Professional Documents

Culture Documents

Free Ts 16949 Audit Checklist

Uploaded by

Kumaravel100%(1)100% found this document useful (1 vote)

1K views8 pagesuseful for TS audits

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentuseful for TS audits

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views8 pagesFree Ts 16949 Audit Checklist

Uploaded by

Kumaraveluseful for TS audits

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

De System Mob-09213283599, www.desystem.co.

in

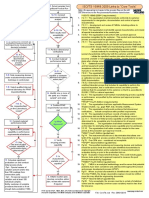

ChecklistISO/TS 16949

UNIQUE REQUIREMENTS CHECKLIST FOR ISO/TS 16949

Auditor:

Area/Dept. Audited:

Date:

4.2.3.1 Review, distribution and implementation of customer engineering standards & specifications

Process for timely review

Process for distribution

Process for implementation

Record of date of change

Associated documents update

4.2.4.1 Retention of quality related documents and records

Defined retention periods

Complies with customer rqrts

Satisfies regulatory requirements

Disposition includes disposal

5.1.1 Monitor and support processes to assure efficiency

Process monitoring methods

Process support examples

5.4.1.1 Objectives for achieving quality must be included in business plan

Objectives included the business plan

Measurements defined

Address customer expectation

5.5.1.1 Responsibility for quality in management and production

Do personnel have authority to stop production to correct quality problems?

Quality responsibility designated across all shifts

5.5.2.1 Designated customer representatives Who are designated personnel for

Setting quality objectives

Selecting special char.

Training

Corrective & Preventive Action

5.6.1.1 Reviews of quality management system performance

Includes all elements

Metrics on performance trends

Monitoring of quality objectives

Reporting cost of poor quality

Evidence of achievement of objectives in business plan

Evidence of customer satisfaction

5.6.2.1 Management review inputs Does review include analysis of actual & potential field failure?

What action plans?

6.2.2.1 Product design skills Are product design personnel qualified with design skills?

Applicable techniques used?

6.2.2.2 Procedure for identifying training needs.

Personnel performing specific tasks must be qualified

Documented procedure

Training plan and records

De System Mob-09213283599, www.desystem.co.in

Proof of job competence

Certified as applicable

Applies to all employees affecting quality at all levels

6.2.2.3 Training on the job Is on the job training provided for new jobs? (records)

Includes contract personnel?

Are personnel aware of job related quality requirements?

6.2.2.4 Process for employee motivation and empowerment

Is formal program established?

Does environment promote innovation and quality?

Any incentives?

Includes continual improvement?

Do personnel have awareness of relevance of their job to quality objectives?

6.3.1 Multidisciplinary approach to plant, facility and equipment planning

Who makes up this team?

Does layout optimize use of space and material flow

Methods to monitor effectiveness of operations

6.3.2 Contingency plans

Are plans prepared, in event of utility outage, key equipment failure, labor shortage?

6.4.1 Policy to address personnel safety to minimize risks

Is safety policy established?

Personnel training?

Applicable to design?

Applicable to manufacturing?

Hazard warnings?

6.4.2 Cleanliness of premises Inspection for state of order

State of repair

7.1.1 Inclusion of customer requirements and technical specs in quality planning

Must be components of the quality plan

7.1.2 Acceptance criteria, especially for attribute data sampling

Acceptance criteria defined?

Approved by customer, as reqd.

Zero-accept for attribute plans

7.1.3 Confidentiality of customer contracted products and projects under development

What methods are used?

Non-disclosure agreements

Non-compete agreements

7.1.4 Process to control and react to changes that impact product realization

What is the process for control of supplier initiated change?

Assessment of impact

Verification & validation method

Review w/ customer as rqrd.

Applicable to manufacturing changes

7.2.1.1 Customer designated special characteristics

Methods for designation, documentation and control

7.2.2.1 Manufacturing feasibility Feasibility investigated during contract review

Includes risk analysis

Documented feasibility

7.2.3.1 Communication of necessary information to customer

Specified language ability

Specified format compatible

CAD data

De System Mob-09213283599, www.desystem.co.in

Electronic data exchange, EDI

7.3.1.1 Multidisciplinary approach in product realization

Makeup of cross-functional team

What is the quality planning process?

