Professional Documents

Culture Documents

TarFelt BH Hessian Waterproofing Membrane

Uploaded by

Venkatesha HebbarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TarFelt BH Hessian Waterproofing Membrane

Uploaded by

Venkatesha HebbarCopyright:

Available Formats

TarFelt BH

Hessian Based Bituminous Waterproofing Membrane

Description

TarFelt BH, is produced by saturating centre core of hessian with straight grade bitumen and

coated with specially formulated bituminous compound on both sides. Thereafter, Mica / sand is

spread over bituminous surface to prevent inter layer sticking of felt during rolling and storage. It

conforms to IS:1322:1993, Type 3 Grade 1.

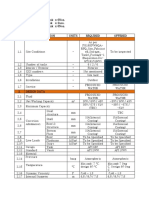

Characteristics

Breaking Strength, kg, Min

Wrap way

Weft way

Pliability, up to 15 OC

Water absorption, %, max

135

90

No crack

2

Heat Resistance at 68 2 OC, 3 hr

Pressure Head Test at 300 mm

height of water

Storage sticking at 55 2 OC, 18 hr

Bitumen content per Roll, Kg

No flow

No Leakage

No Sticking

24.2

Application

TarFelt BH is recommended for above ground waterproofing applications as per IS:1346/1991.

They are suitable for application on various types of surfaces such as concrete, corrugated

asbestos / GI sheet, timber, all types of flat, slope and shell type structure. TarFelt BH is a

proven waterproofing material for application on silos, grain godowns, warehouses, wagons,

trams, buses, etc.

Advantages

Economical.

Rot proof.

Having excellent track record over six decades.

Totally impermeable.

Flexibility to adopt all types of contours.

Application Methodology

Specification regarding the nature of treatment should be decided depending on the type of

structure and climatic conditions. For example, in severe climatic conditions a heavy / extra

heavy treatment should be adopted.

Provide adequate number of drainage outlets of 100 mm diameter at least for every 40 m2 of

roof area.

Clean the surface thoroughly to make it free from any foreign material. Repair all undulation

and surface defect like cracks, honeycombing etc.

PCC / cementitious coving of 75 mm radius shall be provided at all junction between vertical

and horizontal faces.

Apply a coat of ShaliTex Primer minimum @ 0.25 L/m2 and allow it to dry completely.

Use STP Bitumen 85/25 as bonding material which is to be prepared by heating it to the

correct working temperature and be spread over the roof properly and uniformly @ 1.2 kg/m2

per coat for waterproofing application or as specified.

Unroll and fix TarFelt BH by applying uniform pressure with hand for removal of any

entrapped air.

Provide overlap joints of 75 mm in longitudinal direction and 100 mm in transverse direction of

the TarFelt BH roll and seal it properly with hot bitumen.

Terminate TarFelt BH at the top of parapet if the height of parapet is up to 450 mm. In case

the height of the parapet is above 450 mm, terminate TarFelt BH at parapet in a groove 75

mm x 65 mm at parapet at a height of 150 - 300 mm from the finished roof level and groove

shall be filled up with cement-sand mortar (1:4) with addition of ShaliPlast LW @ 200 ml/bag

of cement.

Top coat shall be finished with a layer of stone grit or pea gravel (6 mm and down size) which

shall be laid by spreading it over a hot bitumen coat @ 1.2 Kg/m2 laid over the felt.

In case of non-trafficable roof, over the finished coat of bitumen, apply a coat of

SuperSilverShield, a bituminous based aluminium paint, @ 0.125 L/m2.

For a trafficable roof, protect membrane with PCC / Tiles. In case of PCC, ShaliPolyFibre @

600 grm/m3 and ShaliPlast LW / STP No 1 (Liquid) @ 200 ml/bag of cement to be added to

improve the resistance to crack formation and as well as waterproofing properties of screed.

Use ShaliBond BS/CS cold adhesive wherever hot application is difficult or not permitted.

For multi-layer treatment, stagger all the joints.

