Professional Documents

Culture Documents

Ups

Uploaded by

Mohamad Syukri Abd RahamanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ups

Uploaded by

Mohamad Syukri Abd RahamanCopyright:

Available Formats

1

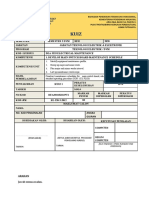

SISTEM BEKALAN KUASA TANPA GANGGUAN (UPS)

1.

PENGENALAN

Bekalan kuasa bantu adalah satu perkara yang sangat mustahak bagi

menjamin agar perjalanan sesuatu sistem itu tidak terganggu. Sistem

bekalan kuasa tanpa gangguan (UPS) adalah salah satu sistem kuasa

bantu yang amat terjamin dan berteknologi tinggi. Kegunaannya

adalah berbeza iaitu mengikut keperluan beban tetapi pada

kebiasaannya ianya terhad kepada beban-beban yang kritikal sahaja

umpamanya komputer, PABX, dsb.

2.

MENGAPA SISTEM UPS ITU PERLU

Untuk pengetahuan, harga bagi sesuatu UPS itu adalah jauh lebih

tinggi daripada harga sebuah set janakuasa tunggusedia. Jadi

kenapakah kita masih mahu menggunakan sistem UPS. Jawapan bagi

soalan ini ialah keperluan kuasa bantu yang stabil dan terjamin bagi

sesuatu beban yang kritikal dimana gangguan kuasa tidak boleh

berlaku walau sesaat pun. Contohnya bagi sistem komputer, jika

berlakunya gangguan kuasa ianya akan kehilangan isian didalam

memorinya. Begitu juga dengan sistem lampu landasan kapal terbang

(bagi kategori II keatas), gangguan kuasa tidak boleh melebehi satu

saat.

3.

JENIS-JENIS SISTEM UPS

Sistem UPS terbahagi kepada beberapa jenis tetapi yang biasa

digunakan ialah:

i)

ii)

Jenis Unitary

Jenis Parallel

Jenis Unitary

Jenis Parallel

4.

PEMILIHAN SISTEM UPS

Perkara-perkara utama yang harus diambilkira semasa membuat

pemilihan sistem UPS yang sesuai dengan kehendak kita adalah:

a.

Kuasa

Kuasa yang dikehendaki bagi sesuatu pemasangan hendaklah

ditentukan. Ada dua cara bagi menentukan kuasa sistem UPS iaitu

memilih saiz sistem UPS yang boleh menampung beban semasa dan

beban tambahan dimasa akan datang. Cara ini akan melibatkan kos

permulaan dan kos penyelenggaraan yang tinggi sedikit oleh kerana

kemungkinan sistem UPS ini beroperasi bukan pada kecekapan yang

tinggi, tetapi dalam jangkamasa panjang ianya boleh menjimatkan.

Cara kedua ialah dengan menghadkan kepada beban tersambung

sahaja. Ini adalah dengan menentukan saiz sistem UPS sahaja tetapi

keperluan bagi membolehkan sistem UPS ini dipertingkatkan dimasa

hadapan perlu diadakan. Kos permulaan dan penyelenggaraan bagi

cara ini adalah lebih murah.

ii)

Peraturan Voltan

Peraturan voltan keluaran dapat memberi panduan mengenai kualiti

peralatan yang dicadangkan itu. Pada kebiasaannya kita hendaklah

menentukan bahawa peraturan voltan adalah plus / minus 1% dalam

keadaan tetap dan perubahan voltan keluaran berada dalam jeda

(range) +10% hingga 2% daripada nilai terkadar keatas jumlah

beban.

iii)

Herotan Harmonik (Harmonic Distortion)

Aras herotan harmonik keseluruhannya hendaklah ditentukan. Ini

sebenarnya mengukur kualiti gelombang bentuk sinus yang

dikeluarkan oleh sistem UPS. Pihak pengeluar komputer biasanya

memberikan kadar maksimumnya sebanyak 5% sahaja.

iv)

Frekuensi

Beban komputer pada kebiasaannya boleh menerima perubahan

frekuensi dalam kadar plus / minus 1% sahaja.

v)

Kemuatan Beban Lebih

Oleh kerana terdapatnya beban yang boleh menyebabkan arus rempuh

(inrush current) masuk yang tinggi semasa ianya dihidupkan,

kemungkinan sistem UPS yang dicadangkan itu terpaksa dinaikkan

saiz sebanyak 100 250%, tertakluk kepada jenis beban.

5.

KOMPONEN UTAMA SISTEM UPS

Antara komponen utama sistem UPS ialah:

a.

b.

c.

d.

e.