Cross-functional review on:

Developing and finalizing special characteristics

FMEA develop & review

Control plan development/review

7.3.2.1 Review of product design inputs to include specified requirements, information and targets

Documented

Does review of inputs include

Customer requirements

Special characteristics

Use of information gained from previous design

Targets for quality, reliability, durability, maintainability, cost

Design FMEA

7.3.2.2 Review of manufacturing process design inputs as specified

Documented

Does review of inputs include

Product design output data

Targets for productivity and cost

Targets for process capability

Customer requirements, if any

Previous experience

Use of error-proofing methods

7.3.2.3 Identification of special characteristics

Are all special characteristics included in control plan?

Complies with customer symbol

Identify process control documents (drawings, FMEA, operator instructions) with SCs

7.3.3.1 Design output expressed in terms that can be verified and validated

Verify that design output includes

Design FMEA, reliability

Product special characteristics

Error-proofing as appropriate

Product definition (e.g. drawing)

Design review results

Diagnostic guidelines, as rqrd.

7.3.3.2 Manufacturing process design output expressed in terms that can be verified and validated.

Verify that design output includes

Specifications & drawings

Process flowchart

Process FMEA

Control plan

Work instructions

Process study basis and approval criteria

Production process parameters

Quality, reliability, maintainability

Error-proofing, examples of

Methods for rapid detection of process nonconformities

7.3.4.1 Stages of design and development shall be monitored with results to management

Defined measurements/stages

Evidence of analyses

Status report to mgmt. (records)

7.3.6.1 Design and development validation in accordance with customer requirements

Customer specified validation method

Within program timing

De System Mob-09213283599, www.desystem.co.in

7.3.6.2 As required, a prototype program and control plan

Prototype example

Control plan

Use of same suppliers, tooling and manufacturing process

Leadership over outsourced prototyping services

7.3.6.3 Conformance to customer specified procedure for product approval and process approval

PPAP or equivalent customer specified method

Includes product and process approvals

Application to suppliers as well

7.4.1.1 All purchased materials satisfy applicable regulatory requirements

Responsible party

Awareness of applicable regulatory requirements

7.4.1.2 Supplier quality management systems and development

Suppliers to organization must be 3rd party registered to ISO- 9001:2000 (by 15 Dec. 2003)

Records in supplier files

Prioritization plan for development of suppliers

7.4.1.3 Use of customer approved sources as specified in contract

Use of specified sources

Includes tool/gauge suppliers

Responsibility for ensuring quality of purchased products

7.4.3.1 Process to assure the quality of purchased product

Defined methods for incoming product test or verification, e.g.

Receipt & evaluation of supplier statistical data

Receiving inspect or test

Assessments of supplier site

Part evaluation by laboratory

Other agreed method

7.4.3.2 Monitoring of supplier performance

Method for performance monitor:

Delivered part quality history

Customer disruptions

Delivery schedule performance

Premium freight incidents

Special status notifications

7.5.1.1 Development of control plans for product supplied, including customer required information and

review/update

Are control plans developed for

System and sub-system level

Component or material level

Pre-launch and production

Considering FMEA

Do control plans address

Manufacturing process controls

Method for monitor of special changes

Customer required information

Reaction plan

Evidence of update if significant product or process change

7.5.1.2 Work instructions for employees having process operations responsibility

Documented

Accessible at the work station

Derived from sources such as control plan, quality plan

7.5.1.3 Verification of job set-ups, according to set-up work instructions

Check set-up verifications at

De System Mob-09213283599, www.desystem.co.in

Initial run of job

Material changeover

Job change

Are work instructions available?

Are statistical methods of verification used?

7.5.1.4 Preventive maintenance programs for key process equipment;

Predictive maintenance programs to continually improve efficiency of production equipment

Includes maintenance objectives

Identification of key process equipment

Resources provided

Preventive maintenance plan

PM plan includes:

Planned activities

Packaging and preservation of equipment, tooling, gauging

Availability of replacement parts

Documented maintenance objectives

7.5.1.5 Production tooling management, including monitor of any outsourced work

Resources for tool and gauge design, fabrication, verification

Tooling management program includes:

