Professional Documents

Culture Documents

hk00d 06-Db-Avn DD 1200-1800tb PDF

Uploaded by

Madalina NituOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

hk00d 06-Db-Avn DD 1200-1800tb PDF

Uploaded by

Madalina NituCopyright:

Available Formats

TECHNICAL DATA SHEET

AVN 1200 TB AVN 1800 TB

AVN 1200 TB AVN 1800 TB

Pipe Jacking

Special Features

Designed for soft ground, mixed ground and

especially hard rock conditions by use of

different cutting wheels (full face excavation).

Central access to cutting wheel for tool

replacement (backloading system).

Highly reliable steering operation due

to inductive measuring system.

Technical Data

1. Articulated Shield

Outer diameter

mm

Pipe OD

mm

Pipe ID

mm

Main drive

Max. torque

kNm

Revolution

LH / RH

rpm

Rated Power

kW

Roll correction

Steering

Steering cylinders

Force per cyl. / oil pressure

kN/bar

Stroke per cyl.

mm

Control

Computer data logging system

Fuzzy control (automatic steering)

Fully visualized process control

Active roll protection (el.-hydr.)

Suitability U.N.S.: ELS

ELS-HWL

GTS-P

2. Machine Can

Lubrication System

3. General Information

Pipe jacking

Drive length (recommended) m

Access to cutting wheel

Waterproofness

bar

Airlock

Telescopic and interjacking station

Slurry line diam.

mm

High pressure water system

Low pressure jet system

Different (variable) flushing modes / jet systems

to suit different ground conditions.

High pressure water system for operation in

cohesive soil.

Providing highly effective cone crusher.

Equipped with heavy duty long-life main bearing

and high torque peripheral drive.

AVN1200TB

Std*

Ext*

1 505

1 490

1 200

1 810

1 780

1 500

AVN1400TB

Std

Ext

1 740

1 720

1 400

1 970

1 940

1 600

AVN1500TB

Std

Ext

1 810

1 780

1 500

2 150

2 120

1 800

Hydraulic power pack in machine can.

Completely remote-controlled.

All machines compatible to U.N.S. Guidance

System.

AVN1600TB

Std

Ext

1 970

1 940

1 600

2 150

2 120

1 800

AVN1600TE

Std

Ext

1 970

1 940

1 600

2 150

2 120

1 800

AVN1800TB

Std

Ext

2 150

2 120

1 800

2 425

2 400

2 000

258

0-6.7

132

258

0-6.7

132

474

0-7.7

160

474

0-7.7

160

431

0-10.4

220

554

0-11.9

250

3

752/500

60

3

752/500

60

4

1 005/500

60

4

1 005/500

60

4

1 005/500

60

4

1 272/500

100

opt.

opt.

opt.

opt.

opt.

opt.

500

opt.

125

opt.

500

opt.

125

opt.

700

3

opt.

opt.

125

opt.

900

3

opt.

opt.

150

opt.

900

3

opt.

opt.

150

opt.

900

3

opt.

opt.

150

opt.

All measures and data represent the main feasibility of the machines. Individual solutions are possible. Errors excepted.

* Std = standard; Ext = extension kit

TECHNICAL DATA SHEET

A V N 12 0 0 T B A V N 18 0 0 T B

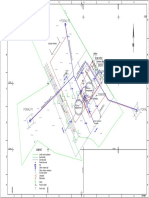

Machine dimensions

Outer Diameter

Length artic. shield

Length machine can

Max. single weight

OD

LAS

LMC

W

mm

mm

mm

kg

AVN1200TB

1 505

3 750

3 200

13 000

AVN1400TB

1 740

3 750

3 200

17 000

AVN1500TB

1 810

3 800

3 200

22 000

AVN1600TB

1 970

3 900

3 200

24 000

AVN1600TE

1 970

4 200

3 200

25 000

AVN1800TB

2 150

4 200

3 200

29 000

Shaft dimensions

1)

2)

1) Compact jacking rig:

- smaller launch shaft needed

2) Main jacking station:

- continuous push with telescopic

cylinders (time advantage)

