Professional Documents

Culture Documents

MCG I2383092nc-Xxxx

Uploaded by

Servo2GoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCG I2383092nc-Xxxx

Uploaded by

Servo2GoCopyright:

Available Formats

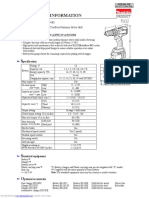

MOTOR I2383092NC-XXXX 176W

• Designed with medium Ke to accommodate low buss voltage applications

• Voltage rating up to 170 Vdc for offline drives

• TENV and IP54 environmental construction

• Compact, optical commutation encoders (optional)

• External NEMA 23 24Vdc holding brake (optional)

• Precision servo and power transmission gearing (optional)

Ratings Symbol Units

Continuous Stall Torque Tcs 0.410 (3.63) Nm (lb-in)

Peak Stall Torque Tps 1.235 10.93 Nm (lb-in)

No Load Max. Speed ω nl 6000 RPM

Continuous Rated Torque Tcr 0.280 (2.48) Nm (lb-in)

Peak Rated Torque Tpr 0.560 (4.96) Nm (lb-in)

Rated Speed ω rated 6000 RPM

Rated Power W (HP) 176 (0.24) Watts (HP)

Inductance L-L L 2.30 mH

Resistance L-L R 1.12 ohms

Max. Terminal Voltage V dc 170 Vdc

WINDING

SINUSOIDAL AC VALUES

Current at Cont. Stall Torque, o-p A rms 3.88 Amp

Current at Peak Torque, o-p A peak 16.44 Amp

Torque Constant L-L Kt rms 0.066 (0.58) Nm/A rms (lb-in/A)

Voltage Constant L-L Ke rms 0.07 (6.85) V/rad/sec (V/kRPM)

TRAPEZOIDAL DC VALUES

Current at Cont. Stall Torque, o-p A dc 5.48 Amp

Current at Peak Torque, o-p A dc 16.44 Amp

Torque Constant L-L Kt dc 0.088 (0.78) Nm/A (lb-in/A)

Voltage Constant L-L Ke dc 0.088 (9.20) V/rad/sec (V/kRPM)

MECHANICAL

Max. Axial Shaft Load Fa 13.34 (3.00) N (lb)

Max. Radial Shift Load Fr 35.59 (8.00) N (lb)

Motor Constant, L-L Trapezoidal Km 0.06 (0.53) Nm/√w (lb-in/√w)

Motor Inertia Jm 0.00001766 (0.0001563) Kg-m² (lb-in-s²)

Motor Weight 1.016 (2.24) Kg (lb)

Thermal Resistance Rth 2.14 °C/Watt

Thermal Time Constant TTC 15.00 min

Max. Winding Temperature Tw 125 °C

*Test conditions: Motor operated at rated winding temperature, mounted to an aluminum heat-sink.

Aluminum Heat-sink: 10 x 10 x 1/4

Sold & Serviced By:

Toll Free Phone: 877-378-0240

Toll Free Fax: 877-378-0249

sales@servo2go.com

www.servo2go.com

MOTOR I2383092NC-XXXX 176W

Configure Order Number

Standard motor assemblies can be configured using the catalog number format above and motor options listed below.

Motor options are typically stocked as separate components and can be quickly assembled to order.

Cables and connector kits are motor accessories and ordered as separate items.

Examples of configured motor assemblies:

I2351014NC-HCXX - I2351014NC Motor w/ HC Hall device feedback

I3482150NC-ZA5X - I3482150NC Motor w/ 1000 Line Encoder (5 Vdc 6 Ch w/ LD) and \'5\' Brake

Contact MCG for any required special features not listed here.

