Professional Documents

Culture Documents

Standard Proctor Compaction Test

Uploaded by

Sami SamiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Proctor Compaction Test

Uploaded by

Sami SamiCopyright:

Available Formats

ME 420L/ME 506L: Soil Mechanics Laboratory

Lab No. 6: Standard Proctor Compaction Test

ASTM D698

Introduction: For the construction of highways, airports, and other structures, it is often

necessary to compact soil to improve its strength. This test is referred to as the standard proctor

compaction test and is based on the compaction of the soil fraction passing U.S. No. 4 sieve.

Procedure

1. Obtain about 10 lb (4.5 kg mass) of air-dry soil on which the compaction test is to be

conducted. Break all the soil lumps.

2. Sieve the soil on a U.S. No. 4 sieve. Collect all of the minus 4 material in a large pan.

This should be about 6 lb (2.7 kg mass) or more.

3. Add enough water to the minus 4 material and mix it in thoroughly to bring the moisture

content up to about 5%.

4. Determine the weight of the Proctor mold + base plate (not the extension), W1 (lb).

(Figure 1)

(a)

(b)

Figure 1: Standard compaction mold (a) isometric view (b) top view

5. Now attach the extension to the top of the mold.

6. Pour the moist soil into the mold in three equal layers. Each layer should be compacted

uniformly by the standard Proctor hammer (Figure 3) 25 times before the next layer of

loose soil is poured into the mold.

Figure 3: Standard Proctor hammer

Note: This lab instruction has been prepared by using the following Soil Mechanics Laboratory Manual:

Das, B. M. (2009). Soil Mechanics Laboratory Manual. 7th Edition, Oxford University Press Inc, New York.

ME 420L/ME 506L: Soil Mechanics Laboratory

Lab No. 6: Standard Proctor Compaction Test

ASTM D698

7. Remove the top attachment from the mold. Be careful not to break off any of the

compacted soil inside the mold while removing the top attachment.

8. Using a straightedge, trim the excess soil above the mold. Now the top of the compacted

soil will be even with the top of the mold.

9. Determine the weight of mold + base plate + compacted moist soil in mold, W2 (lb).

10. Remove the base plate from the mold. Using a hydraulic jack (sample ejector), extrude

the compacted soil cylinder from the mold. (Figure 4)

Figure 4: Sample ejector

11. Take a moisture can and determine its mass, M3 (g).

12. From the moist soil extruded in Step 10, collect a moisture sample in the moisture can

(step 11) and determine the mass of the can + moist soil, M4 (g).

13. Place the moisture can with the moist soil in the over to dry to a constant weight.

14. Break the rest of the compacted soil (to No. 4 size) by hand and mix it with the leftover

moist soil in the pan. Add more water and mix it to raise the moisture content by about

2%.

15. Repeat Steps 6 through 12. In this process, the weight of the mold + base plate + moist

soil (W2) will first increase with the increase in moisture content and then decrease.

Continue the test until at least two successive down readings are obtained.

16. The next day, determine the mass of the moisture cans + soil samples, M5 (g) (from Step

13).

Note: This lab instruction has been prepared by using the following Soil Mechanics Laboratory Manual:

Das, B. M. (2009). Soil Mechanics Laboratory Manual. 7th Edition, Oxford University Press Inc, New York.

ME 420L/ME 506L: Soil Mechanics Laboratory

Lab No. 6: Standard Proctor Compaction Test

ASTM D698

Description of Soil:

Location:

Volume of Mold:

1/30 ft3

Weight of Hammer:

Number of Blows/Layer: 25

5.5 lb

Number of Layers: 3

Specific Gravity:

Tested by:

Date:

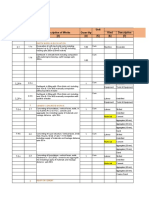

Test

1. Weight of mold and base plate,

W1 (lb)

2. Weight of mold and base plate +

moist soil, W2 (lb)

3. Weight of moist soil, W2 - W1

(lb)

4. Moist unit weight,

5. Moisture can number

6. Mass of moisture can, M3 (g)

7. Mass of can + moist soil, M4 (g)

8. Mass of can + dry soil, M5 (g)

9. Moisture content, w (%)

10. Dry unit weight of compaction

=

1 +

Plot d and ZAV versus w(%). ( =

Note: This lab instruction has been prepared by using the following Soil Mechanics Laboratory Manual:

Das, B. M. (2009). Soil Mechanics Laboratory Manual. 7th Edition, Oxford University Press Inc, New York.

