overexposure may

cause central nervous system depression with narcotic effects (headaches, dizziness). Keep

exposure below OSHA exposure limits.

SECTION 4. FIRST AID MEASURES

EYES: Immediately flush eyes with plenty of water for at least 15 minutes. Get medical attention.

SKIN: Wash with soap and water. Get medical attention if irritation develops or persists. Immediately remove

contaminated clothing.

INGESTION: If swallowed, seek medical attention immediately.

INHALATION: Remove to fresh air. Restore breathing if necessary. Get medical attention. This material can

cause lung damage.

DO NOT LEAVE VICTIM UNATTENDED.

SECTION 5. FIRE-FIGHTING MEASURES

OSHA FLAMMABILITY CLASS: IIIB

FLASHPOINT:

>200F, >93C

Not applicable

LOWER EXPLOSIVE LIMIT:

Released January 2015

Page 1 of 5

930-B MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part B Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

UPPER EXPLOSIVE LIMIT:

Not applicable

GENERAL HAZARD: May release flammable mixtures when temperatures are at or above the flash point. Toxic

gasses will form upon combustion. Closed containers may explode when exposed to extreme

heat. Vapors are heavier than air and may travel a considerable distance.

FIRE FIGHTING EQUIPMENT: Respiratory and eye protection required for firefighting personnel. Full protective

equipment and a self-contained breathing apparatus (SCBA) should be used in all indoor

fires and any large outdoor fires.

HAZARDOUS COMBUSTION PRODUCTS: Carbon monoxide, carbon dioxide, smoke and fumes, hydrocarbon

fragments nitrogen oxides, amino compounds.

SECTION 6. ACCIDENTAL RELEASE MEASURES

GENERAL INSTRUCTIONS: Keep all sources of ignition and hot metal surfaces away from spill. Isolate the danger

area and keep out unauthorized personnel. Stop spill if it can be done with minimal risk. Wear appropriate protective

equipment including respiratory protection as conditions warrant (see section 8). Prevent additional discharge of

material. Notify the appropriate authorities immediately. Contain spilled liquid with sand, earth or other noncombustible inert absorbent material. Prevent run-off from entering storm sewers, ditches or waterways. Transfer

absorbed waste material into properly identified drums. Treat waste material with same precautions as the adhesive.

Do not use solvent or flammable liquid to help clean up an accidental release.

Release to the environment may be reportable under environmental regulations.

SECTION 7. HANDLING AND STORAGE

HANDLING: Open container slowly to relieve any pressure. Do not enter confined spaces such as tanks without

following proper entry procedures as described in OSHA regulations at 29 CFR 1910.146. Do not

breathe vapors. The use of respiratory protection is recommended when airborne concentrations of

vapor exceed exposure guidelines. Wash thoroughly after handling. Do not wear contaminated clothing

or shoes. Wear appropriate protective gloves and clothing to prevent prolonged or repeated skin contact.

Avoid contact with eyes.

STORAGE: Keep containers tightly closed. Use and store this material in a cool, dry, well-ventilated area away

from heat, direct sunlight, hot metal surfaces, and all sources of ignition. Post area No Smoking or

Open Flames. Store only in approved containers. Protect containers against physical damage.

Indoor storage should meet OSHA standards and appropriate fire codes.

EMPTY CONTAINERS: May contain liquid and vapor residue and may be dangerous. Do not pressurize, cut, weld,

braze, solder, drill, grind, or expose such containers to heat, flame, sparks, or other sources of ignition.

They may explode and cause injury and death. Empty drums should be completely drained, properly

bunged, and promptly shipped to the supplier or a drum reconditioner. All containers should be

disposed of in accordance with governmental regulations.

Wash with soap and water before eating, drinking, smoking or using toilet facilities.

Consult NFPA and OSHA codes.

SECTION 8. EXPOSURE CONTROLS/PERSONAL PROTECTION

RESPIRATORY PROTECTION: A NIOSH/MSHA approved air purifying respirator with an organic vapor cartridge

may be used under conditions where airborne concentrations are expected to exceed exposure

Released January 2015

Page 2 of 5

930-B MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part B Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

guidelines. Protection provided by air purifying respirators is limited. Refer to respirator

manufacturers selection guide for appropriate respirator for conditions encountered. If in doubt, seek

the advice of an industrial hygienist or safety professional for appropriate air purifying respiratory

equipment.

Use positive pressure air supplied respirator if there is potential for an uncontrolled release,

exposure levels are not known, or in any other circumstances where air purifying respirators may

not provide adequate protection. When respiratory protection is used, a respiratory protection

program meeting OSHA regulations at 29 CFR 1910.134 must be followed.

