Professional Documents

Culture Documents

WSA02 2002 Part1 2 3

Uploaded by

abhijithavalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSA02 2002 Part1 2 3

Uploaded by

abhijithavalCopyright:

Available Formats

Sewerage Code of Australia

Part 1: Planning and Design

Second Edition

Version 2.3

WSA 022002-2.3

32

CONTENTS

1 GENERAL

1.1 SCOPE

1.2 PURPOSE AND APPLICATION

1.3 PLANNING AND DESIGN RESPONSIBILITIES AND INTERFACES

1.3.1 General

1.3.2 Planning responsibilities

1.3.3 Design responsibilities

1.3.4 Consultation with other parties

1.4 SEWER SYSTEM DESIGN APPROACH

1.4.1 System design life

1.4.2 Objectives of the system design

1.4.3 Design output

38

2 SYSTEM PLANNING

2.1 SEWERAGE SYSTEM PHILOSOPHY AND DEFINITION

2.1.1 Disaggregation

2.1.2 Level 1 Total system

2.1.3 Level 2 Transportation subsystems

2.1.4 Level 3 Operating units

2.1.4.1 Sewers

2.1.4.2 Sewage pumping stations

2.1.4.3 Storage

2.2 PLANNING PRINCIPLES

2.2.1 Planning horizon

2.2.2 Concept Plan

2.2.3 Catchment analysis

2.2.4 Provision for future gauging needs

2.2.5 Terrorism

2.3 PLANNING PARAMETERS

2.3.1 Loading per serviced property

2.3.2 Assessment of future loads

2.3.3 Assessment of existing system loads

2.3.4 Environmental considerations

2.3.5 Geotechnical investigations

2.3.6 Operations and maintenance considerations

2.4 SEWAGE QUALITY

2.4.1 Septicity

2.4.2 Sewage quality / Trade waste management

2.5 PLANNING REVIEW

45

45

45

45

46

46

46

46

47

47

47

47

48

48

49

49

49

49

49

50

50

50

50

50

51

51

3 FLOW ESTIMATION

3.1 DESIGN FLOW ESTIMATION

3.2 DESIGN FLOW ESTIMATION METHOD

3.2.1 General

3.2.2 Traditional design flow estimation method

3.2.3 Design flow estimation incorporating existing systems

3.2.4 Design flow estimationPartially pumped systems

3.2.5 Flow schedule

52

52

52

52

52

53

53

53

4 DETAIL DESIGN

4.1 DETAIL DESIGN PROCESS

4.2 DETAIL DESIGN CONSIDERATIONS

4.2.1 Catchment design

4.2.2 Design accuracy

4.2.3 Sewer layout

54

54

54

54

55

55

COPYRIGHT

38

38

39

39

39

39

40

41

41

41

42

33

4.2.4 Environmental considerations

4.2.4.1 General

4.2.4.2 Urban salinity

4.2.4.3 Vegetation

4.2.4.4 Contaminated sites

4.2.4.5 Tidal zones

4.2.5 Easements

4.2.6 Disused sewers

4.2.7 Special design considerations

4.3 HORIZONTAL ALIGNMENT OF SEWERS

4.3.1 General

4.3.2 Roads, reserves and open space

4.3.3 Railway reserves

4.3.4 Public and private property

4.3.5 Changes in direction using an MH

4.3.6 Dead-ends

4.3.7 Horizontal curves in sewers

4.4 OBSTRUCTIONS AND CLEARANCES

4.4.1 General

4.4.2 Surface obstructions

4.4.3 Clearance from transmission towers and power lines

4.4.4 Clearance from structures

4.4.5 Underground obstructions and services

4.4.5.1 General

4.4.5.2 Clearance requirements

4.5 PIPE SIZING AND GRADING

4.5.1 General

4.5.2 Environmental protection requirements

4.5.3 Minimum air space for ventilation

4.5.4 Minimum pipe sizes for maintenance purposes

4.5.5 Maximum EP for reticulation sewers

4.5.6 Limitation on sewer size reduction

4.5.7 Minimum grades for self-cleansing

4.5.7.1 General

4.5.7.2 Reticulation sewers

4.5.7.3 Property connection sewers and ends of lines

4.5.8 Minimum grades for slime control

4.5.9 Maximum grades for septicity

4.5.9.1 Branch and trunk sewers

4.5.9.2 Reticulation sewers

4.6 VERTICAL ALIGNMENT OF SEWERS

4.6.1 General

4.6.2 Long section design plan

4.6.3 Minimum cover over sewers

4.6.4 Lot servicing requirements

4.6.4.1 General

4.6.4.2 Serviced area requirements for residential lots

4.6.4.3 Serviced area requirements for industrial and commercial lots

4.6.4.4 Partial lot service

4.6.4.5 Servicing of basements

4.6.5 Minimum depth of sewer connection point

4.6.5.1 General

4.6.5.2 Soffit requirement

4.6.5.3 Physical losses in customer sanitary drains

4.6.5.4 Depth of connection point

4.6.6 Grading through MHs

4.6.6.1 General

COPYRIGHT

WSA 022002-2.3

56

56

57

57

57

58

58

58

58

58

58

58

59

59

59

59

60

60

60

61

61

61

61

61

62

63

63

63

63

63

64

64

64

64

66

66

66

66

66

66

66

66

67

67

68

68

68

68

68

69

69

69

69

71

71

72

72

WSA 022002-2.3

34

4.6.6.2 Internal fall through MHs joining sewers of same diameter

4.6.6.3 Internal falls through MHs joining sewers of different diameters

4.6.6.4 Large falls at MHs

4.6.6.5 Effect of steep gradehydraulic jump

4.6.7 Vertical curves

4.6.8 Compound bends

4.7 CORROSION PREVENTION

4.7.1 General

4.7.2 Internal corrosion

4.7.3 External corrosion

4.8 STEEL SEWERS

4.8.1 Sizes and configurations

4.8.2 Joints

4.8.3 Field welding

4.8.4 Flanged joints

72

73

73

73

74

75

75

75

75

75

76

76

76

76

76

5 PROPERTY CONNECTION

5.1 GENERAL

5.2 LIMITATIONS OF CONNECTION TO SEWERS

5.3 METHODS OF THE PROPERTY CONNECTION

5.3.1 General

5.3.2 IO interface method

5.3.3 Buried interface method

5.4 MAXIMUM DEPTH OF PROPERTY CONNECTION

5.5 NUMBER OF PROPERTY CONNECTIONS

5.5.1 Single occupancy lots

5.5.2 Multiple occupancy lots

5.6 LOCATION OF CONNECTION POINTS

5.6.1 Undeveloped lots

5.6.2 Developed lots

5.7 Y PROPERTY CONNECTIONS

5.8 LENGTH OF PROPERTY CONNECTION SEWERS

77

77

77

77

77

77

77

78

78

78

78

78

78

79

79

79

6 MAINTENANCE STRUCTURES

6.1 TYPES OF MAINTENANCE STRUCTURES

6.2 LOCATIONS OF MAINTENANCE STRUCTURES

6.3 SPACING OF MAINTENANCE STRUCTURES

6.3.1 General

6.3.2 Maintenance structure spacingReticulation sewers

6.3.3 Maintenance structure spacingBranch and trunk sewers

6.4 SPECIAL CONSIDERATIONS FOR LOCATION OF MAINTENANCE STRUCTURES

6.5 SPECIAL CONSIDERATIONS FOR CONNECTION OF NEW SEWERS TO EXISTING

