Professional Documents

Culture Documents

CLCP Iom

Uploaded by

Leed ENOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CLCP Iom

Uploaded by

Leed ENCopyright:

Available Formats

TRANE

Installation

Operation

Maintenance

Quantum Climate Changer

Model: CLCP

0.5 - 27 m3/s

(1000 - 58000 CFM)

IND-SVN01A-E4

TRANE

Contents

General Information

Nomenclature

Foreword

Warranty

Warning and Caution

Unit Description

Name Plates

Unit Submittals

Receiving and Handling

Lifting and Rigging

Submittal Drawing (VDT)and (HDT)

Installation

Lifting and Rigging Recommendation

Break Point Joining Method

Vertical Unit and Final Final Filter Joining Method

Removing and Inserting Wedge

Damper Installation

Duct Connections

Piping

Steam Coil Piping

Refrigerat Coil Piping

Pulley and Belt

Wiring/Start-up Procedure

21

Wiring and Start-Up Preparation

Shipping Bracket Removal Detail

Delayed Start-Up and Start-Up Procedures

Sheave Alignment and Fan Belt Tension/Alignment

Deflection Force Table and Belt Tension Measurement

Maintenance

25

Periodic Maintenance Checklist

Trouble Analysis

Trouble Analysis

Appendix B-Unit Weight

Appendix C-Fan Sizes/Arrangements

Appendix D-Air Filter Sizes x Quantity

Appendix E-Motor Detail

Safety Recommendations, Maintenance Contract and Training

i

26

TRANE

Model Nomenclature

TRANE

General Information

Foreword

injury or death, while cautions are

Unit Submittals

designed to alert personnel to

These installations, operation and

conditions that could result in minor

Refer to Figure 2 and 3 for the

maintenance instructions are given as

personal injury or equipment damage.

Horizontal Draw Thru (HDT) and

Vertical Draw Thru (VDT) unit standard

Unit Description

submittals.

Figure 1: Typical Unit Nameplate

a guide to good practice in the

installation, putting into service,

operation and maintenance by the

user, of QCC units. They do not contain

Trane Quantum Climate Changers are

full service procedures necessary for

Central Station Air Handlers designed

for a variety of controlled air application.

The basic unit consists of a fan,

heating and/or cooling coils, filters and

the continued successful operation of

this equipment; the services of a

qualified

technician

should

be

employed through the medium of a

air dampers.

maintenance contract with a reputable

service company.

Warranty

Warranty is based on the general terms

and conditions of the constructor. The

warranty is void if the equipment is

repaired or modified without the written

approval of Trane, if the operating limits

are exceeded or if the control system

of the electrical wiring is modified.

Damage due to misuse, lack of

maintenance or failure to comply with

the manufacturers instructions or

recommendations is not covered by the

warranty obligation. If the user does not

conform to the rules of chapter

Maintenance,

it

may

entail

The Quantum Climate Changer air

handlers are designed for cooling load

conditions of 1000-58000 nominal

CFM. Fans are double width, double

inlet, centrifugal types with forward

curved, backward curved, and airfoil

blade designs.

To ensure fan stability the unit ships

with shipping brackets located

between the fan support frame.

Removal of bolt and spacer is required,

prior to fan operation, to insure proper

vibration isolation.

Units ship as complete units, sections

or subassemblies. Each section is

provided with a nameplate (label)

which includes type of section, unit

serial number, customer tag number

and unit model number.

cancellation of warranty and liabilities

by the constructor.

Warning and Cautions

Notice that Warnings and cautions

appear at appropriate intervals

throughout this manual. Warning are

provided to alert installing contractors

and other personnel to potential

hazards that could result in personal

Nameplate

All Trane Quantum Climate Changer

air handlers are identified by a

multiple-character model number. lts

use enables owner/operator, installing

contractors, and service technicians to

define the operation, components and

options for a particular unit. Be sure to

refer to the information printed on the

unit nameplate (figure1) when ordering

replacement or requesting service.

2

Receiving and Handling

All unit sections are securely fasten to

skids for shipping and handling

purpose.

Upon receipt of the unit(s), inspect for

damage that may have occurred during

shipment and any items, which were

ordered but did not arrive with the unit.

Complete the following checks:

1. Visually inspect the exterior unit

casing and all accessories for any

dents, punctures or shipping and

handling damage.

2. Cut all banding (if applicable) loose

from skid, but do not remove the

skids.

3. Check all access doors to confirm

that they are secured with latches.

4. Manually rotate the fan wheel to

ensure free movement of the shaft

and bearings.

Inspect the fan housing for any

foreign objects.

5. Inspect the coil(s) for fin damage.

TRANE

General Information

lf damage has occurred to the unit

Always apply good rigging procedures

sections during shipment, the

following

instruction should be

when lifting a unit. Before hoisting the

unit into position, be sure that a proper

completed upon receipt .

method of rigging is used, with straps

or slings and spreader bars for

1. Report all claims of shipping

damage to the delivering carrier

protection and safety during lifting.

Always test-lift the unit to determine

immediately.

2. Make specific notations concerning

the damage on the freight bill.

3. Keep damaged material in the

same location as received. lt is the

receivers responsibility to provide

reasonable evidence that damage

was not incurred after delivery.

4. Notify

the

Trane

sales

representative of the damage and

arrange for repair. Do not attempt to

repair the unit without consulting the

sales representative. TRANE IS

NOT

RESPONSIBLE

FOR

SHIPPING DAMAGE.

Lifting and Rigging

Caution: Confirm that factory installed

(if any) attachment brackets are in

place and screws tight, before

rigging.(refer to figure 4, 5 & 6) The unit

will ship either assembled or as

sections. Before preparing the unit for

lifting, estimate the approximate center

of gravity for lifting safety. Because of

placement of internal components, the

unit weight may be unevenly

distributed, with more weight in the coil

and fan area. Approximate unit weights

are given in Appendix B.

exact unit balance and stability before

hoisting it to the installation location.