- higher thrust capacity possible

by adding of main jacks

Launch Shaft

Compact jacking rig

Pipe

length

2 500 mm

3 000 mm

Launch Shaft

Main jacking station

2 500 mm

3 000 mm

Data Sheet AVN1200TB-AVN1800TB 10/2005

Reception Shaft

LAS

Circular

Rectangular

AVN1200TB

AVN1400TB

AVN1500TB

AVN1600TB

AVN1600TE

AVN1800TB

Shaft size

= 4.87m

5.0m x 4.5m

= 4.87m

5.0m x 4.5m

= 8.5m

8.0m x 3.5 m

= 8.5m

8.0m x 3.5m

3 750mm

= 4.5m

4.5m x 2.5m

Shaft size

= 5.27m

5.0m x 4.5m

= 6.5m

5.5m x 4.5m

= 8.5m

8.0m x 3.5m

= 8.5m

8.0m x 3.5m

3 750mm

= 4.5m

4.5m x 2.5m

Shaft size

= 5.27m

5.0m x 4.5m

= 6.5m

5.5m x 4.5m

= 8.5m

8.0m x 3.5m

= 8.5m

8.0m x 3.5m

3 800mm

= 5.0m

4.5m x 2.5m

Shaft size

= 6.5m

5.5m x 4.5m

= 6.5m

5.5m x 4.5m

= 8.5m

8.0m x 4.0m

= 8.5m

8.0m x 4.0m

3 900mm

= 5.0m

5.0m x 3.0m

Shaft size

= 6.5m

5.5m x 4.5m

= 6.5m

5.5m x 4.5m

= 9.0m

8.5m x 4.0m

= 9.0m

8.5m x 4.0m

4 200mm

= 5.5m

5.0m x 3.0m

Shaft size

= 6.5m

5.5m x 4.5m

= 6.5m

5.5m x 4.5m

= 9.0m

8.5m x 4.0m

= 9.0m

8.5m x 4.0m

4 200mm

= 5.5m

5.0m x 3.0m

All dimensions according to 15m shaft depth.

Machine type description e.g. AVN 1) 1800 2) T 3) B 4)

1)

Machine

type

2)

ID of

jacking pipe

3)

Access to

cutting wheel

4)

Type of container, power transfer

from container to machine

X = no access

B = electric cable to machine,

power pack in machine

T = central door

C = hydraulic drive from container

directly into machine

A = door above main drive

or in top of pressure wall

E = electric cable from container

directly into machine

H = medium voltage supply

to machine (> 1000V)

Herrenknecht AG

77963 Schwanau Germany

Tel. +49 (7824) 302 923

Fax +49 (7824) 302 364

utility@herrenknecht.de

www.herrenknecht.com

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Avn800xc Avn2000ac PJ DB GB 14-06-30 HK2052 01Document2 pagesAvn800xc Avn2000ac PJ DB GB 14-06-30 HK2052 01MinaSaeedNo ratings yet

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDocument21 pagesASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- Supply Air Grilles, Diffusers and Duct Components GuideDocument21 pagesSupply Air Grilles, Diffusers and Duct Components Guidemunim87No ratings yet

- Technical Data Products 2009 CompletDocument62 pagesTechnical Data Products 2009 CompletRobert NedelcuNo ratings yet

- Heavy Duty Oil & Gas Pump SolutionsDocument6 pagesHeavy Duty Oil & Gas Pump Solutionsvrider81No ratings yet

- Sperry Drill MotorsDocument4 pagesSperry Drill Motorsjoseahilarrazam100% (1)

- Mar Win SteamDocument33 pagesMar Win SteamChristopher RequintoNo ratings yet

- Komatsu Shop Manual PC400 PC450Document216 pagesKomatsu Shop Manual PC400 PC450Ricardo Diaz88% (50)

- Burst Plug Tubing Drain - Technical DatasheetDocument8 pagesBurst Plug Tubing Drain - Technical DatasheetEvolution Oil ToolsNo ratings yet

- Macho Drum Winches Data v1.4Document2 pagesMacho Drum Winches Data v1.4AdrianSomoiagNo ratings yet

- Cosmos Imtex Die MouldDocument2 pagesCosmos Imtex Die MouldAbhishek Velaga100% (2)

- 197 Hp Daewoo Excavator Technical SpecsDocument12 pages197 Hp Daewoo Excavator Technical SpecsVan ThaoNo ratings yet

- Series 774DCDA Specification SheetDocument2 pagesSeries 774DCDA Specification SheetWattsNo ratings yet

- Mercer (9500 Series)Document24 pagesMercer (9500 Series)Zhi Yao LimNo ratings yet

- Series SS07F Specification SheetDocument2 pagesSeries SS07F Specification SheetWattsNo ratings yet

- P08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualDocument12 pagesP08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualrehanNo ratings yet

- CSU Nut RunnersDocument1 pageCSU Nut RunnersAgus SetiyonoNo ratings yet

- Avn250xc Avn700xc PJ DB GB 14-06-30 HK2052 01Document2 pagesAvn250xc Avn700xc PJ DB GB 14-06-30 HK2052 01MinaSaeedNo ratings yet