SEWERS

6.6 MAINTENANCE HOLES (MH)

6.6.1 General

6.6.2 Types of MH construction

6.6.3 Design parameters for MHs

6.6.4 Property connections into MHs

6.6.5 Diameters of MHs

6.6.6 MH base layout

6.6.7 Flotation

6.6.8 Ladders, step irons and landings

6.6.9 MH covers

6.6.10 Cross-fall on MH covers

6.7 MAINTENANCE SHAFTS (MS)

6.7.1 General

6.7.2 Design parameters for MSs and TMSs

6.7.3 Property connection sewer into MSs and TMSs

80

80

80

80

80

81

82

82

COPYRIGHT

83

83

83

83

83

84

84

84

84

84

85

85

85

85

85

86

35

WSA 022002-2.3

6.8 OTHER MAINTENANCE STRUCTURES AT INTERFACE OF PROPERTY CONNECTION

SEWER AND CUSTOMER DRAINS

86

7 ANCILLIARY STRUCTURES

87

7.1 GENERAL

87

7.2 WATER SEALS, BOUNDARY TRAPS AND WATER-SEALED MHS

87

7.2.1 General design parameters

87

7.2.2 Water seals on reticulation sewers entering branch or trunk sewers

87

7.2.3 Water seals on branch sewers entering trunk sewers

87

7.3 GAS CHECK MHS

88

7.3.1 General

88

7.3.2 Design parameters for gas check MHs

88

7.4 VERTICAL AND NEAR VERTICAL SEWERS

88

7.4.1 General

88

7.4.2 Design parameters for bored, exposed and encased vertical and near vertical sewers88

7.5 VENTILATION

89

7.5.1 General

89

7.5.2 Design parameters for vents

89

7.6 NEAR-HORIZONTAL BOREHOLES

90

7.6.1 General

90

7.6.2 Design requirements

90

7.6.3 Maintenance requirements

91

7.7 VORTEX INLETS AND WATER CUSHIONS

91

7.8 INVERTED SYPHONS

92

7.8.1 General

92

7.8.2 Design parameters for inverted syphons

92

7.9 OVERFLOWS / EMERGENCY RELIEF STRUCTURES (ERS)

93

7.9.1 General

93

7.9.2 Design parameters for ERSs

93

7.10 FLOW MEASURING DEVICES

94

7.11 WET WEATHER STORAGE

94

7.11.1 General

94

7.11.2 Design requirements for wet weather storage

94

8 STRUCTURAL DESIGN

8.1 GENERAL

8.2 PRODUCTS AND MATERIALS

8.3 STRUCTURAL COMPUTATIONS

8.4 EXTERNAL FORCES

8.5 FOUNDATION DESIGN AND GROUND WATER CONTROL

8.6 GEOTECHNICAL CONSIDERATIONS

8.6.1 General

8.6.2 Sewers in engineered or controlled fill

8.6.3 Sewers in non-engineered fill

8.6.4 Filling along route of pipeline

8.6.5 Mine subsidence

8.6.6 Slip areas

8.6.7 Water-charged ground

8.7 ABOVE GROUND CROSSINGS

8.8 PIPE COVER

8.9 TRENCH DESIGN

8.10 BULKHEADS AND TRENCHSTOPS

9 DESIGN REVIEW AND DRAWINGS

9.1 DESIGN REVIEW

9.2 DESIGN DRAWINGS

9.2.1 General

95

95

95

95

96

96

96

96

97

98

98

98

98

98

98

98

99

99

100

100

100

100

9.2.2 Real property information

101

COPYRIGHT

WSA 022002-2.3

36

9.2.3 Sewers

9.2.4 Structures

9.2.5 Longitudinal sections (profiles)

9.2.6 Title block notation and standard notes

9.2.7 Other

9.3 DRAFTING STANDARDS

9.3.1 Scale

9.3.2 Recording of as-constructed information

101

101

101

102

102

103

103

103

APPENDIX A ESTIMATION OF EQUIVALENT POPULATION (EP)

A1 GENERAL

A2 ESTIMATION METHOD

A2.1 Residential component

A2.1.1 Single occupancy lots

A2.1.2 Multiple occupancy lotsMedium density residential

A2.1.3 Multiple occupancy lotsHigh-density / multi-storey residential

A2.2 Commercial and special use components

A2.3 Industrial component

A2.3.1 General

A2.3.2 Use of Tables A2 and A3

A3 WORKED EXAMPLE FOR AN INDUSTRIAL DEVELOPMENT

104

104

104

104

104

104

104

105

105

105

105

105

APPENDIX B FLOW ESTIMATION FOR UNDEVELOPED AREAS

B1 GENERAL

B2 PEAK DRY WEATHER (SANITARY) FLOW

B3 GWI CALCULATION

B4 IIF CALCULATION

B5 WORKED EXAMPLE FOR A RESIDENTIAL DEVELOPMENT

B5.1 Description

B5.2 Peak dry weather flow (PDWF)

B5.3 Ground water infiltration (GWI)

B5.4 Rainwater dependent inflow and infiltration (IIF)

B5.5 Design flow

110

110

110

111

112

114

114

114

114

114

115

APPENDIX C GAUGING OF SEWER OVERFLOWS, FLOWS, LEVELS AND VELOCITIES

C1 GENERAL

C2 PRE-CONSTRUCTED FLUMES AND WEIRS

C3 RETRO-FITTING OF DEVICES

C3.1 Flumes and weirs

C3.2 Doppler HVQ gauges

C3.3 Transit-time HVQ gauges

C3.4 Other HVQ type gauges

C3.5 Using H-only and a rating table at unrated structures

C3.6 Flumes and weirs in conjunction with HVQ gauges

C4 FULL PIPE METERS

C5 OVERFLOW EVENT RECORDERS

APPENDIX D COMPUTER FLOW MODELLING

116

116

116

116

116

117

117

117

117

117

118

118

119

APPENDIX E ANALYSIS OF FLOW GAUGING RESULTS FROM EXISTING SYSTEMS

E1 GENERAL

E2 PEAK DRY WEATHER FLOW (PLUS GROUNDWATER INFILTRATION)

E3 INFLOW AND INFILTRATION (WET WEATHER) FLOW (IIF)

120

120

120

120

TABLES

TABLE 1.1 TYPICAL ASSET DESIGN LIFE

TABLE 1.2 PLANNING AND DESIGN APPROACH

TABLE 4.1 MAXIMUM ALLOWABLE DEFLECTIONS THROUGH A MH

COPYRIGHT

41

43

60

37

WSA 022002-2.3

TABLE 4.2 CLEARANCES BETWEEN SEWERS AND OTHER UNDERGROUND

SERVICES

TABLE 4.3 MINIMUM PIPE SIZES FOR RETICULATION AND PROPERTY

CONNECTION SERVICES

TABLE 4.4 EP CAPACITY LIMITATIONS FOR RETICULATION SEWERS

TABLE 4.5 MANNING COEFFICIENT

TABLE 4.6 ABSOLUTE MINIMUM GRADES

TABLE 4.7 MINIMUM GRADES FOR PROPERTY CONNECTION SEWERS AND

PERMANENT ENDS

TABLE 4.8 MINIMUM COVER OVER SEWERS

TABLE 4.9 MINIMUM INTERNAL FALL THROUGH AN MH JOINING RETICULATION

SEWERS OF SAME DIAMETER

TABLE 4.10 LIMITATIONS ON LARGE FALLS AT MHS USING INTERNAL AND

EXTERNAL DROPS

TABLE 6.1 ACCEPTABLE MH, MS AND TMS OPTIONS FOR RETICULATION

SEWERS

TABLE 7.1 MAXIMUM LIMIT OF DEVIATION IN LEVEL AND LINE OF BOREHOLES

TABLE 7.2 DESIGN REQUIREMENT FOR SILT TRAPS

TABLE 7.3 REQUIREMENTS FOR VORTEX INLETS AND WATER CUSHIONS

TABLE 8.1 REQUIREMENTS FOR BULKHEADS

TABLE A1 EQUIVALENT POPULATIONS FOR SYNCHRONOUS DISCHARGES

TABLE A2 NON-SYNCHRONOUS DISCHARGES - LIST OF INDUSTRIES AND THEIR

EP CLASSIFICATIONS

TABLE A3 EP OF NON-RESIDENTIAL EP/HA CLASSIFICATIONS

TABLE B1 LEAKAGE SEVERITY COEFFICIENT (C)