Penerus (rectifier)/battery charger

Static transistor inverter

Electronic static switch

Bateri

Manual maintenance by-pass circuit

Katalah satu pemasangan mempunyai beban kritikal yang berkadaran

seperti berikut: 40KVA, 30KVA, 15KVA, 10KVA dan 50KVA.

Beban 10KVA mempunyai

selama 200ms, dihidupkan

tidak menyebabkan arus

pemasangan ini ialah 0.2

hadapan yang dijangkakan

maksimum semasa.

arus rempuh masuk bersamaan 4 x In

sekali dalam sehari. Beban-beban lain

rempuh masuk. Faktur kuasa bagi

menyusul. Keperluan tambahan masa

adalah sebanyak 20% daripada beban

Penentuan mengenai tatarajah optimum

Keadaan beban stabil

P = (40+30+15+10+50) KVA = 145KVA

Katalah tambahan beban akan dimasa hadapan sebanyak 20%

P = 20% x 145 = 30KVA

Pu = (145 + 30) = 175KVA

Muatan terpasang tidak boleh kurang daripada Pu. Pa /175KVA

Saiz sistem UPS bagi Unitary Chain piawai yang paling hampir ialah

200KVA

5.1

Kekangan (Constrains)

Beban Lebih Fana (load transient) dari inductive load seperti motor

dan yang seumpamanya.

Kes yang paling berat ialah apabila beban 10KVA dihidupkan selepas

beban-beban lain. Beban puncak akan menjadi:

Pp = 40 + 30 + 15 + (4x10) + 50 + 30 = 205KVA

Muatan beban lebih yang dibenarkan ialah 1.7 kali ganda iaitu 1.7 x

200 = 340KVA.

Oleh itu saiz 200KVA itu adalah memadai.

Sistem UPS memberi kuasa bantu selain bateri apabila bekalan kuasa

terputus. Bateri ini mengeluarkan arus terus oleh itu kuasa yang

dikeluarkan perlu ditukar kepada arus ulangalik. Ini diperolehi dengan

adanya penyongsang (inverter).

Jenis-jenis bateri yang boleh digunakan bagi tujuan ini adalah:

a.

b.

Sel asid plumbum (lead acid cell)

Kadmium-nikel (nikel cadmium)

Jenis bateri yang lazim digunakan ialah kadmium nikel atas sebabsebab penyenggaraan yang minimum, lasak dan ketahanannya

sehingga 10 tahun jika disenggara dengan baik.

5.2

Pemilihan Saiz Bateri

Untuk mendapatkan saiz bateri yang tepat, dua nilai adalah

dikehendaki iaitu:

i) Arus discaj atau kuasa discaj

ii) Tempoh discaj dimana bateri dikehendaki membekal kuasa semasa

kuasa utama terputus.

6.

RUMUSAN AM

Penggunaan sistem UPS adalah yang terbaik bagi menjamin bekalan

kuasa Bantu yang berterusan dan stabil tetapi ada beberapa perkara

yang perlu diambil ingatan semasa membuat pemilihan serta

keputusan bagi memesan dan memasang sistem tersebut. Diantaranya

ialah:

i)

ii)

Oleh kerana kos sistem UPS ini adalah tinggi, keputusan untuk

memasang sistem ini perlulah mendapat justifikasi yang

memuaskan. Beban-beban yang penting dan kritikal perlu

dikenalpasti. Ini sangat mustahak bagi mempastikan bahawa

sistem UPS yang akan dipasang itu nanti akan beroperasi pada

tahap yang optimum.

Selain daripada yang tersebut diatas, penggunaan set janakuasa

tunggusedia sebagai bekalan kuasa Bantu kedua adalah

difikirkan perlu dan mustahak agar tempoh penggunaan sistem

UPS dapat dikurangkan kerana tempoh bantu sistem UPS

bergantung kepada saiz dan keupayaan bateri. Tempoh yang

panjang dari yang sewajarnya akan hanya menambahkan kos

pemasangan.

SENGGARAAN SISTEM UPS

7.1

Rectifier dan Inverter

System UPS jenis rectifier dan inverter tidak memerlukan senggaraan

berkala secara khusus sebab ia adalah alat elektronik. Secara amnya

alat elektronik hendaklah dijaga kebersihannya terutama dari habuk.

Selain itu yang penting adalah suhu dan peredaran udara bilik UPS.

Suhu yang tinggi akan mengakibatkan komponen elektronik cepat

rosak. Kalau bilik UPS mempunyai alat hawa dingin itu adalah yang

sebaiknya. Kalau tidak system peredaran udara hendaklah dipastikan

dalam keadaan baik.

Alat UPS moden mempunyai self-diagnostic system dimana ia akan

memberitahu kita apa-apa masaalah yang terdapat didalam sistemnya.