WARNING:NEVER ASSEMBLE

OR

BOLT

SECTIONS

OR

SUBASSEMBLIES TOGETHER

BEFORE RIGGING. ALWAYS RIG

SECTIONS OR SUBASSEMBLIES AS

RECEIVED FROM THE FACTORY.

WARNING: DO NOT LIFT THE

UNIT WITHOUT TEST-LIFT FOR

BALANCE AND RIGGING. DO NOT

LIFT THE UNIT ABOVE PERSONNEL.

FAILURE TO OBSERVE THESE

WARNINGS MAY RESULT IN

PERSONAL INJURY, DEATH OR

EQUIPMENT DAMAGE. (See

Appendix B for components weight).

TRANE

Submittal Drawing

Horizontal Draw Thru (HDT)

TRANE

Submittal Drawing

Horizontal Draw Thru (VDT)

TRANE

Installation

Lifting and Rigging Recommendation

Figure 4

Figure 5

Move units with Fork-Truck (Forklift)

Recommended Rigging Method1

Figure 6

Recommended Rigging Method2

TRANE

Installation

TRANE

Installation

TRANE

Installation

TRANE

Installation

10

TRANE

Installation

11

TRANE

Installation

12

TRANE

Installation

13

TRANE

Installation

Installation

Unit Location

Recommendations

maintenance access. Refer to

minimizing noise and vibration.

Figure 8.

Typically, about three inches is needed

for this connection to rigid ductwork.

3. Coil piping and condensate drain

requirement must be considered.

Unit handling, LEFT or RIGHT for coil

connections, drain etc. is expressed

when facing the airflow thru the coil.

For dimensional details see the

standard submittals drawing, Figure 2

and 3.

When selecting and preparing the unit

operating location, consider the

following;

1. Consider the weight of the unit.

Appendix B has a complete listing

of

all

component

operating

Allow room for proper ductwork and

electrical connections. Support all

piping and ductwork independently

of unit to prevent excess noise and

vibration.

Duct Connections

All air ducts should be installed in

accordance with the standards of the

National Fire Protection Association for

the installation of Air Conditioning and

Ventilating System other than

Residence Type (NFPA 90A), and

Ducts should be designed as a

function of the fan orientation. Duct

turns and transitions must be made

carefully to minimize air friction losses.

Avoid sharp turns and use splitters or

turning vanes when elbows are

necessary. Make turns in the same

direction of rotation as the fan.

Discharge ductwork should run in a

straight line, unchanged in size or

direction, for at least a distance of 1-1/

2-fan diameters (see Appendix C for

fan diameter).

Refer to Figure 9 and Figure 10 for

typical ductwork installation.

Residence Type Warm Air Heating and

Air Conditioning Systems (90B).

weights.

2. Allow sufficient space for the

recommended

access

panel

clearances,

removal,

and

lnlet and discharge air duct

connections to the unit should be

made with a flexible material

Figure 8

Minimum Service Clearance

Figure 7

Unit LEFT or RIGHT Convention

14

TRANE

Installation

Caution: Do not disconnect ducts from a unit while in operation. Never operate a unit unless it is connected to the duct

system.

Figure 9

Typical Discharge Ductwork Recommendations

Duct turning in the

same direction as

fan rotation

1 1/2 fan dia.

Figure 10

Typical Discharge Ductwork Recommendations

Flexible Connection

Duct Transition

Supply Duct

Not less than 1

fan dia.

1/2

15

TRANE

Installation

Piping

Condensate Drain

Connection

On cooling coil section(s) the drain pan

should always be connected directly

to a trap to ensure proper drainage of

condensate.

Caution: Failure to provide adequate

condensate piping may result in water

damage to the equipment or building.

lmportant: The applicable "rule of

thumb" for amount of condensate may

as high as 6 lbs/hr/ton for units serving

areas with high latent heat.

Male-threaded, BSPT 1 1/2"

condensate drain connection is

provided on one side of the coil

section. The main drain lines and trap

must be the same size as the drain

connection.

Pitch the connection line horizontal or

downward toward an open drain and

install a plugged tee to facilitate

cleaning. Condensate lines should not

be connected to a closed drain. This

is to avoid the possibility of drawing

sewer gasses into the unit.

Figure 11

Drain Trap for Draw-Thru Units

Drain traps must be primed. lf they are

not, the trap is essentially non-existent

and the drain pan will likely overflow.

Make sure the drain pan connection

openings are unobstructed. Trap the

drain line as shown in Figure 11 for

section with negative static pressure.

When more than one section has a

drain pan, trap each section

individually. Do not connect all drains

to a common drain line with only one

trap. Use the following drain

connection recommendations.

Figure 12

Typical Piping for Water Coil

AV - Automatic or

manual air vent

MV - Magnetic valve

GV - Gate valve

Coil Piping and Connection

General Coil Piping Recommendation

Refer to Figure 12 for typical cooling

and heating coil piping.

Proper installation, piping and trapping

is necessary to assure satisfactory

heating/cooling coil operation and to

prevent operational damage. Water

inlet and outlet connections protrude

through the coil section side panel.

Follow standard piping practices when

piping to the coil. Note the following:

1. Support all piping independently of

the coils.

2. Provide swing joints or flexible

fittings in all connections that are

adjacent heating coils in order to

absorb thermal expansion and

contraction strains.

3. When attaching piping to the coil

header, make the connection only

tight enough to prevent leaks, the

maximum recommended torque is

200ft-lbs.

4. Teflon tape or teflon piping

compound should not be used

because of its high lubricity, teflon

16

makes it easier to tighten the pipe

to the header joint past the point

where an effective seal is created,

thus damage to the coil could result.