TABLE B2 APPROXIMATE VALUES OF 1(1,2) FOR VARIOUS LOCATIONS

TABLE B3 CONTAINMENT FACTOR VERSUS ARI

107

109

113

113

114

FIGURES

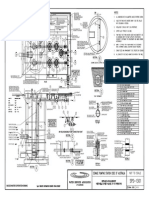

FIGURE 2.1 DISAGGREGATION MODEL FOR TRANSPORTATION SUBSYSTEMS

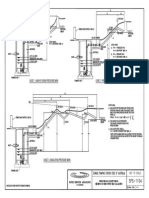

FIGURE 3.1 FLOW COMPONENTS IN A GRAVITY SYSTEM

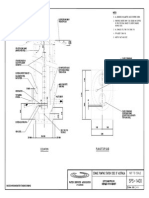

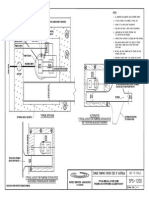

FIGURE 4.1 PHYSICAL LOSSES IN CUSTOMER SANITARY DRAINS

FIGURE 4.2 DEPTH OF POINT OF CONNECTION AND USE OF RISERS

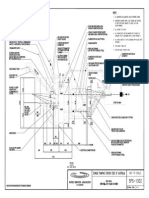

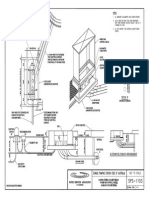

FIGURE 6.1 MULTIPLE MS BETWEEN MH AND "LAST" MH/TMS

FIGURE 6.2 MULTIPLE MSS BETWEEN CONSECUTIVE MHS

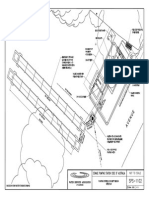

FIGURE B1 "D" FACTOR VERSUS AREA - AREAS < 40 HA

45

52

70

72

82

82

111

COPYRIGHT

62

64

64

65

65

65

68

73

73

81

91

91

92

99

106

WSA 022002-2.3

38

1 GENERAL

1.1 SCOPE

Part 1 Planning and Design of the Sewerage Code of Australia covers Water Agency

requirements for planning and design of gravity sewerage. Identification of the need for

pumping stations is an element of system planning. The design of sewage pumping

stations (SPSs) is addressed in WSA 042001 Sewage Pumping Station Code of

Australia.

Part 1 is applicable to new townships, new urban developments, re-development areas as

well as sewer augmentations and renewals. It provides planning and design inputs to the

processes of:

(a)

Developing servicing strategies;

(b)

Developing Concept Plans; and

(c)

Preparing detail designs and construction documentation.

Part 1 assists Planners and Designers in understanding gravity sewerage requirements

and provides information necessary to carry out a full analysis from the property

connection point to the treatment plant. This Code does not specifically apply to the design

of customers sanitary drainage. However, plumbing Regulators could adopt the Code as a

deemed to comply solution complying with the performance requirements of

AS/NZS 3500.2.1, and could require its application to large scale private developments

such as community title subdivisions.

Sewer system design and construction requirements are presented in performance based

terms combined with deemed to comply and typical solutions. Alternative solutions,

practices, equipment and methodologies will continue to evolve and offer opportunities to

improve the design and construction of sewerage. Individual Water Agencies may specify

additional or varying requirements. Water Agency input should always be sought if an

innovative opportunity is being considered.

For out-sourced planning and/or design services, the Water Agencys contracts or

development agreements should define responsibilities of suppliers. A Water Agency may

use Part 1 of the Code, modified as necessary, as the specification for technical

requirements referenced by its contract.

1.2 PURPOSE AND APPLICATION

Part 1 Planning and Design is primarily intended for Designers, Project Managers and

Water Agency personnel involved in the planning and design of gravity sewerage. Project

Managers of the delivery of services to land developers and/or Water Agencies should

read this Part in conjunction with the procedures, instructions, quality plans, variations and

other relevant documentation provided by the Water Agency, which will ultimately own the

asset.

The requirements contained in this Part are applicable to the majority of situations.

However, variations may be necessary to meet special circumstances or to overcome other

problems not addressed. Whenever the proposed design varies in any way from the

requirements set out in this Part and the Water Agencys specific requirements, the

proposed variation should be authorised by the Water Agency.

Design flow estimation methodology impacts directly on infrastructure sizing and costs and

therefore is an important aspect of any sewerage design. In this second edition, Part 1

Planning and Design adopts a modification of the commonly accepted empirical approach.

It also recognises that there is a need to distinguish between new greenfield sewerage

design and existing system improvement design, where there may be an opportunity to

calculate dry and wet weather loading rates directly from gauged flows rather than simply

COPYRIGHT

39

WSA 022002-2.3

assuming them. Substantial cost savings in sewerage schemes may result from the use of

hydraulic modelling software based on actual flows.

Waterway pollution has emerged as a new driver for overflow containment, based not only

on the ability of the waterway to tolerate pollution, but also on overflow frequency. This

requires Water Agencies to determine both the frequency and total volume of such

overflows so that pollution impacts on waterways can be assessed and controlled. The

modified empirical approach set out in this Code adopts the traditional factor DWF

approach, but varies it with frequency of incidence or design flow containment standard.

For future editions, a greater emphasis on the flow modelling approach is anticipated,

particularly for larger systems and for enabling effective design of detention storage.

1.3 PLANNING AND DESIGN RESPONSIBILITIES AND INTERFACES

1.3.1 General

Planning and design functions and processes may overlap. For a given project, the term

Planner may be applicable to the Designer. This Part assumes that the Water Agencys

contract and development agreements should specify:

(a)

Required planning outputs;

(b)

Responsibility and authority of the Planner and Designer; and

(c)

Interfaces between the Water Agency and out-sourced providers.

1.3.2 Planning responsibilities

The Water Agency is generally responsible for overall planning for the provision of

sewerage to its customers. Unless otherwise agreed between relevant parties, the Water

Agency should provide a Concept Plan setting out essential inputs to be used in design,

such as catchment area, flows, containment standard, average recurrence interval (ARI)

[environmental sensitivity factor], sizing, upstream controls, recommended sewer layout, or

particular requirements of the Water Agency.

1.3.3 Design responsibilities

The term Designer is used in this Code to mean the person(s) responsible for a design

output. Design functions include hydraulic, survey and drafting, geotechnical, structural,

mechanical, materials and other specialist functions required for a project.

The Designer shall be responsible for all aspects of sewerage design, as defined in the

Water Agencys project brief, contract or development agreement.

The Designer shall be responsible for:

(a)

translating the planning output into a detailed system/network design. The Designer

shall undertake the necessary design and prepare Design Drawings compatible with

the Water Agencys Concept Plan and the design parameters (as detailed in this

Code and/or Water Agency requirements);

(b)

identifying potential problems and providing appropriate solutions; and

(c)

justifying any variation from the requirements set out in this Code or specified by the

Water Agency.

The Designer shall obtain prior written approval from the Water Agency for any variation.

Concept Plan formats may vary, ranging from a basic layout sketch to a complete system

specification. The Concept Plan will generally provide notification of the point of connection

for a development or constraints and special requirements applicable.

If the Water Agency does not provide a Concept Plan or system specification, the Designer

shall liaise with the Water Agency, prior to commencement of design, to ensure that

COPYRIGHT

WSA 022002-2.3

40

sufficient planning is completed to enable design to proceed. Alternatively, subject to

contractual or agreement terms, the Designer may determine this information by

investigation, using this Code and engineering principles, and obtain approval from the

Water Agency.

The Designer shall address at least the following aspects and, as appropriate, include in

the design:

(i)

size(s) and grades of sewers throughout the relevant portion of the proposed

transfer /reticulation system to meet Concept Plan requirements;

(ii)

appropriate pipeline material type(s) and class(es) in accordance with Concept

Plan; and

(iii)

sewer layouts and alignments including:

(A)

route selection;

(B)

topographical and environmental aspects;

(C)

easements;

(D)

foundation and geotechnical aspects;

(E)

provisions for future extensions;

(F)

types and locations of maintenance structures, overflows and vents;

(G)

locations and details of bulkheads; and

(H)

property service connection locations.

The Designer shall also document all assumptions in the Specification and the Design

Drawings and specify all relevant requirements related to the design and construction of

the sewer system.

This particularly applies to ancillary sewer structures (Refer to Section 7) and structural

design (Refer to Section 8) where the use of specialist design competencies is necessary

to mitigate against risk to both the construction process and long-term operational and

maintenance performance of the asset.

As appropriate, the Design Drawings and/or Specification shall include provision for

addressing unforeseen ground conditions arising during construction e.g. requirements and

responsibilities for reviewing and amending the Specification and Design Drawings. This is

especially applicable to foundation design and ground water control (Refer to Clause 8.5).