- 12H Global Motor GraderDocument5 pages12H Global Motor GraderEdwin ExecellentNo ratings yet

- Bombas KUDU de Cavidades Progresivas: Series Model M /D BFPD M /D BFPD M FT Altura (M) /gasto (M") @100rpm 2 3/8"Document2 pagesBombas KUDU de Cavidades Progresivas: Series Model M /D BFPD M /D BFPD M FT Altura (M) /gasto (M") @100rpm 2 3/8"momo177sasaNo ratings yet

- Turn To The Experts: Room Air ConditionersDocument2 pagesTurn To The Experts: Room Air Conditionersckyee88No ratings yet

- Kaltfräse W 200 Slipform Paver SP 25 / SP 25 I: Technische Daten Technical SpecificationDocument8 pagesKaltfräse W 200 Slipform Paver SP 25 / SP 25 I: Technische Daten Technical SpecificationRobertHeningNo ratings yet

- High Speed Drilling & Tapping CenterDocument8 pagesHigh Speed Drilling & Tapping CenterAlexandra PanaiteNo ratings yet

- Mud Pump Expendables Gardner DenverDocument8 pagesMud Pump Expendables Gardner Denverleo0% (1)

- Forland Services LLC Long Stroke Pumping UnitDocument3 pagesForland Services LLC Long Stroke Pumping Unitals.persia.sa061No ratings yet

- Series 909RPDA Specification SheetDocument4 pagesSeries 909RPDA Specification SheetWattsNo ratings yet

- Pole RssDocument2 pagesPole Rssgenial72No ratings yet

- Mechanical Filter Data SheetDocument2 pagesMechanical Filter Data Sheetcot_byNo ratings yet

- 0108 Evmu Evmul EvmugDocument44 pages0108 Evmu Evmul EvmugeuricordNo ratings yet

- Fast, Precise Torque Adjustment! Precision Tork™ Clutches and BrakesDocument8 pagesFast, Precise Torque Adjustment! Precision Tork™ Clutches and BrakesFrancisco A. GarcíaNo ratings yet

- Boring Bar ManualDocument41 pagesBoring Bar ManualPranjal Chakraborty100% (1)

- T Ces Series PDFDocument12 pagesT Ces Series PDFDaniel InostrozaNo ratings yet

- Loaia Star Linger MachineryDocument30 pagesLoaia Star Linger MachinerySaif MastoiNo ratings yet

- Bico Handbk 11-11Document88 pagesBico Handbk 11-11faishal hafizhNo ratings yet

- High Pressure PumpsDocument8 pagesHigh Pressure PumpsnicolasbarriosNo ratings yet

- Yanmar Engine Type 6CXM-GTE2Document2 pagesYanmar Engine Type 6CXM-GTE2Yoga_DMNo ratings yet

- Daniel Senior Orifice Fitting: Fastener Torque GuideDocument20 pagesDaniel Senior Orifice Fitting: Fastener Torque GuideDianaMartínezNo ratings yet

- Alloy Chain Sling Working Load LimitsDocument14 pagesAlloy Chain Sling Working Load LimitsjillianixNo ratings yet

- Equipo Hot Tap de 42 inDocument5 pagesEquipo Hot Tap de 42 inSerch Villa100% (1)

- High Speed, Water Cooled 5 To 18 HPDocument5 pagesHigh Speed, Water Cooled 5 To 18 HPapi-311397395No ratings yet

- Hitachi ZX850Document11 pagesHitachi ZX850Andi MercuryNo ratings yet

- Series 709 Specification SheetDocument4 pagesSeries 709 Specification SheetWattsNo ratings yet

- Hammer MillDocument4 pagesHammer MillLinh Tran100% (2)

- 14 General Shop ToolsDocument14 pages14 General Shop ToolsEbied Yousif AlyNo ratings yet

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocument2 pagesStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771No ratings yet

- ORBINOX-DA-CYLINDER-DATADocument5 pagesORBINOX-DA-CYLINDER-DATALuis CarlosNo ratings yet

- York Fan Coil UnitDocument16 pagesYork Fan Coil Unitjaja100% (3)

- Inverter Microprocessor-Controlled: Certified Kubota Mfg. CorpDocument4 pagesInverter Microprocessor-Controlled: Certified Kubota Mfg. CorpTotok SurotoNo ratings yet