5. "White Zinc" compound is

recommended, instead.

Caution: Use "Back-up Wrench" when

attaching piping to coils with copper

headers. Do not use brass fitttings or

brass pipe connectors. Brass distorts

easily and causes connection leaks.

TRANE

Installation

Steam Coil Piping

Type A, AA Steam Coils

These

are

for

central

following steps:

system,

industrial and process application with

one row, opposite-end connections.

Caution: Condensate must flow freely

from coil at all times to prevent physical

coil damage from water hammer,

unequal thermal stresses, freeze-up

and/or corrosion.

Complete

the

following

recommendations to prevent coil

6.

condensate return tapping, this

provides sufficient hydrostatic

Caution: Always open the steam

supply control valve slowly to

head pressure to overcome trap

losses and assure complete

prevent

possible

damage.

Do not

modulatecoil

systems

with

condensate removal.

Float and thermostatic traps are

7.

recommended because of gravity

overhead or pressurized returns

unless the condensate is drained

by gravity to a receiver (vented to

the atmosphere) and returned to

drain and continuos discharge

operation.

the main by a condensate pump.

At start-up on units with fresh air

Use float and thermostatic traps

are recommended because of

8.

gravity drain and continuos

discharge operation.

damage.

1. lnstall a 1/2 inch, 15 degree swing

check vacuum breaker in the

unused condensate

return

tapping as close as possible to the

coil.

2. Vent the vacuum breaker line to the

atmosphere or connect it to the

return main at the discharge side of

the steam trap.

Note: Vacuum breaker relief is

mandatory when the coil is controlled

by a modulating steam supply or a twoposition (ON-OFF) automatic steam

supply valve.

Select trap based on maximum

possible condensate rate.

Locate the steam trap discharge

Use a V-port modulating valve to

obtain gradual modulating action.

at least 12 inches below the

Maximum standard operating limits:

Copper tubes: 100 psig and 400oF

Type AA coils feeds alternate tubes.

Refer to Figure 13 for typical steam coil

piping.

5.

dampers, slowly turn the steam on

full at least 10 minutes before

opening the fresh air.

Pitch all supply and return steam

piping down minimum of 1-inch

per 10 feet in the direction of flow.

Use float and thermostatic traps

with atmospheric pressure gravity

9.

condensate return, with automatic

control or where the possibility of

low-pressure supply steam exists.

Use bucket traps ONLY when the

supply steams in unmodulated

and 25 psig or higher.

Always install strainers as close

as possible to the inlet side of the

Do not modulate Type A, AA coils.

trap.

Use two position (ON-OFF) steam

supply controls.

10. Do not drain the steam mains or

take-off through the coils. Drain the

mains ahead of the coils through

a steam trap to the return line.

11. Overhead return require 1 psig of

pressure at the steam trap

discharge for each 2 - feet

elevation to assure continuous

condensate removal.

Figure 13

Typical Piping for Steam Coil

3. Run the return pipe at the full size of

the steam trap connection except

for the short nipple screwed directly

into the coil condensate connection.

Do not bush or reduce the coil return

tapping size.

4. Proper steam trap selection and

installation

is

necessary

for

satisfactory coil performance and

service life. For installation, use the

AV

GV

VB

OV

- Automatic or manual air vent

- Gate valve

- Vacuum breaker

- Automatic two-position control valve

17

MV - Magnetic valve

FT - Float and thermostatic steam trap

ST - Strainer

TRANE

Installation

Refrigerant Coil Piping

practices,

1. Type FD coils have been dehydrated

Caution:

which

To

must

avoid

follow.

avoid direct flame (figure 15) to the valve

body and avoid excessive heat on

equipment

diaphragm. As an extra precaution. a

and sealed with 10-20 psig dry

nitrogen holding charge.

malfunction, use care when brazing or

soldering so that distributor tubing is

wet cloth may be around the body and

element during brazing operation.

2. Refer to the "Trane Refrigeration

Manual" for refrigeration-piping

not restricted or blocked. To braze

Thermostatic Expansion Valves (TXV)

Figure 14

Typical Piping for Refrigerant Coil

Figure 15

Solder Technique

Note: Flame should heat away from

TXV element

18

TRANE

Installation

Pulley and Belt

bottomed out. The resulting

slippage shortens belt life.

carrying tensile cords of the belt

and the belts will break or turn over

Proper installation techniques will

c) Wobbling and/or damaged pulleys.

assure that you get full service life and

minimum down time from your belt

Generally caused by improper

pulley or bushing installation,

Take up sleck until belts fit snugly.

drives.

1. Turn machine OFF and lock out

wobbling and/or damaged pulleys

can unbalance a drive, wear out

6. Check pulley alignment.

Place a straight edge or taut string

power source.

2. Remove belt guard, loosen motor

belt rapidly, and damage bearings

and bend shafts.

across pulleys faces to correct

alignment.

mounts and shorten center distance

between pulleys. Remove old belts.

3. lnspect. Repair or replace drives

components.

Clean oil, grease and debris from

Check and repair worn bearings and

bent shafts.

Check parallel position of shafts

and correct alignment or grooves.

Note: Mount pulleys as close to

bearing as possible.

pulleys, remove rust with wire

brush.

matched set from UNI-DRIVE.

a) Do not mix old and new belts on a

lnspect and replace damage

pulleys. Get your moneys worth

from a new set of belts by checking

and replacing worn or damaged

pulleys. ln the long run,

drive. A new belt will ride higher in

the pulley groove and operate at a

higher tension than an old belt.