In the construction of the work, the Designer should also be responsible for confirming that

any assumptions made in design were correct and for revising the Specification and

Design Drawings as a result of any incorrect assumptions or changed conditions. Any

design variations should be made in accordance with the requirements of any project

specific contract.

1.3.4 Consultation with other parties

Planners and Designers shall comply with Water Agency policies with regard to

consultation with all stakeholders affected by the Works.

Stakeholders may include, but are not limited to:

(a)

Property owners served or affected by the Works.

(b)

Tenants.

(c)

Heritage groups.

(d)

Indigenous people groups.

COPYRIGHT

WSA 022002-2.3

41

(e)

Municipal councils.

(f)

Other utility agencies.

(g)

Road, rail and tram authorities.

(h)

Planning authorities.

(i)

Developers of adjacent works.

(j)

Environmental and community groups.

1.4 SEWER SYSTEM DESIGN APPROACH

The overall objective of the sewerage design is to provide a functional sewer system that

meets the Water Agency obligations under its operating licence and customer contract for

provision of sewerage services to its customers.

1.4.1 System design life

Buried sewer systems shall be designed for a nominal asset life of at least 100 years

without rehabilitation. Some components such as pumps, valves, flow metering and control

equipment may require earlier renovation or replacement.

Typical designed asset lives for sewer system items are shown in Table 1.1.

TABLE 1.1

TYPICAL ASSET DESIGN LIFE

ITEM

Sewers

Maintenance

structures

Pumps

Valves

SCADA

100

100

20

30

15

Minimum design life, years

1.4.2 Objectives of the system design

The sewer system shall provide:

(a)

Least life cycle cost;

(b)

A single gravity connection for each property with maximum drainage of the property;

(c)

A level of service to the Water Agencys customers in accordance with the Water

Agencys policies, customer charters and operating contracts;

(d)

Minimal adverse environmental and community impact;

(e)

Compliance with environmental requirements;

(f)

Compliance with OH&S requirements;

(g)

Sufficient hydraulic capacity to service the full catchment;

(h)

Minimal maintenance;

(i)

No infiltration at commissioning;

(j)

Minimal infiltration / exfiltration over the life of the system;

(k)

Resistance to entry of tree roots;

(l)

Control of septicity;

(m)

Safe and easy access for operations and maintenance;

(n)

Resistance to internal and external corrosion and chemical degradation; and

(o)

Resistance to applied loads.

COPYRIGHT

WSA 022002-2.3

42

A summary of the planning and design approach adopted in this Code is shown in

Table 1.2.

1.4.3 Design output

For each design only or design and construct project, the design output shall satisfy

requirements of this Code and the Water Agency Concept Plan, as well as other design

requirements.

The design output shall include:

(a)

Design Drawings showing, inter alia and as appropriate, pipe sizes and grades,

location and types of maintenance structures, vents, pipe materials and detailed

construction methods; and

(b)

A Specification that addresses materials, site investigation and other technical

matters as required for construction, testing and commissioning.

The Design Drawings and Specification may comprise elements of Parts 2, 3 and 4 of this

Code, modified as appropriate.

COPYRIGHT

43

WSA 022002-2.3

TABLE 1.2

PLANNING AND DESIGN APPROACH

Development plan for the area (established in liaison

with the planning authority)

Identification of geographical constraints

Catchment analysis / flow modelling to determine

hydraulic loads

Network analysis using theoretical design techniques

and/or hydraulic models

Preliminary sizing of sewers

Summary of existing infrastructure capacity and need for

augmentation / replacement

Alternative servicing options, considering:

Develop servicing strategy

PLANNING

System configuration

Environmental constraints

Overflows / ERSs

Sewage septicity / detention time / ventilation

Odour control

Impact of grades / depth / hydraulic flow

Pumping stations

Trunk and branch main sizes

Reticulation network connectivity

Future system expansion

Preferred strategy using least community cost for whole

lifecycle

Develop Concept Plans

As development planning becomes more detailed, eg

local structure plans are developed, refine the servicing

strategy to develop a plan for staging creation of the

assets

Develop preliminary designs

Trunk and branch sewer size and location and staging.

(As development proceeds and

works need to be constructed,

develop major infrastructure)

preliminary designs.

Pump station location and duty points

Overflow / ERS locations (licensed) / detention storage

Odour, septicity controls

Preliminary reticulation layout

COPYRIGHT

WSA 022002-2.3

44

TABLE 1.2

PLANNING AND DESIGN APPROACH

continued

Sewer layout

Pipe sizing

Determine layout of trunk and branch sewers, addressing:

Connection details to existing sewer

Geotechnical conditions

Access for construction, repairs and maintenance

Road reserves

Clearances from obstructions

Easements

Environmental impacts

Horizontal alignment / deflections via MHs

Vertical alignments / drops

Special requirements for steep grades

Crossings of other major infrastructure assets

Calculate the design flow including:

Inflow and infiltration

Peak dry (sanitary) flow

Ground water infiltration

and determine pipe sizes

Determine grade subject to constraints on min / max velocity

at design flow

DESIGN

Maintenance structures

Determine balance of maintenance structures (MSs and

MHs) and their configuration and spacing

In MH design determine:

Other measures and

structures

Type (see Standard Drawings)

Precast or cast in situ

Channel details

Drop details

Water seals (boundary trap area)

Surface covers

Ventilation

Corrosion protection

Overflows / ERSs

Detention / storage

Property connections

Location and type of property connections

Connection depthsfull lot servicing, soffit requirements etc

Junctions

Risers

Location and grade of property connection sewers

Location of TMS / rodding points

Identification of boundary trap areas

Location of boundary traps and water-sealed MHs

COPYRIGHT

WSA 022002-2.3

45

2 SYSTEM PLANNING

The function of system planning is to develop servicing strategies for meeting customer

requirements, subject to business and regulatory constraints.

The design of a sewer system should be preceded by feasibility studies that justify the

development of infrastructure to service land. The outcome of system planning is a

Concept Plan that defines the structure of the hydraulic system required to service a

particular area.

The process of system planning is closely aligned to design, it is generally iterative and is

commonly preformed by the Water Agency. If out-sourced, it generally requires a high level

of interaction between the Water Agency and the service provider with regard to design

inputs. This is particularly necessary for flow estimation.

This Section of the Code provides guidance on the methodology and default design inputs

for planning sewerage schemes. Because of the complexity and imprecise nature of

system planning, the Water Agency should endorse a Concept Plan prior to commissioning

detail design or construction.

2.1 SEWERAGE SYSTEM PHILOSOPHY AND DEFINITION

2.1.1 Disaggregation

A total sewer system is composed of three basic processestransportation, treatment and

disposal / reuse. The transportation process consists of three functional elements, namely

trunk, branch and reticulation sub-systems. Each of these sub-systems may comprise of a

network of sewers, storage structures and SPSs that collect and transport sewage from

households, businesses and industries to a sewage treatment plant for treatment and

disposal of effluent and other by-products. This can be shown under a disaggregation

model as indicated in Figure 2.1.

LEVEL

1 TOTAL SYSTEM

DISPOSAL /

REUSE

TREATMENT

TRANSPORT

TRUNK

2 TRANSPORT SUBSYSTEMS

BRANCH

RETICULATION

3 OPERATING UNITS

SEWERS

SPSs

STORAGE

FIGURE 2.1 DISAGGREGATION MODEL FOR TRANSPORTATION SUBSYSTEMS

Clauses 2.1.2 to 2.1.4 inclusive describe in more detail the disaggregation model in Figure 2.1.

2.1.2 Level 1 Total system

The total sewer system is made up of transport, treatment and disposal.

COPYRIGHT

WSA 022002-2.3

46

The transportation network is designed to effectively service customer properties and

convey the collected sewage to treatment plants for processing.

Sewage treatment plants are designed to treat all dry weather flows and part of or all wet

weather flows delivered by the transportation network to effluent standards commensurate

with the environmental impact of their discharges on receiving waters and any associated

reuse schemes. Disposal of treated effluent and other by-products follows and is subject to

each Water Agencys corporate and environmental goals. Effluent may be further treated

for reuse of varying quality from reuse within the plant processes to spray irrigation to

reuse in reticulated reuse schemes. Bio-solids may be reused for fertiliser and other

agricultural purposes.