Maintenance and repair

Set-up, storage, recovery

Tool change, for perishable tools

Tool modification documentation

Tool identification & status

7.5.1.6 Production scheduling must meet customer requirements

Defined customer requirements

Just-in-time or Order-driven

Real-time information system on production status at key stages

7.5.1.7 Process for feedback of information from service

Established process

Includes service concerns

Includes manufacturing, engineering/design functions

Personnel awareness of issues external to the organization

7.5.1.8 Verifying effectiveness of servicing agreement with customer

How does organization verify effectiveness of

Service centres

Special purpose tools/measure

Training of servicing personnel

7.5.2.1 Requirements of 7.5.2 must apply to all processes for production & service provision

Verify scope of application

Verify actual examples from products offered/jobs running

7.5.3.1 Requirements for identification of product must apply through entire product realization

Defined method

Suitable means

Traceability identification

7.5.4.1 Marking of customerowned production tooling

Marking must be permanent and visible for following:

Customer owned tools

Manufacturing equipment/tooling

Test or inspection equipment

7.5.5.1 System to control product in stock, storage and inventory

What is inventory management system?

How is stock rotation ensured?

How is obsolete product controlled?

Is condition of stock assessed at intervals?

De System Mob-09213283599, www.desystem.co.in

7.6.1 Requirement for statistical studies to analyze variation in measuring/test equipment.

System must conform to those in customer reference manual (such as MSA, GR&R)

Statistical basis and analysis

Applicable to IMTE systems referenced on control plan

7.6.2 Specific requirements for records of calibration activity

Must include gauges, measuring and test equipment including employee-owned and customer owned gauges

Records must include following:

Equipment identification

Revisions after engineering chg

Out-of-spec readings as received

Assessment of impact

Statement of conformance to spec after calibration

Notification to customer if suspect product shipped

7.6.3.1 Internal laboratory must have a defined scope, and meet listed technical requirements

Laboratory scope defined

Documented in quality system

Meet technical requirements for:

Adequate procedures

Qualification of lab personnel

Testing of commodities

Capability to perform tests

Traceability to standard

Quality records

7.6.3.2 External laboratory must have Use of external/commercial lab appropriate scope for capability to

perform inspections, tests or calibrations facilities, e.g. calibration

Records of lab scope

Accreditation to ISO/IEC 17025

Evidence of lab acceptable to the customer

8.1.1 Determination of appropriate statistical tools during advance

quality planning

Methods cited

Included on control plan

8.1.2 Knowledge of basic statistical concepts

Interview employees on basic concept/applications of:

Variation

Control/stability

Process capability

Over-adjustment

Evaluate charts for interpretation

8.2.1.1 Performance indicators for customer satisfaction

How is customer satisfaction monitored?

Does objective data include:

Delivered part quality

Customer disruptions

Delivery schedule performance

Incidents of premium freight

Customer notification on quality or delivery issues

8.2.2.1 Internal audits must cover entire quality system and verify compliance with all TS16949 and additional

requirements

Does the audit plan provide for audits of the entire quality management system to TS 16949, including any

additional requirements, such as customer

Interview audit manager

Review audit reports

Audit reports on specific customer requirements

De System Mob-09213283599, www.desystem.co.in

8.2.2.2 Manufacturing process audit Does audit program include audits of each manufacturing process for

effectiveness?

Scope of audit plan

Links to related objectives

8.2.2.3 Product audit Does audit program include audits of products at appropriate stages of

production and delivery, e.g.

Product dimensions

Functionality

Packaging/labelling

8.2.2.4 Scope of internal audit plans Verify internal audit plan covers...

Quality management processes

Quality activities

All shifts

Is there an annual plan?

Is audit frequency adjusted if complaints/nonconformities?

8.2.2.5 Qualifications of internal auditors

Auditor training records

Appropriate content of training

Interview auditors, for familiarity with ISO/TS 16949 criteria

8.2.3.1 Monitoring and measurement of manufacturing processes, to verify and maintain process

capability and include objectives and acceptance criteria.

How are process studies done?

Does this include all new manufacturing processes

Are process study results documented, with specs?

Objectives for process capability, such as Cpk

Objectives for reliability, maintainability

Defined acceptance criteria

Is process operated per control plan and process flow diagram?

Notation of significant events on process control charts

Reaction plans, established and initiated when needed

Corrective action plans

Records of effective date of process changes

8.2.4.1 Layout inspection and functional testing

Performed on all products at sufficiently frequent intervals?