MOTOR OPTIONS

Gearboxes

Gear Reducer - External "Bolt-On" Mounting

G3005 NEMA 23, Gearhead, 3 deg. Backlash, w/ 1/2 inch output shaft

G3010 NEMA 23, Gearhead, 3 deg. Backlash, w/ 1/2 inch output shaft

G3015 NEMA 23, Gearhead, 3 deg. Backlash, w/ 1/2 inch output shaft

G3025 NEMA 23, Gearhead, 3 deg. Backlash, w/ 1/2 inch output shaft

G3050 NEMA 23, Gearhead, 3 deg. Backlash, w/ 1/2 inch output shaft

G3100 NEMA 23, Gearhead, 3 deg. Backlash, w/ 1/2 inch output shaft

Feedback

Hall Effect Device

HC2 Hall Effect for I2380, Factory Installation Only

Brakes

Holding Brakes - Eternal "Bolt-On" Mounting

3 Brake, 24 Vdc, B3 NEMA 23 w/ 1/4 inch output shaft

Shaft Seal

Shaft Seal

S2 Shaft Seal, I2380 series

MOTOR ACCESSORIES

Cables & Connectors

Connector Kits - Power and Feedback

9700527 Mating Power Connector Kit, body and 4 crimp contacts (P2)

9700523 Mating ComTrack Encoder Connector Kit, body and 16 crimp contacts (FC)

9700526 Mating Hall Connector Kit, body and 6 crimp contacts (FH)

Sold & Serviced By:

Toll Free Phone: 877-378-0240

Toll Free Fax: 877-378-0249

sales@servo2go.com

www.servo2go.com

You might also like

- MCG I2351030nc-XxxxDocument2 pagesMCG I2351030nc-XxxxServo2GoNo ratings yet

- MCG Ib23831Document2 pagesMCG Ib23831Servo2GoNo ratings yet

- MCG Ib34002Document2 pagesMCG Ib34002Servo2GoNo ratings yet

- MCG Ib46001Document2 pagesMCG Ib46001Servo2GoNo ratings yet

- MCG Ib34005Document2 pagesMCG Ib34005Servo2GoNo ratings yet

- MCG I4681159nc-XxxxDocument2 pagesMCG I4681159nc-XxxxServo2GoNo ratings yet

- MCG Ib23002Document2 pagesMCG Ib23002Servo2GoNo ratings yet

- MCG Ib17000Document2 pagesMCG Ib17000Servo2GoNo ratings yet

- MOTOR ID23005 128W: Ratings Symbol UnitsDocument2 pagesMOTOR ID23005 128W: Ratings Symbol Unitsdoppler9effectNo ratings yet

- DC Tacho 3604Document1 pageDC Tacho 3604Mahesh NaikNo ratings yet

- Greenstar Max BrochureDocument4 pagesGreenstar Max Brochuremanoj gokikarNo ratings yet

- S2 Optical Kit Encoder Technical SpecificationsDocument4 pagesS2 Optical Kit Encoder Technical SpecificationsFrancisco TeruelNo ratings yet

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- USDigital SM23 Data 5pDocument5 pagesUSDigital SM23 Data 5pHayk MartirosianNo ratings yet

- AEROTECH Motor1210Document13 pagesAEROTECH Motor1210zhen yongjieNo ratings yet

- Torque Systems Bnr3000 SpecsheetDocument4 pagesTorque Systems Bnr3000 SpecsheetElectromateNo ratings yet

- Dutymax HDSR Brochure PDFDocument7 pagesDutymax HDSR Brochure PDFGaith Ghaleb SharabatiNo ratings yet

- 10 A 8 DDDocument7 pages10 A 8 DDElectromateNo ratings yet

- Kollmorgen - Nema 23 T - SpecsheetDocument4 pagesKollmorgen - Nema 23 T - SpecsheetElectromateNo ratings yet

- DX B Ironless Linear Motor - PBASystemsDocument28 pagesDX B Ironless Linear Motor - PBASystemsjuliangoalNo ratings yet

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogElectromateNo ratings yet

- BTW Series Rechargeable Electric Torque Wrench - TorcStark®Document5 pagesBTW Series Rechargeable Electric Torque Wrench - TorcStark®NSK SupportNo ratings yet

- Echnical Information: Oncept and Main ApplicationsDocument12 pagesEchnical Information: Oncept and Main ApplicationsStefan UrsanNo ratings yet

- CITILED COB Series Data SheetDocument15 pagesCITILED COB Series Data SheetJuan TricariqueNo ratings yet

- Datasheet Panasonic Msma042Document39 pagesDatasheet Panasonic Msma042thiagofininhoNo ratings yet

- G5A 237P DC5 OmronDocument8 pagesG5A 237P DC5 OmronGhilang TriputraNo ratings yet

- Manual de Operacion DGW310MC 220Document11 pagesManual de Operacion DGW310MC 220Uma A. UcheNo ratings yet

- Compact AC Servo Motor GuideDocument8 pagesCompact AC Servo Motor GuideDương Trương Tấn100% (1)