7.2

Bateri

Jika bateri jenis tanpa senggaraan (maintenance free battery) tiadalah

senggaraan yang perlu dibuat kepada bateri kecuali pastikan caj bateri

adalah baik dan masih mempunyai kuasa yang mencukupi.

Jika bateri jenis lead acid, paras elektrolid hendaklah sentiasa

dipastikan melebihi paras minima, ketumpatan bandingan elektrolid

diantara 1.1 ke 1.2.

Periksa keadaan caj bateri masih NORMAL, kalau lemah hendaklah

ditukar kepada yang baru

Sambungan kepada bateri-bateri hendaklah dalam keadaan bersih dan

baik (good contact).

Sekali sekala atau sebulan sekali ujian hendaklah dibuat untuk

memastikan system UPS berfungsi dengan baik iaitu dengan

memutuskan bekalan normal (TNB) dan pastikan UPS boleh

berfungsi seperti yang diharapkan.

Untuk trouble shooting dan pembaikan komponen elektronik didalam

alat UPS selalunya pembekal dipanggil untuk kerja-kerja tersebut

disebabkan kepakaran yang mereka ada serta bekalan alat ganti yang

hanya boleh diperolehi dari pembekal jenama tersebut sahaja.

8 Specification for UPS

Scope

The UPS shall be continuous duty, solid state, transistorized. It shall operate

in conjunction with existing electrical system to provide continuous quality

power for electronic equipment loads.

System Description

Components

The UPS shall consist of the following major components

-

Rectifier / battery charger

Static transistor inverter

Electronic static switch and reserve supply

Manual maintenance by pass circuit

Input, battery, reverse, output and by pass switches

Battery / optional battery cubicle

Microprocessor Control and Diagnostic

Operation and control of the UPS shall be provided through the use of

microprocessor control logic. Indications, measurements and alarms together

with power history and battery autonomy shall be shown on an eight

characters liquid crystal display.

Start up, shut down, manual transfer offload to reserve and retransfer

back to inverter shall be by clear step by step routines shown on the display.

Options

a. Remote mimic to display status of remote alarm, with audible alarm,

audible alarm mute, test pushbutton and mimic AC supply on/off

switch

b. Computer interface via a 15way D connector to signal UPS on,

reserve to load, AC input fail and battery low

c. Remote terminal display up to 10 meters distance of the alpha

numeric diagnostic via a RS 232C port

d. Easy 10 remote colour or monochrome terminal display up to 10

meters distance of the diagnostic both graphically and alpha

numerically

e. Easy 1000 as (d) above except transmission by a RS 422 interface

allowing a distance of up to 1000 meters

f. Life remote monitoring of the UPS status by a service center

g. Remote emergency power off to STOP the inverter

h. Thermal and magnetic shunt trip circuit breakers in lieu of main

switches

i. Input and/or output isolation transformers mounted in a matching

cabinets

j. Input current harmonic distortion filter mounted within the UPS, to

limit the THD to less than 10% and improve input power factor to 0.9

k. 12 pulse rectifier / battery charger to limit input current THD to less

than 12%

l. Input current harmonic distortion filter. Mounted in a matching

cubicle in conjunction with (k) above to limit input current THD to

less than 5%

m. Input and/or output RFI suppression filters to external to the UPS

n. Battery insulation alarm dependent if isolation transformers option

fitted

o. Cooling air inlet dust filters to increase protection to IP40

p. Parallel operation for both a common battery and common output with

up to 6 UPS

MODES OF OPERATION

The UPS shall be designed to operate as an on-line reserve transfer system in

the following modes:

Normal

The critical load is supplied continuously by the inverter. The

rectifier/battery charger derives power from the commercial AC source and

supplies DC power to the inverter whilst simultaneously maintaining the

battery in fully charged condition. The static switch monitors and ensures the

inverter tracks the reserve supply frequency. This means any automatic

transfer to the reserve supply due to an overload etc. is frequency

synchronized and does not cause an interruption to the critical load.

10

Overload

In the event of an inverter overload, manual stop or failure the static

switch will automatically transfer the critical load to the reserve

supply, without interruption.

Emergency

Upon failure or reduction (-15%) of the commercial AC power the

critical load is supplied, without any switching, by the inverter

drawing its power from the associated battery.

There shall be no interruption to the critical load upon failure,

reduction or restoration of the commercial AC power.

Recharge

Upon restoration of the commercial AC power, the rectifier/charger

powers the inverter and simultaneously recharges the battery. This

shall be an automatic function and shall cause no interruption to the

critical load.