Per control plan and customer performance standards

Layout results documented

8.2.4.2 Appearance items Appropriate resources, e.g. lighting evaluation

Masters, for color, grain, gloss

Control of appearance masters

Qualified personnel

8.3.1 Supplemental controls over nonconforming product

How is suspect product treated?

How is unidentified product treated?

8.3.2 Controls over reworked product to include instructions for rework and re-inspection

How are rework instructions provided?

Verification of use of instructions

8.3.3 Customer information Any examples of nonconforming product having been shipped?

How was customer notified?

8.3.4 Customer waiver, whenever product or process is different from that approved

Examples?

Customer deviation permit

Record of expiration date or qty

Compliance to original spec afterwards

Applies also to purchased product

De System Mob-09213283599, www.desystem.co.in

8.4.1 Analysis and use of data to lead to action toward objectives

What data is gathered on quality and operational performance?

How is this trend-analyzed?

Examples of actions generating priorities for prompt solutions to customer related problems

Decision making regards key customer-related trends

Information system for timely reporting

Are data compared to benchmarks?

8.5.1.1 Continual improvement

How is the process of company wide continual improvement implemented?

8.5.1.2 Manufacturing process improvement must focus on control and reduction of variation

Examples of product characteristics, from control plan, with improvement

Examples of process parameters related to above

8.5.2.1 Problem solving Defined problem solving process, in customer prescribed format

Examples of root-cause identification and elimination

8.5.2.2 Use of error-proofing Examples of error-proofing applications

Related to corrective actions

8.5.2.3 Corrective action impact Examples of application of corrective action to other similar

products/processes

Method of control implemented

8.5.2.4 Returned product test and analysis, with records and associated corrective action

Returned product log

Records of analyses of returns

Examples from rejected parts, dealerships

Records of associated corrective action

Minimization of cycle time

You might also like

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- TS16949 Audit ChecklistDocument40 pagesTS16949 Audit ChecklistZoli0984100% (1)

- Paradise IATF IA Presentation PDFDocument211 pagesParadise IATF IA Presentation PDFSameer SaxenaNo ratings yet

- IATF 16949 mandatory documentsDocument3 pagesIATF 16949 mandatory documentsOscar Solis MartirNo ratings yet

- VDA 6.3 Management: R. Dan ReidDocument61 pagesVDA 6.3 Management: R. Dan ReidAlpha Excellence consultingNo ratings yet

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- IATF 16949:2016 Process Audit TrainingDocument4 pagesIATF 16949:2016 Process Audit TrainingisolongNo ratings yet

- Draft Quality Manual IATF 16949 Version 0.0Document67 pagesDraft Quality Manual IATF 16949 Version 0.0Ashish Kumar Dahiya100% (2)

- Free IATF Audit Checklist For Manufacturing ProcessesDocument14 pagesFree IATF Audit Checklist For Manufacturing ProcessesvidushiNo ratings yet

- Summary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesDocument8 pagesSummary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesStephen Lim Kean Jin100% (2)

- ISO 9001 Quality Procedure Context of the OrganizationDocument1 pageISO 9001 Quality Procedure Context of the OrganizationKarim HakimNo ratings yet

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixhmp9060% (5)

- Gap Analysis IATF 16949Document15 pagesGap Analysis IATF 16949Elena BabinetchiNo ratings yet

- Core Tools PDFDocument1 pageCore Tools PDFsentrakerjaan100% (3)

- IATF 16949-2016 Audit ChecklistDocument129 pagesIATF 16949-2016 Audit ChecklistRajeshLSNo ratings yet

- CSR Matrix (Example Only)Document24 pagesCSR Matrix (Example Only)hmp90100% (1)

- Project Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneDocument2 pagesProject Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneNikita Fatah EntingNo ratings yet

- Pecb Iatf 16949 Lead Auditor Exam Preparation GuideDocument14 pagesPecb Iatf 16949 Lead Auditor Exam Preparation GuideR.BALASUBRAMANI100% (1)

- Iatf 16949 Clause To Eqms ModuleDocument8 pagesIatf 16949 Clause To Eqms Modulepodrao100% (3)

- IATF 16949 Awareness Exam TitleDocument1 pageIATF 16949 Awareness Exam Titlenichecon1No ratings yet

- The Process Approach QuestionsDocument6 pagesThe Process Approach QuestionsDwinanda SeptiadhiNo ratings yet