Running them together will

damaged the new belt as it cannot

carry its share of the load.

b) Do not mix belt from different make,

because

dimensions

and

constructions will vary running such

"Mis-Matched" belts will not give full

service life.

c) Replace with correct type and cross

section belt. Matched SPA section

belt with SPA section pulleys. Do not

put a SPA belt section on a SPB

section pulley. Also dimensionally

similar belts can have very different

horsepower rating.

replacement pulley cost will more than

be recovered in increased belt life,

reduced downtime, and lower

maintenance expenses.

Check following:

a) Worn groove sidewalls, "Dishing"

should not exceed 1/32" for

individual belts. With a banded belt,

dishing should not exceed 1/64".

When a banded belt rides too low

in worn pulley grooves the tie band

can be cut by the flanges between

the grooves.

b) Shiny pulley groove bottoms. This

is a sure sign that the belt has

4. Select replacement belts.

Replace all belts on a drive with a new

5. lnstall new belts

Loosen the drive take up and place

the new belts on the pulley. Press

the belts with your hand to position

the slack of each belt on the same

side of the drive. lf the slack is on

different sides. start up loads can

break belt tensile cords.

Do not pry or force belts onto the

pulleys. This can break the load

19

shortly after installation.

TRANE

Installation

7. Tension Belts.

Note: Store belts in a cool, dry place

Ideal tension for a UNI belt is the

out of direct sunlight.

lowest tension at which a belt will

not slip under peak load.

Types of sheave and shaft misalignment

Tension belts, replace belt guard

run the drive for 15 minutes and

Parrallel

apply full load. Retighten slopping

or squeaking belt.

Retention after 24 to 48 hrs.

running,

when

belt

will

Horizonal Angular

be

completely seated into grooves.

Do not use belt dressing. If the

belt slips, tighten and/or check for

Align with straightedge along

Vertical Angular

worn pulley grooves.

20

sheave faces

TRANE

Wiring/Start-Up Procedure

Shipping Bracket Removal Detail

21

TRANE

Wiring/Start-Up Procedure

1. Check fan hub setscrews; sheave

d) For long stocking periods, remove

setscrews and bearing setscrews

for proper torques. Fan sheaves

electrical equipment and store in a

should be tight and aligned. See

Maintenance section for alignment.

2. Check the piping and valves for

leaks. Open and close the valves to

check for proper operation. Drain

line should be open.

Caution: The use of untreated or

improperly treated water in unit coils

may cause scaling, erosion,

corrosion, algae, slime or other

equipment damage. Consult a

qualified water treatment specialist to

determine if water treatment is

required. The Trane Company

assumes no responsibility for

equipment damage caused by

untreated or improperly treated water.

3. Check that the air filter is in place.

4. Remove all foreign material from the

drain pan. Check the drain pan.

Check the drain pan and

condensate line to make sure they

are not obstructed.

5. Close and secure all unit access

doors. Check that the latches are

tight.

Delayed Start-Up

lf installation and start-up do not occur

immediately after delivery, take the

following precautions:

a) Protect equipment in an area not

exposed to excessive heat and

humidity.

b) Take special care to protect

electrical components.

c) Periodically, manually turn all

moving parts to avoid any possibility

of jamming or blocking.

in the numerator of the equation are

absolute values. Disregard whether

dry atmosphere.

e) Verify the motor lubrication before

start-up and follow the motor

they are positive or negative when

adding the values.

manufacturer recommendations.

5% from the original designed rpm, or

if parts such as shaft, fan wheels,

bearings, or other drive components

f) lt should be noted that the bearings

are prelubricated. lt is however

possible that start-up will be noisy

until the grease is evenly

distributed.

Start-Up Procedures

After completing all items under

preparation the unit may be started.

The following checks and adjustments

should be made during initial start-up:

1. Bump-start unit and observe the fan

wheel for proper rotation. As

indicated by indicated by rotation

arrow located on fan housing.

2. Measure the motor voltage and

amperage on all phases to ensure

proper operation The readings

should fall within the range given

on the motor nameplate. Never

overload the motor.

3. Maximum allowable voltage

imbalance is two percent. Voltage

imbalance can cause motor

overheating and failure. Voltage

unbalance is calculated as follows:

(L avg -L1)+(L avg-L2 )+(L avg-L3) x100 = %unbalance

2 x L avg

L avg = Average line voltage of lines

L1, L2 and L3

L1

= Line 1 voltage

L2

= Line 2 voltage

L3

= Line 3 voltage

The difference of the bracketed value

22

lf the fan speed is changed more than

are replaced, the unit vibration should

be checked. Do not exceed max. fan

RPM.

Pay particular attention to any vibration,

noise or overheating of the fan

bearings and motor (bearings may run

warm during break in)

Note: During break in period, bearing

temperature may be 1500F and 1600F.

For normal running, bearing

temperature is 900F to 1000F.

Excessive Vibration-must be corrected

to prevent bearing and shaft damage.

The trouble shooting section details

the common causes for vibration.

Determining fan FPM - can be

determine by using a strobe-type

tachometer, or revolution counter.

Sheave Alignment

Align the fan and motor sheaves by

using a straight edge as shown in the

Figure 16.

The straightedge must be long

enough to span the distance between

the outside edges of the sheaves.

When the sheaves are aligned, the

straightedge will touch booth sheaves

at points A through D.

TRANE

Wiring/Start-Up Procedure

Figure 16

readjust to the maximum value.

Sheave Alignment

To measure belt tension, use a belt

tensioner as shown in Figure 18.

Determine actual deflection by

depressing one belt with the belt

tensioner and measuring the

deflection relative to the other belts or

to belt line. Adjust the belt tension to

the correct force (Newton) and tighten

all setscrews to the proper torques.

Figure 17

Belt Tension Measurement

Fan Belt Tension/Alignment

Note: Fan belt tension should be

checked at least twice during the first

day of operation, since there is a rapid

decrease in tension until belts are run

in.