By-pass Mode

If UPS maintenance is required or repair necessary, by manually

operating the by-pass switch in the correct sequence, it shall be

possible to isolate the main modules for maintenance or repair but

continue to supply the load from the reserve supply.

Transfer/retransfer of the critical load is accomplished by

automatically synchronizing the UPS to the reserve supply and

paralleling the inverter with the reserve source, before closing or

opening the by-pass switch as appropriate.

Battery Servicing

If the battery is taken out of service for maintenance, it shall be

disconnected from the rectifier/charger and inverter by means of a

switch. The UPS shall continue to function and meet all the

performance criteria specified except for the standby period.

11

GENERAL REQUIREMENTS

Applicable standards

BS 2772 part 1/IEC 2041 (CE) 44-5) Electrical equipment of

industrial machines

BS 5486 part 1 and 2/IEC 439.2 (CEI 17-13) Low-voltage switchgear

assemblies

BS 4417/IEC 146 (CEI 22-1) Uninterruptible power supplies

BS 5490/IEC 529 (CEI 70-1) Protection enclosure degree

BS 3182/IEC 364 Building electrical installation

BS 5645/IEC 76 TBA (CEI 14-4, CEI 64-8, CEI 20-22)

Components

All active electronic devices shall be solid-state and shall not exceed

manufacturers recommended operating parameters for maximum

reliability.

Grounding

The UPS output AC neutral shall be electrically isolated from the UPS

chassis. The UPS chassis and signal ground system shall be connected

together and to a common ground point.

The UPS output AC neutral shall be connected to the commercial AC

power neutral ground in the installation.

EMI Suppression

Electromagnetic effect shall be minimized to ensure that computer

system or other similar electronic systems shall neither adversely

affect nor be affected by the UPS.

Materials

All materials and parts comprising the UPS shall be new and of

current manufacture.

12

RECTIFIER/BATTERY CHARGER

General / Input

Incoming commercial AC power shall be converted to a regulated DC

output by the rectifier/battery charger. Commercial AC normal voltage

380, 400 or 415 volts + 10% -15%, 3 phase, 3 wire, frequency 50Hz

(or 60Hz option) plus minus 5%.

The rectifier/battery charger shall be a 6 pulse, 3 phase fully

controlled rectifier bridge with constant voltage/constant current

characteristic.

Voltage Regulation

The rectifier/battery charger output voltage shall not deviate by more

than plus minus 1% RMS under the following conditions:

a. No load to 100% load variation

b. Primary input voltage and frequency variations up to the stated

limits

c. Ambient temperature variations within specified range

Walk-in/Soft Start

The rectifier/battery charger shall contain a timed walk-in circuit that

causes the unit to assume the load gradually over a period of 10

seconds after the input voltage is applied.

Power Factor

The rectifier/battery charger shall have an input power4 factor of

equal or greater than 0.8 lagging with nominal input voltage and in the

automatic float charge state.

Ripple

The rectifier/battery charger shall be provided with an output L-C

filter to limit the ripple to equal or less than 2% RMS maximum in the

automatic float charge state with the battery disconnected.

13

Total Harmonic Distortion (THD)

The maximum voltage THD on the input shall be equal or less than

15%.

The maximum current THD on the input shall be equal or less than

30%. The current drawn is not sinusoidal but includes harmonics

expressed in % of the fundamental as shown in Table (A) below. If a

5th harmonic trap option is specified the expected harmonics will be as

shown below (B).

Harmonic

5 Harmonic

7th Harmonic

11th Harmonic

13th Harmonic

17th Harmonic

19th Harmonic

THD

th

A

29%

5%

7%

1%

3%

1%

30%

B

5%

5%

7%

1%

3%

1%

10%

Capacity

The rectifier/battery charger shall have sufficient capacity to support a

fully loaded inverter and simultaneously maintain the battery in a fully

charged float condition.

After partial or complete discharge of the battery, the rectifier/charger

powers the inverter and automatically starts recharging the battery as

follows:

- at constant current (set at 10% of nominal capacity at 10 hour

rate) up to the recharge voltage level.

- at recharge voltage level until the threshold value of the

automatic return to float voltage has been reached.

A pushbutton located inside the equipment shall also be provided for

manually initiating a first charge or recharge boost cycle. The rectifier

output voltage shall be normally adjustable up to 2.7volt per cell. An

internal switch shall be provided to automatically select the correct

14

float charge voltage for sealed lead-acid or vented nickel cadmium or

vented lead acid cells.

The recharge cycle shall be preset at 12 or 24 hours.

Overvoltage Protection

The rectifier/battery charger shall be automatically turned-off if the

DC voltage exceeds the maximum preset value.

Automatic Battery Checking

The charging status of the battery shall be automatically continuously

checked by monitoring the charge current ripple and if out of preset

limits, an alarm shall be shown on the LCD display.