- Questionnaire IATF 16949-2016Document6 pagesQuestionnaire IATF 16949-2016shelke1010100% (1)

- Manual ProceduresDocument140 pagesManual ProceduresWes Westberg60% (5)

- IATF 16949 2016 Gap Tool InstructionsDocument11 pagesIATF 16949 2016 Gap Tool InstructionsJosé María Moreno63% (8)

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- IATF 16949 - 2016-Exam Paper With AnswersDocument11 pagesIATF 16949 - 2016-Exam Paper With Answersrashwin singhNo ratings yet

- AUDITMANUALDocument44 pagesAUDITMANUALRajula Gurva ReddyNo ratings yet

- Quality Manual TemplateDocument67 pagesQuality Manual TemplateMohini Marathe100% (4)

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- IATF Auditor Guide PDFDocument32 pagesIATF Auditor Guide PDFJosé Carlos GarBad100% (4)

- ISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDocument116 pagesISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDL50% (2)

- IATF Process Audit Check Sheet FormatDocument14 pagesIATF Process Audit Check Sheet Formatukavathekar71% (7)

- IATF 16949 - 2016 - List of Mandatory DocumentsDocument3 pagesIATF 16949 - 2016 - List of Mandatory DocumentsSenthil_KNo ratings yet

- IATF 16949 Documentation Toolkit GuideDocument4 pagesIATF 16949 Documentation Toolkit GuideOscar Solis MartirNo ratings yet

- IATF 16949 Documentation Toolkit GuideDocument4 pagesIATF 16949 Documentation Toolkit GuideRahul SharmaNo ratings yet

- IATF 16949 Mandatory Documents ListDocument2 pagesIATF 16949 Mandatory Documents ListLuis Alejandro60% (5)

- Iatf Process Audit Check Sheet FormatDocument14 pagesIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduNo ratings yet

- Woxevekototaporilube PDFDocument2 pagesWoxevekototaporilube PDFharish puNo ratings yet

- ISO-TS 16949 IQA Course MaterialDocument31 pagesISO-TS 16949 IQA Course Materialazadsingh1No ratings yet

- ISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingDocument7 pagesISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingSudhagarNo ratings yet

- IATF 16949:2016 IntroductionDocument20 pagesIATF 16949:2016 IntroductionDisha Shah100% (4)

- Processaudit VDA 6.3 2010 enDocument37 pagesProcessaudit VDA 6.3 2010 enAdilson DoboszNo ratings yet

- IATF 16949 Types of AuditsDocument32 pagesIATF 16949 Types of AuditsJohn OoNo ratings yet

- Process Audit Turtle DiagramDocument1 pageProcess Audit Turtle DiagramJoel Alcantara100% (3)

- Required Documents For IATF - 16949Document5 pagesRequired Documents For IATF - 16949Rajesh Sahasrabuddhe0% (1)

- Fit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) DefinitionsDocument3 pagesFit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) Definitions57641No ratings yet

- IATF 16949 Mandatory DocumentsDocument2 pagesIATF 16949 Mandatory DocumentsLuis AlejandroNo ratings yet

- Internal Audit ChecklistDocument37 pagesInternal Audit ChecklistSumeet Rathee100% (5)

- IATF 16949:2016 Training on Quality Management Systems and Audit ConceptsDocument62 pagesIATF 16949:2016 Training on Quality Management Systems and Audit ConceptsMadhukar Sinha100% (6)

- ISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontDocument3 pagesISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontPratik Ardhapurkar100% (1)

- Turtle Diagram For AuditDocument5 pagesTurtle Diagram For AuditSelvaraj Simiyon100% (3)

- ISO9 - IATF16 - Combo - GAP - March - 2017 - 1Document100 pagesISO9 - IATF16 - Combo - GAP - March - 2017 - 1Bruce GilchristNo ratings yet

- Fmea Vda AiagDocument63 pagesFmea Vda AiagfquysxlahyytpxpwgqNo ratings yet

- SPC Training Material Ver 4.0Document56 pagesSPC Training Material Ver 4.0krunalparikhNo ratings yet

- Iatf 16949 TrainingDocument136 pagesIatf 16949 Trainingpreetam kumar100% (1)

- IATF 16949 Frequently Asked Questions October 2017Document12 pagesIATF 16949 Frequently Asked Questions October 2017Armando FloresNo ratings yet