2.1.3 Level 2 Transportation subsystems

The Code defines the various functional sewers as trunk, branch and reticulation

generically as follows:

(a)

Reticulation sewers are a network of pipes including property connection sewers

nominally up to and including DN 300 that receives sewage from customer properties

(residential, commercial and industrial).

(b)

Branch sewers are a network of pipes nominally DN 375 to DN 600 that connect the

reticulation pipes within a reticulation area or a group of reticulation areas. Property

connection sewers are not generally connected directly to branch sewers.

(c)

Trunk sewers are a network of pipes nominally DN 750 and greater that connect the

branch sewers and transport sewage to a treatment facility.

These descriptions are generally applicable to larger sewer systems. In smaller systems,

DN 150DN 300 pipes may be defined as branch or trunk sewers while DN 100 pipes may

be acceptable as reticulation sewers subject to the approval of the Water Agency.

The transport sub-system may also include SPSs and storage facilities.

2.1.4 Level 3 Operating units

2.1.4.1 Sewers

Each sewer comprises pipes as well as any fittings, maintenance structures and ventilation

facilities used in association with such pipes. These components are generically defined as

follows:

(a)

Maintenance structures that allow sewer pipes to be inspected and maintained, and

which are usually installed at changes of level, sewer line direction and/or sewer pipe

size.

(b)

Ventshafts that are typically above ground structures and that have a dual purpose of

admitting air to the sewer system to reduce the likelihood of sewage turning septic or

corrosive and causing offensive odours, and allowing odours to be dispersed.

(c)

Overflow or emergency relief structures (ERSs) that are used to provide controlled

overflow from the sewer system so as to protect public health by reducing the risk of

sewage being surcharged from maintenance holes, customer gully traps and fittings

such as floor wastes, sinks and toilets.

2.1.4.2 Sewage pumping stations (SPSs)

Where possible, the sewer system should be designed to use gravity to convey the sewage

away from where it is generated. However, steep terrain and other variations in the local

landscape may preclude or limit the viability of a gravity system. When this happens, one

option is to pump sewage by SPSs through pressure mains (rising mains) into the most

suitable nearby sewer, where it drains by gravity to another pumping station or a sewage

treatment plant. Other options also rely upon pumps e.g. vacuum sewerage and pressure

COPYRIGHT

47

WSA 022002-2.3

sewerage systems. Structural and economical considerations may also determine the need

for pumps e.g. in very flat terrain where there is a limit on the practical depth of sewer.

SPSs should be designed and constructed to minimise adverse impacts and to provide

sewer systems that are totally integrated and perform at the lowest life cycle cost. For

planning and design of SPSs and associated pressure mains and flow control, refer to

WSA 04 Sewage Pumping Station Code of Australia. Codes on vacuum sewerage and

pressure sewerage are planned.

2.1.4.3 Storage

Sewer systems should be designed to operate separately from any stormwater system,

and ideally no rainwater should enter the system. Nevertheless, sewers can over time

develop faults, such as cracks and separated joints and can be subject to damage from

other activities and tree root intrusions. These faults and intrusions may allow rainwater

and groundwater to enter, or infiltrate, during wet weather. The extent to which water

infiltrates is variable, and dependent upon the condition of pipes, joints and maintenance

structures, rainfall, topography, soil conditions and the flow capacity of the particular sewer

system. Water may also inflow into the sewer system from illegal stormwater connections,

low house gullies and broken maintenance structure covers. Storage may therefore be

designed as part of the sewer system to manage these additional flows (surcharge) in

emergency conditions to reduce the likelihood of overflows from the system.

2.2 PLANNING PRINCIPLES

2.2.1 Planning horizon

Ideally, a sewer system should be planned and designed to convey the estimated peak

flow from its service area when the area has reached its maximum population and has

been fully developed commercially and industrially. However, it is not always economically

feasible to construct some of the major sewers in a system large enough to convey the

ultimate peak flow from its service area. Under these circumstances the sewers may be

designed to convey peak flows that are estimated to occur within an appropriate design

period, generally ranging from 10 to 30 years. Provisions should be made when planning a

system to provide augmentation of the system before the actual flows become greater than

the design flows.

2.2.2 Concept Plan

The Concept Plan is the critical starting point of the design process as it determines the

extent of sewers and the possible need for pumping stations, either pressure or vacuum. It

should incorporate the outcomes of an analysis of the catchment and the options for

servicing future development.

The Concept Plan should define asset options and their configurations, sufficiently

quantified to enable detail designs and a construction specification to be prepared.

In developing concepts, system Planners should use the technical requirements of this

Part, including those for:

(a)

Dissection of the catchment into subcatchments for efficient servicing.

(b)

Flow estimation (Refer to Section 3).

(c)

Pipe sizing and grading (Refer to Clause 4.5).

(d)

Controlled overflows (Refer to Clause 7.9).

(e)

Septicity control (Refer to Clause 2.4.1).

(f)

Horizontal and vertical alignment (Refer to Clauses 4.3 and 4.6).

(g)

Obstructions and clearances (Refer to Clause 4.4).

COPYRIGHT

WSA 022002-2.3

48

(h)

Property connections (Refer to Section 5).

(i)

Lot servicing requirements (Refer to Clause 4.6.4).

(j)

Maintenance structures (Refer to Section 6).

(k)

Water seals, ventilation, syphons, overflows and storage (Refer to Section 7)

(l)

Structural and civil engineering (Refer to Section 8).

(m)

Materials and Standard Drawings (Refer to Parts 2 and 4).

2.2.3 Catchment analysis

In developing a Concept Plan for a catchment, the Planner shall carry out a catchment

analysis to determine the holistic servicing requirements. The analysis may cover a specific

new catchment area with totally new infrastructure including treatment facilities (as in a

township or remote area) or, as is in most cases, an extension to an existing sewer system.

In order to carry out this analysis, the Planner shall undertake the following actions:

(a)

Calculate the hydraulic load (anticipated total design flow) of the proposed

development and any potential future development of the subject catchment. As

necessary, conduct a system analysis or determination of Equivalent Population (EP)

(Refer to Section 3 and Appendix A).

(b)

Perform a system analysis to:

(i)

assess the adequacy of existing infrastructure to accept the additional hydraulic

load arising from the new scheme;

(ii)

determine the impacts of the new development proposal upon existing

infrastructure (both local and associated remote infrastructure); and

(iii)

determine augmentation and/or replacement needs.

(c)

Determine the extent and sizing of new infrastructure required e.g. trunk sewers,

branch sewers and pumping facilities, to service the proposal and to serve the likely

development in the entire catchment using reasonable estimates for ultimate

development scope. Design flow determination shall address constraints arising from

the design flow containment standard ARI (environmental sensitivity factor) specified

by the Water Agency.

(d)

Determine resource and financial estimates in accordance with Water Agency

requirements.

(e)

Broadly plan the localised reticulation networks for the development scheme.

2.2.4 Provision for future gauging needs

Gauging facilities should be incorporated as an integral part of the as-built system rather

than retrofitting them, since it improves their accuracy and avoids operational problems.

The Concept Plan shall include:

(a)

provision for a flow gauge network and rain gauges; and

(b)

calibration check points for the initial and the ongoing calibration of all proposed

gauging facilities.

Gauging sites should include:

(i)

major overflow points; and

(ii)

pumping stations and gravity subsystem outlets.

Appendix C provides guidance on the design of gauging systems.

COPYRIGHT

49

WSA 022002-2.3

2.2.5 Terrorism

High risk infrastructure shall incorporate appropriate safeguards designed to minimise the

potential risk and impact of terrorist attack. Such measures shall be addressed during

planning and in the concept and detail design phases.

2.3 PLANNING PARAMETERS

2.3.1 Loading per serviced property

Loading rates per serviced property can be impacted significantly, both geographically and

over time, by changes in land-use, industrial processes, business relocations, climate,

holiday and seasonal factors. The Water Agency should establish and maintain a suitable

geographically based database of current and intended future land use zoning, covering all

catchments of interest.

Records of gauged sewage loading per land use type, in conjunction with water

consumption records, should be kept and analysed to determine the:

(a)

Proportion of sewage flow versus water consumption i.e. internal usage factor.

(b)

Average loading rates per serviced unit or land area (ha).

(c)

Average Equivalent Population (EP) per unit or per area rating, based on an assumed

loading rate of 180 L/EP/d.