Proper belt tensioning is required to

ensure maximum bearing and drive

component life and is based on fan

brake horsepower requirement.

Belt Tension Measurement

Check the belt tension as follows:

Measure the span length of the drive

(in mm). With a belt tensioner at the

center of the span. apply a force K

(perpendicular to the span) large

enough to deflect the belt 15mm per 1

meter of span. Refer to figure 17.

DEFLECTION = SPAN X 15/1000mm

The deflection force for the belt should

be within the minimum and maximum

force shown in the Table A. When the

tension drops to the minimum value,

23

TRANE

Wiring/Start-Up Procedure

Table A

Deflection Force Table

Figure 18

Belt Tension Measurement

24

TRANE

Maintenance

Periodic

Checklist

Maintenance

[*] Check greasing on fan and motor.

[*] Check condition of gasketing and

insulation around unit, door and

[*] Align fan and motor sheaves

damper.

Every Three to Six Months

The following checklist describes the

(pulley). Tighten sheaves setscrews to

suggested maintenance schedule to

maintain proper operation of the unit.

the proper torque.

Detailed procedures for owneroperator maintenance checks are

[*] Check and adjust fan belt tension.

given after this checklist.

Warning: Disconnect electrical power

and allow rotating parts to stop before

servicing the unit. Exercise caution if

unit must be on for test or maintenance

procedures. Failure to do so may result

in injury or death from electrical shock

or moving parts.

[*] Examine flex connections for cracks

[*] Tighten electrical connection.

[*] lnspect coils for dirt build-up or coil

freeze up

Every Year

[*] lnspect the unit casing for corrosion.

lf damage is found, clean and repaint

the surface with a rust-resistant primer

Warning: Disconnect electrical power

prior to access into fan or ductwork.

Even when locked out electrically, fans

may cause injury or damage if the

impeller is subject to "windmilling". The

impeller should be secured to

physically restrict rotational movement

can cause severe personal injury or

death.

and vinyl chlorinated lacquer.

[*] Clean the fan wheels and fan shaft.

Remove rust with emery cloth and

apply a coat of LPS#3 or an equivalent.

[*] lnspect the condensate drain pan

and drain line, remove sludge or

foreign materials that might obstruct

After 48 Hours Operation

[*] Belts have acquired their

permanent stretch. Readjust but do not

overtighten(Ref. Start-Up Procedures

section in this manual).

proper drainage. Remove obstacles.

Weekly

[*] Observe unit weekly for any change

in running condition and any unusual

noise.

[*] lnspect the control and power box

Every Month

[*] Check air filters. Clean or replace if

clogged or dirty. Coat permanent filters

with oil after cleaning. Change bag

filters when pressure drop is 1-inch

W.G.

[*] Check damper linkages, set-screws

and blade adjustment for proper

damper operation.

wiring for secure connections and

insulation.

[*] Rotate the fan wheel and check for

obstruction in the fan housing. The

wheel should not rub on the fan

housing. Adjust the center if necessary

and tighten wheel setscrews to the

proper torque.

25

or leaks. Repair or replace damage

material.

TRANE

Trouble Analysis

Trouble Analysis

Use the tables in this section to assist in identifying the cause or cause of a malfunction in Quantum Climate Changer

operation. The column header RECOMMENDED ACTION will suggest repair procedures.

Note: This table is intended as a diagnostic aid on:

26

TRANE

Trouble Analysis

27

TRANE

Trouble Analysis

Maintenance Procedures

cannot be relubricated.

Grease Type:

Warning: Disconnect electrical power

W.E motors up to 132 frame and TECO

and Brook Hansen motors up to 180

TECO/Brook Hansen motor - Use

Esso Unirex Lithium N3 grease.

W.E motor - Use Shell Alvania R3.

source before sevicing the unit or

connecting electrical wires. Failure to

do so may result in personal injury or

death from electrical shocks or

entanglement in moving.

Air Filters

Appendix D provides filter size, type and

quantity. To replace throwaway filters,

install new filters with the directional

arrows pointing in direction of airflow.

To clean permanent filters wash under

a stream of water to remove dirt and

lint. Remove oil filter (aluminum or

grease filter) with a wash of mild alkali

solution. Rinse in clean, hot water and

allow to dry. Coat both sides of the filter

by immersing or spraying it with Air

Maze Filter Lote W or equivalent. Allow

to drain and dry for about 12 hours.

Fan Bearings Lubrication

Fan bearings are permanently sealed

and lubricated. Do not attempt to

lubricate bearings.

frame comes with sealed for life

bearings, while motors above this

Coil Cleaning

range, have open bearings with "flush

through" re-greasing facilities.

Steam, hot water and chilled water

!

WARNING: DISCONNECT POWER

SOURCE

FOR

MOTOR

LUBRICATION. FAILURE TO DO SO

MAY RESULT IN INJURY OR DEATH

FROM ELECTRIAL SHOCK OR

MOVING PARTS.

To re-lubricate the motor, complete the

following:

1. Turn the motor off. Make sure it

cannot accidentally restart.

2. Remove the relief plug and clean out

any hardened grease.

3. Add fresh grease through the fitting

with low pressure grease gun.

4. Run the motor for few minutes to

expel any excess grease through

the relief vent.

5. Stop the motor and replace the relief

plug.

Table1

Motor Greasing lntervals

Fan Motors

lnspect periodically for excessive

vibration or temperature. Operating

conditions will vary the frequency of

inspection and lubrication. Contact the

motor manufacturer or Trane for

lubrication instruction. Most smaller

frame motors comes without oil tubes

or grease nipple where the bearings

are permanently sealed.

The motors with double shielded

bearings are lubricated for life and

Standard condition: 8 hour operation

per day with rated or light loading in a

clean and low vibration environment.