Health & Safety

Use goggles, hand gloves and shoes during application

Clean hands with a mild solvent and thereafter wash with warm soap water

Packing

Available in 1 m x 20 m roll with a weight of minimum 46 kg per roll.

Storage

Keep under shed away from heat. Do not stack more than three rolls in one column.

STPs Businesses

Waterproofing & Insulation

Road Surfacing

Pipeline Coating

Repairs & Rehabilitation

GARA (Grouts & Admixtures)

Other Powder Products

Sealant & Additives

Epoxy Flooring

Protective / Anti-Corrosive Coating

Other Products

Visit us at : www.stpltd.com or Email at : info@stpltd.com

1192014

You might also like

- Sikatop®-107 Seal KH: Product Data SheetDocument4 pagesSikatop®-107 Seal KH: Product Data SheetReab SimanthNo ratings yet

- Revised MS For WaterproofingDocument9 pagesRevised MS For WaterproofingChamux skalNo ratings yet

- FloArm Screed Eco Ver7Document4 pagesFloArm Screed Eco Ver7imsNo ratings yet

- Thermal insulation and waterproofing liquid membraneDocument4 pagesThermal insulation and waterproofing liquid membranemaga2292No ratings yet

- T 570 RubbersealDocument5 pagesT 570 RubbersealVinitJory100% (1)

- Conbextra GP2 (T)Document4 pagesConbextra GP2 (T)Vikas Singh ChandelNo ratings yet

- Boscoseal Torch OnDocument3 pagesBoscoseal Torch OnjbonvierNo ratings yet

- Sikatop 130 FlexkeDocument3 pagesSikatop 130 FlexkeNagarajan KumaranNo ratings yet

- Sikalastic-1 KMYDocument3 pagesSikalastic-1 KMYboyzesNo ratings yet

- Nitocote cm210Document4 pagesNitocote cm210pravi3434No ratings yet

- ShaliTex Sealing CompoundDocument2 pagesShaliTex Sealing CompoundHimagiriNo ratings yet

- Bitustick XLS HynkleDocument2 pagesBitustick XLS HynkleMohamed ShehataNo ratings yet

- High-Strength Concrete Screed Data SheetDocument6 pagesHigh-Strength Concrete Screed Data Sheetiask5275No ratings yet

- Tds - Emaco s88c TDocument2 pagesTds - Emaco s88c TVenkata RaoNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Uzin NC 152Document2 pagesUzin NC 152FloorkitNo ratings yet

- BASF MasterEmaco T 1200 PG Tech DatasheetDocument5 pagesBASF MasterEmaco T 1200 PG Tech DatasheetMike KuczynskiNo ratings yet

- Seal FlexDocument2 pagesSeal Flexpravi3434No ratings yet

- ShaliUrethane WPUDocument3 pagesShaliUrethane WPURana MahatoNo ratings yet

- 323 Plastimul GBDocument4 pages323 Plastimul GBklp_kedarpNo ratings yet

- 2-Part Polyurethane Sealant for Airport Runways & Concrete JointsDocument2 pages2-Part Polyurethane Sealant for Airport Runways & Concrete JointsjoshepNo ratings yet

- TDS Bitulastic BituflexDocument3 pagesTDS Bitulastic Bituflexd TjonasanNo ratings yet

- Bituthene 1000X HC: DescriptionDocument2 pagesBituthene 1000X HC: DescriptionPradeep KumaraNo ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELmilanbrasinaNo ratings yet

- LANKEM CEYLON PLC (SPECIAL PROJECTSDocument2 pagesLANKEM CEYLON PLC (SPECIAL PROJECTSniroshniroshNo ratings yet

- Water Profing Application MethodologyDocument2 pagesWater Profing Application MethodologyRajarshi KarNo ratings yet

- Basf Masterseal m808 TdsDocument8 pagesBasf Masterseal m808 TdsOkan KalendarNo ratings yet

- en-GB - Flo-Grout 2.03012016065544 PDFDocument2 pagesen-GB - Flo-Grout 2.03012016065544 PDFHassan SleemNo ratings yet