Electrical Characteristic

15

Battery

When operated with a sealed maintenance free lead-acid battery, the

preset operating parameters shall be as follows:

Input Voltage

Nominal voltage

Float voltage

Boost voltage

End of battery discharge

voltage

380V

384 V

435 V

441 V

320 V

400V

408 V

463 V

468 V

340 V

415V

420 V

476 V

483 V

350 V

TRANSISTOR INVERTER

General/Input

The inverter shall use pulse width modulation (PWM) technology to

generate three phase sinusoidal AC power. The inverter shall operate

within specification over the nominal rectifier/battery charger output

voltage range.

Output

The inverter output shall be controlled by a microprocessor.

Voltage 380, 400, or 415 volts and neutral 50Hz or 60Hz option, 3

phase, 4 wire.

Maximum power in kVA or kW or both at 0.8 power factor lagging

shall be declared.

Voltage Regulation

The inverter steady state output voltage shall not deviate by more than

plus or minus 1% in a steady state condition for input voltage

variations within quoted limits and plus 10% - 8% for 0 to 100% load

step and vice versa.

16

Frequency Regulations

The inverter steady state output frequency when synchronized to

reserve shall not deviate by more than plus minus 1% or optionally

4%.

Frequency Slew Rate

Frequency slew rate shall be less than 0.8Hz per second and

controlled by the microprocessor controlled logic.

Frequency Control

The output frequency of the inverter shall be controlled by a quartz

oscillator, which can be operated as a free running unit or as a slave

for synchronized operation with a separate AC source.

The accuracy of the frequency control shall be plus minus 0.0005%

when free running and be controlled by the microprocessor controlled

logic.

Total Harmonic Distortion

The inverter shall provide harmonic neutralization and filtering to

limit the total harmonic distortion in the output voltage to less than

2% with a linear load.

Voltage Transient Response

The inverter transient voltage shall not exceed +105 8% when

subjected to a load application of 0 to 100% load.

Transient Recovery

The output voltage shall return to within plus minus 2% within 50

miliseconds after a load step application of 100%.

Overload

17

The inverter shall be capable of supplying an overload of 125% for 10

minutes, 150% for 10 seconds at 0.8 PF lagging. Short circuit current

for 1 second shall be 200%.

Voltage Adjustment

The inverter shall have the option to compensate for line voltage drop

of 0%, 2%, 4% or 5%.

Inverter Shut-down

Upon sensing an internal failure, the inverter electronic-control shall

instantaneously remove the inverter from the critical load, transfer to

reserve if within limits and then shut itself down.

Inverter DC Protection

The inverter shall be prorected against DC overvoltage and

undervoltage according to the following recommended values for the

standard number of sealed lead acid cells.

DC overvoltage protection: 2.5 volts per cell

DC undervoltage warning: 1.8 volts per cell

DC undervoltage protection: 1.67 volts per cell

Output Voltage Symmetry

The inverter shall guarantee the symmetry of the oiutput voltages at

plus minus 1% for balanced loads or plus minus 3% for 100%

unbalanced load.

Phase Displacement

Phase angle displacement between the three phase voltage shall be:

-120 degree plus mminus 1 degree balanced load

-120 degree plus minus 100% unbalanced load

18

Load Fuses

The inverter shall be capable of rupturing within 10milisecond the

following fuse types:

Extra fast semiconductor: equal or less than 50% nominal UPS output

current

Fast: equal or less than 30% nominal UPS output current

Slow: equal or less than 10% nominal UPS output current

ELECTRONIC STATIC SWITCH

General

The electronic static switch shall be a naturally commutated, fully rated,

high speed, solid state transfer device and rated for continuous duty

operation.

The electronic static switch shall provide the following transfer and

retransfer operations.

- Uninterrupted transfer to by-pass automatically initiated by the

following conditions:

a. Output overload period expired

b. DC voltage out of limit

c. Inverter failure

d. Over temperature period expired

- Uninterrupted manual transfer/retransfer to/from bypass

initiated from the control panel

- Uninterrupted automatic transfer from bypass whenever the

inverter is capable of assuming the load

- Uninterrupted automatic retransfer shall be inhibited by the

following conditions:

a. Manual transfer to bypass

b. Multiple transfers shall be limited to three transfers

/retransfer operation. The fourth transfer shall leave the

load on the by-pass source

c. UPS failure

- All transfer and retransfers are inhibited by the following

conditions:

19

a. By=pass voltage out of limits

b. By-pass frequency synchronization out of limits

Voltage

The maximum operating voltage shall be 480V with a transfer inhibit

voltage setting of plus minus10% of nominal.