You might also like

- BS 1924-Part 2-90 PDFDocument104 pagesBS 1924-Part 2-90 PDFsatheeshvm75% (4)

- Report Field Density - Sand Replacement MethodDocument9 pagesReport Field Density - Sand Replacement Methodwanfaiz12382% (11)

- Compaction Test ReportDocument5 pagesCompaction Test ReportMahmoud Khalifa91% (22)

- CBR Lab Report: Soil Subgrade TestingDocument4 pagesCBR Lab Report: Soil Subgrade Testingsdcsdcdcw33% (3)

- Sand Cone Test ExplainedDocument9 pagesSand Cone Test ExplainedNasrul100% (1)

- 25) Softening Point of BitumenDocument5 pages25) Softening Point of BitumenPn Ekanayaka100% (4)

- Aggregate Impact ValueDocument7 pagesAggregate Impact ValueAisyah Ibrahim84% (25)

- Method Statement For Construction of Substructure Elements)Document8 pagesMethod Statement For Construction of Substructure Elements)Akash Yadav100% (2)

- ASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesDocument6 pagesASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesPablo Antonio Valcárcel Vargas100% (1)

- JTG D30-2015 Highway Subgrade DesignDocument261 pagesJTG D30-2015 Highway Subgrade DesignSyed Imtiaz AhmedNo ratings yet

- Standard Proctor Compaction TestDocument7 pagesStandard Proctor Compaction TestGnabBang75% (4)

- Proctor Standard Soil CompactionDocument11 pagesProctor Standard Soil Compactionikhwan100% (2)

- Proctor Standard Soil Compaction Test ReportDocument7 pagesProctor Standard Soil Compaction Test ReportMohamad Haris Fadhilah Bin Mohamad RazaliNo ratings yet

- Falling Head Permeability TestDocument8 pagesFalling Head Permeability Testdwivediashish2100% (2)

- Sand Replacement MethodDocument8 pagesSand Replacement MethodMudin DinNo ratings yet

- Falling Head Permeability Lab TestDocument6 pagesFalling Head Permeability Lab TestHamierul MohamadNo ratings yet

- Falling Head Permeability TestDocument9 pagesFalling Head Permeability TestFaeez Zain83% (6)

- Soil Density Core Cutter MethodDocument7 pagesSoil Density Core Cutter MethodPn Ekanayaka100% (2)

- The California Bearing Ratio TestDocument6 pagesThe California Bearing Ratio TestNurin Adlina100% (4)

- Proctor Compaction Test GuideDocument7 pagesProctor Compaction Test GuidePn Ekanayaka100% (4)

- Sand ReplacementDocument4 pagesSand ReplacementHidayah MuzaimilNo ratings yet

- CBR Test Determines Subgrade StrengthDocument5 pagesCBR Test Determines Subgrade StrengthSamanta Pandey100% (1)

- Compaction ReportDocument6 pagesCompaction ReportharinderNo ratings yet

- Lab7 ReportDocument4 pagesLab7 ReporthelensongyNo ratings yet

- Los Angeles Abrasion TestDocument5 pagesLos Angeles Abrasion Testদেওয়ানসাহেবNo ratings yet

- Constant N Permeability ReportDocument24 pagesConstant N Permeability Reportilasensei50% (2)

- CBR TestDocument7 pagesCBR TestNanaNo ratings yet

- O.E.Lab - Docx For Direct Shear TestDocument14 pagesO.E.Lab - Docx For Direct Shear TestAmirah SyakiraNo ratings yet

- Mackintosh Probe TestDocument2 pagesMackintosh Probe TestBruce Lim50% (2)