- Avn1200tb Avn1800tb PJ DB GB 14-06-30 HK2052Document2 pagesAvn1200tb Avn1800tb PJ DB GB 14-06-30 HK2052Enri05No ratings yet

- Your Complete Raise Boring Solutions PDFDocument6 pagesYour Complete Raise Boring Solutions PDFIng del PeleNo ratings yet

- MODEL 400: Raise BoreDocument2 pagesMODEL 400: Raise BoreAprianto Sahat Pardamean SigalinggingNo ratings yet

- Hydraulic Motors Epms: Cutaway of EPMS MotorDocument16 pagesHydraulic Motors Epms: Cutaway of EPMS MotorDavíð Örn FriðrikssonNo ratings yet

- Backflow PreventersDocument4 pagesBackflow PreventersSam WeberNo ratings yet

- EZ Pilot RSS Brochure HalliburtonDocument2 pagesEZ Pilot RSS Brochure Halliburtonnstl0101100% (2)

- Kvkew 0089 enDocument4 pagesKvkew 0089 enksathishgreenNo ratings yet

- 2061 e Vthlip103 en Voith Internal Gear Pumps IpvaDocument12 pages2061 e Vthlip103 en Voith Internal Gear Pumps IpvaAnonymous ARcPWq7L38No ratings yet

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Utresco Gsof GabefsresatDocument4 pagesUtresco Gsof GabefsresatMadalina NituNo ratings yet

- Plan Retele GRADISTEA - Var 1-Layout1Document1 pagePlan Retele GRADISTEA - Var 1-Layout1Madalina NituNo ratings yet

- STR SG FSKJDocument10 pagesSTR SG FSKJMadalina NituNo ratings yet

- Bibliografue CanadaDocument3 pagesBibliografue CanadaMadalina NituNo ratings yet

- Uibulus CurulusDocument4 pagesUibulus CurulusMadalina NituNo ratings yet

- ReadmeDocument1 pageReadmeChechaa PerezNo ratings yet

- ASUS Republic of Gamers brand (ROG) history and leadership in PC gamingDocument2 pagesASUS Republic of Gamers brand (ROG) history and leadership in PC gamingMadalina NituNo ratings yet

- Ponug RefulDocument5 pagesPonug RefulMadalina NituNo ratings yet

- ASUS Republic of Gamers brand (ROG) history and leadership in PC gamingDocument2 pagesASUS Republic of Gamers brand (ROG) history and leadership in PC gamingMadalina NituNo ratings yet

- Muyevoua BaprostilorDocument2,501 pagesMuyevoua BaprostilorMadalina NituNo ratings yet

- DOP Renddderoc FC July 201dds3Document2 pagesDOP Renddderoc FC July 201dds3Madalina NituNo ratings yet

- Bdo Fkwewds1Document8 pagesBdo Fkwewds1Madalina NituNo ratings yet

- Echipament Caracteristici NR Buc ActiveDocument8 pagesEchipament Caracteristici NR Buc ActiveMadalina NituNo ratings yet

- Beheover Urse DT Uudyttr Uresecckta Mig Das SGTDocument2,721 pagesBeheover Urse DT Uudyttr Uresecckta Mig Das SGTMadalina NituNo ratings yet

- Apa Fantani23 4Document2 pagesApa Fantani23 4Madalina NituNo ratings yet

- Utr RRR T Dasjh HF Abum Dabivala TresssDocument454 pagesUtr RRR T Dasjh HF Abum Dabivala TresssMadalina NituNo ratings yet

- P 10 04 PDFDocument11 pagesP 10 04 PDFMadalina NituNo ratings yet

- Geferete RetefardfDocument18 pagesGeferete RetefardfMadalina NituNo ratings yet

- Ayhnjuikl TresfvgddteddDocument68 pagesAyhnjuikl TresfvgddteddMadalina NituNo ratings yet

- Geferete RetefardfDocument18 pagesGeferete RetefardfMadalina NituNo ratings yet

- Geferete RetefardfDocument18 pagesGeferete RetefardfMadalina NituNo ratings yet

- Geferete RetefardfDocument18 pagesGeferete RetefardfMadalina NituNo ratings yet

- Geferete RetefardfDocument18 pagesGeferete RetefardfMadalina NituNo ratings yet

- Hterfg Terhs DDocument23 pagesHterfg Terhs DMadalina NituNo ratings yet

- 05 Microtunneling Machines 22Document13 pages05 Microtunneling Machines 22Madalina Nitu100% (1)

- Geferete RetefardfDocument18 pagesGeferete RetefardfMadalina NituNo ratings yet