Average loading rates shall be used as the basis for future load assessments using the

same land-use categories. Estimates of loadings must be consistent with water

consumption (internal usage) planning assumptions. The Water Agency should be

consulted regarding any specific local variation to the loading.

2.3.2 Assessment of future loads

Increases in average daily loading shall be calculated as the product of the estimated EP

draining to the point of design interest, and the residential loading rate of 180 L/EP/d.

Equivalent future population shall be calculated for each land use type to be developed by

identifying the number of units to be developed from the categories in Tables A1, A2 and

A3 (or Water Agency supplements) or from the developers or local or planning authorities.

For residential areas without density classifications or areas where future changes to

residential zonings are anticipated, a most likely density consistent with town planning

policies shall be determined. In summary:

(a)

Use the EP loadings per unit type listed in Appendix A.

(b)

Calculate EP as the sum of the products of unit numbers multiplied by EP/unit rates.

2.3.3 Assessment of existing system loads

Where existing system loads are likely to limit the spare hydraulic capacity available for

new development, the existing system loads shall be determined by gauging. Where not

practicable, the area or number of properties per land-use serviced shall be determined by

one or more of the following:

(a)

Zoning maps and planning instruments.

(b)

A field house count.

(c)

Interrogation of census data.

(d)

Interrogation of GIS system data.

Existing loads on ungauged areas shall then be estimated as the sum of the products of

unit numbers multiplied by EP/unit rates.

If catchment development is likely to be spread over a long time frame, then planning and

design of transport, pumping and treatment facilities shall be suitably phased / staged.

COPYRIGHT

WSA 022002-2.3

50

2.3.4 Environmental considerations

The Planner shall consider the environmental impact of the project for design, construction

and operational phases in the light of Commonwealth, state, territory and local government

environmental and heritage laws and regulations and Water Agency policies, instructions

and guidelines. Legal requirements and Water Agency policies require the Planner to

consider the environmental impact to the fullest extent possible. In some instances, an

environmental impact assessment may need to be completed during the planning stage, in

which case it should be documented as directed by the Water Agency (Refer to

Clause 4.2.4 for a more detailed explanation of environmental considerations).

2.3.5 Geotechnical investigations

The Planner shall consider whether the nature of the ground, with respect to instability and

ground water infiltration (GWI), requires special geotechnical assessment and

consideration. Where required, assessment by a competent geotechnical engineer shall be

carried out. The Planner shall prepare a Concept Plan in accordance with any controlling

or regulatory authority.

The impact of a sewer trench on potential draining of the water table may require the

installation of bulkheads (Refer to Clause 8.10).

2.3.6 Operations and maintenance considerations

The Planner shall consider operations and maintenance requirements in the Concept Plan.

These may include:

(a)

Location of sewers to provide safe and easy access for maintenance and condition

assessment.

(b)

Location of sewers clear of other services and adjoining structures, particularly with

deep sewers under structures / facilities, heavy structural foundation loadings and

adverse trench / foundation conditions.

(c)

Control of gas generation to enhance asset life, the safety of maintenance workers,

prevention of gas flows from sewers to sanitary drains and comply with licence

requirements.

(d)

Requirements for bypassing of flows to allow maintenance and asset condition

assessment, repair and/or rehabilitation.

(e)

The impact of unstable or water charged ground.

(f)

Storage and its cleansing and odour control.

2.4 SEWAGE QUALITY

2.4.1 Septicity

One of the main factors affecting sewage quality is septicity. It is caused by the prolonged

retention of sewage under anaerobic conditions, particularly during low flow periods. It can

be avoided by limiting the retention time in pumping stations, pressure mains and syphons

and by designing for self-cleansing velocities in all sewers. Septicity of sewage leads to

offensive odours and damage to sewers and is difficult to treat.

Septic sewage may produce gases such as methane and hydrogen sulphide. When mixed

with air in certain proportions, methane is highly explosive. Hydrogen sulphide is lethal in

high concentrations and in part-full pipes may be converted into sulphuric acid by microorganisms on the damp soffit of the pipe. This acid may cause serious corrosion of work

constructed with normal Portland cement and some metallic components e.g. galvanised steel.

Hydrogen sulphide is formed under anaerobic conditions at low flow velocities and warm

temperatures. The rate of release is increased at points of high turbulence and at the

COPYRIGHT

51

WSA 022002-2.3

outlets of inverted syphons and pressure mains. Corrosion of susceptible materials may

occur at these points and downstream of them.

To minimise the likelihood of septicity, the Planner / Designer shall:

(a)

use adequate grades for self-cleansing and slime control;

(b)

minimise detention periods by avoiding use of SPSs wherever practicable;

(c)

avoid any unnecessary turbulence at junctions and changes in grades, particularly

where pressure mains enter the gravity system, at drop junctions and at vortex drops

(d)

ensure adequate natural and/or forced ventilation; and

(e)

investigate and report on the use of chemical dosing, as appropriate.

Where an SPS is unavoidable, the Planner / Designer shall address septicity and its

minimisation. This may require staging of storage and pumping capacity (Refer to WSA 04).

The Hydrogen Sulphide Control Manual provides more detailed information on the impact

and control of H2S in the sewer system.

NOTE: Hydrogen Sulphide Control ManualSepticity, Corrosion and Odour Control in Sewerage Systems,

Technological Standing Committee on Hydrogen Sulphide Corrosion in Sewerage Works, Volumes 1 and 2,

Melbourne Metropolitan Board of Works, Dec 1989. Reprints available from WSAA.

2.4.2 Sewage quality / Trade waste management

The Water Agency should have strategies in place to monitor and control non-domestic

sewage entering the system from commercial and industrial sources. The methods of

control are normally managed through a trade waste program that provides commercial

and industrial i.e. non-residential customers with a liquid waste acceptance service in

accordance with the principles of environmental sustainability.

In relation to the design of a sewer, the Planner / Designer shall consider the known and

likely discharges of each industry so that the correct flows may be estimated and suitable

materials can be specified for each element of the system.

2.5 PLANNING REVIEW

Once the system has been planned and a layout established, a review shall be undertaken

to demonstrate compliance with Water Agency requirements and at least the following:

(a)

All existing and likely licence and customer contract requirements for all existing and

future customers (unless this is part of a future augmentation project) can be met.

(b)

All appropriate geotechnical considerations have been included.

(c)

Service capability is provided at the lowest property connection in each zone.

(d)

Maximum and minimum flow estimates have been made in accordance with Water

Agency requirements.

(e)

Sewer capacities and any storage capacity and/or overflow structures satisfy system

requirements.

(f)

Potential for future septicity problems and odour is minimised at the various stages of

development or as an inherent outcome of the design.

(g)

Ventilation and slime control measures are adequate within individual zones.

(h)

Sewer layout and alignment meet Water Agency requirements.

(i)

All environmental requirements have been identified and addressed.

COPYRIGHT

WSA 022002-2.3

52

3 FLOW ESTIMATION

This Section specifies methodologies for determining design flows generated from a

particular area, based on the existing and/or future zoning and land usage.

3.1 DESIGN FLOW ESTIMATION

The flow in a sewer comprises domestic sewage, industrial wastes, groundwater infiltration

and storm inflows and rainfall dependent infiltration.

Flow (in L/s) is composed of the three components, illustrated in the pipe cross section in

Figure 3.1, where the overall design flow is represented by the equation:

Design flow = PDWF + GWI + IIF

NOTES:

1

Components are indicative only and will differ due to location, rainfall, strata, pipe material and jointing methods

and other factors.

The component shown as IIF is also the air space / ventilation allowance during dry weather flows.

FIGURE 3.1 FLOW COMPONENTS IN A GRAVITY SYSTEM

The estimated design flow shall be used for hydraulic design of the gravity pipeline i.e.

sizing and grading of pipes as detailed in Clause 4.5.

NOTE: For SPS design refer to WSA 04.

3.2 DESIGN FLOW ESTIMATION METHOD

3.2.1 General

Methods for determining design flow vary depending on the availability of calibrated

models that represent the area under consideration. For reticulation sewers the Water

Agency may use empirical relationships between EP and flow (Refer to Clause 4.5).

3.2.2 Traditional design flow estimation method

Where a calibrated model, applicable to the system under consideration, is not available

e.g. greenfield development sewers that will not receive upstream flows from an existing

system, the method for determining the design flow shall be in accordance with the

methodology specified by the Water Agency.