- Bitustick XLSDocument2 pagesBitustick XLSAbed DaherNo ratings yet

- ConcreteDocument3 pagesConcreteTran DtrungNo ratings yet

- Uzin NC 110Document4 pagesUzin NC 110FloorkitNo ratings yet

- Plastimul GBDocument4 pagesPlastimul GBMichel CalcinNo ratings yet

- Masterseal 550 El v3Document2 pagesMasterseal 550 El v3rangarajan1989No ratings yet

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodNo ratings yet

- TDS - Emaco S88 PlusDocument2 pagesTDS - Emaco S88 PlusVenkata RaoNo ratings yet

- 599 PDFDocument2 pages599 PDFbizottsagNo ratings yet

- RIPSTAR 130 acrylic polymer cement modifierDocument3 pagesRIPSTAR 130 acrylic polymer cement modifierAnkita Baban GavadeNo ratings yet

- Tar PlasticDocument2 pagesTar PlasticChander MohanNo ratings yet

- Sikagrout®-114 Ae: Product Data SheetDocument3 pagesSikagrout®-114 Ae: Product Data SheetAlexander Jonas Zach ValdrizNo ratings yet

- ALS PolycarbonateInstallationInstructions Laserlite Dec2011Document3 pagesALS PolycarbonateInstallationInstructions Laserlite Dec2011patlolanugmailcomNo ratings yet

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- Basf Masterflow 950 TdsDocument3 pagesBasf Masterflow 950 TdsplmoNo ratings yet

- Bituplast: Compound Base Polyester Reinforced Bituminous Waterproofing MembraneDocument2 pagesBituplast: Compound Base Polyester Reinforced Bituminous Waterproofing MembraneVaittianathan MahavapillaiNo ratings yet

- Gallery 0768498605 Sika Level 100TDocument5 pagesGallery 0768498605 Sika Level 100TRobert EshwerNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Conbextra GP2Document4 pagesConbextra GP2Sikander GirgoukarNo ratings yet

- Sikalastic - 1 KmyDocument4 pagesSikalastic - 1 KmyEric LewNo ratings yet

- 31 Ultralite Rapid Flex s1 Uk NoRestrictionDocument4 pages31 Ultralite Rapid Flex s1 Uk NoRestrictionFloorkitNo ratings yet

- UP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Document3 pagesUP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Francesco FanaraNo ratings yet

- High-flow renovation screedDocument2 pagesHigh-flow renovation screedfaysal91No ratings yet

- Durakol G HMDocument3 pagesDurakol G HMpbodooNo ratings yet

- Tikidan Tds - Tiki Aquaseal Pu-She, r9Document3 pagesTikidan Tds - Tiki Aquaseal Pu-She, r9sandeepNo ratings yet

- 122 Keralastic GB NoRestrictionDocument4 pages122 Keralastic GB NoRestrictionFloorkitNo ratings yet

- Abe DIY BookletDocument89 pagesAbe DIY BookletFrancois-No ratings yet

- Aqua Shield 4Document2 pagesAqua Shield 4aneeshp_4No ratings yet

- Alumino Silicate Fibre Mesh Product DataDocument2 pagesAlumino Silicate Fibre Mesh Product DataKesavan DhuraiNo ratings yet

- 7GS 5000Document5 pages7GS 5000subhaschandraNo ratings yet

- Cemtop 250T PDFDocument4 pagesCemtop 250T PDFriverwilliamsNo ratings yet

- Abrasion-Resistant Epoxy Lining MortarDocument4 pagesAbrasion-Resistant Epoxy Lining MortarBalasubramanian AnanthNo ratings yet

- TDocument1 pageTVenkatesha HebbarNo ratings yet

- KC-5125-01-Foundation Details-AvadiDocument1 pageKC-5125-01-Foundation Details-AvadiVenkatesha HebbarNo ratings yet

- Scanned by CamscannerDocument25 pagesScanned by CamscannerVenkatesha HebbarNo ratings yet