- Fachisurt DefectddursDocument6 pagesFachisurt DefectddursMadalina NituNo ratings yet

- Bagadta Terd KashfDocument2 pagesBagadta Terd KashfMadalina NituNo ratings yet

- Pavalopulis GdgtulutusDocument2 pagesPavalopulis GdgtulutusMadalina NituNo ratings yet

- Programming 1 - Sample Milestone Assignment 2 Questions: Milestone 2 On 10/25/2021, In-Class Released: October 21, 2021Document7 pagesProgramming 1 - Sample Milestone Assignment 2 Questions: Milestone 2 On 10/25/2021, In-Class Released: October 21, 2021Kayam Brahmaiah AchariNo ratings yet

- Bobcat Loader t590 Hydraulic Electrical SchematicDocument22 pagesBobcat Loader t590 Hydraulic Electrical Schematicscottmartin240600xro100% (130)

- HubSpot Reporting Certification AnswersDocument23 pagesHubSpot Reporting Certification AnswersE KaynaklarNo ratings yet

- 151820L (G) - 7M Manual de Servicio Montacargas HyundaiDocument247 pages151820L (G) - 7M Manual de Servicio Montacargas Hyundaihernando ramosNo ratings yet

- Difference Between Mis and DssDocument16 pagesDifference Between Mis and DssKelly BaileyNo ratings yet

- Computer Organization PDFDocument2 pagesComputer Organization PDFCREATIVE QUOTESNo ratings yet

- Samiul Assignment Staad ProDocument30 pagesSamiul Assignment Staad ProMd. Samiul IslamNo ratings yet

- TN40CMSP002 2 0 2Document192 pagesTN40CMSP002 2 0 2emmasustechNo ratings yet

- KA7630/KA7631: Fixed Multi-Output RegulatorDocument6 pagesKA7630/KA7631: Fixed Multi-Output RegulatorTecnico GenioNo ratings yet

- Productivity Tools For AutoCAD Civil 3D 2015Document1 pageProductivity Tools For AutoCAD Civil 3D 2015Arturo Joel Polanco UrracaNo ratings yet

- Volvo MID 140 Fault CodesDocument20 pagesVolvo MID 140 Fault CodesModestas89% (19)

- 6, HM.2023Document5 pages6, HM.2023Want ONo ratings yet

- Document SummaryDocument13 pagesDocument SummaryjagannathNo ratings yet

- 8051 Microcontroller External Interrupt ProgrammingDocument28 pages8051 Microcontroller External Interrupt ProgrammingsharadaNo ratings yet

- SG Frenic Lift en 1 8 0Document42 pagesSG Frenic Lift en 1 8 0محمدحمادNo ratings yet

- Lockout TagoutDocument41 pagesLockout Tagoutm_alodat6144100% (1)

- MCQ Question BankDocument20 pagesMCQ Question BankmunnaarsenalNo ratings yet

- Fusite: With Fusite, Mission Critical Becomes Mission AccomplishedDocument4 pagesFusite: With Fusite, Mission Critical Becomes Mission AccomplishedkEWQ 865kNo ratings yet

- Vehicle Tracking Using Android AppDocument2 pagesVehicle Tracking Using Android AppmonkeNo ratings yet

- Advanced Security Audit Policy Step-By-Step GuideDocument19 pagesAdvanced Security Audit Policy Step-By-Step GuideVictor CastroNo ratings yet

- DataKom 309J - USERDocument61 pagesDataKom 309J - USERKhaleel KhanNo ratings yet

- Technical Specification-ABT MeterDocument17 pagesTechnical Specification-ABT MeterAnkit Airun100% (2)

- NG10 Manual 01 2011Document164 pagesNG10 Manual 01 2011nknfiveNo ratings yet

- TB 971Document5 pagesTB 971rybthenry engineNo ratings yet

- Business Continuity and Disaster RecoveryDocument18 pagesBusiness Continuity and Disaster RecoveryUsaid KhanNo ratings yet

- Managing e BusinessDocument3 pagesManaging e BusinessNeelesh KumarNo ratings yet

- 9661 HF Ground Radio Family 1424Document2 pages9661 HF Ground Radio Family 1424Quoc Mai0% (1)

- Using LSTM and GRU Neural Network Methods For Traffic Ow PredictionDocument6 pagesUsing LSTM and GRU Neural Network Methods For Traffic Ow PredictionClara RontoméNo ratings yet

- Growatt 50 - 60KWDocument2 pagesGrowatt 50 - 60KWmk gandhiNo ratings yet

- E AadharDocument1 pageE AadharPranita RathodNo ratings yet