SKIN PROTECTION: The use of gloves impermeable to the specific material handled is advised to prevent

prolonged or repeated skin contact. Where splashing is likely to occur, aprons impermeable to the

specific material may be worn. Refer to the glove and protective clothing manufacturers selection

guide for appropriate material.

EYE PROTECTION: Approved chemical splash goggles should be worn to safeguard against potential eye

contact, irritation or injury. Where splashing is likely to occur, hard hats and face shields may be

used to provide additional protection. Eye wash facilities should be available in the work area.

ENGINEERING CONTROLS: Provide sufficient mechanical ventilation to maintain exposure below TLV(s). The use of

local exhaust ventilation is recommended. Provide mechanical ventilation of confined spaces. If

current ventilation practices are not adequate to maintain airborne concentrations below the established

exposure guidelines, additional ventilation or exhaust systems may be required

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

APPEARANCE AND ODOR: Grey paste with ammonia odor.

SPECIFIC GRAVITY:

Approx 1.5 (68F -20C)

pH:

Not applicable

BOILING POINT

>390oF, >199oC

FREEZING POINT:

<30oF, <-1oC

SOLUBILITY IN WATER:

Slightly Soluble

% SOLIDS (BY WEIGHT):

>99%

% VOLATILE (BY WEIGHT): <1%

VAPOR PRESSURE (MM of MERCURY): <1mm of Hg @ 68oF, 20oC

VAPOR DENSITY(air=1):

Heavier than air.

EVAPORATIONRATE (BUTYL ACETATE = 1): Slower than butyl acetate

EVAPORATION RATE (ETHYL ETHER = 1): Slower than ethyl ether

SECTION 10. STABILITY AND REACTIVITY

CHEMICAL STABILITY: Keep away from flames and spark producing equipment. Not dangerously unstable.

Avoid buildup of static electricity.

INCOMPATIBLE MATERIALS: Strong oxidizing agents, strong reducing agents, acids, bases, or unstable

chemicals, chloroform, peroxides, sulfur dichloride, strong alkalis, anhydrides, mercaptans, materials

that react with amines.

HAZARDOUS DECOMPOSITION PRODUCTS: Hazardous decomposition is unlikely to occur, but under fire

or extreme heat conditions, carbon monoxide, carbon dioxide, smoke and fumes, hydrocarbon fragments,

nitrogen oxides and amino compounds can be released.

HAZARDOUS POLYMERIZATION: Will not occur.

Released January 2015

Page 3 of 5

930-B MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part B Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

SECTION 11. TOXICOLOGICAL INFORMATION

MATERIAL:

Benzyl alcohol

Polyamide resin

Polyamine

Nonylphenol

4.4-Methylene biscyclohexanamine

Calcium carbonate

SKIN (Dermal LD50):

Not available

>2,000 mg/kg (Rabbit)

>1,000 mg/kg (Rabbit)

Not available

Not available

Not available

INGESTION (Oral LD50):

Not available

>1,230 mg/kg Oral/Rat

>1,620 mg/kg Oral/Rat

Not available

Not available

6,450 mg/kg Oral/Rat

CHRONIC:

Liver and kidney damage. May cause corneal opacity. May cause central nervous

system depression causing headaches, nausea, and dizziness.

CHRONIC / CARCINOGENICITY (CANCER CAUSING):

IARC:

Not suspected as a human carcinogen.

OSHA:

Not suspected as a human carcinogen

NTP

Not suspected as a human carcinogen

OTHER:

This product contains the following chemicals known to the state of California

(Proposition 65) to cause cancer or reproductive toxicity: None known.

None known

OTHER:

SECTION 12. ECOLOGICAL INFORMATION

No data available.

SECTION 13. DISPOSAL CONSIDERATIONS

Incinerate at an EPA approved facility or dispose of in accordance with all federal, state/provincial and local regulations.

JOHNSONITE 930B is a hazardous waste if discarded (CFR., Vol 40, part 261, pgs. 51-114).

See Section 2, Page 1 of this MSDS for hazardous ingredients.

PROPER WASTE DISPOSAL IS THE RESPONSIBILITY OF THE OWNER OF THE WASTE!

Call Johnsonite Inc. if additional information is necessary.

SECTION 14. TRANSPORT INFORMATION

D.O.T./T/D/G/: Not Regulated

All packaged material must be labeled in accordance with DOT and OSHA standards.

SECTION 15. REGULATORY INFORMATION

OSHA: Hazardous material by definition of hazard communication standard (29CFR 1910.1200).

SECTION 313: This product contains the following substances subject to the reporting requirements of Section

313 of TITLE III of Superfund Amendments and Reauthorization Act of 1986 and CFR Part 372: None known.

Released January 2015

Page 4 of 5

930-B MSDS 010315

MATERIAL SAFETY DATA SHEET

Supplier:

Johnsonite, Inc.