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- Total Quality Management: Total-Made Up of Whole Quality-Degree of Excellence A Product orDocument6 pagesTotal Quality Management: Total-Made Up of Whole Quality-Degree of Excellence A Product orKumaravelNo ratings yet

- 4M Changing Point ManagementDocument7 pages4M Changing Point ManagementKumaravelNo ratings yet

- Iatf Gap Analysis ToolDocument100 pagesIatf Gap Analysis ToolKumaravel100% (3)

- 4M Change Management Rule RevisedDocument2 pages4M Change Management Rule RevisedKumaravelNo ratings yet

- CMR For 2gs Am CrackDocument7 pagesCMR For 2gs Am CrackKumaravelNo ratings yet

- Chemical & Mechanical Properties Comparison at External LabDocument4 pagesChemical & Mechanical Properties Comparison at External LabKumaravelNo ratings yet

- 2044IATF BDocument3 pages2044IATF BKumaravelNo ratings yet

- Nabl Scope 1Document1 pageNabl Scope 1KumaravelNo ratings yet

- Attribute Measurement System Analysis Timesheet Processing Cost Data Integrity Project PurposeDocument10 pagesAttribute Measurement System Analysis Timesheet Processing Cost Data Integrity Project PurposensadnanNo ratings yet

- Koya India Quality ReportDocument1 pageKoya India Quality ReportKumaravelNo ratings yet

- List of Special CharacteristicsDocument2 pagesList of Special CharacteristicsKumaravelNo ratings yet

- Internal / External Communication PlanDocument3 pagesInternal / External Communication PlanKumaravelNo ratings yet

- Attribute Measurement System Analysis Timesheet Processing Cost Data Integrity Project PurposeDocument10 pagesAttribute Measurement System Analysis Timesheet Processing Cost Data Integrity Project PurposensadnanNo ratings yet

- APQP & PPAP Training Evaluation QuestionnaireDocument2 pagesAPQP & PPAP Training Evaluation QuestionnaireKumaravel81% (16)

- 2GS AM Spline Thickness Seggregation DataDocument1 page2GS AM Spline Thickness Seggregation DataKumaravelNo ratings yet

- Weighing Machine Maintenance Check SheetDocument1 pageWeighing Machine Maintenance Check SheetKumaravel100% (2)

- Packing standards for parts deliveryDocument4 pagesPacking standards for parts deliveryKumaravelNo ratings yet

- QA Lot Management Sheet Quantity CheckDocument4 pagesQA Lot Management Sheet Quantity CheckKumaravelNo ratings yet

- 3h56 KoyamaDocument2 pages3h56 KoyamaKumaravelNo ratings yet

- IATF Implementation Plan and Co-Ordinator RolesDocument3 pagesIATF Implementation Plan and Co-Ordinator RolesKumaravel50% (2)

- ISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDocument116 pagesISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDL50% (2)

- Lot analysis report for special characteristicsDocument1 pageLot analysis report for special characteristicsKumaravelNo ratings yet

- (2-01) QAM Registration SheetDocument1 page(2-01) QAM Registration SheetKumaravelNo ratings yet

- IATF 16949 ClientsDocument126 pagesIATF 16949 ClientsKumaravel100% (1)

- Quality Biweekly Report Mar 2018Document3 pagesQuality Biweekly Report Mar 2018KumaravelNo ratings yet

- (2-22) Process ChangeDocument6 pages(2-22) Process ChangeKumaravelNo ratings yet

- India Yamaha Motor Pvt Ltd safety audit checklist for supplier partsDocument1 pageIndia Yamaha Motor Pvt Ltd safety audit checklist for supplier partsKumaravelNo ratings yet

- ISO 9001-2015 Vs ISO 9001-2008 Matrix ENDocument11 pagesISO 9001-2015 Vs ISO 9001-2008 Matrix ENTomas Morales100% (1)

- Traceability Check Sheet - Koyama IndiaDocument12 pagesTraceability Check Sheet - Koyama IndiaKumaravelNo ratings yet

- Process Check Sheet - Koyama IndiaDocument8 pagesProcess Check Sheet - Koyama IndiaKumaravelNo ratings yet

- Managing Employee Turnover EbookDocument17 pagesManaging Employee Turnover EbookJoel OkwuohaNo ratings yet