- Consolidation Test of Soil (Complete Report)Document10 pagesConsolidation Test of Soil (Complete Report)Bshfirnaudz89% (38)

- Consolidation Test ReportDocument8 pagesConsolidation Test Reportemre usluNo ratings yet

- Determining Soil Permeability Using Falling Head MethodDocument5 pagesDetermining Soil Permeability Using Falling Head MethodSaleem Anas100% (3)

- Determination of PenetrationDocument57 pagesDetermination of Penetrationtunlaji0% (2)

- Falling Head PermeabilityDocument7 pagesFalling Head PermeabilityArjun Kumar100% (1)

- Direct Shear Test ResultsDocument19 pagesDirect Shear Test ResultsAh Gus100% (9)

- Highway Lab ReportDocument9 pagesHighway Lab Reportcarlton0878% (9)

- Atterberg LimitsDocument8 pagesAtterberg LimitsrbhavishNo ratings yet

- Proba MackintoshDocument18 pagesProba Mackintoshnazlie170750% (2)

- Sieve Analysis Determines Soil Particle SizesDocument7 pagesSieve Analysis Determines Soil Particle SizesNurHaziqahNo ratings yet

- 4 Unconfined CompressionDocument12 pages4 Unconfined CompressionShoaib Alam100% (1)

- Standard Proctor TestDocument6 pagesStandard Proctor TestJulius BaniquedNo ratings yet

- Falling Head Permeability Test Lab ReportDocument7 pagesFalling Head Permeability Test Lab ReportHaziq ZuhaimiNo ratings yet

- Exp 4 Unconfined TestDocument6 pagesExp 4 Unconfined TestumarNo ratings yet

- Experiment Penetration TestDocument6 pagesExperiment Penetration TestKyra Claire Zaharr90% (42)

- Determining Permeability of Sands Using Constant Head TestDocument12 pagesDetermining Permeability of Sands Using Constant Head TestArisan Iqma100% (2)

- 6th Report (Skid Resistance)Document23 pages6th Report (Skid Resistance)Nurul Izzati Raihan Ramzi100% (1)

- Softening Point ReportDocument10 pagesSoftening Point Reportmuhd qayyumNo ratings yet

- Falling Heat Permeability TestDocument10 pagesFalling Heat Permeability TestAiryn UyienNo ratings yet

- CBR TestDocument8 pagesCBR TestAnonymous mF6tM5gPNo ratings yet

- Mohammad Yunus Salehi I11007770 Experiment 4: Unconfined Compression TestDocument6 pagesMohammad Yunus Salehi I11007770 Experiment 4: Unconfined Compression TestMohammad Yunus Salehi75% (4)

- UU Triaxial Test (Quick TestDocument4 pagesUU Triaxial Test (Quick TestSharunieRavikumar33% (3)

- Civil Engineering Center Consolidation TestDocument4 pagesCivil Engineering Center Consolidation TestrbhavishNo ratings yet

- Determination of Field Density of Soils by The Core Cutter Method PDFDocument4 pagesDetermination of Field Density of Soils by The Core Cutter Method PDFShafiq Kadir100% (3)

- Elongation IndexDocument17 pagesElongation IndexNurul Ain MohdNo ratings yet

- Lab Experiment #5: Standard Proctor Compaction TestDocument4 pagesLab Experiment #5: Standard Proctor Compaction TestfadyNo ratings yet

- Laboratory No 5-6Document7 pagesLaboratory No 5-6mapoygenesislanaNo ratings yet

- Lab Experiment #5: Standard Proctor Compaction TestDocument4 pagesLab Experiment #5: Standard Proctor Compaction TestNaba Kumar BhaumikNo ratings yet

- Proctor TestDocument3 pagesProctor TestAzrizal EzlianaNo ratings yet

- Report Standard Compaction TestDocument14 pagesReport Standard Compaction TestLuqman Yusof100% (1)

- Astm D698Document7 pagesAstm D698Annilyn EncinasNo ratings yet

- Particle Density SoilDocument4 pagesParticle Density SoilKamil KhairiNo ratings yet