Product: 930

16910 Munn Road, Chagrin Falls, Ohio 44023

Part B Epoxy Caulking Compound

24-Hour Emergency Telephone - Chemtrec: (800-424-9300)

CALIFORNIA VOC (Volatile Organic Compound) COMPLIANCE

SCAQMD Rule 1168

VOC Compliant

SCAQMD Rule 443.1: Grams of VOC per Liter of Material < 12 gram/liter

WHMIS INFORMATION:

Class E, Corrosive Material

SECTION 16. OTHER INFORMATION

HMIS RATINGS:

Health = 2

Flammability = 1 Reactivity = 0

Personal Protective Equipment = Depends on application and ventilation.

Hazard rating scale: 0=Minimal

1=Slight

2=Moderate

TSCA: = Components of this product are listed on the TSCAA inventory.

3=Serious

4=Severe

Johnsonite believes the statements, technical information and recommendations contained herein are reliable. They

are given without warranty or guarantee of any kind, expressed or implied.

DATE ISSUED: January 3, 2015

Released January 2015

CONTACT: Don Styka

Page 5 of 5

930-B MSDS 010315

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 2013 2Document112 pages2013 2Dang Minh HuongNo ratings yet

- Qa7-Assessment and Training Staff Registration FormDocument3 pagesQa7-Assessment and Training Staff Registration FormDang Minh HuongNo ratings yet

- EMS Tank HandBook 2011 Rev1Document90 pagesEMS Tank HandBook 2011 Rev1Dang Minh HuongNo ratings yet

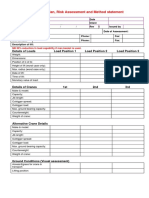

- STFC Lifting Plan, Risk Assessment and Method Statement: Details of Loads Load Position 1 Load Position 2 Load Position 3Document4 pagesSTFC Lifting Plan, Risk Assessment and Method Statement: Details of Loads Load Position 1 Load Position 2 Load Position 3Muhammad Azhar AliNo ratings yet

- Qa5-Application To Become An Approved CentreDocument4 pagesQa5-Application To Become An Approved CentreDang Minh HuongNo ratings yet

- 7 Point Container InspectionDocument1 page7 Point Container InspectionDang Minh Huong100% (1)

- Con-Centre Recognition PolicyDocument4 pagesCon-Centre Recognition PolicyDang Minh HuongNo ratings yet

- Qa6-Application To Offer Additional Qualifications-UnitsDocument3 pagesQa6-Application To Offer Additional Qualifications-UnitsDang Minh HuongNo ratings yet

- Con-Qcf Requirements For Approved CentresDocument25 pagesCon-Qcf Requirements For Approved CentresDang Minh HuongNo ratings yet

- 93201277Document3 pages93201277Dang Minh HuongNo ratings yet

- Risk Assessment for Slinging LoadsDocument2 pagesRisk Assessment for Slinging LoadsDang Minh HuongNo ratings yet

- Mechanical handling safety guideDocument8 pagesMechanical handling safety guideDang Minh HuongNo ratings yet

- Contur KatalogDocument48 pagesContur KatalogDang Minh HuongNo ratings yet

- Tirfor OMDocument12 pagesTirfor OMDang Minh HuongNo ratings yet

- Beaver Tech Manual s4 Shackles LRDocument22 pagesBeaver Tech Manual s4 Shackles LRDang Minh HuongNo ratings yet

- Advanced Rigging Fundamentals: Price: $595 Per StudentDocument1 pageAdvanced Rigging Fundamentals: Price: $595 Per StudentDang Minh HuongNo ratings yet

- Hoisting Re QB TH InspectDocument9 pagesHoisting Re QB TH InspectPerwez21No ratings yet

- 7 Point Container InspectionDocument1 page7 Point Container InspectionDang Minh Huong100% (1)

- Safe Towing GuideDocument14 pagesSafe Towing GuideDang Minh HuongNo ratings yet

- Design of Monorail Systems WhitepaperDocument40 pagesDesign of Monorail Systems Whitepaperhelden50229881No ratings yet

- 6.ENGLISH International ER Guidelines Final Rev 0 Amendment 2 MASTERDocument65 pages6.ENGLISH International ER Guidelines Final Rev 0 Amendment 2 MASTERdangminhhuongNo ratings yet

- Beaver Tech Manual s4 Shackles LRDocument22 pagesBeaver Tech Manual s4 Shackles LRDang Minh HuongNo ratings yet

- 501 453 RacDocument1 page501 453 RacJacqueline AdamsNo ratings yet

- Honeywell Gas Detector Impact Pro (In English)Document4 pagesHoneywell Gas Detector Impact Pro (In English)Dang Minh HuongNo ratings yet