- Air Pollution Control Equipments: (Design, Manufacture & Commissioning)Document11 pagesAir Pollution Control Equipments: (Design, Manufacture & Commissioning)Venkatesha HebbarNo ratings yet

- Calculation of Beam/Column Splice: HB-300x300x10x15Document5 pagesCalculation of Beam/Column Splice: HB-300x300x10x15mustika05No ratings yet

- 4Document2 pages4Venkatesha HebbarNo ratings yet

- Structural Steel Design Project: Calculation SheetDocument14 pagesStructural Steel Design Project: Calculation SheetJoey Johnson100% (2)

- Dynamic Analysis VerificationDocument8 pagesDynamic Analysis VerificationMichael DixonNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- 3Document4 pages3Venkatesha HebbarNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Moment Connection Beam Column Is Bs Section For Is800Document27 pagesMoment Connection Beam Column Is Bs Section For Is800Ramesh SelvarajNo ratings yet

- IJEE1497Document11 pagesIJEE1497Muluken TemesgenNo ratings yet

- Load Input File: CHKD VRH Appd VRH Date 13-SEPT-2019Document31 pagesLoad Input File: CHKD VRH Appd VRH Date 13-SEPT-2019Venkatesha HebbarNo ratings yet

- 24 Sample ChapterDocument14 pages24 Sample ChapterRomyMohanNo ratings yet

- KC-5125-01-Foundation Details-AvadiDocument1 pageKC-5125-01-Foundation Details-AvadiVenkatesha HebbarNo ratings yet

- Air Blasters Prevent Jamming and Boost Throughput in South African Coal PlantDocument3 pagesAir Blasters Prevent Jamming and Boost Throughput in South African Coal PlantVenkatesha HebbarNo ratings yet

- KC-5125-01-Foundation Details-AvadiDocument1 pageKC-5125-01-Foundation Details-AvadiVenkatesha HebbarNo ratings yet

- Recommended Size of Gutter Slopes Draining Roofs Can Be Found in The Table BelowDocument1 pageRecommended Size of Gutter Slopes Draining Roofs Can Be Found in The Table BelowVenkatesha HebbarNo ratings yet

- (Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsDocument22 pages(Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsVenkatesha HebbarNo ratings yet

- Volume CalculationDocument1 pageVolume CalculationVenkatesha HebbarNo ratings yet

- 24 Sample ChapterDocument14 pages24 Sample ChapterRomyMohanNo ratings yet

- XssDocument16 pagesXssVenkatesha HebbarNo ratings yet

- 08-12-2011 Ambient Data PDFDocument1 page08-12-2011 Ambient Data PDFVenkatesha HebbarNo ratings yet

- Steel Connection DesignDocument68 pagesSteel Connection DesignPushkar KokaneNo ratings yet

- Ke Building 2009Document639 pagesKe Building 2009JosseNo ratings yet

- Crane Rail Fixing StandardsDocument5 pagesCrane Rail Fixing StandardsVenkatesha HebbarNo ratings yet

- 740 Single MASSDocument2 pages740 Single MASSVenkatesha HebbarNo ratings yet

- CivilBay Crane Load Crane Runway Beam Design 1.0.0 ManualDocument112 pagesCivilBay Crane Load Crane Runway Beam Design 1.0.0 Manualwudongxiao3953100% (2)

- NBC000-1994 State of ArtDocument16 pagesNBC000-1994 State of ArtPrateek Raj PanditNo ratings yet

- A Humanistic Approach To Medical PracticeDocument3 pagesA Humanistic Approach To Medical PracticeFilipos ConstantinNo ratings yet

- Effects of Sucrose Concentration On Cell Respiration in YeastDocument7 pagesEffects of Sucrose Concentration On Cell Respiration in YeastRachel Utomo83% (23)

- Comparison of Infrastructure in Punjab and Andhra PradeshDocument7 pagesComparison of Infrastructure in Punjab and Andhra PradeshDivyam GXNo ratings yet