Severe condition: 24 hour operation per

day with rated/light loading or in a dirty/

dusty environment or where the motor

is subject to vibration/light shock

loading.

28

coils should be kept clean to maintain

maximum performance. lf fins become

dirty, clean with steam and detergent,

hot water spray and detergent, or one

of the commercially available chemical

coil cleaners. Rinse coils throughly

after cleaning.

Warning: Follow all directions provided

with chemical cleaners to avoid

personal injury and/or coil damage.

Commercially available chemical

cleaners may contain caustic or

hazardous agents.

TRANE

Trouble Analysis

Refrigerant coils should be kept clean

to maintain maximum performance. lf

fins become dirty, clean with cold water

and detergent or one of the

commercially available chemicals coil

cleaners. Rinse coils thoroughly after

cleaning.

Warning: Never use steam or hot water

to clean a refrigerant coil. Dangerous

pressures may be built up by improper

application of heat resulting in

equipment damage or personal injury.

Coil Winterization

Provisions must be made to drain

those

coils that are not in use when subjected

to freezing temperatures.

Caution: Failure to properly drain and

vent coils when not in use during

freezing temperatures may result in

coil freeze-up damage. Drain and vent

hardware provided by installing

contractor.

To drain these coils, blow out the coils

with compressed air, fill and drain the

tubes with full-strength ethylene glycol

several times, and then drain the coil

as completely as possible.

Trouble Analysis

Use the tables in this section to assist

in identifying the cause or causes of a

malfunction in Modular Climate

Changer operation. The column

header RECOMMENDED ACTION will

suggest repair procedures.

Note: These tables are intended as a

diagnostic aid only. For detailed repair

procedures, contact your local Trane

Service Company.

29

WARNING: DISCONNECT

ELECTRICAL POWER SOURCE

AND ALLOW ALL ROTATING

EQUIPMENT

COMPLETELY

TO

STOP

BEFORE

INSPECTING OR SERVICING THE

UNIT. FAILURE TO DO SO MAY

RESULT IN PERSONAL INJURY OR

DEATH FROM ELECTRICAL SHOCK

OR MOVING PARTS.

WARNING: DISCONNECT

ELECTRICAL POWER PRIOR TO

ACCESS INTO A FAN OR

DUCTWORK.

EVEN

WHEN

LOCKED OUT ELECTRICALLY,

FANS MAY CAUSE INJURY OR

DAMAGE IF THE IMPELLER

SHOULD BE SECURED TO

PHYSICALLY

RESTRICT

ROTATIONAL MOVEMENT FAILURE

TO SECURE IMPELLER CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH.

TRANE

Trouble Analysis

Pulley and Belt

30

TRANE

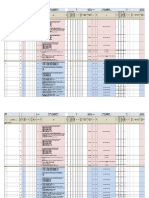

Appendix B

HDT - Unit Weight

HDT Unit Weight (kg) _ Fan and Coil Sections (without motor weight)

50mm Casing

25mm Casing

1.

Coil weight is the operating weight.

Motor Weight (kg)

31

TRANE

Appendix B

HDT - Unit Weight

HDT Unit Weight (kg) - Fan + Coil + Filter Sections (without motor weight)

50mm Casing

25mm Casing

1.

2.

Coil weight is the operating weight.

Filter weight include filter media.

Motor Weight (kg)

32

TRANE

Appendix B

HDT - Unit Weight

HDT Unit Weight (kg) - Fan + Coil + Filter and Mixing Sections (without motor weight)

50mm Casing

25mm Casing

Note:

1.

Coil weight is the operating weight.

2.

Filter weight includes filter media.

Motor Weight (kg)

33

TRANE

Appendix B

VDT - Unit Weight

VDT Unit Weight (kg) - Fan and Coil Sections (without motor weight)

50mm Casing

25mm Casing

Note:

1. Coil weight is the operating weight.

Motor Weight (kg)

34

TRANE

Appendix B

VDT - Unit Weight

VDT Unit Weight (kg) _ Fan + Coil + Filter Sections (without motor weight)

50mm Casing

25mm Casing

Note:

1. Coil weight is the operating weight.

2. Filter weight includes filter media.

Motor Weight (kg)

35

TRANE

Appendix CFans and Arrangement

Fan Size and Diameter

36

TRANE

Appendix DFilter and Quantity

Filter Dimension and Arrangement

Flat Filter, Bag Filter & Cartridge Filter

37

TRANE

Appendix DFilter and Quantity

Filter Dimension and Arrangement

High Capacity Filter

38

TRANE

Appendix DFilter and Quantity

Filter Dimension and Arrangement

Final Filter

39

TRANE

Appendix EMotor Detail

Three-Phase Squirrel - Cage (Standard Induction Motors) 50Hz Totally Enclosed Fan Cooled (TEFC) Horizontal Foot

Mounting, 4 Poles

OUTPUT

HP

Kw

0.25 0.18

0.5

0.37

0.75 0.55

1

0.75

1.5

1.1

2

1.5

3

2.2

4

3

5

3.7

5.5

4

7.5

5.5

10

7.5

15

11

20

15

25

18.5

30

22

40

30

50

37

60

45

75

55

100

75

TORQUE, Tf

(kg.m)

0.134

1

1.61

1.99

2.91

3.66

5.08

6.62

8.03

8.95

12

15.2

22

29.3

36.2

42.9

56.6

72.1

86

102

129

FRAME

NO.