- Lab Sheet - Standard CompactionDocument7 pagesLab Sheet - Standard CompactionLuqman YusofNo ratings yet

- Kabul University Civil Engineering Proctor TestDocument4 pagesKabul University Civil Engineering Proctor TestAssad YaqubiNo ratings yet

- Ap T29 03 PDFDocument60 pagesAp T29 03 PDFstefpanNo ratings yet

- District CouncilBahawalnagarDocument880 pagesDistrict CouncilBahawalnagarmuhammad iqbalNo ratings yet

- Wick DrainsDocument2 pagesWick Drainsdarkobogd75No ratings yet

- Method Statement FOR Earthwork: ProjectDocument6 pagesMethod Statement FOR Earthwork: ProjectKelvin Lau Hin HuatNo ratings yet

- All Check ListDocument14 pagesAll Check ListTwin BullsNo ratings yet

- Compressive Strength Test (IS: 4031 (Part 6) - 1988)Document2 pagesCompressive Strength Test (IS: 4031 (Part 6) - 1988)সন্দীপ চন্দ্রNo ratings yet

- Concrete Mix Design Using Crushed SandDocument22 pagesConcrete Mix Design Using Crushed SandOlaolu Olalekan50% (2)

- Geotechnical Investigation Report for Proposed Shaft ConstructionDocument45 pagesGeotechnical Investigation Report for Proposed Shaft ConstructionSreedhar BhuduruNo ratings yet

- Density of In-Place Soil and Rock Materials by The Water Replacement Method in A Test PitDocument14 pagesDensity of In-Place Soil and Rock Materials by The Water Replacement Method in A Test PitJP SALDAÑANo ratings yet

- Construction Equipments and Methods PDFDocument944 pagesConstruction Equipments and Methods PDFAnonymous 5B1cgFjyLj33% (3)

- ASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsDocument35 pagesASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsPablo Antonio Valcárcel VargasNo ratings yet

- Ammann Single Drum Roller ASC Tier1 enDocument4 pagesAmmann Single Drum Roller ASC Tier1 ensyahreza0gasfarNo ratings yet

- Ground Improvement TechniquesDocument8 pagesGround Improvement TechniquesV Viswa Teja T0% (1)

- Quality Control Manual Papua New GuineaDocument59 pagesQuality Control Manual Papua New GuineaSmr OnlyNo ratings yet

- SMDocument2 pagesSMHrishikesh BhavsarNo ratings yet

- Ogombo Method StatementDocument28 pagesOgombo Method Statementadetokunbo fapuroNo ratings yet

- Standard ProctorDocument8 pagesStandard ProctorFendi RoonNo ratings yet

- Practical Aspects in The Design of A Compacted Concrete Mixture (RCC) For Construction PurposesDocument21 pagesPractical Aspects in The Design of A Compacted Concrete Mixture (RCC) For Construction PurposesLuis Eloy FeoNo ratings yet

- Construction method statements for civil engineering activitiesDocument499 pagesConstruction method statements for civil engineering activitiesisukuru50% (2)

- Earthworks SpecificationsDocument37 pagesEarthworks SpecificationsconcretemadNo ratings yet

- CE444 Ground Improvement TechniquesDocument2 pagesCE444 Ground Improvement TechniquesprasadNo ratings yet

- Civil 5 PDFDocument29 pagesCivil 5 PDFSwastika ChandaNo ratings yet

- Ground Improvement TechniquesDocument31 pagesGround Improvement TechniquesHamadNo ratings yet

- Course Plan for Geotechnical Engineering I at Manipal Institute of TechnologyDocument4 pagesCourse Plan for Geotechnical Engineering I at Manipal Institute of TechnologyPranjal DixitNo ratings yet

- Description of Works Quan-Tity Unit Input Kind Description (1) (2) (3) (4) (5) (6) (7) Norms Code Item CodeDocument40 pagesDescription of Works Quan-Tity Unit Input Kind Description (1) (2) (3) (4) (5) (6) (7) Norms Code Item Coderashmi bhailaNo ratings yet

- MQC Practice ExamDocument9 pagesMQC Practice ExamStephen RayosoNo ratings yet