- SIMOTICS M-1PH8 data sheetDocument1 pageSIMOTICS M-1PH8 data sheetfaisal kingNo ratings yet

- Torque Systems Bmr2200 SpecsheetDocument4 pagesTorque Systems Bmr2200 SpecsheetElectromateNo ratings yet

- 3.1 - Electrical System, Instruments (OCR)Document138 pages3.1 - Electrical System, Instruments (OCR)mnbvqwert100% (1)

- L011659 - Kinco SMC130D-0200 Servo MotorDocument4 pagesL011659 - Kinco SMC130D-0200 Servo Motorjulio gutierrezNo ratings yet

- L010719 - BLWR23MDA Series Spec SheetDocument2 pagesL010719 - BLWR23MDA Series Spec SheetMohd Asri TaipNo ratings yet

- LINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To AlterationsDocument26 pagesLINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To Alterationsoctavinavarro8236No ratings yet

- SMAC LCR16 Linear Rotary Actuator BrochureDocument2 pagesSMAC LCR16 Linear Rotary Actuator BrochureElectromateNo ratings yet

- SysCat+1S Drives+Datasheet I188E-EN-01A PDFDocument12 pagesSysCat+1S Drives+Datasheet I188E-EN-01A PDFLucas Vinícius CostaNo ratings yet

- 1S DRIVER-datasheet enDocument14 pages1S DRIVER-datasheet enGiacomo UncinoNo ratings yet

- Motors For Motion Control ApplicationDocument2 pagesMotors For Motion Control Applicationalfredo_fredo_1No ratings yet

- RTS DC Servo DriveDocument4 pagesRTS DC Servo DriveJunaid YNo ratings yet

- I188e r88d-1sn - Ect 1s-Series Servo Drive Datasheet enDocument20 pagesI188e r88d-1sn - Ect 1s-Series Servo Drive Datasheet enElianjur GuerraNo ratings yet

- 1PH8163-1HF00-1FA2 Datasheet enDocument1 page1PH8163-1HF00-1FA2 Datasheet enagusNo ratings yet

- Analog Servo Drive: Description Power RangeDocument7 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Voith TurboDocument23 pagesVoith TurboAnonymous zMWvcT0% (1)

- Analog Servo Drive: Description Power RangeDocument7 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- CPM2A DatasheetDocument63 pagesCPM2A Datasheetp daNo ratings yet

- Smartstep 2 Servo Motors: @, R88M-Gp@Document6 pagesSmartstep 2 Servo Motors: @, R88M-Gp@HammadMehmoodNo ratings yet

- Danfoss VLT2800Document2 pagesDanfoss VLT2800omarNo ratings yet

- Fabricator 181i BrochureDocument2 pagesFabricator 181i Brochuremkpasha55mpNo ratings yet

- 2KJ3514-3KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet enDocument2 pages2KJ3514-3KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet encaukhoeoNo ratings yet

- LCD Display VID29 - Manual - EN-080606Document10 pagesLCD Display VID29 - Manual - EN-080606RacielMCNo ratings yet

- Mariposa Motorizada VisteonDocument2 pagesMariposa Motorizada Visteonsrz1976No ratings yet

- Analog Servo Drive: Description Power RangeDocument7 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Ultract-T A Aimon PermanantDocument12 pagesUltract-T A Aimon PermanantIBRAHIM MAKHLOUKANo ratings yet

- Mot-Ec - enDocument8 pagesMot-Ec - enYERKO ANDRÉS GONZÁLEZNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Victor SPX User's GuideDocument19 pagesVictor SPX User's Guidelily.huang3No ratings yet

- Analog Servo Drive: Description Power RangeDocument6 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- AMC Digital Servo Amplifiers For Embedded Applications New Product Press ReleaseDocument1 pageAMC Digital Servo Amplifiers For Embedded Applications New Product Press ReleaseServo2GoNo ratings yet

- Dyadics SCN6 New Product Press ReleaseDocument2 pagesDyadics SCN6 New Product Press ReleaseServo2GoNo ratings yet

- New ESMART HMI Series From Exor Features Cloud-Based SolutionsDocument2 pagesNew ESMART HMI Series From Exor Features Cloud-Based SolutionsServo2GoNo ratings yet

- Exor's EX700 Series Features Harsh Environment OperationDocument1 pageExor's EX700 Series Features Harsh Environment OperationServo2GoNo ratings yet