Transfer Time

The switching time from inverter to reserve and vice versa shall be less than

0.5milisecond when synchronized.

The automatic retransfer delay time back to inverter from reserve after a

transfer from inverter to reserve shall be 10 seconds.

The transfer time when out of synchronization shall be 20milisecond

Overload

The electronic static switch shall be capable of supplying an overload of

150% continuously. The overload capability for shorter periods shall be in

the range of milliseconds.

Manual Maintenance By-pass

A manually initiated make-before-break transfer to bypass shall be provided

for routine maintenance purposes.

MIMIC PANEL

The UPS shall have a mimic panel with LED to indicate the configuration of

the main switches and sub-assemblies.

Measurement

The UPS mimic panel shall be able to display the following measurement:

Frequency

Phase voltages to neutral

20

Phase currents

Rectifier current

Battery current (with polarity indicated)

Battery voltage

Indications:

Rectifier Status:

Rectifier healthy/failure

DC voltage within/outside limits

Battery connected/disconnected

Battery charging/charged

Battery discharging

Battery discharged

Inverter Status:

Inverter voltage within limits

Inverter off

Inverter running

Inverter in manual control mode

Inverter inhibited

Inverter healthy

Inverter in synchronization with reserve supply

Reserve Status:

Reserve voltage within/outside limits

Reserve frequency within/outside limits

Output Status:

Load on inverter

Load on reserve

Load on bypass

Load disconnected

Time on inverter

Time on reserve

21

Alarms

Rectifier:

AC mains input failure

AC mains input incorrect phase rotation

AC mains input out of limits

Battery charge failure

Rectifier bridge fault

Battery switch open

Battery earth fault

Battery discharging level 1

Battery discharging Level 2

Battery recharging

Maximum battery recharge time exceeded

Battery disconnected or earth fault

Inverter:

Over temperature

Operating in overload

Overload shutdown

VCE saturation shutdown

Current limit shutdown

Over temperature inhibit

DC high voltage shutdown

DC low voltage shutdown

Inverter out of synchronization

Reserve:

Input switch open

Input failure

Incorrect phase rotation

Voltage out of limits

Frequency high

Frequency low

Static switch transfer inhibited

Static switch in manual mode

22

Output:

Output switch open

Bypass switch closed

Load on reserve

Load on bypass

Load not supplied

REMOTE ALARMS AND CONTROL

Volt-free change-over contacts rated at 125V 1A shall be provided for the

following conditions:

Rectifier ON

Battery shutdown imminent

Inverter ON

Load on reserve

Summary alarm

Rectifier on is activated by:

AC mains input present

Correct input phase rotation

AC mains input within tolerance

Rectifier/battery charger fault

Battery shutdown imminent is activated by:

Battery switch closed

Battery shutdown imminent

Inverter on is activated by:

Inverter in synchronization with reserve

Inverter output voltage within tolerance

Load on reserve is activated by:

Reserve switch closed

Output switch closed

23

Bypass switch closed

Load not supplied by inverter

Any of the above will cause the appropriate N.O contact to close and

N.C contact to open. In every case the summary alarm contacts will

operate as above.

In addition there shall be the following facilities:

Battery fuse blown indication to UPS

Emergency power off to provide an electronic stop signal to the

inverter. It does NOT disconnect the AC supplies, load or battery.

Auxiliary contact for diesel generator changeover inhibits the static

switch when the generator is operating

Battery insulation failure indication to UPS

MECHANICAL SPECIFICATION

Enclosure

The UPS shall be housed in a free-standing modular enclosure with

removable panels to the back and sides and protection as standard to IP20.

Ventilation

Forced redundant air-cooling shall be provided to ensure that all components

are operated within specification with air entry in the base and exit in the

top. The enclosure shall be mounted with 800mm of free space at the top for

ventilation.

Cable Entry

Cable entry shall be from the bottom or side of the cabinet.

Painted Surface

Painted surface shall be cleaned and finished with an electrostatically

applied epoxidic enamel of a minimum of 60 microns thickness of the

manufacturers standard color.

24

Access

All internal subassemblies shall be accessible from the front of the unit via

hinged doors. Rear access shall not be required for installation nor servicing.

The UPS shall be fork liftable from the front after the removal of bottom

trim panels.

ENVIRONMENTAL CONDITIONS

The UPS shall be capable of withstanding any combination of the following

environmental conditions. It must operate without mechanical or electrical

damage or degradation of operating characteristic.

Ambient temperature

0 degree to +40 degree C

Relative Humidity

Up to 90% (non condensing) for temperature of 20 deg C

Altitude

Maximum altitude of 1000 meters above sea-level, without derating

Audible Noise at 1 Meter Distance (dBA)

Between 60 to 65 dBA

ASSOCIATED BATTERY

Optional matching battery cubicles complete with a battery fuse shall be

available to accommodate maintenance free sealed lead-acid batteries.