63

71

80

80

90S

90L

100L

100L

112M

112M

132S

132M

160M

160L

180MC

180LC

200LC

225SC

225MC

250SC

250MC

FULL LOAD

EFFICIENCY (%)

POWER FACTOR (%)

FULL LOAD 0.75 LOAD

0.5 LOAD FULL LOAD 0.75 LOAD

0.5 LOAD

63.5

63.0

58.0

70.0

61.0

49.0

67.0

65.0

59.0

70.0

60.0

48.0

71.5

70.5

65

74.0

65.0

52.0

74.0

73.0

69.0

77.0

68.0

54.0

74.0

74.0

70.0

79.0

71.0

58.5

76.5

77.0

74.0

81.0

73.5

61.0

81.0

80.5

78.5

82.5

76.0

63.0

83.5

83.0

80.5

82.0

75.5

63.0

84.5

84

82.5

83.5

76.5

65.0

85.0

84.5

83.0

82.0

77.0

65.0

86.0

85.0

83.5

82.5

76.0

64.0

88.0

88.0

86.5

85.0

80.0

70.0

89.5

89.0

88.0

86.5

82.5

74.0

90.0

90.0

88.5

86.0

81.5

73.0

91.0

91.5

91.0

86.0

83.0

78.0

91.5

91.5

91.5

86.5

83.5

76.5

92.5

92.5

92.0

86.5

84.0

77.0

92.5

92.5

92.0

85.0

81.5

75.5

92.5

92.5

92.0

85.5

83.5

77.0

93.5

93.0

91.5

89.0

87.5

83.0

94.0

94.0

93.0

93.5

94.0

92.5

FULL LOAD

CURRENT (AMP)

415V

380 V

0.59

0.64

0.261

1.11

0.387

1.47

0.518

1.82

0.778

2.66

1.033

3.35

1.528

4.66

2.03

6.06

2.523

7.35

2.772

8.19

3.767

11

5.006

13.9

7.432

20.1

9.943

26.8

12.47

33.2

14.91

39.3

19.75

51.9

24.61

66

29.63

78.7

39.91

93.5

49.21

119

LOCKED - ROTOR

CURRENT (AMP)

415V

380 V

2.4

2.6

4.8

5.3

7.7

8.4

10

11

14

16

19

21

31

34

45

49

58

63

58

63

72

79

101

111

140

153

188

205

207

226

260

284

366

400

414

453

467

511

627

684

896

979

40

SPEED

(RPM)

1350

1390

1405

1400

1400

1405

1425

1430

1440

1440

1445

1450

1465

1460

1455

1460

1470

1475

1470

1475

1475

LOCKED

ROTOR (%)

260

265

260

260

210

220

250

330

220

250

240

275

235

240

200

215

230

200

190

200

180

TRANE

Training

Safety Recommendations

To avoid accidents and damage, the

following recommendations should be

observed during maintenance and

service visits:

1. Disconnect the main supply before

any servicing on the unit.

2. Service work on the refrigeration

system and the electrical system

should be carride out only by

qualified

and

experienced

personnel.

Maintenance Contract

The manufacturer has a policy of

continuous product improvement, and

reserves the right to alter any details of

the products at any time without notice.

This publication is a general guide to

install, use and properly maintain our

products. The information given may

be different from the specification for a

particular country or for a specific order.

ln this event. Please refer to your

nearest office.

ln no event shall Trane be liable for

any incldental or consequential

damages resulting from the use,

misuse or inability to use the product.

lt is strongly recommended that you

sign a maintenance contract with your

local Service Agency. This contract

provides regular maintenance of your

installation by a specialist in our

equipment. Regular maintenance

ensures that any malfunction is

detected and corrected in good time

and minimizes the possibility that

serious damage will occur. Finally,

regular maintenance ensures the

maximum operating life of your

equipment. We would remind you that

failure to respect these installation and

maintenance instructions may result

in immediate cancellation of the

warranty.

The equipment described in this

manual is the result of many years

of research and continuous

development. To assist you in

obtaining the best use of it and

maintaining it in perfect operating

condition over a long period of time,

the manufacturer has at your

d i s p o s a l a r e f r i g e r a t i o n a nd a ir

conditioning service school. The

principal aim of this is to give

operators and technicians a better

knowledge of the equipment they

are using, or that is under their

charge. Emphasis is particularly

give to the importance of periodic

checks on the unit operating

parameters as well as on preventive

maintenance. which reduces the

cost of owning the unit by avoiding

serious and costly breakdown.

For additional information, contact:

Distirbutor / Installer stamp

41

TRANE

Literature Order Number IND-SVN01A-E4 (December 2006)

File Number

Trane

A business of American Standard Companies

www.trane.com

For more information, contact your local

district office

Supersedes

IND-SVN01A-E4 (April 2005)

Stocking Location

MALAYSIA

Trane has a policy of continuous product and product data improvement and reserves the right to change

design and specifications without notice. Only qualified technicians should perform the installation and

servicing of equipment referred to in this publication.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CP02 CD Documents StatusDocument4 pagesCP02 CD Documents StatusLeed ENNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- CLCP IomDocument44 pagesCLCP IomLeed ENNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Dim Ewwqc1013b Xs ModelDocument1 pageDim Ewwqc1013b Xs ModelLeed ENNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CP02 Design Data ListDocument26 pagesCP02 Design Data ListLeed ENNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Tri-Services Color MappingsDocument1 pageTri-Services Color MappingsATRSBOOKSNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Question 3: How Do You React, What Happens, When You Believe That Thought?Document2 pagesQuestion 3: How Do You React, What Happens, When You Believe That Thought?Leed EN100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 1Document18 pages1Leed ENNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- CS3 50Hz 60HzDocument12 pagesCS3 50Hz 60HzLeed ENNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 1Document18 pages1Leed ENNo ratings yet

- Carbon Steel Pipe and Fittings GuideDocument10 pagesCarbon Steel Pipe and Fittings GuideavazcNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Section HH2Document8 pagesSection HH2Leed ENNo ratings yet