- Directive037 - Service Rig InspectionDocument133 pagesDirective037 - Service Rig InspectionAnonymous yWgZxGW5d100% (1)

- Offshore Drilling WorkerDocument5 pagesOffshore Drilling WorkerDang Minh HuongNo ratings yet

- CSE Common MistakesDocument3 pagesCSE Common MistakesDang Minh HuongNo ratings yet

- Hawke PL612 EnclosureDocument2 pagesHawke PL612 EnclosureDang Minh HuongNo ratings yet

- ABB FPSO Solutions RefDocument22 pagesABB FPSO Solutions RefDang Minh HuongNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- fLOW CHART FOR WORKER'S ENTRYDocument2 pagesfLOW CHART FOR WORKER'S ENTRYshamshad ahamedNo ratings yet

- QRF HD785-7Document2 pagesQRF HD785-7Ralf MaurerNo ratings yet

- Workplace Hazard Analysis ProcedureDocument12 pagesWorkplace Hazard Analysis ProcedureKent Nabz60% (5)

- Model Fs CatalogDocument4 pagesModel Fs CatalogThomas StempienNo ratings yet

- Bentel J408Document64 pagesBentel J408Bojan MarkovicNo ratings yet

- Synthesis, Experimental and Theoretical Characterizations of A NewDocument7 pagesSynthesis, Experimental and Theoretical Characterizations of A NewWail MadridNo ratings yet

- The Secret of The House WTDocument22 pagesThe Secret of The House WTPetr -50% (2)

- GTT Module 5Document156 pagesGTT Module 5ABDULRAHIMAN RAJEKHANNo ratings yet

- CHAPTER3 Foundations of Individual BehaviorDocument32 pagesCHAPTER3 Foundations of Individual BehaviorLynoj AbangNo ratings yet

- Reading and Listening 2Document4 pagesReading and Listening 2Hải Anh TạNo ratings yet

- Material Safety Data Sheet: WWW - Smartlab.co - IdDocument8 pagesMaterial Safety Data Sheet: WWW - Smartlab.co - Idlalan suparlanNo ratings yet

- Hypertension Protocol Mukta VatiDocument18 pagesHypertension Protocol Mukta VatiDr. Avnish UpadhyayNo ratings yet

- 2024 - Chung 2024 Flexible Working and Gender Equality R2 CleanDocument123 pages2024 - Chung 2024 Flexible Working and Gender Equality R2 CleanmariaNo ratings yet

- Hinduism Today April May June 2015Document43 pagesHinduism Today April May June 2015jpmahadevNo ratings yet

- ItilDocument11 pagesItilNarendar P100% (2)

- Alternate Mekton Zeta Weapon CreationDocument7 pagesAlternate Mekton Zeta Weapon CreationJavi BuenoNo ratings yet

- Venus in MulaDocument2 pagesVenus in MulaGovind BallabhNo ratings yet

- ASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderDocument1 pageASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderCatalin BailescuNo ratings yet

- FinalsDocument8 pagesFinalsDumpNo ratings yet

- Material Handling EquipmentsDocument12 pagesMaterial Handling EquipmentsRahul SheelavantarNo ratings yet

- RA8485 Animal Welfare Act (Carabao Slaughter)Document2 pagesRA8485 Animal Welfare Act (Carabao Slaughter)Jazreth Gaile100% (1)

- Junayed - 19 39800 1Document11 pagesJunayed - 19 39800 1gurujeeNo ratings yet

- B.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSDocument31 pagesB.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSgur jazzNo ratings yet

- Emission of Volatile Organic Compounds (Vocs) From Dispersion and Cementitious Waterproofing ProductsDocument16 pagesEmission of Volatile Organic Compounds (Vocs) From Dispersion and Cementitious Waterproofing ProductsKrishna KusumaNo ratings yet

- Hydrogeological Characterization of Karst Areas in NW VietnamDocument152 pagesHydrogeological Characterization of Karst Areas in NW VietnamCae Martins100% (1)

- Theories of Motivation and Child Moral DevelopmentDocument5 pagesTheories of Motivation and Child Moral DevelopmentPamela mirandaNo ratings yet

- Q1 Tle 4 (Ict)Document34 pagesQ1 Tle 4 (Ict)Jake Role GusiNo ratings yet

- Chapter 3 - CT&VT - Part 1Document63 pagesChapter 3 - CT&VT - Part 1zhafran100% (1)

- General Specifications: Detail ADocument1 pageGeneral Specifications: Detail AJeniel PascualNo ratings yet

- Vturn-NP16 NP20Document12 pagesVturn-NP16 NP20José Adalberto Caraballo Lorenzo0% (1)