- Women in Hospitality Travel and Leisure Final ReportDocument80 pagesWomen in Hospitality Travel and Leisure Final ReportZafar Imam KhanNo ratings yet

- Harshada SIP ProjectDocument47 pagesHarshada SIP ProjectSaurabh NeveNo ratings yet

- Analyzing Employee Satisfaction in a Software FirmDocument106 pagesAnalyzing Employee Satisfaction in a Software FirmPatan Najeema100% (1)

- Advanced Human Resource Management Ii: Study Pack ONDocument201 pagesAdvanced Human Resource Management Ii: Study Pack ONBukola ElishaNo ratings yet

- Sanskruti+ +CV+Document1 pageSanskruti+ +CV+shrutika.vstretchNo ratings yet

- Tanglewood Case Study 3Document9 pagesTanglewood Case Study 3Megan Purdy0% (1)

- 5E - Job Embeddedness - A Theoretical Foundation For Developing A ComprDocument25 pages5E - Job Embeddedness - A Theoretical Foundation For Developing A ComprM Vega Arrafah SNo ratings yet

- Effect of Downsizing On Employees MoraleDocument71 pagesEffect of Downsizing On Employees MoraleZindgiKiKhatir100% (1)

- Strategies and Practices of Talent Manag PDFDocument10 pagesStrategies and Practices of Talent Manag PDFÁvì ĎûăNo ratings yet

- Essay #4 CURRICULUMDocument3 pagesEssay #4 CURRICULUMEarthangel AngieNo ratings yet

- E-Journal GJMBR (A) Vol 15 Issue 8Document103 pagesE-Journal GJMBR (A) Vol 15 Issue 8Laksmi PuspitaNo ratings yet

- HRElective - Project - Nithin NDocument7 pagesHRElective - Project - Nithin NNithin TiniNo ratings yet

- Phri Exam Content Outline Refresh PDFDocument13 pagesPhri Exam Content Outline Refresh PDFMohammed HammoNo ratings yet

- Study of HRM Practices On Employees Retention: A Review of LiteratureDocument8 pagesStudy of HRM Practices On Employees Retention: A Review of LiteratureReny NapitupuluNo ratings yet

- Pi Global Talent Trends 2023 v11Document54 pagesPi Global Talent Trends 2023 v11lefkisNo ratings yet

- Journal Homepage: - : IntroductionDocument9 pagesJournal Homepage: - : IntroductionNikhita KrishnaiahNo ratings yet

- Recruitment and Selection PracticesDocument28 pagesRecruitment and Selection PracticesSnigdha ChadhaNo ratings yet

- 28 - People Resourcing StrategyDocument6 pages28 - People Resourcing Strategyjoe0% (1)

- Unit Nexus Interview Questions and Answers Guide.: Global GuidelineDocument13 pagesUnit Nexus Interview Questions and Answers Guide.: Global GuidelineVenkatesanNo ratings yet

- HR Carter Cleaning Case 2Document11 pagesHR Carter Cleaning Case 2Hussein ElsawafNo ratings yet

- Resume - Huzaifa Khan 23Document2 pagesResume - Huzaifa Khan 23Huzaifa KhanNo ratings yet

- Experienced Learning & Development Professional Yash PallichaDocument4 pagesExperienced Learning & Development Professional Yash PallichavvvvNo ratings yet

- Succession Planning For Nurse LeadersDocument7 pagesSuccession Planning For Nurse LeadersLicense Sure ReviewersNo ratings yet

- Sales and Distribution-A Case Study On CG Engineers LTDDocument6 pagesSales and Distribution-A Case Study On CG Engineers LTDDeven RanaNo ratings yet

- Tanker Management and Self Assessment 3 (TMSA 3)Document89 pagesTanker Management and Self Assessment 3 (TMSA 3)soner100% (2)

- Solved SRCC GBO 2017 Paper With Solutions PDFDocument49 pagesSolved SRCC GBO 2017 Paper With Solutions PDFJay DixitNo ratings yet

- Centum Learning ProjectDocument24 pagesCentum Learning ProjectKushal RajNo ratings yet

- GROUP ASSIGNMENT Managerial EconomicsDocument26 pagesGROUP ASSIGNMENT Managerial Economicsmahedre100% (1)

- Effectieness of CRM at AirtelDocument97 pagesEffectieness of CRM at Airtelgrewal267% (3)