A traditional approach has been to estimate the equivalent population to be serviced by

the sewer and to calculate flows on the basis of an allowance per EP. Appendix B details a

default model for estimating the design flow, primarily for undeveloped areas, albeit it may

be used for developed areas for which gauged data is not available. The model adopts an

allowance for sanitary flow (daily average) of 180 L/d/EP (0.0021 L/s/EP) and details a

method for estimating peak flows, including GWI and IIF.

COPYRIGHT

53

WSA 022002-2.3

Where the estimated or actual EP has not been provided, it shall be determined using the

methodology specified by the Water Agency. A default method for estimating EP for

undeveloped areas or ungauged systems is given in Appendix A.

Determination of design flow using Appendix B requires the Water Agency to specify the

containment standard ARI and other factors.

3.2.3 Design flow estimation incorporating existing systems

For sewers that will connect to an existing upstream system, the method for determining

the design flow shall be in accordance with the methodology, including computer models

and design inputs, specified by the Water Agency.

It is recommended that a computer model of the existing system be developed, and that it

be calibrated to actual flows. This is considered to be the best means for performing

hydraulic evaluations of the existing system capacity and for determining impacts of

infrastructure upgrades and future loading impacts. Guidelines for a flow modelling

methodology are provided in Appendix D.

3.2.4 Design flow estimationPartially pumped systems

Where pumped flows discharge into a gravity sewer upstream of a point of interest for

design, the gravity sewer shall be designed to accept the total pumped flow plus the design

flow from any gravity area contributing to the point of interest.

At such points in a system having pumped flows discharging upstream thereof, design flow

shall be calculated as follows:

Design flow = design flow Gravity + Capacities

where:

design flowGravity = design flow for the gravity drainage portion, calculated as per the

design flow estimation procedures for gravity systems given above

Capacities

= sum of the maximum capacities of all upstream pumped discharges

Where possible, a computer model of the existing system and its calibration to actual

flows, should be developed since it is considered to be the best tool for performing the

above described hydraulic evaluations, both for existing system capacity and for

determining impacts of infrastructure upgrades and future loading impacts. No detailed

description of flow modelling methodology is given in this Code, but general guidelines are

provided in Appendix D. The same approach may be used for optimising the sizing and

arrangement of new schemes by ignoring the points relating to gauge data.

3.2.5 Flow schedule

A schedule of all flows into the sewer shall be documented in a format nominated by the

Water Agency.

COPYRIGHT

WSA 022002-2.3

54

4 DETAIL DESIGN

4.1 DETAIL DESIGN PROCESS

Following the definition of the servicing strategy for a catchment, detail design of the major

infrastructure for the area and the individual reticulation and property connection sewers

shall be carried out. Detail design shall ensure that the following principal requirements are

met:

(a)

the design reflects the Water Agencys servicing strategy, Concept Plan and/or other

brief for the subject catchment;

(b)

the design incorporates the most appropriate location, size, depth and grade of

sewers;

(c)

the design takes account of any physical features (buildings, underground

utilities/services, creeks etc) previously identified in the field;

(d)

projected life cycle costs are minimised;

(e)

each property has a point of connection; and

(f)

each property has the required extent of drainage.

Outputs of the detail design process shall include but not be limited to a Specification and

Design Drawings that incorporate a plan and elevation of all sewers and all necessary

construction drawings.

A typical procedure for designing a sewer is:

(i)

Initial predesign, which utilises a services search, contour plan and cadastral

information to define the route of the sewer. This is appropriate for all sizes of

sewers and may be done to different degrees of accuracy depending on the

detail available to the Designer e.g. full subdivision layout versus zoning layout.

(ii)

Field survey, carried out to ascertain the exact location of the proposed sewer,

physical features and services along the route of the sewer and the elevation of

the land. This is required to enable the sewer to be correctly graded and to

satisfy clearance requirements for services, crossings etc.

(iii)

Office-based design including plotting of plan and elevation from field records.

Proposed services should be addressed at this stage.

(iv)

Preparation of detailed construction drawings and specifications covering

materials and other technical matters relevant to design and construction.

4.2 DETAIL DESIGN CONSIDERATIONS

4.2.1 Catchment design

Sewers within any project area shall be designed to drain the specified catchment.

To ensure future extension of the system, it may be necessary to carry out preliminary

designs for large areas of nearby land (actual proposals or hypothetical developments) that

make up the catchment.

As appropriate, sewers within any project area shall be designed to enable future

extension of the system to service the whole physical catchment. The optimum depth and

diameter of any future extension shall be determined. Any potential stormwater systems or

other major services shall also be considered.

COPYRIGHT

55

WSA 022002-2.3

4.2.2 Design accuracy

The location and final design elevations of the sewer(s) shall be determined to the

following levels of design accuracy and specified in the Design Drawings:

(a)

in plan, to 0.01 m.

(b)

in level where grade is < 0.5% (1:200) to the nearest 0.005 m.

(c)

in level where grade is > 0.5% (1:200) to the nearest 0.01 m.

Levels shall be referenced to the Australian Height Datum (AHD). Location in plan shall be

referenced either to the local cadastral boundaries, or to the Geodetic Datum of Australia

(GDA 94).

4.2.3 Sewer layout

The preferred layout / location of sewers within roads, public reserves and private property

may vary and will be dictated by the requirements of each Water Agency. Local municipal

councils, road Owners and other service Owners in each state and territory may also

influence sewer locations.

In many cases, more than one possible alignment of a sewer may be feasible. It is often

necessary to prepare alternative concepts to determine the most suitable, practicable and

lowest life cycle cost solution.

As a gravity sewer system design is generally preferred to other options, the sewer layout

shall conform to the natural fall of the land as far as practicable. The design shall address

the following factors in determining the location of sewers:

(a)

Road reserve size and layout;

(b)

Topography and geotechnical considerations;

(c)

Location of property service connections and maintenance structures;

(d)

Lot control requirements and limitations on depths of connections;

(e)

Underground services;

(f)

Operations and maintenance requirements including maintenance structure locations;

(g)

Existing / proposed building alignments;

(h)

Proposed zoning / land use;

(i)

Planning information regarding proposed or possible future development on the site

e.g. road re-alignments, landscaping;

(j)

Easements, with existing sewerage easements being used where possible;

(k)

Physical surface obstructions;

(l)

System security;

(m)

Construction methods e.g. normal excavation or trenchless methods;

(n)

Historical information regarding previous use of the site;

(o)

Environmental and heritage considerations;

(p)

Preference for sewer location in accordance with Water Agency requirements;

(q)

Preferences expressed by property owners;

(r)

Preferences of municipal councils and other authorities;

(s)

Future development plans and the need to avoid unnecessarily reducing the

development potential of adjoining lands: and

COPYRIGHT

WSA 022002-2.3

(t)

56

The siting of overflow structures.

Taking all the above factors into consideration, the following list is indicative of where

sewers should be positioned (no particular order):

(i)

Within the street reserve according to the locally applicable utilities allocation

code; in the absence of a code, a location clear of carriageways is preferred.

(ii)

Within public land with the permission of the controlling authority.

(iii)

Within drainage reserves outside 1 in 100 year flood area.

(iv)

Within private property parallel to front, rear and/or side boundaries.

The final sewer alignment shall comply with Water Agency requirements, any local space

allocation code and applicable statutory requirements.

The final sewer design and layout should be flexible enough to achieve the design

requirements stated in Clause 4.1, but also be practicable when considering the most

efficient design. For example, in areas where the cross-fall is not substantial, sewers may

be designed slightly deeper to serve lots on both sides of the sewer. Where this is not

practicable, it may be necessary to locate additional sewers along the side or front

boundaries of properties to achieve acceptable lot drainage.

4.2.4 Environmental considerations

4.2.4.1 General

When selecting the route of a sewer, the Designer shall comply with the requirements of

the project EIA. Where an EIA does not exist, the Designer shall consider the

environmental impact of the project for both construction and operational phases in the

light of Commonwealth, state, territory and local government environmental and heritage

laws and regulations and Water Agency policies, instructions and guidelines.

The following sensitive areas shall be avoided wherever practicable:

(a)

National parks, nature reserves, proclaimed reserves, state forests, stands of native

vegetation etc.