OPERATION WITH DIESEL GENERATOR

The UPS shall have an auxiliary contact to inhibit transfer to reserve in the

case of generator instability.

25

Generally a generator output of at least twice the UPS rating is required

because of the total harmonic distortion (<15%) generated by the UPS. A

generator of the same power rating is possible if the UPS is fitted with input

current harmonic distortion filter with a 5th harmonic trap.

The generator and UPS suppliers shall liaise to ensure compatibility.

You might also like

- Chargeman STDocument16 pagesChargeman STAffan Zainun100% (4)

- Soalan Teknikal Chargeman Dan WiremanDocument28 pagesSoalan Teknikal Chargeman Dan Wiremanmohamadfirdaus8480% (20)

- JANAKUASADocument36 pagesJANAKUASAMohamad Syukri Abd Rahaman85% (20)

- Motor Control CentreDocument11 pagesMotor Control CentreDanish Hasanah100% (1)

- Nota GensetDocument15 pagesNota GensetSyed HakimNo ratings yet

- Nota Kuliah 1Document32 pagesNota Kuliah 1Roger JohnNo ratings yet

- PencawangDocument13 pagesPencawangsharulazri0% (3)

- JanakuasaDocument12 pagesJanakuasanfahmilah0% (2)

- Switch Gear AssignmentDocument23 pagesSwitch Gear AssignmentdanishHM0% (1)

- Janakuasa Tunggu SediaDocument32 pagesJanakuasa Tunggu SediaSabri Rusli50% (6)

- B12 Sistem BekalanDocument24 pagesB12 Sistem BekalanNoresham ManafNo ratings yet

- Pemutus Litar Voltan TinggiDocument23 pagesPemutus Litar Voltan Tinggiazhar_puaka88% (17)

- ETE 7033 PencawangDocument26 pagesETE 7033 Pencawangsyahadah98No ratings yet

- Kapasitor Bank Faktor KuasaDocument37 pagesKapasitor Bank Faktor KuasaKhairurrijal Osman100% (1)

- Talian Aerial V.RDocument43 pagesTalian Aerial V.RMohamad Syukri Abd Rahaman100% (5)

- Nota Pusat Kawalan MotorDocument35 pagesNota Pusat Kawalan MotorLehrer Gjoule60% (10)

- B12 Sistem BekalanDocument24 pagesB12 Sistem BekalanSiti Amirah HamzahNo ratings yet

- Ujian TekananDocument5 pagesUjian TekananMohamad Syukri Abd Rahaman80% (5)

- UpsDocument25 pagesUpskasturi ridzuan0% (1)

- Janakuasa Tunggu Sedia 3 FasaDocument24 pagesJanakuasa Tunggu Sedia 3 Fasahamizah50% (2)

- Bab 3 - Prinsip Susunan PencawangDocument54 pagesBab 3 - Prinsip Susunan PencawangMARZIAH9167% (3)

- Jenis Kawalan MotorDocument9 pagesJenis Kawalan Motorsuhailae100% (5)

- PembumianDocument29 pagesPembumianNur Farahin Mohd Tahir0% (2)

- Pengenalan Suis Gear Dan Pemutus Litar MinyakDocument11 pagesPengenalan Suis Gear Dan Pemutus Litar MinyakKudin FutriNo ratings yet

- Asas ElektrikDocument54 pagesAsas ElektrikMohamad Syukri Abd RahamanNo ratings yet

- Janakuasa Tunggu SediaDocument32 pagesJanakuasa Tunggu SediaMuhammad IskandarNo ratings yet

- Nota Power FactorDocument57 pagesNota Power FactorMohamad Syukri Abd Rahaman25% (4)

- LNP 3 Pengujian Fire Fighting Alarm SystemDocument22 pagesLNP 3 Pengujian Fire Fighting Alarm Systemsyukurkk0% (1)

- Penca WangDocument9 pagesPenca WangMohamad Syukri Abd Rahaman100% (1)

- Penatahan (Calibration)Document22 pagesPenatahan (Calibration)Mohamad Syukri Abd Rahaman50% (10)

- Umbang Dan TupangDocument12 pagesUmbang Dan TupangMohamad Syukri Abd Rahaman91% (11)

- Ring Main Unit (RMU)Document20 pagesRing Main Unit (RMU)Mohamad Syukri Abd Rahaman80% (5)

- Folio ImanDocument30 pagesFolio ImanMDanish AimanNo ratings yet

- Susutan Kabel Dan Keupayaan Membawa ArusDocument22 pagesSusutan Kabel Dan Keupayaan Membawa ArusObOy S RIsonNo ratings yet