- AC7101.1 Rev G 2Document37 pagesAC7101.1 Rev G 2Namelezz ShadowwNo ratings yet

- Exudate Detection For Diabetic Retinopathy With Circular HoughDocument7 pagesExudate Detection For Diabetic Retinopathy With Circular HoughAshif MahbubNo ratings yet

- Project Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.Document6 pagesProject Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.EIRI Board of Consultants and Publishers0% (1)

- What It Is and The Six Steps Necessary To Achieve ItDocument40 pagesWhat It Is and The Six Steps Necessary To Achieve ItMalory RobayoNo ratings yet

- Asbestos exposure bulletinDocument2 pagesAsbestos exposure bulletintimNo ratings yet

- Installation Procedure.Document11 pagesInstallation Procedure.er_paramjeetgillNo ratings yet

- Atlas Copco Generators: 15-360 kVA 15-300 KWDocument10 pagesAtlas Copco Generators: 15-360 kVA 15-300 KWAyoub SolhiNo ratings yet

- Maxicare Individual and Family ProgramDocument43 pagesMaxicare Individual and Family Programbzkid82No ratings yet

- Rexnord Thomas Flexible Disc Couplings - Series 71 - 8Document2 pagesRexnord Thomas Flexible Disc Couplings - Series 71 - 8Orlando ReisNo ratings yet

- Rorschach y SuicidioDocument17 pagesRorschach y SuicidioLaura SierraNo ratings yet

- Frontier DL650 Maintenance Guide Ver 1.0Document25 pagesFrontier DL650 Maintenance Guide Ver 1.0philippe raynalNo ratings yet

- Measles/ Rubella & VPD Surveillance:: Allotment of EPID Number and Outbreak IDDocument7 pagesMeasles/ Rubella & VPD Surveillance:: Allotment of EPID Number and Outbreak IDDevendra Singh TomarNo ratings yet

- Prof Educ 2: Foundation of Special and Inclusive EducationDocument12 pagesProf Educ 2: Foundation of Special and Inclusive EducationNerissa Custosa BastoNo ratings yet

- Transpo Printable Lecture4Document10 pagesTranspo Printable Lecture4Jabin Sta. TeresaNo ratings yet

- Chemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsDocument5 pagesChemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsShalini KumariNo ratings yet

- Physical Security Audit Checklist PDFDocument3 pagesPhysical Security Audit Checklist PDFHendrawan StbNo ratings yet

- M96SC05 Oleo StrutDocument6 pagesM96SC05 Oleo Strutchaumont12345No ratings yet

- LLL'DSWD: Administrative Order No. Series 2017Document18 pagesLLL'DSWD: Administrative Order No. Series 2017SGTNo ratings yet

- Penicillin G Benzathine-Drug StudyDocument2 pagesPenicillin G Benzathine-Drug StudyDaisy Palisoc67% (3)

- HRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and ReceptaclesDocument2 pagesHRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and Receptaclesa wsNo ratings yet

- Gas Booster Systems Brochure r7Document12 pagesGas Booster Systems Brochure r7ridwansaungnage_5580No ratings yet

- Fuel System D28Document4 pagesFuel System D28Ian MuhammadNo ratings yet

- 1154ec108nanoelectronics PDFDocument3 pages1154ec108nanoelectronics PDFLordwin CecilNo ratings yet

- Self-Adhesive Resin Cements Ph-Neutralization, HydrophilicityDocument7 pagesSelf-Adhesive Resin Cements Ph-Neutralization, HydrophilicityCarolina Rodríguez RamírezNo ratings yet

- Portfolio FOR ANADocument6 pagesPortfolio FOR ANAholdap toNo ratings yet

- Anexo A2 - Ficha Panel CSUN250-60PDocument2 pagesAnexo A2 - Ficha Panel CSUN250-60PRobin Andres Quezada SanhuezaNo ratings yet

- IEC60947 3 Approved PDFDocument3 pagesIEC60947 3 Approved PDFosmpotNo ratings yet