(b)

Habitats of threatened species.

(c)

Steep slopes.

(d)

Waterways and floodways.

(e)

Wetlands, swamps, estuaries, sand dunes, foreshore areas.

(f)

Bushland and vegetation communities and/or fauna.

(g)

Heritage items and precincts.

(h)

Aboriginal relics and sacred sites.

(i)

Unstable areas subject to rock falls, slips and flows including areas steeper than 33%

grade.

(j)

Aggressive ground conditions e.g. mining areas, acid

contaminated land, including suspected contaminated land.

(k)

Land fill sites and mine subsidence areas.

sulphate

soils

and

Where it is not practicable to bypass sensitive areas, the following measures shall be

considered during selection of the route and construction methods so as to minimise

effects, contact, damage or disturbance:

(i)

Use of no-dig excavation methods such as tunnelling, boring, directional drilling

and micro-tunnelling.

COPYRIGHT

57

WSA 022002-2.3

(ii)

Use of de-watering and rock excavation less likely to cause damage or

disturbance.

(iii)

Use of construction equipment of type and size less likely to damage or disturb

sensitive areas

(iv)

Local deviations around significant flora and particularly sensitive parts of a site.

(v)

Minimising the area of disturbance.

(vi)

Undertaking construction when there would likely be drier weather and firmer

ground conditions

(vii) Minimising transport of soil borne disease and non-native flora and fauna into

sensitive areas.

(viii) Very high standard rehabilitation of the site after construction is complete.

Owners and controlling and regulatory authorities shall be consulted on proposed methods

of construction in sensitive areas and measures to avoid or minimise damage or

disturbance. Any requirements for avoiding or minimising effects, contact, damage,

disturbance and rehabilitation of sensitive areas shall be included in the Design Drawings

and/or Specification.

4.2.4.2 Urban salinity

The Designer shall consult the local planning authority to determine whether urban salinity

management strategies are in force so as to ensure that appropriate precautionary

measures are adopted.

Location of infrastructure and construction activities may contribute to the salinity problems

by affecting drainage or by disturbing native soils in salinity hazard areas. Salinity may

cause accelerated deterioration of built infrastructure. Salinity management strategies may

constrain options for positioning of infrastructure, materials, or construction methods.

4.2.4.3 Vegetation

Vegetation along the proposed route of a sewer shall not be removed unnecessarily,

particularly mature and sound stands of trees. Dead trees, either fallen or standing, shall

also be considered as they may provide a natural habitat for fauna. Trees of significance

located along the proposed route of the sewer shall be identified for protection and a

record, including details of their health, stability and importance, shall be established.

Specialist advice should be sought as a permit may be required for tree removal and the

cost and constraints of such action may be a design consideration.

4.2.4.4 Contaminated sites

If selecting the route of a sewer where a contaminated site cannot be avoided, prior written

approval to proceed shall be obtained from the environmental Regulator and the Water

Agency. Confirmation of the following issues shall be provided to the Water Agency:

(a)

Need for site contamination assessment by environmental Regulator (if applicable).

(b)

Compliance with statutory requirements.

(c)

Options to de-contaminate the area, including sites identified for disposal of

contaminated spoil.

(d)

Selection of appropriate materials and jointing techniques to maintain sewer integrity

and fulfil life expectancy.

(e)

Selection of appropriate foundation and embedment materials to maintain structural

integrity.

(f)

Safety of construction, operation and maintenance personnel.

COPYRIGHT

WSA 022002-2.3

(g)

58

Special maintenance considerations / requirements.

The Design Drawings and Specification shall nominate details of contaminated sites and

safety precautions, as appropriate.

4.2.4.5 Tidal zones

For sewers located below high tide level, the following requirements shall be specified:

(a)

The weir crest of any ERS (Refer to Clause 7.9) to be set at least 0.5 m, and

preferably 0.8 m above maximum high tide AHD level.

(b)

The tops of maintenance structures to be at least 0.9 m above maximum high tide

AHD and fitted with watertight type metal access covers.

(c)

A sewer material and jointing system suitable for marine environments and protected

as necessary from external abrasion, vandalism and UV radiation.

(d)

A suitable installation technique for the tidal zone ground conditions (Refer to

Clause 8.6.7).

4.2.5 Easements

Where required by state or territory legislation and/or the Water Agency and where sewers

are located within private property, easements shall be created which provide access to

the Water Agency for future operations and maintenance activities and restrict any

construction over the sewer (Refer Standard Drawing SEW1105 for typical easement

installations).

Easement widths and placement of the sewer within the easement shall be as specified by

the Water Agency and detailed in the Design Drawings.

4.2.6 Disused sewers

Where a design results in the disuse of an existing sewer, the Design Drawings and

Specification shall detail proposed treatment such as demolition of top 300 mm of an MH

top and/or capping both ends of the sewer at each MH or complete removal of the sewer

and structures.

Sewers should not be designated abandoned. Disused sewers offer potential for the

placement of other utility conduits, such as telecommunications, and should not be

destroyed or filled without careful consideration. Sewers of age greater than 50 years may

have heritage protection.

4.2.7 Special design considerations

When determining the route of a sewer in difficult areas, there may be a need to identify at

the design stage some special design requirements. The detailed requirements for these

special designs are explained in Section 8 and include geotechnical considerations such

as filled, mine subsidence and slip areas as well as water charged ground.

4.3 HORIZONTAL ALIGNMENT OF SEWERS

4.3.1 General

Subsequent to determining the preliminary location of the sewer, the following more

detailed aspects shall be incorporated into the final detail design, as appropriate.

4.3.2 Roads, reserves and open space

Sewers that are to be constructed in roads, drainage reserves and/or public open spaces

shall be located in accordance with the Water Agencys requirements.

Crossings of all roads, creeks, drains and underground services shall, as far as

practicable, be at right angles (Refer to Standard Drawings SEW1400, SEW1401, SEW

COPYRIGHT

59

WSA 022002-2.3

1402, SEW1403 and SEW1404). As necessary, these drawings (or alternatives if

acceptable to the Water Agency) shall be used to develop detailed construction drawings.

Where sewers cross freeways, arterial roads and other designated major road reserves,

the following design criteria shall apply:

(a)

Size the sewer one size larger than hydraulically necessary at those crossings to

cater for future growth; or

(b)

Specify dual pipelines to avoid operational problems at a later date.

All maintenance structures shall be located outside the road pavement. In the case of

freeways they shall be outside the freeway reserve. If the maximum spacing requirements

as specified in Clause 6.2 cannot be met, the Water Agency shall be consulted.

4.3.3 Railway reserves

Sewers shall not be laid within railway reserves unless it is necessary to cross that land, in

which case, the crossing shall be in accordance with AS 4799. Consultation and approval

of the Water Agency shall be sought prior to finalisation of any design requiring sewers in

railway reserves (Refer to Standard Drawing SEW1401).

4.3.4 Public and private property

Where sewers are designed to traverse any vacant or occupied public or private

properties, the design shall as far as practicable allow for possible future building plans,

preclude maintenance structures and specify physical protection of the sewer within or

adjacent to the normal building areas and all engineering features (existing or likely) on the

site e.g. retaining walls.

The design shall allow access for all equipment required for construction and future

maintenance. Except where obstructions and/or topography dictate otherwise, sewers shall

run parallel to boundaries at minimum offsets of 1.0 m.

Where sewers are designed to traverse properties containing existing structures e.g.

retaining walls, buildings and swimming pools, the current and future stability of the

structure shall be considered. Sewers adjacent to existing buildings and structures shall be

located clear of the zone of influence of the foundations. If this is not possible, protection

of the sewer and associated structures shall be specified for evaluation and approval by

the Water Agency.

4.3.5 Changes in direction using an MH

Achievable changes in direction at an MH are dependent on the diameter of the sewer, the

physical ability of the MH to accommodate the deviation in direction and the type of

inlet / drop across the MH. The maximum allowable deflection of a sewer through an MH,

excluding horizontal bends external to the MH, shall be in accordance with Table 4.1.

Clause 4.3.7 specifies requirements for external horizontal bends.

No compensation for friction head loss through bends incorporated in the MH base is

required for MHs located on branch and trunk sewers.

4.3.6 Dead-ends