- Inertia Dynamics SAB Brakes New Product Press ReleaseDocument1 pageInertia Dynamics SAB Brakes New Product Press ReleaseServo2GoNo ratings yet

- S2G Exor ETOP500 Press ReleaseDocument1 pageS2G Exor ETOP500 Press ReleaseServo2GoNo ratings yet

- DVC Series Motor Controller New Product Press ReleaseDocument1 pageDVC Series Motor Controller New Product Press ReleaseServo2GoNo ratings yet

- New Washdown Servo Gearboxes From Gam 2019Document1 pageNew Washdown Servo Gearboxes From Gam 2019Servo2GoNo ratings yet

- NEMA Brakes For Servo and Step MotorsDocument1 pageNEMA Brakes For Servo and Step MotorsServo2GoNo ratings yet

- S2G Exor ETOP500 Press ReleaseDocument1 pageS2G Exor ETOP500 Press ReleaseServo2GoNo ratings yet

- New 1-Axis Controller Box With Internal 800W Sine Drive Press ReleaseDocument1 pageNew 1-Axis Controller Box With Internal 800W Sine Drive Press ReleaseServo2GoNo ratings yet

- AMC Releases Z Servo DrivesDocument1 pageAMC Releases Z Servo DrivesServo2GoNo ratings yet

- Dyadics SCN6 New Product Press ReleaseDocument2 pagesDyadics SCN6 New Product Press ReleaseServo2GoNo ratings yet

- Meet AMC's Family of Servo Amplifiers Press ReleaseDocument2 pagesMeet AMC's Family of Servo Amplifiers Press ReleaseServo2GoNo ratings yet

- Extended Environment Plug-In Servo Drives From AMC New Product Press ReleaseDocument2 pagesExtended Environment Plug-In Servo Drives From AMC New Product Press ReleaseServo2GoNo ratings yet

- S2G AMC Release Full Family of EtherCAT Drives New Product Press ReleaseDocument2 pagesS2G AMC Release Full Family of EtherCAT Drives New Product Press ReleaseServo2GoNo ratings yet

- S2G STAC5 New Lower Price New Product Press ReleaseDocument2 pagesS2G STAC5 New Lower Price New Product Press ReleaseServo2GoNo ratings yet

- S2G AMC Release Full Family of EtherCAT Drives New Product Press ReleaseDocument2 pagesS2G AMC Release Full Family of EtherCAT Drives New Product Press ReleaseServo2GoNo ratings yet

- Inertia Dynamics NEMA Brakes New Product Press ReleaseDocument1 pageInertia Dynamics NEMA Brakes New Product Press ReleaseServo2GoNo ratings yet

- AMC Releases Four New EtherCAT Z-Drives New Product Press ReleaseDocument2 pagesAMC Releases Four New EtherCAT Z-Drives New Product Press ReleaseServo2GoNo ratings yet

- AMC Releases 14 New Servo Drives New Product Press ReleaseDocument1 pageAMC Releases 14 New Servo Drives New Product Press ReleaseServo2GoNo ratings yet

- New ATEX HMI Solutions From ExorDocument1 pageNew ATEX HMI Solutions From ExorServo2GoNo ratings yet

- S2G STAC5 New Lower Price New Product Press ReleaseDocument2 pagesS2G STAC5 New Lower Price New Product Press ReleaseServo2GoNo ratings yet

- Gam Washdown Servo Gearbox New Product Press ReleaseDocument1 pageGam Washdown Servo Gearbox New Product Press ReleaseServo2GoNo ratings yet

- Servo2Go Introduce B060A400AC, B100A400AC Servo AmplifiersDocument1 pageServo2Go Introduce B060A400AC, B100A400AC Servo AmplifiersServo2GoNo ratings yet

- Servo2Go Galil DMC-30016 New Product Press ReleaseDocument2 pagesServo2Go Galil DMC-30016 New Product Press ReleaseServo2GoNo ratings yet

- Servo2Go AMP BLDC Drives New Product Press Release.Document3 pagesServo2Go AMP BLDC Drives New Product Press Release.Servo2GoNo ratings yet

- Applied Motion Products STM23 With EtherNet New Product Press ReleaseDocument1 pageApplied Motion Products STM23 With EtherNet New Product Press ReleaseServo2GoNo ratings yet