- Assignment MCCDocument32 pagesAssignment MCCdanishHMNo ratings yet

- Sop Papan SuisDocument1 pageSop Papan SuisZakry HashimNo ratings yet

- UpsDocument4 pagesUpskasturi ridzuanNo ratings yet

- 1.0 Identify Power Eletronic Devices-Dea4232Document37 pages1.0 Identify Power Eletronic Devices-Dea4232safwanjamilNo ratings yet

- Kuiz 1Document5 pagesKuiz 1Roger JohnNo ratings yet

- Ete 703 PencawangDocument31 pagesEte 703 Pencawangchippychip60% (5)

- E2001UNIT5Document20 pagesE2001UNIT5JayCey Cheng100% (1)

- Jenis Kabel Elektrik Di MalaysiaDocument3 pagesJenis Kabel Elektrik Di MalaysiaMuhammad HafizuddinNo ratings yet

- Kertas Penerangan ETE502Document36 pagesKertas Penerangan ETE502Zunnur Zamzam100% (1)

- Ete 7023 NK Nota KursusDocument94 pagesEte 7023 NK Nota KursusSyed HakimNo ratings yet

- Projek Motor ControlDocument10 pagesProjek Motor ControlMuhammad ZuhairiNo ratings yet

- WS 4 - (Penyelenggaraan Motor)Document11 pagesWS 4 - (Penyelenggaraan Motor)Jumrang Mendeng0% (1)

- Autotrans IskandarDocument10 pagesAutotrans IskandarMuhammad IskandarNo ratings yet

- Nota Kuliah 2Document24 pagesNota Kuliah 2Roger JohnNo ratings yet

- Pencawang 1Document13 pagesPencawang 1Helmi Ahya Ilmudin75% (8)

- Penghidup Motor Bintang DeltaDocument2 pagesPenghidup Motor Bintang DeltaFaiz Fauzi0% (1)

- Perlindungan Mekanik KabelDocument20 pagesPerlindungan Mekanik KabelAzrulamri ZulkifliNo ratings yet

- Pengenalan & Cara Menilai KerosakanDocument13 pagesPengenalan & Cara Menilai KerosakanChing Suit Li0% (1)

- Papan Suis UtamaDocument13 pagesPapan Suis UtamaasaassNo ratings yet

- Nota Penggera KebakaranDocument14 pagesNota Penggera KebakaranHernani HamidNo ratings yet

- Assignment ElektrikDocument18 pagesAssignment ElektrikMuhammad HazimNo ratings yet

- Dea 3314 (KS - Teori)Document7 pagesDea 3314 (KS - Teori)Mohd Taufik SumariNo ratings yet

- Kertas Penerangan ETE502Document28 pagesKertas Penerangan ETE502Zunnur ZamzamNo ratings yet

- Lecture1 (Pengubah)Document99 pagesLecture1 (Pengubah)Ramakrisnna Gunasegaran50% (2)

- Jenis-Jenis KabelDocument16 pagesJenis-Jenis KabelMohamad Syukri Abd Rahaman50% (2)

- Assignment CompletedDocument47 pagesAssignment CompletedShereen Choo57% (7)

- Komponen Pengubah KuasaDocument4 pagesKomponen Pengubah Kuasaaimiza83% (6)

- Nota Ringkas Kumpulan Vektor PengubahDocument9 pagesNota Ringkas Kumpulan Vektor PengubahsakinahzahirNo ratings yet

- 1ke2 Sistem Penghataran Talian ElektrikDocument35 pages1ke2 Sistem Penghataran Talian Elektrikmuhammadsharizal67% (3)

- Industrial Automation SystemDocument27 pagesIndustrial Automation SystemAhmad AfiqNo ratings yet

- Sistem Penghantaran ElektrikDocument27 pagesSistem Penghantaran Elektriksitinormay100% (1)

- Lampu Jalan#Document9 pagesLampu Jalan#aimizaNo ratings yet

- Cocu 8Document16 pagesCocu 8Ravin AwesomeNo ratings yet

- Soalan Teknikal Chargeman Dan WiremanDocument23 pagesSoalan Teknikal Chargeman Dan WiremanMazuan WanzNo ratings yet

- Sistem PenghantaranDocument16 pagesSistem PenghantaranUmmie WafieNo ratings yet

- Jenis-Jenis KabelDocument16 pagesJenis-Jenis KabelMohamad Syukri Abd Rahaman50% (2)

- Alatan Dan Ukuran ElektrikDocument16 pagesAlatan Dan Ukuran ElektrikMohamad Syukri Abd RahamanNo ratings yet