- Q21302221Konia DunhamBush Big C Dalat 2TDocument1 pageQ21302221Konia DunhamBush Big C Dalat 2TLeed ENNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 7-QC-QA Plan For ProjectDocument99 pages7-QC-QA Plan For ProjectJaouad Id BoubkerNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- IT Services Design Firm ExperienceDocument2 pagesIT Services Design Firm ExperienceLeed ENNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- RPUB00003Document40 pagesRPUB00003Ko PaukNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- RPUB00003Document40 pagesRPUB00003Ko PaukNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Early Striking and Improved BackproppingDocument4 pagesEarly Striking and Improved Backproppingrami1964100% (1)

- Reinforced Concrete Council - Tiltup10Document4 pagesReinforced Concrete Council - Tiltup10Gyorgy AdrienneNo ratings yet

- Pham Hung Residences Offices Floor Plan, PDFDocument11 pagesPham Hung Residences Offices Floor Plan, PDFLeed ENNo ratings yet

- Section HH2Document8 pagesSection HH2Leed ENNo ratings yet

- CLCP IomDocument44 pagesCLCP IomLeed ENNo ratings yet

- ColumnsDocument10 pagesColumnsnahzemNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bs 6100 1-3-2Document24 pagesBs 6100 1-3-2Leed ENNo ratings yet

- CCIP How2 ExtractDocument3 pagesCCIP How2 ExtractLeed ENNo ratings yet

- BS 5628-3Document136 pagesBS 5628-3Leed EN100% (5)

- Reinforcement Standard en 10080 and The ECDocument1 pageReinforcement Standard en 10080 and The ECLeed ENNo ratings yet

- BS 5628-2Document68 pagesBS 5628-2Leed EN100% (5)

- Eurocode 1 Part 2,6 - DDENV 1991-2!6!1997Document35 pagesEurocode 1 Part 2,6 - DDENV 1991-2!6!1997afqan1No ratings yet

- Manual of Methods OF Analysis of Foods: Pesticide ResiduesDocument270 pagesManual of Methods OF Analysis of Foods: Pesticide ResiduesAnonymous XuiUo2ThNo ratings yet

- Yeom 2012Document10 pagesYeom 2012Deysi Suarez GomezNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Quality Assurance Plan Product Name: Stone Ware PipesDocument3 pagesQuality Assurance Plan Product Name: Stone Ware PipesAnonymous ciKyr0tNo ratings yet

- Rigaku Nex QCDocument12 pagesRigaku Nex QCLuis ReyesNo ratings yet

- Homogenization and Lysis (2021!06!12)Document22 pagesHomogenization and Lysis (2021!06!12)Wreck of HeartsNo ratings yet

- 2014 Ifa Phosphate Method PDFDocument21 pages2014 Ifa Phosphate Method PDFsanford siegelNo ratings yet

- Atomic Structure Part 6Document38 pagesAtomic Structure Part 6xenaNo ratings yet

- Binary and TernaryDocument13 pagesBinary and TernaryRosemarie Degala LateNo ratings yet

- Chem 31.1 Experiment 9 Synthesis of Organic CompoundsDocument68 pagesChem 31.1 Experiment 9 Synthesis of Organic Compoundshello87623100% (1)

- Assignment 2Document1 pageAssignment 2Varun PahujaNo ratings yet

- Organic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Document3 pagesOrganic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Akira SantosNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFDocument6 pagesCHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFNikoli MajorNo ratings yet

- Role of DSS in RefineryDocument24 pagesRole of DSS in Refineryramadoss_alwar7307100% (1)

- CAB Cable Rings and SaddlesDocument5 pagesCAB Cable Rings and SaddlesgoyalmanojNo ratings yet

- Technology Guide No. 19: SSPC: The Society For Protective CoatingsDocument3 pagesTechnology Guide No. 19: SSPC: The Society For Protective CoatingsMia AndinoNo ratings yet

- Omeprazole: by Jennica Mae V. CuicoDocument7 pagesOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイNo ratings yet

- Steps in Balancing Redox ReactionsDocument28 pagesSteps in Balancing Redox ReactionsRUZCHEMISTRYNo ratings yet

- List I (16 5 2011)Document585 pagesList I (16 5 2011)Ayaz Mani50% (2)

- Extract Organometallic Chemistry PDFDocument10 pagesExtract Organometallic Chemistry PDFj pooranaNo ratings yet

- LCGC Europe 2001Document4 pagesLCGC Europe 2001Jhonattan BaezNo ratings yet

- Dust Collection Design and Maintenance GuideDocument36 pagesDust Collection Design and Maintenance GuideMadan YadavNo ratings yet

- Index TO XV: ArsphenamineDocument7 pagesIndex TO XV: ArsphenamineAlex12No ratings yet

- Onions: Vegetable Crops Production Guide For The Atlantic ProvincesDocument8 pagesOnions: Vegetable Crops Production Guide For The Atlantic ProvincesEglNo ratings yet

- Rapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum HoneysDocument9 pagesRapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum Honeysasel ppNo ratings yet

- Istory of Jellyfish Envenomation: 3.1.1. Class Cubozoa - Cubozoan JellyfishDocument16 pagesIstory of Jellyfish Envenomation: 3.1.1. Class Cubozoa - Cubozoan JellyfishRangsiyo BeabeoNo ratings yet

- ArcelorMittal Projects Steel Pipe ProductionDocument20 pagesArcelorMittal Projects Steel Pipe Productionanil-kumar-singh-6674No ratings yet

- TubingDocument6 pagesTubingkevin wongNo ratings yet

- Against Water Hummer PDFDocument36 pagesAgainst Water Hummer PDFDenstar Ricardo SilalahiNo ratings yet

- Astm D1785-15Document11 pagesAstm D1785-15david franco0% (1)

- Lightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiDocument6 pagesLightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiAfzalNo ratings yet

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)