- Servo2Go Galil RIO-47142 New Product Press ReleaseDocument2 pagesServo2Go Galil RIO-47142 New Product Press ReleaseServo2GoNo ratings yet

- Advanced Motion Controls 2012 CatalogDocument26 pagesAdvanced Motion Controls 2012 CatalogServo2GoNo ratings yet

- High Resolution MilliOhm Meter GuideDocument4 pagesHigh Resolution MilliOhm Meter GuideIeremeiov VladimirNo ratings yet

- Garys Resume'Document2 pagesGarys Resume'gssutherlandNo ratings yet

- Computer Organization and Architecture Module 1: Interconnection of ComponentsDocument12 pagesComputer Organization and Architecture Module 1: Interconnection of ComponentsWINORLOSENo ratings yet

- Lighting DomesticDocument123 pagesLighting DomesticjifzerodotcomNo ratings yet

- FMC 661Document56 pagesFMC 661Leonel MelchorNo ratings yet

- HP G7000 Compaq Presario C700 Compal LA-3732P Spartan1.0 SchematicsDocument42 pagesHP G7000 Compaq Presario C700 Compal LA-3732P Spartan1.0 SchematicsLeonardo DiegoNo ratings yet

- Elektron C6 Users Manual 0Document6 pagesElektron C6 Users Manual 0jeanjean33No ratings yet

- Fuel AditiveDocument3 pagesFuel AditiveopralinaNo ratings yet

- Moulded Case Circuit Breakers GuideDocument84 pagesMoulded Case Circuit Breakers GuideKishore Krishna92% (13)

- Permanent Magnet Linear Transverse Flux MotorsDocument6 pagesPermanent Magnet Linear Transverse Flux Motorsarnika33No ratings yet

- C4 Service ManualDocument23 pagesC4 Service ManualDany Coello LeónNo ratings yet

- TransformersDocument43 pagesTransformersDavid LeviNo ratings yet

- Olympus MU-1 Light Source - Service ManualDocument28 pagesOlympus MU-1 Light Source - Service ManualJorge AnayaNo ratings yet

- CI-1580A ENG User ManualDocument50 pagesCI-1580A ENG User ManualBac Nguyen Viet67% (3)

- Jest QuestionDocument16 pagesJest QuestionThirumugam SNo ratings yet

- Street Lighting Design Guide 4th EditionDocument26 pagesStreet Lighting Design Guide 4th EditionEE PeermadeNo ratings yet

- SBL 1Document2 pagesSBL 1Muhammad NaveedNo ratings yet

- Hwuaei Es1201 ManualDocument30 pagesHwuaei Es1201 ManualAnonymous fnFwazyINo ratings yet

- Semester Basic Electronics 11thDocument12 pagesSemester Basic Electronics 11thSunil ShekharNo ratings yet

- Registrador TR3000Document4 pagesRegistrador TR3000ParramanuelNo ratings yet

- LCR-Meter ElektorDocument5 pagesLCR-Meter ElektorFernando VidalNo ratings yet

- BEL - Organisational Chart PDFDocument2 pagesBEL - Organisational Chart PDFnitinnang50% (2)

- Codigo-Error - Bios - DellDocument6 pagesCodigo-Error - Bios - DellregistersNo ratings yet

- SM65 Supervisory Module Handbook E2 LTRDocument73 pagesSM65 Supervisory Module Handbook E2 LTRdlgt63100% (1)

- HHO - DL Phase Lock Loop Parts PDFDocument3 pagesHHO - DL Phase Lock Loop Parts PDFМарко Сајић0% (1)

- Elnet GR User Manual PDFDocument85 pagesElnet GR User Manual PDFStyler2No ratings yet

- Base conversion and binary arithmetic practice questionsDocument47 pagesBase conversion and binary arithmetic practice questionsrahul kNo ratings yet

- Digital Angle Gauge CMTDocument2 pagesDigital Angle Gauge CMTorione1953No ratings yet

- DIN Rail Mounting Controller Instruction ManualDocument35 pagesDIN Rail Mounting Controller Instruction Manualmjayaprakash225230No ratings yet

- Analysis of Helical Transmission Lines by Means of The Complete Circuit Equations-JoiDocument12 pagesAnalysis of Helical Transmission Lines by Means of The Complete Circuit Equations-JoieragonindiaNo ratings yet